Electromechanical Relay Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443139 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Electromechanical Relay Market Size

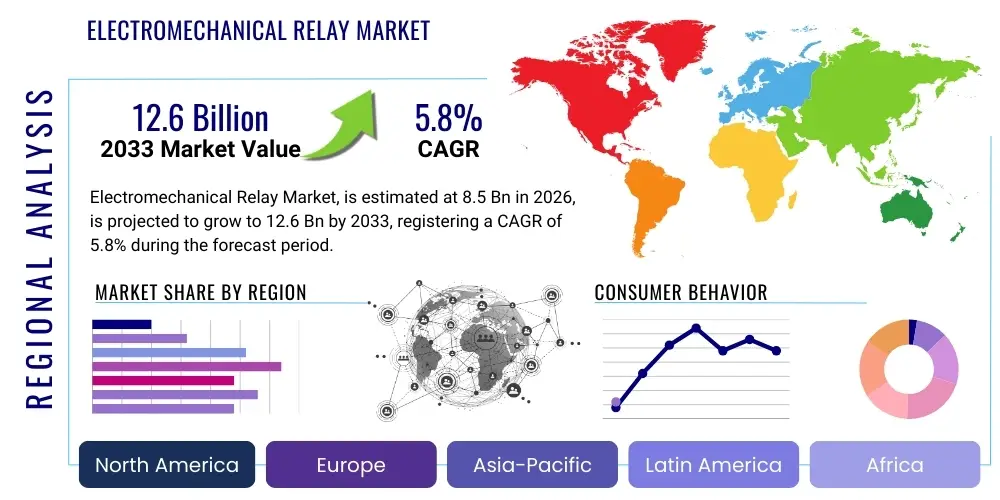

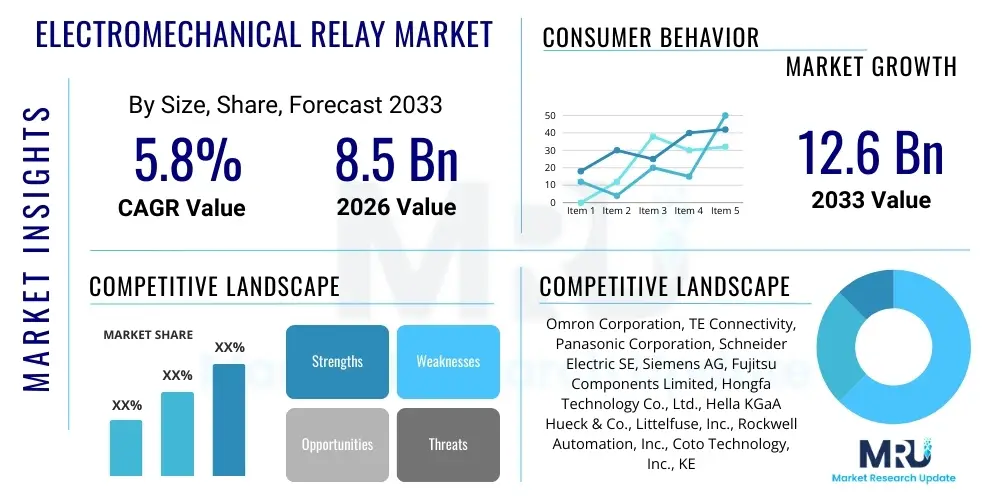

The Electromechanical Relay Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.6 Billion by the end of the forecast period in 2033.

Electromechanical Relay Market introduction

The Electromechanical Relay (EMR) Market encompasses devices that use an electromagnet to operate mechanical contacts, thereby switching an electrical circuit. These relays are fundamental components in a vast array of electronic and electrical systems, serving as vital interfaces between control circuitry and power loads. Functionally, EMRs offer galvanic isolation between the control signal and the load circuit, ensuring safety and protecting sensitive components from high voltage or current surges. The core strength of EMRs lies in their ability to handle significant current loads with low on-resistance, making them indispensable in heavy-duty industrial machinery, power distribution systems, and complex automotive applications where reliability under extreme conditions is paramount.

Major applications of electromechanical relays span critical sectors including automotive manufacturing, industrial automation (specifically Programmable Logic Controllers or PLCs), telecommunications infrastructure, consumer electronics, and energy management systems, such as smart grids and metering devices. Their robust design allows for switching both AC and DC loads effectively, a capability that ensures their continued relevance despite the rise of solid-state alternatives in certain low-power, high-speed applications. The primary benefits driving their adoption include high switching capacity, exceptional durability, simple operational principles, and a competitive cost structure compared to solid-state relays (SSRs) for high-current requirements.

The market growth is primarily propelled by the accelerating pace of industrial automation, particularly in developing economies, which necessitates robust, proven switching mechanisms for machinery control and safety interlocks. Furthermore, the massive expansion of the electric vehicle (EV) sector is acting as a significant catalyst, as high-voltage and high-current relays are essential for battery management systems (BMS), charging infrastructure, and power distribution within the vehicle architecture. Driving factors also include ongoing infrastructural development globally, especially in smart grid implementation and renewable energy integration, where specialized power relays are crucial for managing fluctuating energy flows and ensuring system stability.

Electromechanical Relay Market Executive Summary

The global Electromechanical Relay market is characterized by consistent technological refinement focused on miniaturization, enhanced arc suppression, and improved thermal performance to meet the demanding specifications of modern electronic integration. Key business trends indicate a strategic pivot towards developing specialized high-voltage DC relays, primarily in response to the surging demand from the Electric Vehicle and renewable energy storage sectors. Manufacturers are investing heavily in material science—specifically contact material optimization (e.g., silver alloy variants) and improved coil designs—to increase relay life cycles and reliability, differentiating themselves in a market marked by intense competition and rigorous application standards. Consolidation among smaller regional players by large multinational corporations is also a notable trend aimed at securing specialized technological capabilities and expanding geographical reach, particularly across high-growth Asian markets.

Regionally, the Asia Pacific (APAC) market maintains undeniable dominance, driven by massive domestic industrial output, substantial investments in telecommunications infrastructure, and the region's position as the global manufacturing hub for automotive and consumer electronics. Rapid urbanization and subsequent smart city projects in countries like China and India further bolster the need for reliable power and signal control devices. North America and Europe, while mature markets, exhibit strong growth trajectories in niche, high-value segments, specifically in advanced industrial controls (Industry 4.0 applications), aerospace, defense, and the rapid deployment of EV charging networks, which demand relays capable of extreme power switching and robust safety mechanisms. Regulatory environments surrounding electrical safety and energy efficiency in these Western regions often necessitate higher specifications, driving innovation in product design.

Segment trends highlight the increasing importance of high-voltage relays (>100V) and specialized power relays tailored for DC switching applications. In terms of type, latching relays are gaining traction over non-latching counterparts in applications where energy efficiency is critical, such as smart metering and remote control systems, as they require power only during the switching operation, not to maintain the contact position. The industrial automation and automotive segments remain the largest end-user categories, though the medical devices segment is showing accelerated growth, requiring highly reliable, precise miniature relays for diagnostic and therapeutic equipment. Furthermore, the push towards standardized, globally compliant components drives manufacturers to ensure their product portfolios meet international safety and quality standards (e.g., UL, VDE, CQC).

AI Impact Analysis on Electromechanical Relay Market

Common user inquiries regarding the intersection of Artificial Intelligence (AI) and the Electromechanical Relay Market frequently center on whether AI will render EMRs obsolete, how AI can improve relay manufacturing and predictive performance, and the potential for incorporating ‘smart’ diagnostics directly into traditional relay infrastructure. Users are concerned about the competitive threat posed by solid-state relays (SSRs) which inherently offer faster switching speeds suitable for AI-driven real-time control systems. Conversely, there is significant interest in utilizing AI for quality assurance, optimizing complex supply chain logistics, and designing relays with enhanced longevity by simulating mechanical stress and thermal loading under varied operational profiles. The consensus expectation is that AI will not eliminate EMRs but rather enhance their operational context, enabling sophisticated predictive maintenance protocols in industrial settings and optimizing smart grid power flow management where EMRs handle the physical power disconnects.

The most tangible impact of AI currently resides in the manufacturing process and quality control domain. Machine learning algorithms are now employed to analyze production line data, including real-time contact resistance measurements and coil winding precision, identifying potential component failures long before they manifest, thereby significantly improving the overall yield and consistency of the final product. Furthermore, AI-driven process optimization minimizes material wastage, especially precious metals used in contact tips, contributing directly to cost efficiency. This application ensures that EMRs maintain their competitive edge against more complex electronic alternatives by guaranteeing superior long-term reliability and reducing lifetime operational costs for end-users in critical applications like power generation and rail transport.

In terms of application, the rise of industrial IoT (IIoT) frameworks, often underpinned by AI for data processing and autonomous decision-making, leverages EMRs as the final physical actuator. For instance, in smart factory environments, AI analyzes sensor data to detect anomalies and initiates safety shutdowns; the EMR is the non-negotiable component that physically isolates the power source. This integration requires EMRs to be compatible with advanced monitoring systems, necessitating enhanced diagnostic features (e.g., auxiliary contacts or integrated current sensors). The ongoing development of ‘smart contactors’ and hybrid relays demonstrates the market’s response, where traditional mechanical reliability is paired with electronic intelligence to fulfill the demands of predictive analytics and complex automated control architectures dictated by AI systems.

- AI optimizes EMR manufacturing quality control through real-time data analysis of contact welding and coil performance.

- Predictive maintenance schedules for industrial control systems are enhanced by AI monitoring of relay cycle counts and operational stress, minimizing unexpected failures.

- AI algorithms improve supply chain efficiency by forecasting material demand, specifically precious metal alloys, reducing inventory costs.

- Integration into smart grid management allows AI to calculate optimal switching patterns, increasing the efficiency and lifespan of power relays.

- AI-driven simulation tools accelerate R&D for new relay designs, optimizing thermal dissipation and mechanical robustness for demanding EV applications.

DRO & Impact Forces Of Electromechanical Relay Market

The Electromechanical Relay market is shaped by a robust interplay of driving forces, inherent limitations, and emergent opportunities. Key drivers include the pervasive growth of industrial automation (Industry 4.0), demanding rugged and reliable switching solutions, and the accelerating transition towards electric vehicles, which mandates specialized, high-performance DC power relays for battery and charging management. Furthermore, global investment in infrastructural projects, particularly smart grid modernization and renewable energy integration (solar and wind power systems), necessitates reliable power relays capable of handling bidirectional current flow and managing power fluctuations effectively. These infrastructural demands provide a sustained, high-volume requirement for the core functionality that EMRs efficiently provide.

Conversely, the market faces significant restraints, primarily stemming from the formidable competition offered by Solid-State Relays (SSRs). SSRs possess inherent advantages in applications requiring extremely high switching frequencies, noise-free operation, and compatibility with low-voltage logic circuits, often challenging EMR dominance in high-speed data processing and consumer electronics. EMRs are also limited by their fundamental operating principle, exhibiting slower switching speeds, potential contact bounce issues, audible noise, and finite mechanical lifespan, which can be a drawback in continuously operating, sensitive systems. Additionally, the increasing focus on miniaturization in electronic design sometimes favors SSRs over EMRs, which require a certain physical size to accommodate the mechanical components (coil, armature, contacts).

Opportunities for market expansion are centered around the technological convergence of mechanical and solid-state capabilities, leading to hybrid relay solutions that leverage the best aspects of both technologies (low on-resistance of mechanical contacts with the fast response of electronics). The proliferation of IoT devices and smart home systems creates a new niche for ultra-miniature, energy-efficient latching relays. Furthermore, the specialized requirements of high-voltage DC switching in the burgeoning EV and energy storage segments represent a major opportunity, as current EMR technologies are being radically redesigned to mitigate severe DC arcing issues. Successfully addressing these specialized technical challenges will be crucial for sustained long-term growth and maintaining relevance against electronic alternatives in critical power domains. The stringent safety regulations in aerospace and defense also necessitate continued reliance on EMRs due to their proven isolation capabilities and robustness in harsh environments.

Segmentation Analysis

The Electromechanical Relay market is comprehensively segmented based on Type, Current Rating, Voltage Type, and End-User Industry, reflecting the diversity of application needs across the global economy. Understanding these segments provides critical insights into market dynamics, technological focus areas, and regional consumption patterns. Segmentation by Type, such as Power, Signal, Automotive, and Latching relays, directly correlates with the functional requirements and capacity demands of the end application, ranging from high-current circuit protection to low-current data transmission within control systems. The ongoing trend of miniaturization impacts all segments, driving the demand for smaller form factors without compromising switching capability or reliability metrics.

Further segmentation by Current Rating (e.g., less than 5A, 5A–20A, and above 20A) dictates the primary deployment environment, differentiating between consumer-grade electronics, industrial control panels, and heavy-duty power distribution systems. This categorization is particularly crucial in industrial sectors where specific load characteristics necessitate relays rated precisely for the task. Voltage Type segmentation, distinguishing between AC and DC relays, is increasingly important due to the rapid shift toward DC-dominant applications, particularly in battery-powered systems, data centers, and the electric vehicle ecosystem, requiring relays optimized for DC arc suppression which is technically more challenging than AC switching.

The End-User Industry segmentation reveals market penetration and growth potential, with Automotive, Industrial Automation, Telecommunications, HVAC, and Energy & Utilities being the predominant consumers. The automotive segment, propelled by the complexities of EV architectures, is experiencing the highest growth rate and driving the development of specialized, sealed, and shock-resistant relays. Meanwhile, the industrial automation sector demands robust, long-life general-purpose relays for PLCs and safety circuits. Strategic investment is highly concentrated towards satisfying the stringent reliability and environmental requirements of these top three end-user verticals.

- By Type:

- Power Relays

- Signal Relays

- Latching Relays

- Automotive Relays (Miniature and Micro)

- Solid State Relays (for comparative analysis and hybrid integration)

- By Current Rating:

- Low Current (Up to 5A)

- Medium Current (5A to 20A)

- High Current (Above 20A)

- By Voltage Type:

- AC Relays

- DC Relays (Low and High Voltage)

- By End-User Industry:

- Automotive (EVs, Powertrain, Chassis Control)

- Industrial Automation & Control

- Telecommunications

- Energy & Utility (Smart Grid, Renewables)

- HVAC & Consumer Electronics

- Aerospace & Defense

- Medical Devices

Value Chain Analysis For Electromechanical Relay Market

The Electromechanical Relay value chain begins with the complex upstream processes involving the procurement of highly specialized raw materials, notably copper for coils, specialized plastics and ceramics for housing, and crucial precious metal alloys (primarily silver, cadmium oxide, or palladium/ruthenium alloys) for contact points. Upstream analysis focuses heavily on supply chain stability and price volatility of these metals, which directly impacts manufacturing costs and, consequently, final product pricing. Material engineering excellence is concentrated in this stage, where selecting the optimal contact material is essential for determining the relay's switching capacity, mechanical life, and environmental resilience, especially in high-temperature or corrosive environments. Strategic partnerships with key metal suppliers are common among large relay manufacturers to secure consistent quality and volume.

The manufacturing and assembly phase constitutes the core of the value chain, where precision engineering and advanced automation are critical. EMR production involves intricate processes like coil winding, armature assembly, contact welding, and highly precise calibration to ensure consistent switching characteristics and minimize contact bounce. Quality assurance, including rigorous testing for thermal cycling, shock resistance, and life cycle verification, adds significant value at this stage. Effective process management and lean manufacturing techniques are essential to maintain cost competitiveness against global rivals, particularly those based in Asia Pacific regions known for high volume production capabilities. Innovation is focused on automation to reduce manual assembly errors and improve product consistency across massive production runs.

Downstream analysis covers the distribution channels, which are segmented into direct sales to large Original Equipment Manufacturers (OEMs) and indirect sales through a network of specialized distributors and wholesalers catering to smaller industrial users, MRO (Maintenance, Repair, and Operations) markets, and the aftermarket. Direct sales require close technical collaboration with OEMs, particularly in the automotive and aerospace sectors, often involving customized relay designs tailored to specific platform requirements. Indirect channels, conversely, rely on broad inventory management and efficient logistics to ensure rapid delivery of standard components. The shift towards digitization and e-commerce platforms is influencing the indirect channel, enabling smaller buyers globally to access specialized relay products directly, optimizing inventory holdings and reducing lead times for MRO requirements.

Electromechanical Relay Market Potential Customers

Potential customers for Electromechanical Relays are predominantly high-volume Original Equipment Manufacturers (OEMs) and system integrators operating across heavily regulated and technology-intensive industries where circuit isolation and reliable power switching are non-negotiable. The largest and fastest-growing customer segment comprises Tier 1 and Tier 2 suppliers within the automotive industry, specifically those focused on manufacturing components for electric vehicles (EVs), including battery management systems (BMS), high-voltage DC charging controls, and auxiliary power distribution modules. These customers require relays that can withstand significant shock, vibration, and thermal stress while handling DC currents up to several hundred amperes, making them highly strategic targets for specialized power relay manufacturers globally.

Another major category includes industrial control system integrators and manufacturers of Programmable Logic Controllers (PLCs) and industrial safety equipment. These customers demand general-purpose and specialized interface relays characterized by extreme long life, high operational reliability, and modularity for easy integration into complex machinery control panels. The adoption of Industry 4.0 principles necessitates EMRs capable of interfacing seamlessly with digital control logic while providing robust protection against motor loads, solenoids, and heavy machinery, ensuring operational continuity in 24/7 manufacturing environments across sectors like food processing, chemicals, and heavy engineering.

The third substantial customer base resides in the Energy & Utilities sector, encompassing smart grid developers, manufacturers of smart meters, and producers of renewable energy equipment (inverters, charge controllers). For these customers, specialized power relays are essential for automatic transfer switches, grid tie-in protection, and managing the bidirectional flow of power in distributed generation systems. Reliability and compliance with rigorous international standards (e.g., IEC standards for utility equipment) are paramount. The sustained governmental and private investment in energy infrastructure modernization ensures that these utility customers remain long-term, high-volume purchasers of specialized, robust electromechanical relay technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Omron Corporation, TE Connectivity, Panasonic Corporation, Schneider Electric SE, Siemens AG, Fujitsu Components Limited, Hongfa Technology Co., Ltd., Hella KGaA Hueck & Co., Littelfuse, Inc., Rockwell Automation, Inc., Coto Technology, Inc., KEMET Corporation (now part of YAGEO), Eaton Corporation plc, NEC Corporation, Standex Electronics, Inc., Zhejiang Forward Relay Corp., Ltd., Finder S.p.A., ABB Ltd., Alstom SA, CIT Relay & Switch. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electromechanical Relay Market Key Technology Landscape

The core technological evolution in the Electromechanical Relay market centers around material science, specifically the selection and engineering of contact materials and the development of advanced arc suppression techniques. For high-power applications, particularly in DC switching (critical for EVs and solar inverters), manufacturers are investing heavily in innovative gas-filled or ceramic-sealed relay designs. These designs use inert gases, often hydrogen or nitrogen, to rapidly cool and extinguish the electric arc formed upon contact separation, significantly extending the relay’s lifespan and enabling safer, higher-voltage DC switching. Material research focuses on developing cadmium-free contact alloys (e.g., silver tin oxide or silver nickel) to comply with environmental regulations while maintaining superior current-carrying capacity and resistance to contact welding, a critical failure mode in high-current scenarios.

Miniaturization technology remains a persistent theme across all segments, driven by the need for higher component density on Printed Circuit Boards (PCBs) in modern electronics. This involves sophisticated Finite Element Analysis (FEA) to optimize the magnetic circuit (coil and armature) to ensure adequate switching force within a much smaller footprint, without incurring excessive power consumption or thermal buildup. Advancements in surface mount technology (SMT) packaging are also crucial, allowing EMRs to be placed using automated assembly equipment alongside other electronic components, simplifying the manufacturing process for high-volume consumer and telecommunications equipment. This miniaturization requires meticulous control over component tolerances, demanding ultra-precise tooling and assembly robotics to maintain high reliability.

Furthermore, the market is increasingly defined by the development of hybrid and intelligent relay systems. Hybrid relays combine the benefits of mechanical contacts (low on-resistance) with solid-state elements (fast response and zero-crossing switching) to optimize performance, particularly for heavy industrial loads. Intelligent relays integrate microcontrollers and diagnostic capabilities directly into the housing, enabling continuous self-monitoring of parameters like coil temperature, cycle count, and contact resistance. This technological integration facilitates true predictive maintenance capabilities, allowing the relay to communicate its remaining useful life status to the control system, aligning EMR technology with the broader principles of Industry 4.0 and advanced asset management systems in critical infrastructure.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, primarily fueled by extensive industrialization, its status as the world's manufacturing hub for electronics and automotive components, and massive infrastructure investments. China, Japan, South Korea, and India are key drivers. China, in particular, dominates consumption due to its sprawling EV manufacturing sector, massive telecommunications expansion (5G deployment), and large-scale smart grid projects. The region is characterized by high-volume production and aggressive competitive pricing, although there is a growing demand for high-reliability, premium relays in the Japanese and Korean high-tech sectors.

- North America: This region is a mature market focused heavily on high-value, specialized relays for advanced industrial automation, aerospace, and defense applications. The robust adoption of electric vehicles and the associated need for advanced charging infrastructure (high-voltage DC power relays) is a major growth driver. Stringent safety and environmental regulations necessitate high-specification components. Innovation in North America is centered on smart relays capable of IIoT integration and robust thermal management for extreme operating environments.

- Europe: Europe is characterized by strict regulatory standards (e.g., REACH, RoHS compliance) driving demand for environmentally friendly and high-performance relays. Germany, as a major automotive and industrial automation power, leads consumption. Significant market growth is derived from renewable energy projects (wind and solar) and the continued modernization of the rail transport sector, which requires extremely durable, specialized relays capable of meeting rigorous EN and ISO standards for shock and vibration resistance.

- Latin America: This region presents emerging opportunities, mainly tied to infrastructure modernization, particularly in power generation and distribution projects in Brazil and Mexico. Market growth is stable but moderate, relying heavily on imported components. Demand is generally focused on cost-effective, standard industrial relays for manufacturing and energy sectors.

- Middle East and Africa (MEA): Growth in MEA is highly localized and driven by large-scale governmental investment in energy infrastructure and smart city development (e.g., Saudi Arabia, UAE). The high ambient temperatures in parts of the region necessitate specialized relays with superior thermal performance and environmental sealing. Investment in power utility modernization remains the primary catalyst for market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electromechanical Relay Market.- Omron Corporation

- TE Connectivity

- Panasonic Corporation

- Schneider Electric SE

- Siemens AG

- Fujitsu Components Limited

- Hongfa Technology Co., Ltd.

- Hella KGaA Hueck & Co.

- Littelfuse, Inc.

- Rockwell Automation, Inc.

- Coto Technology, Inc.

- KEMET Corporation (now part of YAGEO)

- Eaton Corporation plc

- NEC Corporation

- Standex Electronics, Inc.

- Zhejiang Forward Relay Corp., Ltd.

- Finder S.p.A.

- ABB Ltd.

- Alstom SA

- CIT Relay & Switch

Frequently Asked Questions

Analyze common user questions about the Electromechanical Relay market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between an Electromechanical Relay (EMR) and a Solid-State Relay (SSR)?

The primary difference lies in the switching mechanism; EMRs use physical, mechanical contacts for switching, providing true galvanic isolation and low on-resistance for high currents. SSRs use semiconductor devices (like thyristors or transistors) with no moving parts, offering faster switching speeds, longer life, and silent operation, though they often exhibit higher on-state resistance and require complex heat dissipation for high loads.

Which application segment is driving the highest growth in the Electromechanical Relay Market?

The Automotive segment, specifically the proliferation of Electric Vehicles (EVs), is currently driving the highest growth. EVs require specialized, high-voltage DC power relays for critical battery management systems (BMS) and fast-charging circuit protection, demanding robust and reliable switching components capable of handling intense DC arcing challenges.

How is technological innovation addressing the limitations of EMRs, such as contact wear?

Innovation addresses contact wear through the development of advanced hybrid relays, which combine mechanical contacts with electronic switching for enhanced lifespan, and through material science advancements, utilizing new precious metal alloys (e.g., Silver Tin Oxide) and sealed, gas-filled chambers to minimize arc erosion and contact welding.

Which geographical region dominates the consumption of electromechanical relays globally?

The Asia Pacific (APAC) region dominates global consumption due to its extensive manufacturing base for electronics and vehicles, coupled with massive ongoing investments in 5G infrastructure, industrial automation, and smart grid development across major economies like China and India.

What impact does industrial automation (Industry 4.0) have on EMR demand?

Industrial automation significantly drives EMR demand by increasing the complexity and reliability requirements of control panels and safety circuits (PLCs). While high-speed controls may use SSRs, EMRs remain crucial as the robust interface for reliably switching heavy industrial loads like motors and valves, often integrated now as ‘smart relays’ capable of diagnostic communication.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electromechanical Relay Market Statistics 2025 Analysis By Application (Consumer Electronics, Industrial Automation, Automotive, Aerospace), By Type (Reed Relays, Heavy Duty and High Voltage Relays, Aerospace/MIL-SPEC Relays), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Electromechanical Relay Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Reed Relays, Heavy Duty and High Voltage Relays, Aerospace/MIL-SPEC Relays), By Application (Consumer Electronics, Industrial Automation, Automotive, Aerospace, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager