Dry Strand Pelletizers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441070 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Dry Strand Pelletizers Market Size

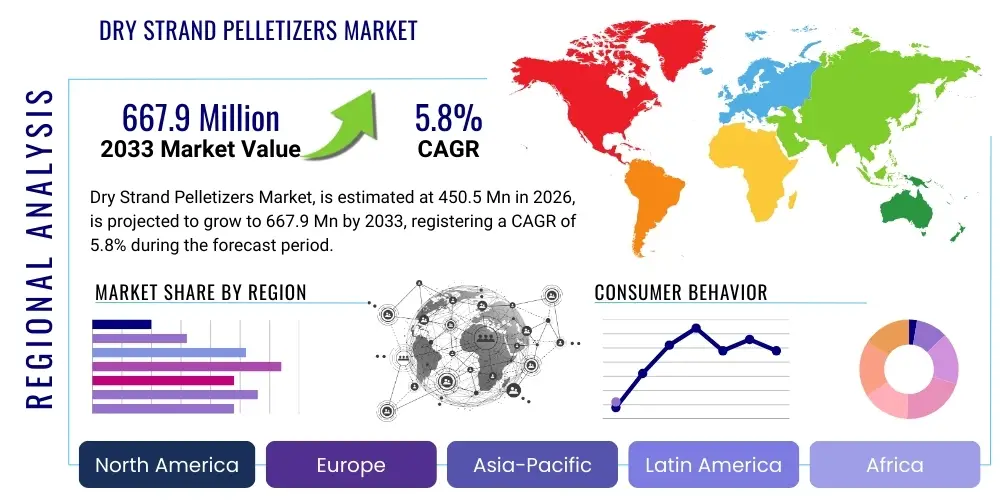

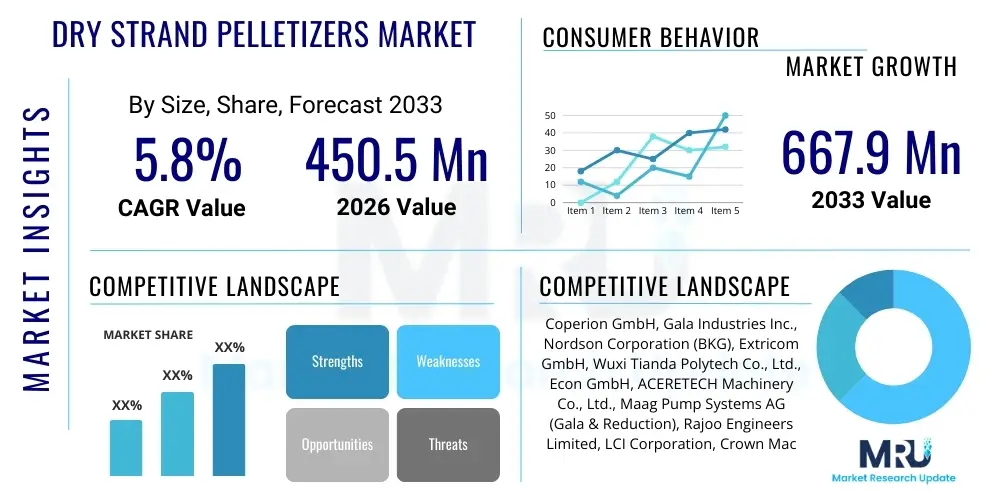

The Dry Strand Pelletizers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 667.9 Million by the end of the forecast period in 2033.

Dry Strand Pelletizers Market introduction

The Dry Strand Pelletizers Market encompasses the manufacturing, distribution, and utilization of specialized machinery designed to convert extruded polymer strands into uniform, high-quality pellets. These systems are fundamental to the plastics processing, compounding, and recycling industries, serving as a critical post-extrusion step that ensures material consistency for subsequent molding or forming operations. Dry strand pelletizing involves cooling the extruded polymer strands, usually via a water bath or air cooling system, followed by pulling the hardened strands into a pelletizing unit where rotating knives cut them into precise granular dimensions. This process is essential for materials sensitive to moisture or those requiring high dimensional uniformity, offering superior control over pellet shape and size compared to underwater or water ring systems, particularly for engineering plastics and highly filled compounds.

Dry strand pelletizers offer significant advantages, including high throughput capabilities, robust operational stability, and flexibility in processing a wide array of thermoplastic and elastomeric materials, ranging from standard polyolefins (PE, PP) to demanding engineering polymers (Nylon, PET, PEEK). The core application spectrum is extensive, covering virgin polymer compounding, masterbatch production, and notably, high-volume plastics recycling, where consistent material quality is paramount for reintroduction into manufacturing cycles. Key driving factors accelerating market expansion include the global surge in plastics production, necessitating efficient post-processing solutions; the increasing demand for high-performance engineered plastics in automotive and aerospace sectors; and stringent regulatory focus on plastics recycling and circular economy initiatives, which mandate reliable pellet quality from recovered materials.

Product descriptions typically highlight modular design, automated strand threading, and precise cutting geometries capable of producing pellets ranging from micro-pellets to larger industrial sizes. Major applications span automotive components requiring lightweight and durable materials, packaging films demanding specific density and flow characteristics, medical devices necessitating high purity and sterilization compatibility, and construction materials benefiting from enhanced structural integrity provided by uniform pellets. The benefits derived from using dry strand pelletizers include reduced material waste, superior material handling properties, enhanced feed consistency into injection molding or extrusion equipment, and the ability to manage thermally sensitive or abrasive compounds effectively, thus safeguarding subsequent machinery and optimizing overall production efficiency.

Dry Strand Pelletizers Market Executive Summary

The Dry Strand Pelletizers Market is currently characterized by robust technological development focused on automation, energy efficiency, and enhanced adaptability to difficult-to-process materials, particularly high-viscosity and highly abrasive compounds derived from recycling streams. Business trends indicate a strong focus on predictive maintenance integration using IoT sensors and software, minimizing unplanned downtime which is highly costly in continuous production environments. Furthermore, manufacturers are responding to end-user demands for turnkey solutions that integrate cooling, drying, and pelletizing into seamless, space-efficient systems. Strategic collaborations between machinery manufacturers and specialized compounders are also becoming prevalent to co-develop pelletizing solutions optimized for novel polymer formulations. The imperative to achieve zero-defect pellet quality for sophisticated applications in electronics and medical sectors is driving investment in high-precision cutting systems and advanced quality control mechanisms, including optical sorting integrated directly into the pelletizing line.

Regional trends demonstrate that Asia Pacific (APAC) remains the dominant region due to massive plastic manufacturing capacities, particularly in China, India, and Southeast Asia, driven by rapid industrialization and escalating consumer goods production. However, North America and Europe are exhibiting significant growth, primarily fueled by legislative mandates promoting high-quality recycling infrastructure and the localized production of high-value engineering plastics. European growth is particularly noteworthy due to stringent EU regulations favoring circular economy models, pushing processors toward highly efficient and versatile dry strand systems suitable for post-consumer recycled (PCR) materials. Investment in highly automated lines is concentrated in high-labor-cost regions like Western Europe and North America to maintain cost competitiveness and ensure operational consistency across fewer shifts.

Segmentation trends highlight the increasing prominence of high-output capacity machines (above 1,500 kg/hr) as manufacturers seek economies of scale, especially in commodity polymer processing and large-scale recycling operations. Conversely, the demand for mid-range, highly flexible systems designed for specialized compounding and masterbatch production is also accelerating, catering to niche markets requiring frequent material changeovers and exceptional cleanliness. Material segmentation analysis reveals strong growth in pelletizers optimized for bio-plastics and compostable polymers, reflecting market shifts toward sustainable materials. End-user segmentation shows that the recycling industry is becoming the fastest-growing segment, requiring specialized features such as enhanced dust management and improved wear resistance due to the inconsistent and abrasive nature of feedstocks. The interplay between throughput requirements and material sensitivity continues to define product development trajectories across all segments.

AI Impact Analysis on Dry Strand Pelletizers Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Dry Strand Pelletizers Market often revolve around how AI can enhance operational efficiency, reduce material waste, and improve pellet consistency. Key concerns frequently raised include the feasibility of integrating complex AI algorithms into existing legacy machinery, the required investment in sensor infrastructure for data capture, and the ability of AI models to effectively handle the variability inherent in recycled feedstocks. Users are primarily interested in predictive maintenance schedules to minimize costly downtime, optimizing cutting blade lifespan, and achieving real-time adjustments to strand tension and cooling rates based on continuous material property feedback. There is also significant interest in using AI-driven vision systems for automated quality control, identifying and rejecting substandard pellets instantaneously, thus guaranteeing final product quality without manual intervention. The overarching expectation is that AI will move dry strand pelletizing from a reactive maintenance process to a highly proactive, self-optimizing manufacturing stage.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and current data from motors and gearboxes, forecasting potential equipment failures (e.g., cutter head misalignment or bearing degradation) significantly before they occur.

- Real-time Process Optimization: Employing AI models to dynamically adjust key parameters—such as water bath temperature, strand speed, and cutting velocity—based on material viscosity changes or fluctuations in incoming material melt temperature, ensuring consistent pellet size and shape.

- Enhanced Quality Control (QC): Integrating AI-powered vision systems (deep learning/computer vision) to inspect every pellet, identifying subtle defects (e.g., agglomerations, double pellets, dust contamination) at high speeds and automating rejection protocols.

- Automated Recipe Management: Using AI to suggest or automatically load optimal processing parameters for new or varying material formulations (e.g., changing filler concentrations or additive packages), drastically reducing setup and changeover times.

- Energy Consumption Reduction: Implementing AI-based energy management systems that optimize motor usage and cooling system operation according to immediate throughput needs and environmental conditions, leading to substantial reductions in specific energy consumption (SEC).

DRO & Impact Forces Of Dry Strand Pelletizers Market

The Dry Strand Pelletizers Market is propelled by compelling drivers, notably the sustained global increase in demand for high-quality plastic compounds across essential sectors like automotive, construction, and healthcare, which necessitate precise and consistent pellet geometry for advanced manufacturing. Furthermore, the intensifying focus on the circular economy and regulatory pressures requiring higher recycled content in finished products significantly boost demand for robust pelletizing solutions capable of handling diverse and often challenging post-consumer and post-industrial waste streams. The continuous push for process automation and energy efficiency in polymer processing facilities worldwide also acts as a primary driver, favoring modern, high-throughput dry strand systems that minimize labor dependence and operational costs. However, the market faces restraints, chiefly the substantial initial capital investment required for high-end pelletizing lines, which can deter smaller compounding operations, alongside the technical challenge of managing highly abrasive materials that cause rapid wear on critical components like cutting knives and dies, leading to increased maintenance frequency and costs. Opportunities abound in developing pelletizers specifically tailored for emerging bio-polymers and sustainable composites, addressing the rapidly growing niche market for eco-friendly materials, and expanding application reach through integration with sophisticated downstream equipment, thereby offering comprehensive material preparation solutions. These dynamics are shaped by impact forces that include stringent international environmental standards pushing for cleaner processing technologies and fluctuating raw material prices, which drive processors toward maximizing yields and minimizing waste, thereby increasing reliance on high-efficiency pelletizing technology.

The most significant drivers include the rapid expansion of plastics manufacturing capacity in emerging Asian economies, particularly for packaging and consumer electronics, coupled with the increasing adoption of engineering plastics globally. As polymers become specialized—incorporating high levels of fillers, flame retardants, or glass fibers—the need for reliable, damage-free pelletization provided by dry strand systems intensifies. Moreover, the inherent efficiency and flexibility of dry strand pelletizers make them suitable for toll compounding operations where frequent material changes are common, adding to market momentum. Regulatory frameworks, such as the European Green Deal and various national zero-waste initiatives, fundamentally alter the processing landscape, making the efficient and high-quality processing of recycled plastics mandatory, thus favoring advanced dry strand technology over less robust alternatives.

Key restraints, beyond the initial high cost, involve the complexity associated with processing highly elastic or very low-viscosity materials, which can lead to strand breakage or inconsistent cutting if not precisely managed, demanding highly specialized technical expertise and training for operators. Competition from alternative pelletizing methods, specifically underwater pelletizing which is often preferred for high-volume, low-viscosity materials like polyethylene, also limits market penetration in certain segments. However, the vast opportunity presented by the integration of Industry 4.0 technologies—such as IoT, AI, and cloud connectivity—into pelletizing lines represents a paradigm shift. This integration facilitates predictive diagnostics, remote troubleshooting, and unparalleled process control, transforming the pelletizing process into a data-driven operation, which in turn enhances overall equipment effectiveness (OEE) and strengthens the business case for adopting modern dry strand systems.

- Drivers:

- Surging demand for high-quality engineering plastics in high-growth industries (Automotive, Aerospace).

- Global increase in plastics recycling and mandates for high-content PCR material usage.

- Focus on enhanced process automation and operational efficiency to reduce labor costs.

- Technical superiority in handling temperature-sensitive and highly filled compounds.

- Restraints:

- High initial capital expenditure required for advanced, high-capacity systems.

- Wear and tear challenges associated with processing abrasive, glass-filled, or highly contaminated recycled feedstocks.

- Operational complexities in maintaining strand stability and uniform tension during high-speed processing.

- Opportunities:

- Development of specialized pelletizers for sustainable materials (bio-plastics, compostable polymers).

- Integration of advanced digital technologies (AI, IoT) for predictive maintenance and real-time optimization.

- Expansion into emerging markets with rapidly developing plastics conversion industries.

- Impact Forces:

- Stringent global environmental regulations pushing for minimized material waste and maximized recycling yields.

- Technological advancements in cutting head design improving lifespan and precision.

- Global supply chain volatility influencing component costs and delivery timelines.

Segmentation Analysis

The Dry Strand Pelletizers Market is rigorously segmented based on throughput capacity, the material processed, end-user industry, and key components utilized, providing granular insights into market dynamics and localized demand patterns. Throughput segmentation, categorized into low (less than 500 kg/hr), medium (500–1,500 kg/hr), and high (above 1,500 kg/hr) capacity, is crucial as it directly correlates with the scale of compounding or recycling operations; large commodity producers favor high-capacity systems, while specialized compounders prefer the flexibility of medium capacity units. Segmentation by material processed highlights the growing importance of systems optimized for demanding materials like PVC, fluoropolymers, and engineering resins, which require specific cooling and handling characteristics distinct from standard polyolefins. Analyzing the end-user landscape reveals specialized requirements for sectors like healthcare (requiring ultra-clean systems), automotive (demanding high-performance, durable pellets), and the recycling sector (requiring robust, wear-resistant machinery). Component segmentation, focusing on cooling systems (water bath vs. air cooling) and cutter head technology, allows for evaluation of technological preferences and performance benchmarks across different applications and geographical regions.

- By Throughput Capacity:

- Low Capacity (Less than 500 kg/hr)

- Medium Capacity (500 kg/hr – 1,500 kg/hr)

- High Capacity (Above 1,500 kg/hr)

- By Material Processed:

- Polyolefins (PE, PP)

- Engineering Plastics (Nylon, ABS, PET)

- PVC and Halogenated Polymers

- Thermoplastic Elastomers (TPEs)

- Bio-plastics and Composites

- Highly Filled and Abrasive Materials

- By End-User Industry:

- Compounding and Masterbatch Production

- Recycling and Waste Management

- Automotive and Transportation

- Packaging

- Building and Construction

- Medical and Healthcare

- Electronics and Electrical

- By Key Component/Technology:

- Cooling Systems (Water Bath, Air Conveyance)

- Cutter Heads (Standard Geometry, Helical Cut)

- Automation Level (Semi-automatic, Fully Automated)

Value Chain Analysis For Dry Strand Pelletizers Market

The value chain for the Dry Strand Pelletizers Market begins with upstream activities, primarily involving the sourcing of highly specialized raw materials for machine construction, including high-grade steel alloys for wear parts (like cutting knives and dies), advanced electronic components for control panels (PLCs, sensors, drives), and precision-engineered mechanical components (gearboxes, motors, bearings). Key suppliers include specialized metallurgical firms, industrial automation hardware manufacturers, and precision engineering companies. The quality and reliability of these upstream inputs directly dictate the durability and operational lifespan of the final pelletizing unit, making secure supply chains for specialized wear-resistant alloys a critical competitive factor. Disruptions or price volatility in critical electronic components, particularly due to global semiconductor shortages, significantly impact manufacturing lead times and final product costs.

The core manufacturing stage involves the precision machining, assembly, and rigorous testing of the pelletizer systems. Market participants focus on integrating modular design principles to facilitate customization and rapid maintenance, ensuring high throughput efficiency and superior pellet quality. Manufacturers invest heavily in R&D to enhance automation features, optimize cooling system thermodynamics, and develop wear-resistant coatings for cutting surfaces, aiming for maximum uptime and minimum specific energy consumption (SEC). Testing and validation are critical steps, ensuring the machinery meets stringent industry standards for safety, noise reduction, and performance across a range of polymer viscosities and processing temperatures. This stage adds the highest value through intellectual property, precision engineering, and quality assurance protocols, differentiating specialized manufacturers from generic machinery providers.

Downstream analysis focuses on distribution channels and final end-use. Direct distribution is common for high-value, bespoke pelletizing lines, where manufacturers engage directly with large compounding houses or major polymer producers, offering comprehensive installation, training, and long-term maintenance contracts. Indirect channels utilize specialized industrial equipment distributors and regional agents, particularly for mid-to-low capacity standard machines, offering localized sales support and faster service response times. The end-users—ranging from primary resin producers and independent compounders to large-scale recycling facilities—determine the ultimate demand characteristics. Their purchasing decisions are heavily influenced by factors such as machine longevity, throughput capacity, pellet quality consistency (AEO optimization factor for final product), and overall total cost of ownership (TCO), including energy usage and maintenance expenditure. Effective after-sales service and spare parts availability are crucial components of the downstream value proposition, ensuring customer loyalty and maximizing machine productivity over its lifetime.

Dry Strand Pelletizers Market Potential Customers

The primary customers for Dry Strand Pelletizers are multifaceted, operating within diverse industrial sectors that rely on the efficient and high-quality production of polymer pellets. Large-scale virgin polymer manufacturers constitute a fundamental segment, requiring robust, high-throughput systems to pelletize newly synthesized resins before shipping them to converters. These customers prioritize reliability, massive capacity, and seamless integration into continuous production lines. Independent custom compounders and masterbatch producers represent another significant segment, characterized by their need for highly versatile and flexible pelletizers capable of rapid material changeovers, stringent cleanliness standards, and processing specialized, low-volume formulations containing high concentrations of additives or pigments. Their requirement is often precision and ease of cleaning over raw throughput, ensuring product integrity between batches.

A rapidly expanding customer base is the plastics recycling industry, including both post-industrial recyclers (PIR) and post-consumer recyclers (PCR). These customers require pelletizers built with exceptional wear resistance and robust construction to handle challenging, often inconsistent, and abrasive feedstocks. For recyclers, the ability of the dry strand system to produce high-quality, dense pellets that flow well and minimize air entrapment is essential for making recycled content appealing to subsequent processors. Additionally, companies specializing in materials for regulated industries, such as medical device manufacturing and food contact packaging, are key customers, demanding pelletizing solutions that adhere to strict validation and cleanliness protocols, often favoring systems designed to prevent cross-contamination and ensure material purity, directly impacting patient safety and regulatory compliance.

Furthermore, major manufacturing companies operating in sectors like automotive and building materials often utilize in-house compounding capabilities to tailor materials precisely to their product specifications, making them direct buyers of high-specification dry strand pelletizing equipment. The continuous technological upgrades in these sectors, driven by demands for lighter vehicles or more sustainable building materials, necessitate frequent investments in advanced pelletizing technology. This diverse customer landscape ensures sustained market demand, where buying criteria range from pure cost efficiency for commodity processors to unparalleled precision and material integrity for specialized compounders and regulated sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 667.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coperion GmbH, Gala Industries Inc., Nordson Corporation (BKG), Extricom GmbH, Wuxi Tianda Polytech Co., Ltd., Econ GmbH, ACERETECH Machinery Co., Ltd., Maag Pump Systems AG (Gala & Reduction), Rajoo Engineers Limited, LCI Corporation, Crown Machine, Coway Machinery Co., Ltd., Process Control Corporation, Nanjing Kerke Extrusion Equipment Co., Ltd., Everplast Machinery Co., Ltd., Technovel Corporation, TEMA Process B.V., Nanjing Tengda Extrusion Machinery Co., Ltd., Nanjing Haisi Extrusion Equipment Co., Ltd., Wuxi JKS Machinery Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dry Strand Pelletizers Market Key Technology Landscape

The technological landscape of the Dry Strand Pelletizers Market is continuously evolving, driven by the need for higher precision, greater energy efficiency, and improved wear resistance, especially when processing complex and abrasive compounds. A key area of innovation is the optimization of the cooling and drying stages. While traditional water baths remain prevalent, modern systems utilize sophisticated design elements such as high-velocity water circulation and vacuum dewatering systems to minimize residual moisture content, which is critical for materials like PET and nylon that are highly moisture-sensitive. Furthermore, air-cooling pelletizers, while lower in throughput for some applications, are gaining traction for niche, highly sensitive polymers where any contact with water is detrimental, offering alternative controlled cooling environments.

Cutter head technology is another central focus. Manufacturers are moving towards helical-cut designs and advanced geometric arrangements of rotor knives to ensure extremely uniform pellet length and shape consistency, minimizing dust generation and reducing noise levels during operation. The lifespan of cutting tools is being extended through the application of advanced materials, such as specialized tungsten carbide coatings or ceramic inserts, designed to withstand the high abrasion encountered when processing glass-filled or highly mineral-filled compounds common in recycling and engineering plastics. The integration of quick-change mechanisms for cutter heads significantly reduces downtime during maintenance, a major benefit for high-volume processors aiming to maximize OEE.

Perhaps the most transformative technological advancement is the incorporation of sophisticated process controls and digitalization. Modern dry strand pelletizers feature highly advanced Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that allow for precise, automated control of all critical parameters, including strand tension via automated puller belts, cutter speed synchronization, and temperature management. Integration with plant-wide Manufacturing Execution Systems (MES) allows for comprehensive data logging, traceability, and remote diagnostics. The adoption of gravimetric dosing systems upstream, combined with immediate feedback loops, ensures that material input is perfectly matched with pelletizer output, optimizing overall system performance and reducing material variability, paving the way for full Industry 4.0 compliant manufacturing environments.

Regional Highlights

Regional dynamics heavily influence the Dry Strand Pelletizers Market, primarily segmented across five major geographies, each presenting unique demand characteristics and technological adoption rates.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, driven by its massive installed base for plastics manufacturing, particularly in China, India, and Southeast Asia. The region benefits from lower manufacturing costs and booming domestic demand for consumer goods, automotive parts, and packaging, necessitating high-volume pelletizing solutions. Investment is heavily focused on high-capacity systems for commodity polymers, though rising environmental consciousness is quickly driving demand for advanced, efficient pelletizers suitable for handling complex, local recycling streams. Government policies supporting industrial modernization and material self-sufficiency further fuel market expansion.

- Europe: Europe represents a mature market characterized by stringent quality requirements and a pioneering regulatory environment centered on the circular economy. Growth here is primarily driven by the mandatory incorporation of recycled content (PCR) into packaging and other products, creating intense demand for dry strand pelletizers optimized for highly variable recycled feedstocks, requiring superior wear resistance and precise filtering capabilities. Technological adoption is high, with a strong preference for highly automated, energy-efficient, and precision-engineered European and German machinery.

- North America: The North American market is driven by robust manufacturing in the automotive, aerospace, and medical sectors, which demand high-specification engineering plastics. While throughput requirements are high, the focus is also on process reliability and advanced automation to offset high labor costs. Recent shifts toward localized supply chains and significant investment in regional recycling infrastructure, particularly in the US, are boosting demand for mid-to-high capacity dry strand pelletizers capable of consistent output from challenging materials.

- Latin America (LATAM): LATAM is an emerging market with gradual growth, concentrated primarily in Brazil and Mexico. Demand is generally focused on reliable, cost-effective mid-range pelletizers for local packaging and construction industries. The region is starting to see increased foreign direct investment in plastics recycling, creating a nascent but growing opportunity for advanced equipment providers focused on durability and ease of maintenance suitable for fluctuating operational conditions.

- Middle East and Africa (MEA): The MEA market, specifically the GCC nations, is driven by significant investments in petrochemical production. Demand centers around high-capacity dry strand systems for virgin polymer processing (polyolefins). While recycling infrastructure is still developing, the long-term potential exists as governments prioritize diversification away from oil, leading to increased plastics manufacturing and consumption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dry Strand Pelletizers Market.- Coperion GmbH

- Gala Industries Inc.

- Nordson Corporation (BKG)

- Extricom GmbH

- Wuxi Tianda Polytech Co., Ltd.

- Econ GmbH

- ACERETECH Machinery Co., Ltd.

- Maag Pump Systems AG (Gala & Reduction)

- Rajoo Engineers Limited

- LCI Corporation

- Crown Machine

- Coway Machinery Co., Ltd.

- Process Control Corporation

- Nanjing Kerke Extrusion Equipment Co., Ltd.

- Everplast Machinery Co., Ltd.

- Technovel Corporation

- TEMA Process B.V.

- Nanjing Tengda Extrusion Machinery Co., Ltd.

- Nanjing Haisi Extrusion Equipment Co., Ltd.

- Wuxi JKS Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dry Strand Pelletizers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of dry strand pelletizing over underwater systems?

Dry strand pelletizing offers superior control over cooling and crystallization rates, preventing material degradation and water absorption. This makes it ideal for highly sensitive polymers, high-viscosity materials, and compounds requiring ultra-precise pellet geometry and minimal residual moisture, such as engineering plastics and recycled PET.

How are Dry Strand Pelletizers adapting to the challenges of processing recycled plastics?

Pelletizer manufacturers are introducing heavy-duty, wear-resistant components, specifically cutter heads and dies made from advanced alloys, to handle the abrasive fillers and contaminants found in recycled streams. Additionally, integrated melt filtration and sophisticated tension control systems are being employed to manage material inconsistency and ensure high-quality output from Post-Consumer Recycled (PCR) feedstocks.

Which geographical region dominates the demand for Dry Strand Pelletizers?

The Asia Pacific (APAC) region currently dominates the demand due to its massive plastic manufacturing base, rapid industrial growth, and high volume requirements for commodity and engineering plastics production, particularly in countries like China and India.

What role does automation play in optimizing dry strand pelletizing operations?

Automation, utilizing advanced PLC controls and sensor technology, ensures precise synchronization between the extruder, puller belts, cooling bath, and cutter head. This integration minimizes strand breaks, maintains consistent pellet length, reduces operator intervention, and facilitates the adoption of predictive maintenance protocols, significantly boosting overall equipment effectiveness (OEE).

What is the typical lifespan and maintenance schedule for dry strand pelletizer cutting knives?

The lifespan of cutting knives varies significantly based on the processed material's abrasiveness. For standard polyolefins, knife sets can last thousands of hours; however, when processing highly filled or glass-fiber reinforced compounds, specialized tungsten carbide knives might require inspection or replacement much more frequently, often requiring predictive monitoring systems to determine optimal service intervals and minimize unscheduled downtime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager