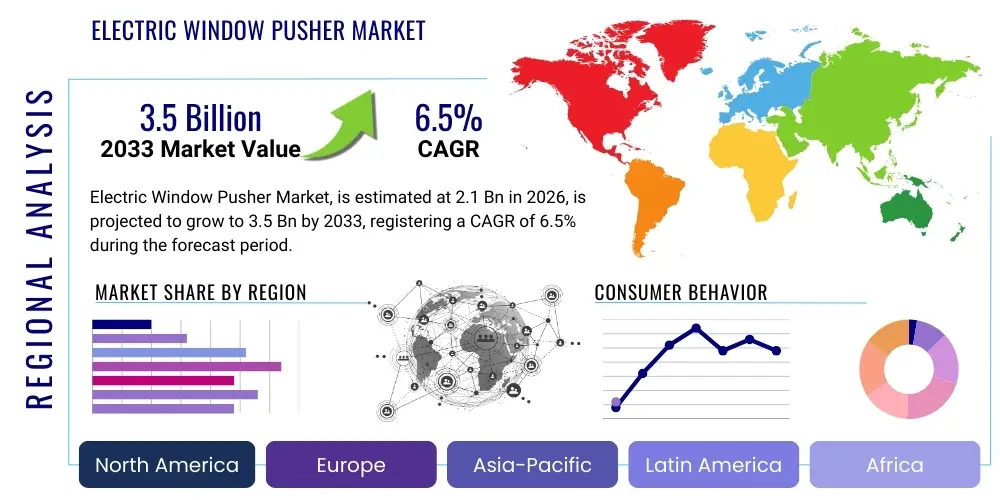

Electric Window Pusher Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440985 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Electric Window Pusher Market Size

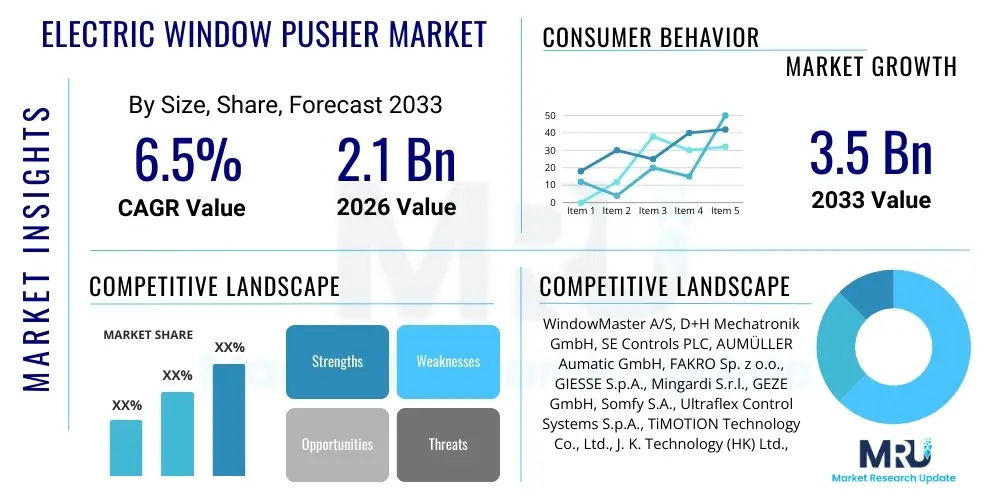

The Electric Window Pusher Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.5 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating global focus on smart building technologies, energy efficiency mandates, and improved climate control systems within commercial, residential, and industrial infrastructure. The increasing adoption of automated ventilation solutions in greenhouses and specialized agricultural facilities further contributes significantly to the market valuation and sustained growth trajectory across all major geographic regions, particularly in densely populated and technologically advanced economies.

Electric Window Pusher Market introduction

The Electric Window Pusher Market encompasses a specialized segment within the building automation and HVAC industries, focusing on motorized devices designed to open, close, and position windows, skylights, vents, and façade elements remotely or automatically. These systems are crucial components in modern sustainable architecture, enabling sophisticated natural ventilation strategies, smoke and heat extraction systems (SHEVS), and enhanced daylight management. The core functionality centers around linear or chain actuators that provide reliable, controlled movement, integrating seamlessly with Building Management Systems (BMS) and smart home platforms to optimize indoor air quality and energy consumption based on environmental parameters such as temperature, wind speed, and CO2 levels. These devices offer significant advantages over manual operation, particularly in scenarios involving large, heavy, or high-level windows that are inaccessible to standard occupants, ensuring safety and compliance with international building codes.

The primary applications for Electric Window Pushers span a wide array of vertical industries, from high-end residential complexes and luxury villas demanding aesthetic integration and superior comfort, to large commercial facilities such as shopping malls, airports, and corporate headquarters prioritizing energy efficiency and occupant health. Crucially, the implementation in institutional settings, including schools and hospitals, is becoming mandatory due to stringent air circulation standards designed to mitigate airborne pathogen transmission. Furthermore, the specialized agricultural sector utilizes these devices extensively for precise climate control within sophisticated greenhouse environments, where minute adjustments to ventilation are critical for crop yield optimization and protecting high-value horticulture assets from sudden weather changes. The robust design and capability for integration into fire safety systems distinguish these actuators as essential infrastructure components rather than mere convenience products.

The market expansion is underpinned by several compelling factors, notably the global legislative push for 'Net Zero' buildings and sustainable infrastructure development, which mandates the reduction of mechanical cooling reliance through optimized natural ventilation. Technological advancements in actuator design, leading to quieter operation, increased force capacity, and miniaturization, make them suitable for a broader range of window types and aesthetic applications. Benefits include enhanced security through automated locking mechanisms, improved energy performance by reducing HVAC load, and superior occupant comfort derived from consistent, controlled air exchange. These driving forces—sustainability, technological refinement, and regulatory requirements—solidify the Electric Window Pusher as a high-growth segment within the broader architectural hardware and smart technologies landscape, attracting significant investment in R&D for next-generation wireless and solar-powered solutions.

Electric Window Pusher Market Executive Summary

The Electric Window Pusher Market is currently characterized by rapid technological innovation and strategic consolidation, responding primarily to accelerating demand for integrated building automation solutions across North America and Europe. Business trends indicate a strong shift towards developing IoT-enabled actuators that facilitate predictive maintenance, remote diagnostics, and seamless communication within complex BMS ecosystems. Manufacturers are increasingly focusing on modular designs and interoperability standards (such as BACnet and Modbus) to simplify installation and integration, addressing the labor shortage and high installation costs that previously acted as market restraints. Furthermore, competitive pressures are driving continuous improvements in operational efficiency, durability (especially regarding weather resistance in exterior installations), and acoustic performance, making premium automated solutions more accessible to mid-tier commercial projects and mass residential developments, thus broadening the total addressable market significantly.

Regionally, the market exhibits diversified growth patterns. Asia Pacific (APAC), led by China, Japan, and South Korea, presents the highest growth potential due, not only to massive urbanization and unprecedented construction volumes but also to tightening government regulations concerning environmental pollution and indoor air quality in rapidly developing metropolitan areas. Europe maintains its leadership in terms of technological maturity and adoption rates, particularly driven by German and Scandinavian countries, where strict energy efficiency directives (like the European Union’s Energy Performance of Buildings Directive) mandate optimized ventilation systems in new builds and retrofits. Conversely, North America shows steady adoption, particularly in high-performance green building projects (LEED certified structures), where electric window pushers are critical for achieving high sustainability scores and premium operational efficiency, reflecting a strong correlation between investment in smart technology and superior building asset valuation.

Analysis of segment trends reveals that the linear rod and chain actuators continue to dominate the market by product type, primarily due to their versatility and high force capabilities, essential for heavy commercial windows and skylights. However, the rack and pinion segment is gaining traction in specialized industrial applications requiring extremely high precision and robust performance. By application, the commercial segment (including offices and retail) remains the largest revenue generator, but the residential sector is demonstrating the fastest CAGR, driven by the proliferation of smart home technology and increased consumer willingness to invest in comfort and energy saving features. Furthermore, the segmentation by operating voltage shows a clear move toward 24V DC systems for safety and ease of integration into low-voltage building control networks, overshadowing the traditional 110V/230V AC solutions in most new installations across all primary market verticals.

AI Impact Analysis on Electric Window Pusher Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Electric Window Pusher Market frequently revolve around two primary themes: optimization capability and predictive maintenance integration. Users are keen to understand how AI algorithms can move beyond simple threshold-based automation to truly predictive environmental control—asking questions like, "Can AI predict weather changes accurately enough to adjust ventilation proactively, thus saving energy?" and "Will AI integration reduce actuator failure rates and maintenance costs?" A significant concern is the balance between system autonomy and human override, particularly regarding safety systems like smoke ventilation, where reliability is paramount. Expectations center on AI enhancing the actuator’s role from a simple mechanical device to an intelligent, self-regulating component within a holistic smart building ecosystem, maximizing natural light utilization, minimizing reliance on mechanical HVAC systems, and optimizing air quality parameters in real-time based on occupancy patterns and historical data analysis, thereby transforming energy management and occupant comfort profiles.

The integration of deep learning models and machine learning algorithms is fundamentally restructuring the operational parameters of electric window pusher systems. Instead of reacting to immediate sensor inputs (e.g., temperature exceeds 25°C), AI systems process vast datasets, including forecasted external weather data, real-time occupancy monitoring via IoT sensors, localized pollen counts, and building thermal inertia characteristics. This complex processing allows the system to initiate precise, minimal adjustments proactively—for instance, slightly opening high-level vents an hour before predicted peak internal heat gain to preemptively stabilize the room temperature profile, thus achieving much finer control over climate and consuming dramatically less energy than reactive systems. This shift elevates the value proposition of the pusher system from a passive automation tool to an active energy management instrument, directly correlating AI integration with quantifiable operational savings and superior occupant satisfaction scores within the managed facility.

Furthermore, AI is instrumental in extending the service life and ensuring the continuous operational integrity of the actuators themselves. By continuously monitoring subtle operational metrics—such as motor load current, cycle time variations, and acoustic signatures—AI can detect minute anomalies indicative of impending mechanical failure (e.g., worn gears, misalignment, or excessive friction) long before they result in catastrophic breakdown. This predictive maintenance capability allows facility managers to schedule non-urgent maintenance during off-peak hours, minimizing operational disruption and preventing costly, emergency repairs. This predictive diagnostic functionality, powered by AI, transforms the total cost of ownership (TCO) calculation for large-scale deployments, justifying higher initial investment costs for intelligent actuators based on guaranteed long-term reliability and reduced maintenance expenditure over the building's lifecycle. Consequently, manufacturers heavily advertising AI integration are gaining significant competitive advantage.

- AI enables predictive natural ventilation scheduling based on weather forecasts, occupancy, and thermal modeling, optimizing energy use by minimizing mechanical HVAC engagement.

- Machine learning algorithms enhance system reliability by monitoring operational performance metrics (current draw, speed variance) to predict and flag potential mechanical failures (predictive maintenance).

- Deep learning models refine smoke and heat extraction procedures, ensuring actuators open optimal vents based on fire source localization and complex airflow dynamics within the facility structure.

- AI-driven optimization allows for precise management of indoor air quality (IAQ), automatically modulating ventilation rates in response to real-time CO2, volatile organic compound (VOC), and particulate matter sensor data.

- Integration with smart grids allows actuators to dynamically adjust operational cycles based on peak energy pricing periods, potentially delaying ventilation during high-cost intervals without compromising thermal comfort.

- AI facilitates adaptive acoustic management, ensuring the quietest possible operation of chain actuators by learning optimal acceleration and deceleration profiles tailored to different environmental noise levels and building usage times.

- Enhanced security features via AI-driven anomaly detection; systems can identify unusual or forced movement attempts on windows and automatically trigger localized security alerts or additional locking mechanisms.

- Improved commission and calibration processes through automated self-learning cycles, where the actuator determines the optimal force required for specific window sizes and weights post-installation, minimizing setup time and maximizing longevity.

DRO & Impact Forces Of Electric Window Pusher Market

The Electric Window Pusher Market is shaped by a robust combination of compelling drivers, necessary restraints, significant opportunities, and external impact forces. A primary driver is the accelerating trend of green building certifications (e.g., LEED, BREEAM), which increasingly favor automated natural ventilation as a pathway to achieving superior energy efficiency targets and high indoor environmental quality scores. This regulatory push is supplemented by growing consumer awareness regarding the health benefits of fresh air and natural light, particularly following global health crises that underscored the importance of effective air exchange systems in enclosed spaces. However, the market faces restraints, chiefly the high initial investment cost associated with high-quality, integrated automated systems compared to manual mechanisms, and the complexity involved in retrofitting existing buildings, which often requires significant structural modification and specialized labor. Overcoming these cost and complexity barriers is essential for widespread adoption outside the premium construction segment, representing a key strategic challenge for market stakeholders attempting to penetrate cost-sensitive markets and regions.

Opportunities for future expansion are vast, centering primarily on technological evolution and untapped geographical markets. The emergence of wireless, battery-powered, and solar-charged electric actuators presents a major opportunity to drastically simplify installation, eliminating the expensive and intrusive wiring required by traditional systems, thereby lowering the barrier to entry for residential and renovation projects. Furthermore, strategic opportunities lie in developing highly specialized applications, such as integrating actuators with façade cleaning robots or specialized security access systems for high-risk industrial environments. The burgeoning market for high-tech agricultural greenhouses globally, particularly in regions facing water scarcity or extreme climate variability, provides a distinct vertical opportunity, demanding precise, resilient automated ventilation solutions to protect high-value crops, far exceeding the scale of typical commercial building installations in terms of volume and complexity requirements.

External impact forces exert significant pressure on the market dynamics. Economic volatility, particularly fluctuating raw material prices (steel, aluminum, specialized plastics) and global supply chain disruptions (shipping bottlenecks, component shortages like microcontrollers), directly impact manufacturing costs and product lead times, affecting project timelines and pricing stability. Furthermore, evolving building safety regulations, especially concerning fire safety and smoke extraction (SHEVS mandates), act as a powerful and non-negotiable force, compelling facility owners to adopt compliant, certified electric pusher systems regardless of initial cost concerns. The competitive landscape is intensely impacted by rapid technological diffusion, where companies that fail to adopt IoT capabilities, cybersecurity protections, and intuitive user interfaces risk rapid market share erosion. Overall market trajectory is thus determined by a balance between mandatory regulatory compliance driving baseline sales and technological differentiation fueling premium segment growth and competitive advantage in saturated markets.

- Drivers:

- Increasing global implementation of green building standards and energy performance mandates (e.g., European EPBD, LEED certification requirements) promoting natural ventilation strategies.

- Growing awareness and demand for superior indoor air quality (IAQ) and thermal comfort in commercial and educational environments post-pandemic, driving investment in automated air exchange systems.

- Advancements in IoT and smart building technologies facilitate seamless integration of actuators with Building Management Systems (BMS) for centralized, highly efficient control.

- Rising construction activities in major developing economies, coupled with significant modernization and renovation projects in established markets.

- Mandatory regulatory compliance for Smoke and Heat Exhaust Ventilation Systems (SHEVS) in public and large commercial buildings necessitates reliable electric actuators.

- Restraints:

- High initial procurement and installation costs associated with sophisticated, certified electric actuation systems, deterring adoption in budget-sensitive projects.

- Technical complexity and specialized labor requirements for integrating automated systems into older, legacy building infrastructure during retrofit operations.

- Potential failures or malfunctions in integrated electronic systems, leading to high repair costs and operational downtime if maintenance protocols are neglected.

- Competition from simpler, non-automated or less expensive ventilation solutions in low-cost construction markets.

- Opportunities:

- Development and commercialization of wireless, solar-powered, and low-voltage (24V DC) electric pushers, drastically simplifying installation and expanding market penetration into residential and decentralized applications.

- Expansion into high-growth vertical markets such as automated agricultural greenhouses and specialized industrial climate control facilities requiring precise environmental regulation.

- Integration of advanced AI and machine learning for predictive maintenance and highly optimized, proactive climate control scheduling.

- Strategic partnerships with global smart home platform providers (e.g., Google Home, Amazon Alexa ecosystems) to integrate residential window automation features.

- Impact Forces:

- Global supply chain volatility affecting the availability and pricing of electronic components (microcontrollers, sensors) and raw materials (metal alloys).

- Evolving international standards and local building codes for energy efficiency, dictating product specifications and performance requirements.

- Macroeconomic conditions influencing investment in new construction and major renovation capital expenditure budgets globally.

- The rapid pace of digitalization and cybersecurity concerns requiring continuous updates and development of secure, encrypted communication protocols for connected devices.

Segmentation Analysis

The Electric Window Pusher Market is meticulously segmented across product type, operating voltage, application, and distribution channel, providing a granular view of market dynamics and strategic focus areas for manufacturers. Understanding these segments is crucial for accurate market forecasting and for identifying specialized niche markets offering high-margin growth. The segmentation by product type reflects the mechanical execution of movement, primarily differentiating between linear, chain, and rack and pinion mechanisms, each suited to specific window weights, opening strokes, and aesthetic requirements. Operating voltage segmentation highlights the technological shift towards safer, easier-to-integrate low-voltage systems, crucial for compliance in automated fire safety systems. Application segmentation confirms the market's reliance on the commercial sector while pointing towards accelerated growth in the increasingly digitized residential and specialized industrial verticals, reflecting diversified end-user demand patterns globally.

- By Product Type:

- Linear Actuators (Rod Pushers): Highly robust mechanisms offering high force output and long stroke lengths, primarily utilized for heavy skylights, roof vents, and large façade windows in commercial settings.

- Chain Actuators: Characterized by flexibility and compactness when retracted, making them aesthetically suitable for standard sash and casement windows, preferred in residential and lower-profile commercial environments.

- Rack and Pinion Actuators: Used for extremely heavy-duty applications or where rotary motion conversion is required, typically found in industrial facilities, large louvre systems, or massive, complex vent assemblies.

- By Operating Voltage:

- 24V DC Systems: Dominant segment due to safety regulations, ease of integration with centralized BMS controls, and suitability for battery backup in fire safety applications (SHEVS).

- 110V/230V AC Systems: Utilized primarily in older installations or in high-power industrial applications where direct connection to mains power is simpler and force requirements are extreme.

- By Application:

- Commercial Buildings: Includes corporate offices, retail complexes, hotels, airports, and public institutions, representing the largest revenue share due to scale and mandatory SHEVS implementation.

- Residential Buildings: Encompasses smart homes, high-end villas, and multi-story apartment complexes, showing the fastest growth rate driven by smart technology adoption and aesthetic preferences.

- Industrial Facilities: Covers factories, warehouses, and agricultural greenhouses, requiring specialized, often highly weather-resistant actuators for temperature and humidity control.

- Healthcare and Education: Hospitals, schools, and universities where strict air quality control and reliable automation are critical for safety and learning environment optimization.

- By Distribution Channel:

- Direct Sales (B2B): Primarily for large-scale construction projects and integration specialists, allowing direct communication regarding customization and system integration requirements.

- Indirect Sales: Through distributors, wholesalers, and specialized HVAC/security system integrators, catering to smaller projects, retrofit markets, and geographical areas lacking direct manufacturer presence.

Value Chain Analysis For Electric Window Pusher Market

The Value Chain for the Electric Window Pusher Market begins intensely at the upstream level, dominated by the sourcing and refinement of specialized raw materials and electronic components. Upstream activities involve acquiring high-grade, often custom-machined metal alloys (aluminum and stainless steel) for mechanical housing and internal gearing, essential for durability and load-bearing capacity. Critical to modern actuators is the procurement of highly sensitive microcontrollers, precise DC motors (often brushless for longevity), limit switches, and various sensor technologies (e.g., encoders for position feedback). Reliance on specific global suppliers for these electronic components, particularly in Asia, introduces points of vulnerability regarding supply chain stability and price fluctuations. Successful upstream management requires strategic, long-term contracts with specialized component manufacturers to ensure quality, consistent supply, and technological exclusivity, especially for proprietary motor and gearbox designs that define product performance and competitive advantage.

Moving into the midstream, manufacturing processes focus heavily on precision engineering, assembly, and rigorous testing. Manufacturers must invest significantly in automated assembly lines to maintain high levels of tolerance required for smooth, quiet operation and long product life. Quality control is paramount, involving extensive cycle testing, weather sealing verification, and compliance checks against international safety standards (elike CE, UL, and specific SHEVS certifications). The midstream phase also involves the integration of firmware and software components, ensuring the actuator can communicate effectively via standard protocols (e.g., Modbus, KNX) with diverse Building Management Systems. Manufacturing differentiation is often achieved here through modular design principles, enabling easy customization of stroke length, force output, and cosmetic finishes to meet the highly varied demands of architectural specifications across different projects.

The downstream distribution channel is highly specialized, moving the finished products from the factory floor to the point of installation. Direct sales channels are crucial for large commercial projects, involving close collaboration between the manufacturer, architectural firms, and system integrators to ensure seamless system design and deployment. Indirect channels, which utilize specialized distributors focusing exclusively on architectural hardware, HVAC equipment, or fire safety systems, cater effectively to smaller contractors, residential markets, and geographically dispersed retrofit projects. Installation and commissioning typically require certified system integrators or specialized contractors trained specifically by the manufacturer, emphasizing technical expertise for correct calibration and integration into complex safety loops. Post-sales service, including long-term maintenance contracts and technical support, is a significant part of the downstream value proposition, enhancing customer loyalty and providing recurring revenue streams within this technically sophisticated market.

Electric Window Pusher Market Potential Customers

Potential customers and end-users of Electric Window Pushers are broadly segmented into entities responsible for large-scale construction, facility operation, and private residential development focused on energy efficiency and technological integration. The largest segment by volume is the commercial construction sector, specifically General Contractors (GCs) and specialized Façade Engineers working on Class A office buildings, high-end retail centers, and institutional facilities such as major universities and governmental complexes. These buyers prioritize product certification (especially for SHEVS), reliability, seamless integration into sophisticated BMS systems, and long-term warranty provisions, viewing the actuators as critical infrastructure that protects assets and ensures occupant safety and well-being, justifying premium pricing for certified, integrated solutions.

A rapidly expanding customer base is the high-end residential market, driven by affluent homeowners and luxury home developers seeking advanced comfort, security, and aesthetic integration through smart home technologies. These customers value quiet operation, sleek design, and integration compatibility with popular consumer automation platforms (e.g., Zigbee, Z-Wave, proprietary wireless systems). While volume per project is lower than commercial, the requirement for custom finishes, often hidden installation, and intuitive user control panels drives high average transaction values. Furthermore, the specialized agricultural industry—including operators of large hydroponic and vertical farming facilities—represents a dedicated B2B customer segment. These buyers prioritize resilience against harsh environmental conditions (humidity, temperature extremes), precision control, and high cycling endurance to manage ventilation critical for specific crop health and yield optimization, placing functional performance above aesthetic concerns.

Finally, Facility Management (FM) companies and building retrofit specialists form a consistent customer segment focused on upgrading existing infrastructure to meet current energy efficiency standards and safety codes. These buyers are motivated by the return on investment (ROI) derived from reduced long-term energy costs and compliance avoidance risks. They require actuators that are easy to install, compatible with legacy wiring and control systems where possible, and highly durable to minimize maintenance intervention. This retrofit market often favors simpler, highly reliable chain actuators for ease of application across varied window types and sizes, contrasting with new construction which often demands complex, integrated linear systems. Manufacturers must tailor their sales pitch to highlight longevity and minimal disruption during installation to capture this significant ongoing maintenance and upgrade market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.5 Billion |

| Growth Rate | CAGR 6.5 % |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WindowMaster A/S, D+H Mechatronik GmbH, SE Controls PLC, AUMÜLLER Aumatic GmbH, FAKRO Sp. z o.o., GIESSE S.p.A., Mingardi S.r.l., GEZE GmbH, Somfy S.A., Ultraflex Control Systems S.p.A., TiMOTION Technology Co., Ltd., J. K. Technology (HK) Ltd., Phos Technology S.r.l., UCS Control Systems S.r.l., Nekos S.r.l., Essmann GmbH, BDC Systems, Ltd., TBO-Stahl GmbH, Hörmann Group, Kintrol Pty Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Window Pusher Market Key Technology Landscape

The technological landscape of the Electric Window Pusher Market is characterized by continuous advancements aimed at improving efficiency, connectivity, and durability, moving far beyond simple electromechanical function. Core innovations center on motor technology, where the transition from traditional brushed DC motors to high-efficiency, long-life brushless DC motors (BLDC) has significantly reduced operational noise, increased actuator lifespan, and improved force-to-size ratios, making them ideal for integration into high-specification architectural projects where aesthetics and silence are crucial. Furthermore, the integration of advanced digital electronics, specifically microcontrollers with embedded positional encoding (like Hall effect sensors or magnetic encoders), provides precise feedback on the window's exact open position, crucial for complex modulation required by intelligent ventilation strategies and SHEVS safety protocols, ensuring windows open to exact, defined angles rather than just fully open or closed states.

Connectivity and networking technologies are currently the fastest evolving areas. The standard shift towards low-voltage 24V DC systems facilitates seamless integration with central Building Management Systems (BMS) utilizing protocols such as BACnet, KNX, and Modbus. However, the cutting edge involves wireless communication standards like Zigbee, Z-Wave, and specialized proprietary mesh networks, which simplify installation in both new and retrofit projects by eliminating extensive cable runs, addressing a major installation cost restraint. The incorporation of IoT capability means actuators are assigned unique IP addresses, allowing for cloud-based remote monitoring, firmware updates, and diagnostic reporting, fundamentally changing the service and maintenance models offered by manufacturers, moving towards proactive, subscription-based maintenance services powered by remote data analysis.

Material science and mechanical design also contribute significantly to the current technology landscape. Manufacturers are leveraging advanced polymers and specialized gear materials (often sintered metals or reinforced plastics) in gearboxes to maximize strength while minimizing weight and acoustic output during operation. Crucially, weather sealing technology is constantly being refined, utilizing specialized gaskets and high-tolerance housing designs to achieve superior Ingress Protection (IP) ratings (e.g., IP65 or higher), ensuring reliable long-term performance in harsh exterior or high-humidity environments like greenhouse roofs. This continuous refinement in mechanical and material design, coupled with sophisticated digital control, establishes a technology base that is simultaneously highly reliable for safety-critical applications and highly efficient for energy management goals, meeting the dual demands of modern sustainable architecture worldwide.

Regional Highlights

The global Electric Window Pusher Market demonstrates distinct growth characteristics across its major geographical segments, influenced by local construction standards, energy policies, and climate control needs. Market maturity levels dictate the adoption rate, with established markets focusing on high-tech replacement and niche applications, while developing markets prioritize initial installation volume and large infrastructure projects.

- Europe: Europe stands as the most mature and technologically advanced market segment, driven primarily by stringent EU directives such as the Energy Performance of Buildings Directive (EPBD) and mandatory SHEVS regulations across member states. Countries like Germany, the UK, and the Scandinavian nations lead in adoption, emphasizing high-quality, certified actuators integrated via KNX or BACnet systems. The focus here is overwhelmingly on energy efficiency optimization through natural ventilation and comprehensive fire safety compliance. High labor costs also drive demand for plug-and-play, easy-installation systems. The retrofit market is exceptionally strong due to extensive efforts to modernize vast existing building stock.

- North America (NA): Characterized by steady, high-value growth, North America sees significant demand originating from premium commercial and institutional construction projects seeking LEED certification or pursuing 'Net Zero' energy goals. While regulations are often jurisdiction-specific, the overall trend is toward automated ventilation systems in large metropolitan centers (e.g., New York, California) where energy costs and sustainability mandates are highest. Adoption rates in the residential smart home segment are robust, favoring wireless connectivity and integration with major smart ecosystems, although the overall penetration rate is slightly lower than Europe due to varied regional building code requirements.

- Asia Pacific (APAC): APAC represents the highest potential growth region, fueled by unprecedented urbanization, massive infrastructural investments (especially in China, India, and Southeast Asia), and rising middle-class disposable income driving residential upgrades. The market is highly price-sensitive but increasingly recognizes the value of modern, quality air management solutions due to escalating urban air pollution concerns. Japan and South Korea lead in adopting high-tech, integrated solutions, while emerging economies focus on high-volume, reliable solutions for commercial complexes and rapidly constructed institutional buildings. Regulatory enforcement of energy efficiency and fire safety is accelerating, creating significant future demand.

- Middle East and Africa (MEA): Growth in the MEA region is concentrated in the Gulf Cooperation Council (GCC) states, driven by large-scale, iconic construction projects (e.g., Saudi Arabia’s Vision 2030, UAE’s sustainable city projects). Demand here is focused on highly durable, weather-resistant actuators capable of handling extreme temperatures and dust ingress, primarily for large glass façades and skylights. The market is often highly specialized, catering to bespoke architectural designs requiring custom-engineered pusher solutions. African markets, while nascent, show potential in commercial and institutional builds where modern climate control infrastructure is being installed for the first time.

- Latin America (LATAM): The LATAM market is growing steadily, primarily driven by commercial development in major economic hubs like Brazil, Mexico, and Chile. Economic fluctuations can impact large project timelines, but the long-term trend favors automated systems for improved building performance and security. The focus often remains on cost-effective, durable solutions, with slower initial adoption of cutting-edge wireless or AI technologies compared to Europe or North America, though regulatory harmonization efforts are gradually increasing the demand for certified products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Window Pusher Market.- WindowMaster A/S (Denmark)

- D+H Mechatronik GmbH (Germany)

- SE Controls PLC (United Kingdom)

- AUMÜLLER Aumatic GmbH (Germany)

- FAKRO Sp. z o.o. (Poland)

- GIESSE S.p.A. (Italy)

- Mingardi S.r.l. (Italy)

- GEZE GmbH (Germany)

- Somfy S.A. (France)

- Ultraflex Control Systems S.p.A. (Italy)

- TiMOTION Technology Co., Ltd. (Taiwan)

- J. K. Technology (HK) Ltd. (Hong Kong)

- Phos Technology S.r.l. (Italy)

- UCS Control Systems S.r.l. (Italy)

- Nekos S.r.l. (Italy)

- Essmann GmbH (Germany)

- BDC Systems, Ltd. (United Kingdom)

- TBO-Stahl GmbH (Germany)

- Hörmann Group (Germany)

- Kintrol Pty Ltd (Australia)

Frequently Asked Questions

What is the primary function of an Electric Window Pusher in modern building automation systems?

The primary function of an Electric Window Pusher is to provide automated and precise control over natural ventilation, opening and closing windows, skylights, and vents based on programmed schedules, sensor inputs (e.g., CO2, temperature), or remote commands. Crucially, they serve as core components in certified Smoke and Heat Exhaust Ventilation Systems (SHEVS) for building safety, ensuring rapid, reliable air exchange during emergencies.

How do Electric Window Pushers contribute to a building's energy efficiency and sustainability rating?

They enhance energy efficiency by maximizing the use of natural ventilation and cooling, significantly reducing reliance on high-energy mechanical HVAC systems. By integrating with Building Management Systems (BMS), they optimize air flow based on occupancy and external conditions, helping buildings achieve high scores in certifications like LEED and BREEAM by minimizing operational carbon footprint and utility consumption.

What is the key advantage of 24V DC systems over 110V/230V AC systems in this market?

The key advantage of 24V DC systems is enhanced safety (low voltage), ease of integration into standard low-voltage control panels, and the critical ability to operate reliably using battery backup in the event of a power failure. This reliability is mandatory for compliance in safety-critical applications, particularly Smoke and Heat Exhaust Ventilation Systems (SHEVS).

Which product type, linear or chain actuator, is most suitable for residential applications?

Chain actuators are generally the most suitable for residential applications. They are compact, highly aesthetic due to their ability to retract fully into the housing when closed, and offer smooth, quiet operation necessary for home environments, fitting well with standard casement and sash window designs without disrupting interior décor.

How is Artificial Intelligence (AI) influencing the future development of Electric Window Pushers?

AI is transforming pushers from simple automation devices into intelligent components by enabling predictive control. AI uses historical data and real-time inputs to proactively optimize ventilation cycles, reduce energy waste, and facilitate predictive maintenance, warning operators of potential mechanical failure before it occurs, thereby maximizing uptime and system longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager