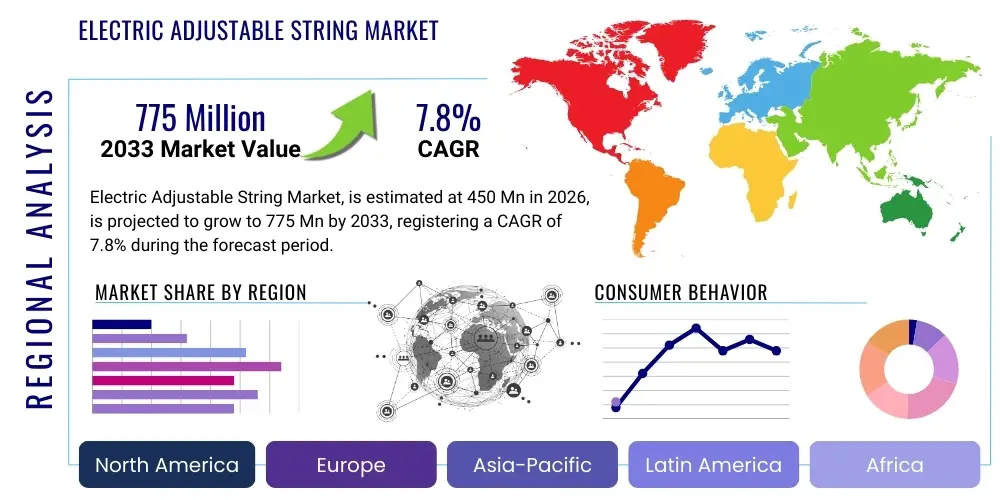

Electric Adjustable String Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441489 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Electric Adjustable String Market Size

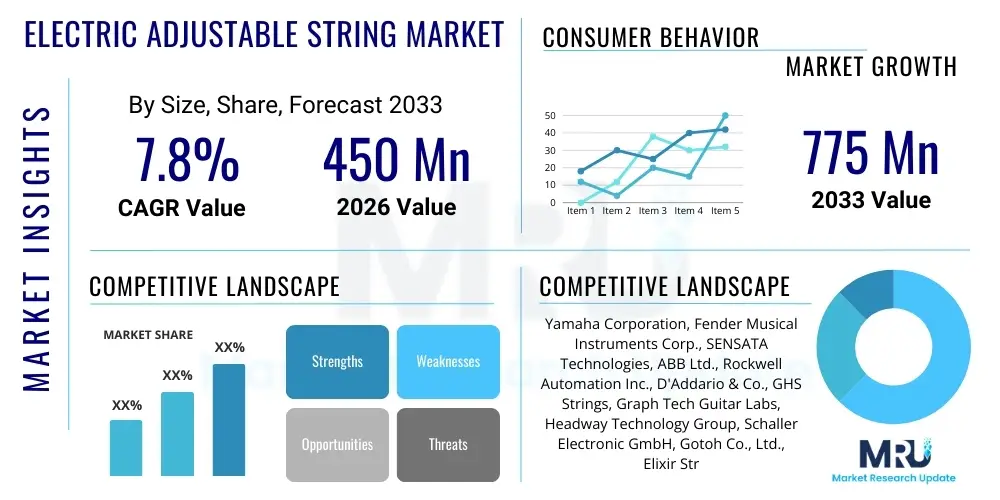

The Electric Adjustable String Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 775 Million by the end of the forecast period in 2033.

Electric Adjustable String Market introduction

The Electric Adjustable String Market encompasses specialized electromechanical systems designed to precisely control the tension, vibration, or length of string-like elements using electric actuation and sophisticated feedback mechanisms. These systems are crucial in applications requiring high fidelity tuning, dynamic sensory input, or controlled structural tension, moving beyond traditional manual or fixed adjustment methods. The product spectrum includes advanced sensor strings, smart tuning pegs, automated tensioning devices, and related control units utilizing micro-actuators and proprietary algorithms for real-time adjustments. Market growth is heavily influenced by the increasing demand for automation in precision manufacturing and the evolution of smart musical instruments and high-fidelity testing equipment. The core function of these products is to provide unparalleled accuracy and repeatability in tension control, which is essential for maximizing performance and minimizing operational variability across diverse end-use sectors.

Major applications of electric adjustable string technology span across professional musical instruments, where they enable instantaneous tuning changes and alternative tunings; industrial testing and diagnostics, particularly in materials science where string resonance is used to measure integrity; and robotics, where controlled tension is needed for delicate gripping or structural stability. The technology leverages high-precision stepper motors or servo systems coupled with sophisticated strain gauges and microprocessors to achieve dynamic and accurate adjustments. This integration allows for remote operability and programmed adjustment sequences, significantly enhancing efficiency and expanding creative possibilities for users in both consumer and industrial settings. The complexity and high cost of initial deployment, however, remain a minor restraint, though the long-term benefits of precision and labor savings often outweigh these initial investments.

Key benefits driving market adoption include enhanced performance accuracy, rapid adjustment capabilities, and the integration of digital control interfaces, facilitating seamless integration with broader Internet of Things (IoT) ecosystems. Factors such as the rising consumer interest in advanced, digitally enhanced musical instruments, the stringent requirements for precision testing in aerospace and automotive sectors, and continued miniaturization of electric actuation components are fueling market expansion. Furthermore, the capacity of these systems to adapt instantly to environmental variables, such as temperature fluctuations or material creep, positions them as indispensable tools in environments where maintaining precise string tension or length is non-negotiable for system functionality or artistic expression. The technological sophistication inherent in these products dictates a highly specialized manufacturing process, contributing to their premium market positioning.

- Product Description: Electromechanical systems providing precise, automated control over string tension, length, or vibration through integrated actuators and digital feedback loops.

- Major Applications: Automated musical instrument tuning, structural health monitoring, high-precision industrial testing, advanced robotics manipulation.

- Benefits: High tuning accuracy, rapid adjustments, integration with digital control systems, enhanced repeatability, compensation for environmental variables.

- Driving Factors: Increased automation demand in precision industries, growth of smart musical instruments, miniaturization of micro-actuators, and stringent quality control requirements.

Electric Adjustable String Market Executive Summary

The Electric Adjustable String Market is characterized by robust technological innovation, driven predominantly by advancements in sensor technology and micro-actuation systems. Key business trends indicate a strong move toward market consolidation among specialized component providers and strategic partnerships between technology developers and established musical instrument manufacturers or industrial equipment suppliers. The high capital expenditure required for R&D in this niche market fosters innovation concentrated in established technology hubs, primarily in North America and Asia Pacific. Companies are increasingly focused on developing proprietary algorithms for predictive tension maintenance and self-calibration, ensuring system longevity and consistent performance. Furthermore, the shift towards subscription-based software services for control units and maintenance is emerging as a new revenue stream, signaling a mature and increasingly digitalized market landscape.

Regionally, North America maintains market leadership due to high levels of technological adoption across the aerospace, defense, and high-end consumer electronics sectors, alongside the strong presence of major musical instrument brands that act as first adopters. The Asia Pacific (APAC) region, however, is projected to experience the fastest growth, propelled by rapid industrial automation in countries like China, South Korea, and Japan, coupled with significant investments in smart manufacturing infrastructure and advanced musical education programs. Europe exhibits steady growth, focusing particularly on regulatory-compliant industrial inspection systems and specialty components for niche, high-value manufacturing processes. Market saturation is currently low globally, providing substantial white-space opportunities for regional players to develop specialized applications tailored to local industrial needs, particularly in Latin America and the Middle East & Africa (MEA).

Segmentation trends highlight the increasing importance of the 'Control Unit and Software' segment, which provides the intellectual backbone for physical adjustments. Within applications, the 'Industrial Testing and Monitoring' segment is expected to outpace the 'Musical Instruments' segment in terms of value growth, driven by non-discretionary spending on structural integrity and compliance testing. The core technology segments, such as micro-stepper motors and piezoelectric actuators, are experiencing intense competition, leading to rapid cost reduction and performance enhancements. Demand is also surging for multi-string control systems capable of simultaneous, independent adjustment, moving beyond single-point solutions. This granular control capability is essential for large-scale industrial machinery monitoring and complex acoustic systems, signifying a market shift from basic automation to integrated, complex system management solutions.

AI Impact Analysis on Electric Adjustable String Market

Common user inquiries concerning the influence of Artificial Intelligence on the Electric Adjustable String Market often center on how AI can enhance predictive maintenance, optimize real-time performance, and facilitate complex autonomous tuning sequences. Users are particularly interested in whether AI algorithms can predict material fatigue in the strings or components based on usage patterns and environmental data, thereby extending system lifespan and reducing downtime. Concerns also revolve around the integration complexity and the computational resources required to deploy AI-driven control systems, especially regarding latency for real-time musical or industrial applications. The expectation is that AI will transform these systems from purely reactive mechanisms to predictive and self-optimizing entities, capable of learning optimal tension profiles for diverse applications and mitigating environmental interference automatically. This shift represents a move towards 'Cognitive String Systems' that proactively manage tension integrity and performance parameters without explicit human intervention.

- Predictive Maintenance: AI algorithms analyze sensor data (strain, temperature, vibration) to forecast component failure or string fatigue, scheduling proactive adjustments.

- Real-Time Optimization: Machine learning fine-tunes string parameters instantaneously based on environmental changes or performance requirements (e.g., acoustic feedback).

- Automated Tuning Protocols: AI facilitates the creation and execution of complex, dynamic tension sequences for specialized industrial testing or multi-tonal musical arrangements.

- Fault Diagnostics: Enhanced AI-powered control units quickly identify and isolate anomalies within the adjustment mechanism or the string itself, improving operational reliability.

- Design Optimization: Generative AI assists in modeling optimal actuator size, material properties, and feedback loop design for new product development, minimizing physical prototyping.

DRO & Impact Forces Of Electric Adjustable String Market

The dynamics of the Electric Adjustable String Market are shaped by a powerful confluence of drivers, technological restraints, and significant opportunities, which collectively define the market’s growth trajectory and competitive landscape. The primary driver is the pervasive industry requirement for ultra-high precision and automated control in electromechanical systems, particularly as industrial processes become more digitized and less tolerant of human error or manual variance. Simultaneously, the restraint imposed by the requirement for extremely high-reliability components operating under varying tension and cyclical stress presents a significant technological hurdle, requiring specialized materials and complex manufacturing tolerances. Opportunities are substantial in integrating these string systems into advanced IoT platforms and developing novel applications in structural health monitoring for infrastructure like bridges and buildings, moving beyond traditional applications. These forces are impacting the market by accelerating innovation cycles and increasing the barriers to entry for new competitors who lack expertise in high-precision actuation and proprietary sensor fusion.

Key drivers include the global expansion of Industry 4.0 initiatives, necessitating sensor-rich and autonomously adjustable machinery, and the accelerating demand from the professional music sector for instruments that offer instant, reliable, and complex tuning flexibility, reducing stage setup time and expanding creative expression. Furthermore, the decreasing size and cost of micro-actuators and microcontrollers make these systems more accessible for integration into mass-market consumer electronics. However, the market faces significant restraints, chiefly related to the proprietary nature of existing feedback algorithms and the high costs associated with developing durable, miniature actuation mechanisms capable of withstanding prolonged mechanical stress. There is also a standardization challenge, as components often need customization to fit specific instrument designs or industrial test rigs, limiting economy of scale.

Opportunities for market players are immense, particularly in establishing dominance in the emerging field of dynamic, responsive materials testing, where precise tension application is critical for simulating real-world operational loads. The development of wireless, battery-powered control systems that minimize integration complexity also represents a significant growth vector. Moreover, strategic exploitation of intellectual property around sensor fusion and predictive maintenance algorithms will be critical for sustained competitive advantage. The interplay between these forces encourages investment in R&D aimed at miniaturization, energy efficiency, and algorithmic intelligence, compelling market participants to continuously enhance product performance while simultaneously seeking avenues for cost reduction and market penetration into less traditionally automated sectors.

- Drivers: Demand for high-precision automated tension control, rise of smart musical instruments, Industry 4.0 adoption, technological advancements in micro-actuation systems.

- Restraints: High R&D costs, technological complexity and miniaturization challenges, lack of standardized components, specialized material requirements for string longevity under dynamic stress.

- Opportunity: Expansion into structural health monitoring, integration with IoT and cloud analytics platforms, development of user-friendly wireless control interfaces, penetration into specialized medical device manufacturing.

- Impact forces: Increasing bargaining power of specialized component suppliers, moderate threat of new entrants due to high technical barriers, high intensity of rivalry among existing key players focused on technological differentiation.

Segmentation Analysis

The Electric Adjustable String Market is meticulously segmented based on the component technology employed, the type of end application, and the geographic regions driving demand. This granular segmentation allows for a detailed understanding of market dynamics, revealing where investment is most concentrated and where untapped potential exists. The technological segmentation focuses heavily on the nature of the actuation mechanism—whether it utilizes micro-stepper motors, piezoelectric systems, or advanced servo controls—as this dictates precision and response speed. Application segmentation separates high-volume consumer markets (musical instruments) from high-value industrial markets (testing and robotics), recognizing the vastly different performance and regulatory requirements of each sector. The market is increasingly defined by the integration capabilities of these systems, pushing components toward modularity and standardized digital communication protocols to ensure compatibility across diverse end-use platforms.

- By Component: Actuators/Motors, Sensors (Strain Gauges, Vibration Sensors), Control Units/Microprocessors, String Materials, Power Supply Modules.

- By Actuator Type: Micro Stepper Motors, Piezoelectric Actuators, Servo Motors, Linear Voice Coil Motors.

- By Application: Musical Instruments (Guitars, Harps, Pianos), Industrial Testing and Measurement (Material Stress Testing), Robotics and Automation, Structural Health Monitoring, Specialized Research and Development.

- By Sales Channel: Original Equipment Manufacturers (OEMs), Aftermarket, Direct Sales, Online Retail.

- By Region: North America, Europe, Asia Pacific (APAC), Latin America (LATAM), Middle East & Africa (MEA).

Value Chain Analysis For Electric Adjustable String Market

The value chain for the Electric Adjustable String Market begins with highly specialized upstream activities centered on the procurement and processing of niche raw materials. This includes high-grade composites and alloys required for durable string materials, precision metals for micro-actuators, and advanced semiconductor components for control units and sensors. Key upstream participants are specialized materials science firms and high-precision component manufacturers, who dictate the quality and reliability of the final product. Due to the high-tolerance manufacturing required, these upstream suppliers wield significant bargaining power. The core value addition occurs during the manufacturing and integration stage, where complex electromechanical assemblies are produced, and proprietary software algorithms are embedded into the control units, transforming raw components into functional, high-precision adjustment systems. Efficiency in the upstream segment directly correlates with the final product's performance specifications and cost structure.

The downstream analysis focuses on the distribution channels and the end-user interaction points. Distribution is bifurcated into direct sales to Original Equipment Manufacturers (OEMs)—such as major musical instrument companies or industrial automation firms—and indirect channels involving specialized distributors who handle aftermarket sales and system integration for smaller industrial clients. Direct distribution is common for high-value industrial contracts requiring customization, ensuring direct technical support and quality control. Indirect channels, including online retail and music equipment stores, cater predominantly to the consumer and small-scale professional market. The effectiveness of the downstream segment relies heavily on providing comprehensive technical training and responsive customer service, as these are technically sophisticated products requiring expert installation and ongoing maintenance advice. Successful downstream operations hinge on established relationships with highly technical integrators and reputable specialized resellers.

The overall efficiency of the value chain is determined by the seamless flow of high-precision components and intellectual property (algorithms) from upstream suppliers through to final integration by manufacturers and delivery through effective distribution channels. Direct channels offer faster time-to-market for innovative products and tighter feedback loops for product improvement, which is crucial in a technology-driven market. Indirect channels, while offering broader geographical reach, often introduce complexities related to inventory management and technical support consistency. Optimizing the blend of these distribution strategies is essential for maximizing market penetration and maintaining control over the brand and product quality, particularly when dealing with global markets where regulatory and logistical challenges differ significantly. Continuous process improvement in both assembly and logistics is paramount for maintaining profitability.

Electric Adjustable String Market Potential Customers

The primary customer base for the Electric Adjustable String Market is highly diverse, spanning specialized professional sectors and high-end consumer markets. End-users fall mainly into two categories: industrial enterprises requiring precision tensioning for monitoring and control, and professional musicians and music equipment manufacturers seeking advanced tuning solutions. Industrial buyers include aerospace and automotive manufacturers who use these systems for precise material stress testing and quality assurance of composite structures, leveraging the system's ability to simulate dynamic load conditions. Furthermore, civil engineering firms are emerging as significant potential customers, utilizing these strings for long-term, remote structural health monitoring of large infrastructure, detecting subtle shifts in material integrity and stress distribution automatically. These industrial applications prioritize reliability, longevity, and data integration capabilities, often requiring bespoke system configurations and compliance with stringent industry standards.

In the consumer and professional audio segment, potential customers are major guitar and string instrument manufacturers who integrate these automated tuning systems as a premium feature into their high-end models, offering a distinct competitive advantage. Individual professional musicians and recording studios also represent a crucial buying group, as the technology allows for instantaneous access to a vast array of alternative tunings, significantly streamlining the creative process during live performances and studio sessions. The demand in this sector is driven by ease of use, speed of adjustment, and acoustic fidelity, often placing a high value on sleek design and seamless digital integration. Education and research institutions, particularly those focused on acoustics, vibration physics, and materials science, also constitute a smaller but highly influential customer segment, purchasing systems for experimental validation and advanced training purposes.

Overall customer demand is shifting toward integrated solutions that combine physical adjustment with advanced data analytics and cloud connectivity. Buyers are increasingly looking for systems that not only adjust tension precisely but also provide actionable insights into the physical state of the material or instrument. This pivot necessitates that market players focus their efforts on developing robust software platforms alongside mechanical components. Strategic marketing must address the distinct needs of these varied customer segments, emphasizing durability and compliance for industrial buyers, while highlighting artistic flexibility and premium performance for the consumer and professional audio clientele, ultimately tailoring value propositions to specific end-user requirements and procurement cycles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 775 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Yamaha Corporation, Fender Musical Instruments Corp., SENSATA Technologies, ABB Ltd., Rockwell Automation Inc., D'Addario & Co., GHS Strings, Graph Tech Guitar Labs, Headway Technology Group, Schaller Electronic GmbH, Gotoh Co., Ltd., Elixir Strings (W. L. Gore & Associates), Roland Corporation, Moog Music Inc., Korg Inc., Honeywell International Inc., TE Connectivity, PCB Piezotronics, Microchip Technology Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Adjustable String Market Key Technology Landscape

The Electric Adjustable String Market is highly dependent on advancements in several interconnected technology domains, primarily centered on precision electromechanics, sensor fusion, and embedded system programming. The core technology lies in the micro-actuation systems, which include high-resolution micro-stepper motors and increasingly, piezoelectric actuators, favored for their rapid response time, minimal physical footprint, and precise displacement control. Stepper motor systems offer higher torque and sustained tension, making them suitable for heavy-duty industrial applications, while piezoelectric components excel in high-frequency, fine-tuning adjustments essential for acoustic fidelity. The transition towards closed-loop control systems, incorporating high-speed digital signal processing (DSP) and proprietary algorithms, is critical for achieving the required stability and repeatability, mitigating issues like backlash and creep that plague simpler mechanical solutions.

Sensor technology constitutes the second pillar of the landscape, where miniature strain gauges, load cells, and highly sensitive vibration sensors (accelerometers) are integrated directly into the string path or the tensioning mechanism. These sensors provide immediate feedback on the actual physical state of the string (tension, resonance frequency, amplitude), enabling the control unit to make necessary, sub-millisecond corrections. The convergence of these sensor inputs—a process known as sensor fusion—is vital for intelligent performance, especially in environments subject to noise or thermal variance. Furthermore, wireless communication technologies, specifically low-power Bluetooth and proprietary mesh networks, are increasingly utilized for remote control and data logging, enhancing the user experience and facilitating easier integration into larger industrial monitoring networks (IoT platforms). This connectivity necessitates robust security protocols to protect proprietary tuning profiles and sensitive industrial data.

The intellectual property surrounding the control software and firmware is arguably the most valuable technological asset in this market. Advanced tuning algorithms must account for non-linear material behaviors, temperature drift, and dynamic load changes to maintain absolute tension accuracy. Current research focuses heavily on developing self-learning algorithms (utilizing AI and machine learning techniques) that can personalize tuning profiles for individual users or specific materials and proactively correct anticipated errors. Furthermore, material science is playing a growing role, with innovations in string composites and low-friction, self-lubricating gear materials extending the operational lifespan and reliability of the adjustable components. This synergy between mechanical precision, advanced sensing, and cognitive software defines the state-of-the-art in electric adjustable string technology.

Regional Highlights

- North America: Dominates the market value due to robust early adoption in the aerospace, defense, and high-end professional audio equipment sectors. The region benefits from significant R&D spending, a highly competitive technological ecosystem, and a strong presence of key market players in California, Massachusetts, and Texas. Demand is driven by advanced industrial automation standards and consumer preference for premium, digitally enhanced musical instruments.

- Europe: Characterized by steady, reliable growth, with a strong focus on regulatory compliance in industrial testing and measurement, particularly in Germany (automotive) and the UK (aerospace). The market emphasizes precision engineering and durable components, often specializing in custom-built solutions for niche manufacturing and specialized scientific research applications.

- Asia Pacific (APAC): Expected to exhibit the highest Compound Annual Growth Rate (CAGR), fueled by massive investment in smart factory infrastructure (Industry 4.0) across China, South Korea, and Japan. Rapid expansion of consumer electronics manufacturing and an increasing middle class with disposable income for sophisticated musical instruments are key drivers, alongside governmental focus on structural monitoring for urban development.

- Latin America (LATAM): Currently a nascent market, primarily driven by imports, but showing increasing potential due to growing industrialization, particularly in Brazil and Mexico. Market growth relies heavily on foreign direct investment in manufacturing and the slow but steady adoption of advanced quality control systems.

- Middle East and Africa (MEA): Smallest regional market, highly dependent on infrastructure projects and oil & gas industry requirements for monitoring and inspection systems. Growth is concentrated in the GCC states (Saudi Arabia, UAE), where large-scale construction and specialized industrial maintenance necessitate high-precision sensory equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Adjustable String Market.- Yamaha Corporation

- Fender Musical Instruments Corp.

- SENSATA Technologies Holding plc

- ABB Ltd.

- Rockwell Automation Inc.

- D'Addario & Co., Inc.

- GHS Strings

- Graph Tech Guitar Labs

- Schaller Electronic GmbH

- Gotoh Co., Ltd.

- Elixir Strings (W. L. Gore & Associates)

- Roland Corporation

- Moog Music Inc.

- Korg Inc.

- Honeywell International Inc.

- TE Connectivity Ltd.

- PCB Piezotronics, Inc.

- Microchip Technology Inc.

- C. R. Bard, Inc. (Specialized Sensing Division)

- Dongguan Aosen Electric Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Electric Adjustable String market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Electric Adjustable String Market?

The primary driver is the accelerating global adoption of Industry 4.0 technologies and the subsequent need for high-precision, automated tension control systems in manufacturing, quality assurance, and structural monitoring applications across industrial sectors.

How does the Electric Adjustable String technology differ from traditional manual tuning methods?

Electric adjustable string systems utilize integrated micro-actuators and digital sensors to achieve instantaneous, highly accurate, and repeatable adjustments based on algorithmic feedback, eliminating the inconsistencies and time required by manual, mechanical adjustment methods.

Which application segment holds the largest market share for electric adjustable strings?

While the musical instruments segment is highly visible, the Industrial Testing and Measurement segment currently accounts for the largest market share by value, driven by high capital expenditure requirements for precision equipment in aerospace, automotive, and civil engineering compliance testing.

What role does AI play in optimizing electric adjustable string performance?

AI is crucial for enabling predictive maintenance by analyzing usage data to forecast component wear, optimizing real-time adjustments based on environmental factors, and facilitating complex, autonomous tuning or tensioning protocols without human intervention.

What are the main technological restraints limiting market expansion?

Key technological restraints include the high complexity and cost associated with developing durable, miniaturized actuation mechanisms, the necessity for specialized materials to handle dynamic mechanical stress, and the proprietary nature of precision control algorithms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager