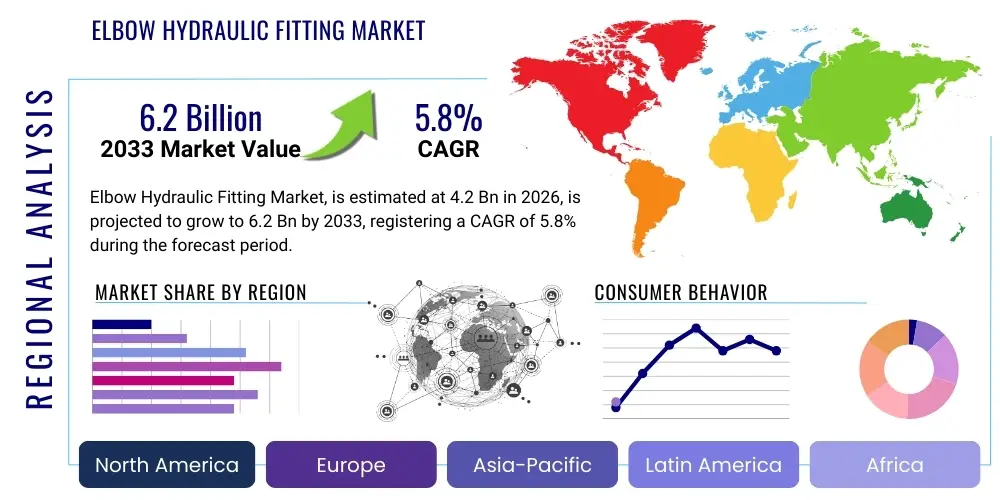

Elbow Hydraulic Fitting Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443643 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Elbow Hydraulic Fitting Market Size

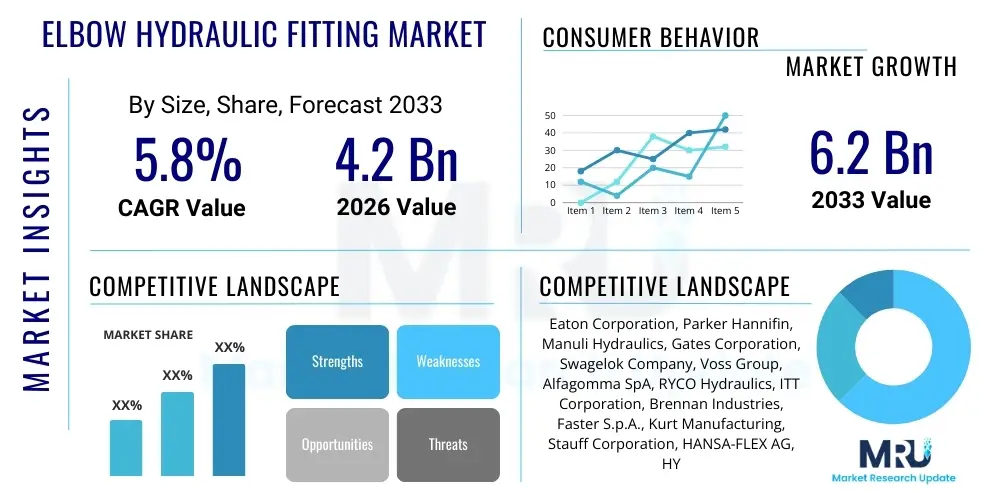

The Elbow Hydraulic Fitting Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2033. This consistent expansion is predominantly fueled by relentless global investments in large-scale infrastructure projects, including transportation networks, municipal water systems, and expansive commercial construction initiatives, particularly across developing economies in the Asia Pacific region. The reliability and crucial function of elbow fittings in managing high-pressure fluid transfer across diverse industrial machinery solidify their necessity, underpinning stable market growth.

Market valuation reflects the increasing adoption of automated and heavy-duty machinery across core sectors such as agriculture, mining, and oil & gas exploration. Elbow hydraulic fittings, essential components for redirecting fluid flow at precise angles (typically 45 or 90 degrees), ensure operational efficiency and system integrity in environments demanding robust performance and minimal leakage. The shift towards higher-pressure systems in modern equipment designs necessitates fittings manufactured from advanced, durable materials, thereby elevating the average selling price and contributing significantly to the overall market size expansion.

Elbow Hydraulic Fitting Market introduction

The Elbow Hydraulic Fitting Market encompasses the manufacturing, distribution, and utilization of components designed to connect, terminate, control, and redirect the flow of hydraulic fluid in industrial and mobile applications. These fittings are crucial for creating leak-proof seals and ensuring the structural integrity of hydraulic circuits, particularly where space constraints require sharp changes in direction. Products range from permanent crimped fittings to reusable screw-together connectors, manufactured primarily from materials like carbon steel, stainless steel, brass, and specialized alloys, tailored to withstand extreme pressures and corrosive operating conditions inherent in hydraulic systems.

Major applications of these fittings span across heavy machinery utilized in construction (excavators, bulldozers), agriculture (tractors, harvesting equipment), mining, material handling, aerospace, and general industrial manufacturing. The primary benefit derived from high-quality elbow hydraulic fittings is the prevention of fluid leakage, which enhances system efficiency, reduces downtime, and ensures safety compliance. Furthermore, the specialized design of elbow fittings provides unparalleled flexibility in system layout, allowing engineers to optimize machine designs by routing high-pressure lines around complex components without compromising flow characteristics.

Key driving factors accelerating market growth include rapid urbanization, which spurs construction and infrastructure demand globally, alongside the ongoing trend of replacing manual processes with automated hydraulic machinery. The stringent regulatory environment emphasizing safety and environmental protection, such as mandates for zero-leak systems, further compels end-users to upgrade to premium, high-performance elbow fittings. Moreover, technological advancements in fitting design, leading to quicker installation times and improved resistance to impulse and vibration, significantly contribute to increased adoption rates across mission-critical applications.

Elbow Hydraulic Fitting Market Executive Summary

The Elbow Hydraulic Fitting Market is characterized by robust business trends centered on material innovation and strategic mergers and acquisitions aimed at supply chain consolidation and geographic expansion. Key manufacturers are increasingly focusing on producing fittings compliant with international standards (SAE, DIN, ISO), offering value-added services such as kitting and assembly solutions to streamline end-user operations. The trend towards miniaturization in certain industrial hydraulic applications, coupled with the need for fittings capable of handling extremely high-pressure surges (upwards of 600 bar), dictates current product development strategies, driving demand for complex, precision-engineered elbow fittings made via advanced CNC machining.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, supported by massive governmental investments in infrastructure, particularly in China, India, and Southeast Asian nations, alongside the booming automotive and heavy equipment manufacturing sectors. North America and Europe maintain stable demand, driven primarily by replacement cycles, modernization of aging infrastructure, and a strong presence of aerospace and defense industries, which require highly specialized and certified fittings. Developing regions are prioritizing durable and cost-effective solutions, while mature markets focus intensely on premium stainless steel and corrosion-resistant options.

Segment trends indicate that the 90-degree elbow fitting segment dominates the market due to its versatility in core industrial and mobile hydraulic systems, although the 45-degree segment shows high growth potential in space-constrained applications. In terms of material, carbon steel remains the volume leader due to its balance of cost and strength, but stainless steel is gaining substantial traction across sectors requiring maximum corrosion resistance, such as marine, offshore oil exploration, and chemical processing. The primary trend across all segments is the increasing consumer preference for bite-type (ferrule-based) and flared fittings, which offer superior sealing mechanisms compared to older thread-sealing methods, thereby enhancing operational reliability.

AI Impact Analysis on Elbow Hydraulic Fitting Market

User inquiries concerning the influence of Artificial Intelligence (AI) on the Elbow Hydraulic Fitting Market often revolve around three central themes: optimizing manufacturing processes, integrating fittings into smart predictive maintenance systems, and improving supply chain resilience. Users are concerned about how AI can enhance the quality control (QC) inspection of complex fitting geometries, minimize material waste during CNC machining, and forecast the degradation or failure rates of fittings in operational hydraulic circuits. The expectation is that AI will move these components from passive flow conduits to active, intelligent nodes within the broader industrial internet of things (IIoT) ecosystem, particularly impacting high-value, critical applications in aerospace and oil & gas.

- AI-driven Predictive Maintenance (PdM): Algorithms analyze pressure, temperature, and vibration data from hydraulic circuits, integrated often via sensors adjacent to fittings, to predict potential fitting failure before catastrophic leakage occurs.

- Optimized Manufacturing & QC: AI-powered computer vision systems enable ultra-fast, highly accurate inspection of complex internal and external fitting dimensions, ensuring zero-defect production runs and conformity to stringent quality specifications.

- Supply Chain Resilience: Machine learning models optimize inventory management for raw materials (steel, brass) and finished goods, forecasting demand fluctuations based on construction cycles and industrial output trends globally.

- Automated Design & Simulation: AI tools accelerate the design iteration process for new, complex elbow fittings, simulating stress points, fatigue limits, and optimal flow dynamics under extreme operating conditions.

- Robotic Assembly Integration: AI guides precision robotic systems in the automated assembly and kitting of hydraulic hose assemblies, ensuring repeatable accuracy in crimping and routing processes involving elbow fittings.

DRO & Impact Forces Of Elbow Hydraulic Fitting Market

The Elbow Hydraulic Fitting Market is fundamentally driven by the extensive expansion of global industrial output and capital expenditure across various heavy-duty sectors. A primary driver is the accelerating pace of infrastructure development, especially in emerging economies, which requires massive fleets of hydraulic-powered construction and earthmoving equipment. Complementary to this is the stringent focus on operational safety and efficiency; hydraulic leaks represent major safety hazards and cost implications, pushing end-users to adopt premium, leak-proof fitting solutions, thereby continually elevating the market standard.

However, the market faces significant restraints, including the high volatility in the prices of primary raw materials like steel and copper, which directly impacts manufacturing costs and profitability margins, especially for standardized, high-volume products. Furthermore, the necessity for fittings to adhere to a myriad of regional and international standardization protocols (e.g., JIC, BSP, Metric standards) creates complexity in manufacturing and inventory management, slowing down global market harmonization. The risk associated with counterfeit or sub-standard fittings entering the market also poses a challenge, undermining the reputation of quality manufacturers and potentially leading to system failures.

Opportunities for growth are abundant, particularly in the realm of developing lightweight and durable composite fittings for niche applications such as aerospace and electric heavy equipment, where weight reduction is a critical performance factor. The integration of smart features, such as embedded RFID tags or micro-sensors in fittings for real-time condition monitoring (part of the IIoT movement), presents a significant avenue for premium market differentiation and value creation. The substantial maintenance, repair, and overhaul (MRO) segment also offers continuous opportunity, driven by the need to replace fittings in aging hydraulic systems across industrial facilities worldwide, ensuring a stable, recurring revenue stream for manufacturers.

Segmentation Analysis

The Elbow Hydraulic Fitting market is highly segmented based on critical factors such as product type (angle), material composition, pressure range, and the specific end-use industry. Understanding these segments is crucial for strategic market positioning, as performance requirements vary drastically between, for example, a high-pressure mining operation and a standard agricultural application. The 90-degree elbow segment maintains volume leadership due to its omnipresence in system layouts requiring a complete directional change, while the distinction between permanent (crimp) and reusable (field-attachable) fittings dictates purchasing decisions based on maintenance frequency and operational access.

Segmentation by material is perhaps the most defining factor, with carbon steel offering cost-effectiveness for general industrial use, and stainless steel commanding a premium for highly corrosive or extreme temperature environments. Pressure rating segmentation (low, medium, high, and ultra-high) directly correlates with the safety standards and performance demands of modern hydraulic machinery. The end-user analysis provides critical insight, showing dominant consumption coming from mobile equipment (construction, agriculture) versus stationary industrial machinery (manufacturing, power generation), each demanding different volume and specification requirements for elbow fittings.

- By Angle/Type: 90-Degree Elbow Fittings, 45-Degree Elbow Fittings, Adjustable Elbow Fittings, Swivel Elbow Fittings.

- By Connection Type: Threaded Fittings (NPT, BSPP, Metric), Flared Fittings (JIC 37-degree), Bite-Type/Compression Fittings (DIN 24-degree), Flange Fittings, Quick Disconnect Couplings.

- By Material: Carbon Steel, Stainless Steel (304, 316), Brass, Aluminum Alloys, Thermoplastics/Composites (Niche Applications).

- By Pressure Rating: Low Pressure (below 100 bar), Medium Pressure (100–250 bar), High Pressure (250–450 bar), Ultra-High Pressure (above 450 bar).

- By End-Use Industry: Construction and Infrastructure, Agriculture and Forestry, Mining and Material Handling, Oil & Gas (Onshore and Offshore), Aerospace and Defense, Automotive and Transportation, Industrial Manufacturing and Automation.

Value Chain Analysis For Elbow Hydraulic Fitting Market

The value chain for elbow hydraulic fittings begins with the sourcing of specialized raw materials, primarily high-grade carbon steel, various stainless steel alloys (like 316L), and brass billets. The upstream analysis highlights that material cost volatility and securing consistent supply meeting strict metallurgic specifications are primary challenges. Key suppliers of raw materials, often major steel mills and specialized alloy producers, exert moderate bargaining power, particularly for stainless steel used in extreme pressure environments. Manufacturing involves precision processes, including forging, complex CNC machining, surface treatment (e.g., zinc plating or passivation), and rigorous quality inspection to ensure dimensional accuracy and pressure resistance, representing the highest value-addition stage.

The distribution channel is multifaceted, relying heavily on specialized industrial distributors and hydraulic components wholesalers who maintain large inventories and provide technical support to end-users. Direct distribution is common for large Original Equipment Manufacturers (OEMs) who have long-term supply contracts with fitting manufacturers, ensuring tailored specifications and just-in-time delivery. Indirect distribution channels leverage regional agents and Maintenance, Repair, and Overhaul (MRO) service providers to reach smaller end-users and replacement markets globally. The efficiency of the distribution network, including rapid availability and logistical optimization, is crucial for market success, given the emergency replacement nature of many fitting sales.

Downstream analysis focuses on the end-users: heavy machinery OEMs, system integrators, and large maintenance departments. The bargaining power of major OEMs is substantial, driving manufacturers to offer competitive pricing and tailored solutions, often requiring custom-engineered fittings. The demand side emphasizes reliability, certification, and ease of installation. The overall value chain is highly dependent on specialized expertise in hydraulic system design, requiring strong collaboration between manufacturers and distributors to ensure correct component application and minimize system failure risk in diverse operating environments.

Elbow Hydraulic Fitting Market Potential Customers

The primary consumers and buyers of elbow hydraulic fittings are concentrated within sectors relying on intensive fluid power transmission for movement, force generation, and control. Original Equipment Manufacturers (OEMs) of heavy mobile machinery, such as construction equipment (Caterpillar, Komatsu, Volvo), agricultural machinery (John Deere, CNH Industrial), and material handling equipment (forklifts, cranes), represent the largest volume purchasers. These OEMs require millions of standardized and proprietary fittings annually, driving long-term contracts based on strict quality control and price performance metrics. Their procurement is characterized by large volume, custom specifications, and rigorous adherence to industry standards like SAE and DIN.

The second major category involves Maintenance, Repair, and Overhaul (MRO) service providers and industrial end-users, including petrochemical plants, steel mills, power generation facilities, and manufacturing assembly lines. These customers purchase fittings predominantly for replacement purposes, driven by the degradation of existing hydraulic infrastructure due to operational fatigue, corrosion, or accidental damage. MRO demand is typically less predictable in volume but demands rapid availability of a wide range of fitting types and sizes, often sourced through local and regional distributors to minimize downtime.

Specialized segments, such as aerospace, defense, and offshore oil exploration, constitute high-value customers. While their volume is lower, these sectors demand fittings made from high-performance materials (e.g., Titanium, high-grade stainless steel) with extremely tight tolerances and specialized certification (e.g., API, military specifications). These end-users prioritize absolute reliability, high-pressure resistance, and material traceability, making them lucrative but demanding customers who require direct engagement with specialized manufacturers capable of delivering certified, mission-critical components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Parker Hannifin, Manuli Hydraulics, Gates Corporation, Swagelok Company, Voss Group, Alfagomma SpA, RYCO Hydraulics, ITT Corporation, Brennan Industries, Faster S.p.A., Kurt Manufacturing, Stauff Corporation, HANSA-FLEX AG, HYDAC International GmbH, DNP Group, Custom Fluidpower, Fluid System Components Inc., Superlok, Hydroscand Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Elbow Hydraulic Fitting Market Key Technology Landscape

The technology landscape in the elbow hydraulic fitting market is increasingly dominated by advancements in precision engineering and material science, crucial for meeting the demands of ever-higher system pressures and endurance requirements. Modern manufacturing processes rely heavily on sophisticated multi-axis Computer Numerical Control (CNC) machining centers and specialized cold-forging techniques. These technologies allow manufacturers to produce fittings with extremely tight tolerances, superior surface finishes, and complex internal geometries that optimize fluid flow characteristics and minimize pressure drops. The continuous drive towards automation in the manufacturing line ensures consistent quality, repeatability, and cost efficiency, positioning advanced production capabilities as a major competitive differentiator.

Material innovation is another core technological area. While traditional carbon steel remains prominent, there is a significant technological push towards developing higher-strength, lighter-weight alloys and specialized treatments. This includes the use of stainless steel 316L for enhanced corrosion resistance in marine and chemical environments, and the exploration of proprietary coating technologies (e.g., specific zinc-nickel plating processes) that dramatically increase resistance to salt spray and harsh operating conditions, often exceeding standard industry specifications. Furthermore, advanced simulation software (Finite Element Analysis - FEA) is integral in the design phase, allowing engineers to virtually test fitting integrity under cyclic loading and impulse pressure conditions before physical prototyping, shortening time-to-market for new, high-performance designs.

The emerging technological focus is on connectivity and integration, aligning fittings with the Industrial Internet of Things (IIoT). This involves the development of 'smart' fittings that can accommodate or integrate micro-sensors for monitoring internal fluid temperature, pressure, or excessive vibration. Although still nascent, this technological leap aims to transform passive fittings into active data points within a hydraulic network, facilitating real-time monitoring and predictive maintenance strategies. Furthermore, innovations in sealing technologies, such as advanced elastomer compounds and metal-to-metal sealing geometries (like face seal O-rings), are continuously refined to ensure zero-leak performance under dynamic and shock-loaded conditions, a critical technological requirement across all high-stakes hydraulic applications.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by unparalleled government spending on infrastructure, including massive rail, road, and dam construction projects, particularly in China, India, and Indonesia. The robust expansion of the domestic automotive and capital goods manufacturing sectors further fuels the demand for hydraulic machinery and, consequently, high volumes of elbow fittings. Price sensitivity remains a factor, yet the increasing focus on locally manufactured components meeting international quality standards is a key regional trend.

- North America: This region holds a significant market share, characterized by high adoption rates of advanced, high-pressure fittings, especially in the oil and gas (shale drilling), aerospace, and heavy construction sectors. The market is driven by technological maturity, stringent safety regulations (OSHA), and a strong preference for premium, high-reliability products. Modernization of aging municipal infrastructure and replacement cycles in mining equipment provide a stable, recurring demand base.

- Europe: The European market is highly mature and innovation-focused, with a strong emphasis on compliance with strict environmental regulations (e.g., REACH) and quality standards (DIN, ISO). Demand is driven by advanced manufacturing (Germany), precision engineering, and the robust agricultural machinery sector. There is a notable trend towards stainless steel and specialty fittings capable of enduring extreme conditions and ensuring leak-free performance as mandated by European safety bodies.

- Latin America (LATAM): Market growth in LATAM is closely linked to commodity cycles, driven primarily by mining operations (Chile, Peru) and agricultural expansion (Brazil, Argentina). The demand often fluctuates but generally favors robust, cost-effective carbon steel fittings, though increasing foreign investment is introducing higher-specification products in critical projects.

- Middle East and Africa (MEA): This region's demand is concentrated in the oil & gas sector (both exploration and refining) and significant infrastructure projects in the GCC countries. The harsh, often desert-like environment mandates the use of fittings with superior corrosion and heat resistance, driving demand for specialized materials and coatings. Political stability and oil price volatility remain key external factors influencing capital expenditure on hydraulic equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Elbow Hydraulic Fitting Market.- Parker Hannifin Corporation

- Eaton Corporation plc

- Manuli Hydraulics

- Gates Corporation

- Swagelok Company

- Voss Group

- Alfagomma SpA

- RYCO Hydraulics

- ITT Corporation

- Brennan Industries

- Faster S.p.A.

- Kurt Manufacturing

- Stauff Corporation

- HANSA-FLEX AG

- HYDAC International GmbH

- DNP Group

- Custom Fluidpower

- Fluid System Components Inc.

- Superlok

- Hydroscand Group

Frequently Asked Questions

Analyze common user questions about the Elbow Hydraulic Fitting market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are most commonly used for manufacturing high-pressure elbow hydraulic fittings?

The most commonly used materials are carbon steel, prized for its excellent strength-to-cost ratio in standard applications, and stainless steel (specifically 316 and 316L), which is essential for environments requiring superior corrosion resistance, such as marine, chemical, and offshore oil & gas operations.

Which end-use industry is the largest consumer of elbow hydraulic fittings globally?

The Construction and Infrastructure sector, encompassing heavy mobile equipment like excavators, loaders, and cranes, is the largest consumer. This dominance is driven by high volume usage and intensive global construction activity, especially in the Asia Pacific region.

What is the primary technical difference between 45-degree and 90-degree elbow hydraulic fittings?

The primary difference is the angle of fluid flow redirection. 90-degree elbows are used for complete, sharp changes in piping direction and are ubiquitous in hydraulic systems. 45-degree elbows offer a gentler directional change, often utilized in applications where space is slightly more available or where minimizing pressure drop is a critical design priority.

How are bite-type fittings different from traditional threaded fittings in hydraulic systems?

Bite-type (compression) fittings, such as DIN 24-degree connectors, utilize a ferrule that "bites" into the external surface of the hydraulic tube, creating a secure, metal-to-metal seal without the need for flaring or specialized thread sealants. They offer higher pressure capabilities and superior leak prevention compared to many traditional threaded connections.

What impact does the increasing adoption of electric vehicles (EVs) have on the hydraulic fitting market?

While pure electric vehicles reduce conventional engine-driven hydraulic systems, the growing market for electric heavy equipment (e-construction, e-mining) still requires robust, often higher-pressure hydraulic systems for movement and actuation. This shift is driving demand for fittings made from lightweight materials and components capable of integration with electronic control units and sensors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager