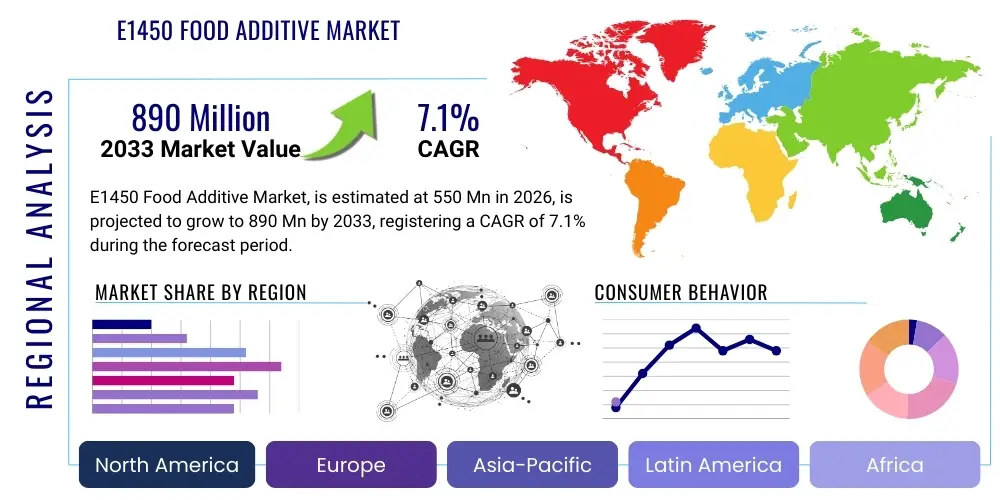

E1450 Food Additive Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442202 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

E1450 Food Additive Market Size

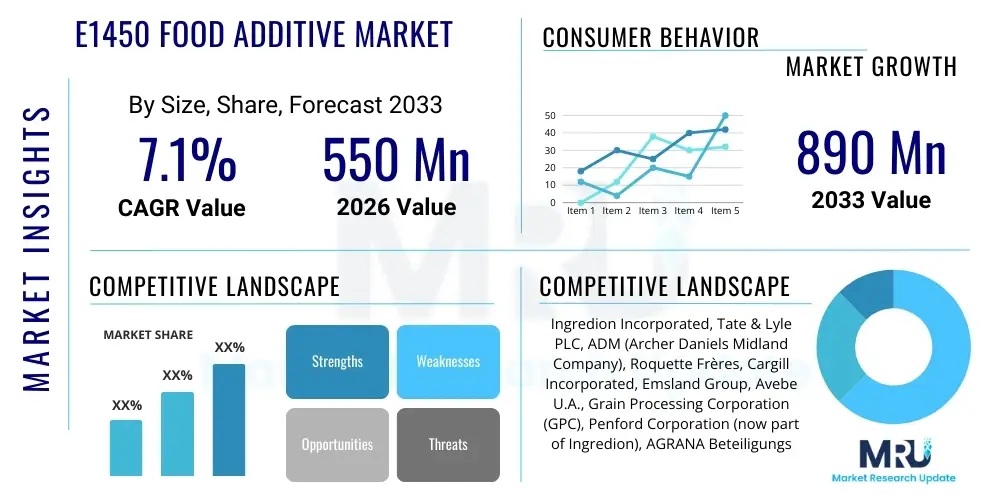

The E1450 Food Additive Market, specifically referring to Starch Sodium Octenyl Succinate (SSOS), is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.1% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 890 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the rising demand for sophisticated, stable emulsion systems across the food and beverage industry, particularly within the fast-growing segments of flavor encapsulation and dairy-free products.

E1450 Food Additive Market introduction

The E1450 food additive, chemically designated as Starch Sodium Octenyl Succinate, is a hydrophobically modified starch derived primarily from corn, potato, or tapioca starch. Its modification involves the esterification of starch with octenyl succinic anhydride (OSA), resulting in an amphiphilic molecule structure which grants it superior emulsification, stabilization, and thickening capabilities, rivaling traditional stabilizers like gum Arabic and caseinates. E1450 is essential in manufacturing products requiring long-term stability and specific textural attributes, particularly in complex aqueous systems containing fats or flavors.

Major applications of E1450 span across beverages, salad dressings, sauces, low-fat spreads, and flavor encapsulation systems. In the beverage sector, it is highly valued for stabilizing cloud agents and enhancing mouthfeel in soft drinks and functional beverages. Its unique capacity for microencapsulation makes it indispensable for protecting volatile flavor oils, vitamins, and sensitive ingredients against oxidation, heat, and moisture, thereby extending product shelf life and ensuring flavor integrity during processing and storage. The regulatory status of E1450, approved widely in regions like the European Union, the United States, and Australia, further supports its widespread adoption.

The market benefits from several powerful driving factors, including the global shift towards processed and convenience foods that necessitate high-performance ingredients to maintain quality and stability. Furthermore, E1450 offers a solution to formulation challenges related to reducing fat content while preserving desirable texture and mouthfeel, aligning perfectly with consumer demand for healthier, low-calorie options. The clean label movement also indirectly favors E1450, as it is often preferred over synthetic stabilizers, provided its modified starch origin is accepted by consumers seeking minimally processed ingredients.

E1450 Food Additive Market Executive Summary

The E1450 market exhibits robust expansion, primarily fueled by the accelerating innovation in functional foods and the necessity for superior flavor delivery systems. Business trends indicate a focus on optimizing manufacturing efficiency through continuous processing and the exploration of sustainable starch sources, such as cassava and potato, to mitigate supply chain volatility associated with corn. Key industry players are increasingly investing in proprietary modification technologies to achieve specialized performance characteristics, such as enhanced heat stability or improved oil-loading capacity, to gain a competitive edge in high-value application areas like pharmaceutical encapsulation and nutritional supplements. Strategic mergers and acquisitions are observed, aiming to consolidate control over raw material sourcing and integrate diverse functional ingredient portfolios, thereby offering comprehensive solutions to global food manufacturers.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, driven by rapidly expanding processed food consumption, urbanization, and increasing regulatory harmonization regarding food additive use in major economies like China and India. North America and Europe remain mature markets characterized by stringent quality standards and a high demand for non-GMO and certified organic starches, pushing manufacturers toward traceable and sustainably sourced raw materials. The European market, despite having strict regulation regarding modification levels, presents consistent demand due to its large, sophisticated consumer base requiring high-quality, shelf-stable products, especially in the bakery and confectionery sectors. Latin America and the Middle East & Africa are emerging as significant markets, driven by infrastructural development in food processing and rising disposable incomes leading to greater adoption of packaged goods.

Segment-wise, the encapsulation segment dominates market value, attributable to the high-value nature of flavor, vitamin, and nutraceutical delivery applications where E1450’s film-forming and barrier properties are crucial. The food and beverage sector remains the largest consumer by volume, particularly within the dressings and sauces segment, where E1450 serves as a crucial emulsifier to prevent phase separation and improve viscosity. Furthermore, the proliferation of plant-based dairy and meat alternatives is creating a specialized niche for E1450, leveraging its texturizing and binding capabilities to mimic the mouthfeel and stability traditionally provided by animal proteins and fats. This high-growth niche is expected to significantly influence segment revenue forecasts over the medium term.

AI Impact Analysis on E1450 Food Additive Market

User inquiries concerning AI's integration into the E1450 market frequently revolve around how artificial intelligence can enhance the consistency and efficiency of the complex starch modification process and predict raw material availability and price fluctuations. Common themes include leveraging machine learning for optimized reaction conditions (temperature, pH, reagent concentration) to maximize the degree of substitution (DS) of the octenyl succinate group, which is critical for functional performance. Additionally, users are concerned about AI's role in rapid quality control testing, predicting the emulsification stability of new E1450 batches under varied application environments, and optimizing supply chain logistics to minimize waste and ensure traceability of starch sources. The overarching expectation is that AI will accelerate the R&D cycle for next-generation modified starches and provide predictive modeling for regulatory compliance and consumer acceptance.

- AI-driven optimization of starch esterification reaction parameters, leading to highly consistent modification levels (Degree of Substitution).

- Predictive modeling for raw material sourcing (corn, potato, tapioca) volatility, ensuring supply chain resilience and cost management.

- Machine learning algorithms applied to quality assurance for rapid assessment of emulsification performance and shelf-life prediction of E1450-containing end products.

- Accelerated discovery and screening of novel functional modifications and formulation combinations using high-throughput data analysis.

- Enhanced traceability systems utilizing blockchain and AI analytics to monitor E1450 origin and compliance with international food safety standards.

- Optimization of energy consumption during the drying and milling stages of E1450 production, contributing to reduced operational costs and improved sustainability metrics.

DRO & Impact Forces Of E1450 Food Additive Market

The E1450 Food Additive Market is influenced by a dynamic interplay of factors encompassing technological advancements, regulatory environments, and shifting consumer preferences. Key drivers include the exponential growth in demand for flavor encapsulation, which necessitates a high-performance, cost-effective wall material for volatile oil protection. Furthermore, the imperative for food manufacturers to reduce fat content in products without compromising texture or stability mandates the use of highly efficient emulsifiers and texturizers like E1450. Conversely, market growth faces restraints from persistent regulatory scrutiny in certain developed economies, particularly concerning the maximum permissible level of modification, which can limit the functional intensity of the additive. High initial investment costs for establishing specialized starch modification facilities and competition from established hydrocolloids (e.g., Xanthan Gum, Guar Gum) and protein-based emulsifiers also pose significant challenges to market penetration.

Opportunities for expansion are abundant, particularly in the rapidly evolving sectors of plant-based foods and personalized nutrition. E1450 provides excellent stability in non-dairy beverages and meat analogue formulations, helping to achieve the desired viscosity and suspension properties essential for consumer acceptance. The development of customized E1450 variants tailored for specific pH or thermal environments, potentially through enzymatic modification techniques, presents a substantial avenue for premiumization and market differentiation. Impact forces, driven by consumer perception and regulatory changes, dictate the pace of market adoption. A major force is the push for ‘clean label’ starches; while E1450 is a modified starch, manufacturers are working to emphasize its natural origin and non-synthetic processing steps to align with consumer trends, utilizing highly localized sourcing strategies to reinforce the clean label narrative.

The intensity of competitive rivalry remains high, driven by major global players with deep expertise in starch chemistry and extensive distribution networks. The threat of substitutes is considerable, as alternative stabilizers like lecithin, whey protein isolates, and certain gums can fulfill similar functional roles, particularly in cost-sensitive applications. However, E1450’s superior film-forming capacity, solubility, and low viscosity at high concentrations—especially vital for encapsulation—provide a unique functional advantage that substitutes often fail to replicate entirely. The increasing complexity of modern food matrices (e.g., highly acidic, low-fat, high-fiber products) further solidifies E1450's position as a preferred functional ingredient capable of solving advanced formulation challenges.

Segmentation Analysis

The E1450 Food Additive Market is comprehensively segmented based on its source material, primary function within the application, and the end-use industry. Analyzing these segments provides critical insights into market dynamics, identifying high-growth areas and formulation trends. Segmentation by source is vital due to regulatory differences regarding GMO status and performance variations inherent to the granular structure of the native starch. Functional segmentation highlights the primary value proposition of E1450—its exceptional emulsifying and encapsulating properties—while end-use segmentation reveals the specific industries driving volume demand and revenue growth, predominantly the food and beverage sector, followed by specialized applications in nutraceuticals and pharmaceuticals.

- By Source:

- Corn Starch

- Tapioca Starch

- Potato Starch

- Wheat/Rice Starch (Niche)

- By Function:

- Emulsifier

- Stabilizer

- Thickener

- Encapsulating Agent

- By Application:

- Food & Beverage

- Beverages (Soft drinks, Functional drinks, Juices)

- Dressings and Sauces

- Dairy and Dairy Alternatives (Yogurts, Milk substitutes)

- Confectionery and Bakery

- Snack Foods

- Nutraceuticals and Pharmaceuticals

- Vitamin and Supplement Encapsulation

- Controlled Drug Release Systems

- Cosmetics and Personal Care

- Food & Beverage

Value Chain Analysis For E1450 Food Additive Market

The value chain for E1450 Food Additive begins with the sourcing and processing of primary agricultural raw materials, which are high-quality native starches (corn, tapioca, or potato). Upstream activities involve bulk cultivation and harvesting, followed by wet milling to isolate and purify the starch granules. Raw material quality is paramount, as the purity and physical characteristics of the native starch significantly influence the efficiency of the subsequent modification steps and the final performance of the E1450 product. Key upstream market players focus heavily on long-term supply agreements and quality control to ensure a steady supply of non-GMO certified or identity-preserved starch, which commands a premium in many international markets, especially Europe and North America.

The midstream segment constitutes the specialized chemical modification process. This involves treating the native starch slurry with octenyl succinic anhydride (OSA) under controlled alkaline conditions, followed by neutralization, washing, drying, and milling. This highly technical stage adds significant value, transforming a commodity ingredient into a high-performance functional additive. Manufacturers invest heavily in proprietary process technology to achieve precise control over the degree of substitution (DS), particle size distribution, and solubility profiles. Regulatory compliance, particularly adherence to E1450 specifications set by bodies like the Codex Alimentarius and regional food safety authorities, is critical at this stage, dictating the maximum allowable OSA content and residual reaction byproducts.

The downstream component involves distribution and application by end-use manufacturers. E1450 is distributed through a mix of direct sales channels, catering to large multinational food and beverage corporations, and indirect channels, utilizing specialized ingredient distributors who service smaller and medium-sized enterprises (SMEs). Direct sales ensure technical support and customization, while indirect channels provide market reach and logistical efficiency. Key end-users—flavor houses, beverage manufacturers, and convenience food producers—integrate E1450 into their formulations, leveraging its functionality to solve complex stability and textural issues. The successful delivery of the additive is heavily reliant on technical consultation provided by the E1450 producers to ensure optimal application and formulation success.

E1450 Food Additive Market Potential Customers

The primary customers for E1450, Starch Sodium Octenyl Succinate, are large-scale food and beverage processors and specialized ingredient manufacturers, particularly flavor and fragrance houses. Flavor encapsulation firms represent a particularly high-value customer segment, utilizing E1450 as a core wall material for spray-dried flavors, essential oils, and functional ingredients. These companies require E1450 for its high oil-loading capacity and exceptional barrier properties against oxidation, ensuring the longevity and potency of their encapsulated products which are then sold to the final food manufacturers. The superior performance in microencapsulation distinguishes E1450 from many other common wall materials, making it indispensable for high-quality flavor systems used in baked goods, snacks, and instant beverages.

Another major consumer group includes manufacturers of dressings, sauces, and low-fat dairy/non-dairy alternatives. In these applications, E1450 functions primarily as a robust emulsifier and stabilizer, crucial for preventing phase separation in high-shear processes or low-pH environments common in salad dressings and mayonnaise. The drive toward healthier formulations, specifically fat reduction, increases the dependence on E1450 to mimic the desirable mouthfeel and creaminess traditionally provided by fat, making it a critical ingredient for meeting consumer health demands while maintaining sensory attributes. Manufacturers of functional beverages and ready-to-drink products also represent significant buyers, utilizing E1450 to stabilize suspended solids and provide a smooth, enhanced texture.

The nutraceutical and pharmaceutical sectors form an expanding niche for E1450 utilization. Companies producing supplements, vitamins, and pharmaceutical ingredients are increasingly using E1450 for controlled release applications and to mask unpleasant tastes associated with certain active compounds. Its biocompatibility and favorable regulatory status in drug excipients make it an attractive choice for solid dosage forms and specialized delivery systems. These buyers require specific, high-purity grades of E1450, often demanding stricter certification and documentation compared to standard food-grade material, resulting in higher transaction values within this specialized application segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 890 Million |

| Growth Rate | 7.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ingredion Incorporated, Tate & Lyle PLC, ADM (Archer Daniels Midland Company), Roquette Frères, Cargill Incorporated, Emsland Group, Avebe U.A., Grain Processing Corporation (GPC), Penford Corporation (now part of Ingredion), AGRANA Beteiligungs-AG, Wihuri Group (Wipak), Chemstar, Inc., Qingdao Tianyi, Nippon Starch Chemical Co., Ltd., SPAC Starch Products (India) Ltd., SMS Corporation, KMC, Beneo GmbH, S&D Starch Processing, Guangxi Wuming Baima Starch Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

E1450 Food Additive Market Key Technology Landscape

The technological landscape for E1450 production is centered on maximizing the efficiency and control of the esterification process while improving product performance characteristics. Current advancements focus heavily on optimizing the uniformity of the octenyl succinate modification (DS) across all starch granules, as inconsistent modification can lead to variability in emulsification capacity. Key technologies include the utilization of continuous reactors, replacing traditional batch processing, which allows for tighter control over temperature, pH, and mixing dynamics, leading to a more homogenous, higher-quality E1450 output. Furthermore, manufacturers are exploring solvent-free or minimal-solvent processes to enhance sustainability and reduce processing costs, moving away from conventional aqueous slurry methods toward dry or semi-dry modification techniques.

A burgeoning area of innovation involves enzymatic modification, which seeks to achieve the functional attributes of E1450 (emulsification and amphiphilicity) using biological catalysts rather than conventional chemical reagents like OSA. This enzymatic approach is highly attractive because it aligns strongly with the clean label trend, potentially allowing the resulting product to be classified as 'enzyme-modified starch' rather than 'chemically modified starch' in certain jurisdictions. While still nascent, the progress in enzyme technology promises tailored starches with precise functional groups, offering superior performance for specific applications like high-salt environments or extreme thermal processing.

The post-modification processing stage is also undergoing technological refinement. Advanced drying techniques, such as spray drying and fluid bed drying combined with optimized milling and sieving, are crucial for controlling the particle size and bulk density of the final E1450 powder. Particle engineering is vital, especially for encapsulation applications, where uniform particle size ensures consistent film formation and coating efficacy. Digitalization and integration of process analytical technology (PAT) are becoming standard, enabling real-time monitoring of critical quality attributes during production, minimizing off-spec batches, and significantly enhancing overall operational efficiency across the E1450 manufacturing value chain.

Regional Highlights

- Asia Pacific (APAC): Characterized by the highest growth rate globally, APAC is driven by rapid industrialization of the food sector, increasing per capita consumption of processed foods, and high investment in flavor and fragrance manufacturing (particularly in China and India). The region is both a major producer of native starches (tapioca, rice) and a massive consumer of modified starch, fueling demand for localized E1450 production and technical service support.

- North America: A mature market defined by innovation and stringent quality requirements. Demand is high for specialized E1450 grades, including non-GMO corn-based variants, used extensively in low-fat functional foods, beverages, and nutraceutical encapsulation. Regulatory compliance, driven by the FDA, ensures high product standards, compelling market players to invest heavily in certifications and traceability.

- Europe: This region maintains stable, high-value demand, heavily influenced by the European Food Safety Authority (EFSA) regulations concerning E1450 usage levels. Consumer trends favor natural and minimally processed ingredients, pushing manufacturers to ensure the E1450 production process is as transparent and sustainable as possible, supporting its use in sophisticated ready meals, dairy alternatives, and high-quality bakery products.

- Latin America (LATAM): Emerging market showing accelerated growth due to urbanization and the entry of global quick-service restaurants and food chains, increasing the need for industrial-scale stabilizers and emulsifiers. Local availability of raw starches (corn, cassava) supports regional manufacturing capacity expansion.

- Middle East & Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries, linked to tourism, population expansion, and large-scale food manufacturing initiatives. Demand focuses on products that offer high thermal stability suitable for local processing and extended shelf life required in challenging climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the E1450 Food Additive Market.- Ingredion Incorporated

- Tate & Lyle PLC

- ADM (Archer Daniels Midland Company)

- Roquette Frères

- Cargill Incorporated

- Emsland Group

- Avebe U.A.

- Grain Processing Corporation (GPC)

- AGRANA Beteiligungs-AG

- Nippon Starch Chemical Co., Ltd.

- SPAC Starch Products (India) Ltd.

- SMS Corporation

- KMC

- Beneo GmbH

- Chemstar, Inc.

- Qingdao Tianyi

- Zhejiang Chaohua Starch Co., Ltd.

- Cerealbase S.p.A.

- Vimal Starch & Chemicals Pvt. Ltd.

- Guangxi Wuming Baima Starch Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the E1450 Food Additive market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of E1450 (Starch Sodium Octenyl Succinate) in food formulations?

E1450 functions predominantly as a high-performance emulsifier and encapsulating agent. Its amphiphilic structure enables it to stabilize oil-in-water emulsions, prevent phase separation in dressings and sauces, and microencapsulate volatile flavors or vitamins for protection and controlled release.

Is E1450 compliant with current clean label food trends?

While E1450 is chemically modified starch, many manufacturers offer non-GMO or sustainably sourced variants, often marketed under functional starch labels. Regulatory acceptance is high globally, but consumer perception regarding modified starches necessitates transparency in sourcing and minimal processing claims to align with modern clean label preferences.

Which application segment drives the highest growth rate for E1450 usage?

The flavor and fragrance encapsulation segment demonstrates the highest value growth due to the critical role E1450 plays in protecting high-value ingredients. Additionally, the fast-growing plant-based dairy alternatives sector is driving significant volume demand for E1450 as a specialized texturizer and stabilizer.

What are the main regulatory concerns impacting the E1450 market?

The primary regulatory concern revolves around the maximum allowed degree of substitution (DS) of the octenyl succinate group, which is strictly controlled by bodies like EFSA and FDA to ensure safety. Compliance requires rigorous testing and documentation of the modification level and purity of the final product.

How does E1450 compare to traditional emulsifiers like Gum Arabic?

E1450 offers comparable or superior emulsifying stability and flavor retention compared to Gum Arabic, often requiring lower usage levels. E1450 generally provides lower viscosity and higher loading capacity, making it technically preferable in applications where low viscosity and high solids content are required, such as clear beverages or intense flavor concentrates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager