Electronic Glue Guns Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442518 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Electronic Glue Guns Market Size

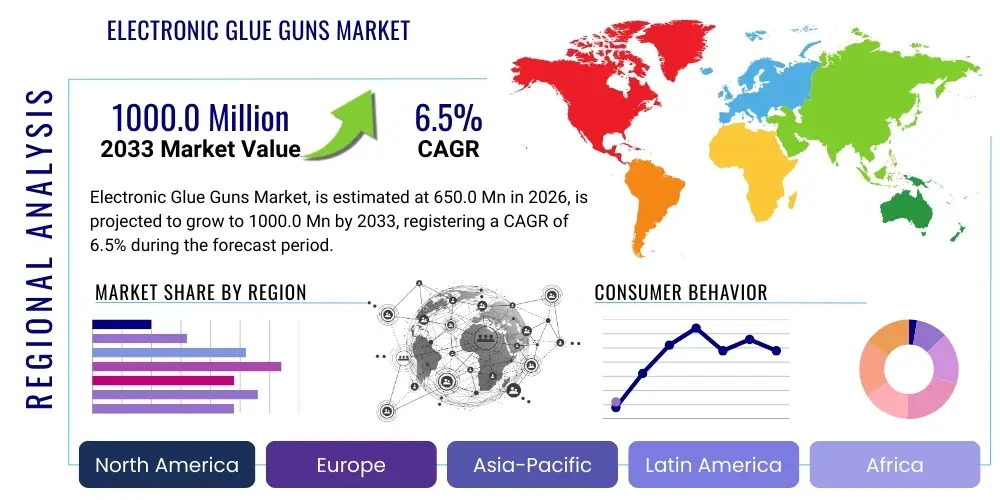

The Electronic Glue Guns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 650.0 Million in 2026 and is projected to reach USD 1000.0 Million by the end of the forecast period in 2033. This consistent expansion is underpinned by increasing consumer engagement in DIY (Do-It-Yourself) projects, coupled with the rising adoption of professional-grade, high-performance cordless models across various industrial and commercial sealing and bonding applications. The shift towards lightweight, ergonomically designed devices featuring enhanced temperature precision and rapid heating capabilities is a primary driver of market valuation growth, particularly within the construction and packaging sectors.

Electronic Glue Guns Market introduction

The Electronic Glue Guns Market encompasses devices used for melting and dispensing thermoplastic adhesive (hot melt glue sticks), facilitating strong, rapid bonds across diverse materials such as wood, plastic, fabric, ceramics, and metal. These tools, which are primarily categorized into corded and cordless (battery-powered) segments, have evolved significantly from basic craft tools into sophisticated industrial equipment integral to manufacturing processes. Modern electronic glue guns feature advanced temperature control mechanisms, ergonomic designs, and rapid heating elements, which enhance efficiency and reliability in high-volume applications.

Major applications of electronic glue guns span across multiple sectors, including consumer crafts and repairs, packaging and assembly lines, automotive repair for cosmetic bonding, and small-scale construction or home improvement projects. The versatility of these devices, combined with the cost-effectiveness and immediate setting time of hot melt adhesives, positions them as indispensable tools for both professional tradespeople and amateur users. Key benefits include superior adhesion strength, reduced curing time compared to traditional liquid adhesives, and ease of use, which significantly lowers the barriers to entry for complex bonding tasks.

The market is predominantly driven by the burgeoning demand for efficient and fast-bonding solutions in industries requiring quick turnaround times, such as electronics assembly and custom fabrication. Furthermore, the sustained global interest in personal hobbies and home renovation activities, intensified by hybrid work models, continues to fuel the demand for consumer-grade, easy-to-handle electronic glue guns. Technological advancements, particularly in lithium-ion battery technology, are further accelerating the transition towards high-powered, long-lasting cordless models, enhancing user mobility and application flexibility across various professional environments.

Electronic Glue Guns Market Executive Summary

The Electronic Glue Guns Market demonstrates robust growth, primarily propelled by favorable business trends emphasizing efficiency and portability, and supported by a continuous flow of technological innovation focused on battery longevity and temperature stability. Business trends indicate a strong focus among manufacturers on developing smart glue guns integrated with IoT capabilities for temperature monitoring and adhesive volume control, particularly targeting high-precision industrial applications like electronics manufacturing and complex assembly operations. This professional segment is witnessing increased investment in specialized high-output, continuous-feed systems, moving beyond traditional trigger-based mechanisms to meet stringent quality and throughput requirements.

Regionally, the Asia Pacific (APAC) market is projected to exhibit the highest growth rate due to rapid industrialization, expansion of manufacturing hubs, and increasing disposable income leading to higher participation in DIY activities, particularly in emerging economies such as China and India. North America and Europe remain mature markets characterized by high penetration of premium cordless tools and stringent regulatory standards demanding safer, energy-efficient products. These regions prioritize ergonomic design and compatibility with diverse adhesive types, focusing heavily on professional and high-end consumer sectors.

Segmentation analysis reveals that the Cordless segment, driven by advancements in battery efficiency and power density, is gaining substantial market share over traditional corded models, despite the latter maintaining dominance in continuous, heavy-duty industrial settings. Application-wise, the DIY/Hobbyist sector continues to be the largest volume driver, while the industrial packaging and assembly segments contribute significantly to revenue growth, driven by the need for quick, reliable, and automated sealing solutions. Companies are strategically investing in expanding distribution networks through e-commerce platforms and specialized hardware retailers to cater effectively to both B2B and B2C demand across all major segments.

AI Impact Analysis on Electronic Glue Guns Market

User inquiries regarding the impact of Artificial Intelligence (AI) and machine learning on the Electronic Glue Guns Market typically revolve around automation potential, enhanced precision in application, and predictive maintenance of industrial equipment. Users are keen to understand how AI algorithms can optimize adhesive dispensing rates based on material sensing, ensure bond integrity through real-time feedback, and predict equipment failure, thereby minimizing downtime in high-stakes manufacturing environments. The key themes include the integration of AI-powered vision systems for quality control in automated assembly lines, the development of adaptive temperature profiles for specialty adhesives, and the use of machine learning to analyze operator efficiency and tool usage patterns, aiming for overall process optimization and defect reduction. This shift represents a move from passive tools to active, intelligent bonding systems.

- AI-Powered Quality Control: Integration of machine vision and AI algorithms to inspect dispensed adhesive beads for volume, consistency, and placement accuracy in real-time, drastically reducing post-assembly defects.

- Predictive Maintenance: Machine learning models analyze operational data (temperature fluctuations, motor load, dispensing cycles) to predict component failure in high-output industrial glue guns, enabling proactive servicing and maximizing uptime.

- Adaptive Dispensing: AI adjusts dispensing speed, pressure, and temperature dynamically based on sensor inputs regarding the material substrate and ambient conditions, ensuring optimal adhesion and material usage efficiency.

- Robotics Integration Optimization: AI guides robotic arms and automated systems using electronic glue guns, optimizing path planning and precision for complex 3D bonding tasks in automotive and electronics assembly.

- Inventory Management: Utilizing AI to track adhesive consumption rates per tool or per assembly line, automating reorder processes and minimizing material waste across large-scale manufacturing operations.

DRO & Impact Forces Of Electronic Glue Guns Market

The dynamics of the Electronic Glue Guns Market are shaped significantly by interconnected drivers, restraints, opportunities, and their combined impact forces, influencing strategic decision-making across the value chain. A primary driver is the pervasive DIY culture globally, coupled with the rapid expansion of the e-commerce packaging sector which heavily relies on hot melt adhesives for fast and secure sealing. Simultaneously, manufacturers are restrained by the inherent limitations of battery technology regarding power longevity in cordless industrial models, requiring frequent recharging, and by increasing regulatory scrutiny concerning environmental sustainability of adhesive materials and the energy efficiency of the heating elements.

Opportunities in the market center on the development of specialized, high-temperature glue guns capable of handling advanced engineering adhesives for demanding industrial tasks, such as bonding composite materials in aerospace and high-performance automotive parts. Furthermore, the push towards integrating smart features, including digital displays for precise temperature setting, IoT connectivity for remote diagnostics, and improved ergonomic designs that reduce user fatigue, represents significant avenues for market penetration and premium pricing strategies. The interplay between the convenience offered by advanced cordless technology (driver) and the persistent cost barrier for high-capacity batteries (restraint) results in a continuous push for cost-effective, high-density energy storage solutions.

The impact forces are largely characterized by strong demand-pull from the construction and automotive sectors for specialized tooling, offset by intensifying competition from alternative bonding technologies like two-part epoxies and specialized tapes in highly sensitive applications. The market environment is currently highly favorable due to technological advancements that enhance product safety and performance, making the tools accessible to a wider demographic. Success in this market is increasingly dependent on the ability of key players to deliver tools that offer exceptional thermal stability, rapid heat-up times, and superior operational runtime, merging professional-grade performance with consumer-friendly accessibility.

Segmentation Analysis

The Electronic Glue Guns Market is highly fragmented and analyzed across several critical dimensions, including Type, Application, and End-User. Understanding these segments is vital for targeted product development and marketing strategies, as performance requirements vary drastically between, for example, a high-throughput industrial packaging operation and a low-volume consumer craft activity. The segmentation highlights the growing prominence of portability, leading to the rapid adoption of cordless tools, while also distinguishing the specialized needs of professional trades, which demand high temperature ranges and consistent output volumes over prolonged periods.

- Type:

- Corded Electronic Glue Guns

- Cordless (Battery-Powered) Electronic Glue Guns

- Application:

- DIY and Crafting

- Industrial Manufacturing and Assembly (e.g., Electronics, Furniture)

- Packaging and Sealing

- Automotive Repair and Customization

- Construction and Renovation

- End-User:

- Residential/Home Use (Hobbyists and Small Repairs)

- Commercial Use (Schools, Small Businesses, Retail Displays)

- Industrial/Professional Use (Factories, Construction Sites, Automotive Shops)

- Temperature Range:

- Low-Temperature Glue Guns (typically 120-150°C)

- High-Temperature Glue Guns (typically 170-200°C+)

Value Chain Analysis For Electronic Glue Guns Market

The value chain for the Electronic Glue Guns Market begins with upstream activities involving the sourcing of core components, primarily specialized plastics for casing (often high-grade nylon or ABS to withstand heat), metal alloys for heating elements and nozzles, and increasingly sophisticated lithium-ion battery cells and management systems for cordless models. Key upstream suppliers include raw material processors and component manufacturers specializing in high-precision thermal parts and electronic controls. Maintaining a reliable supply chain for high-quality, thermally resistant materials is crucial for ensuring product longevity and operational safety, directly impacting the final product's quality and cost structure.

Midstream activities involve the design, manufacturing, and assembly of the finished electronic glue guns. This stage includes complex processes such as injection molding, wiring of the heating elements, integration of Printed Circuit Boards (PCBs) for temperature regulation, and final assembly and testing. Manufacturing is often concentrated in regions with efficient electronics production capabilities, particularly in East Asia. Efficiency in the manufacturing stage is paramount, focusing on lean production techniques and stringent quality control protocols to ensure compliance with international safety standards, especially regarding thermal runaway protection and electrical insulation.

Downstream activities focus on the distribution and end-user engagement. Distribution channels are varied, encompassing direct sales to large industrial customers, indirect sales through wholesalers and specialized industrial suppliers, and robust B2C channels via e-commerce platforms (crucial for DIY segments) and large brick-and-mortar hardware stores. The effectiveness of the distribution network determines market reach and speed of delivery. Direct sales are often utilized for highly specialized, high-volume industrial units requiring technical support, while e-commerce dominates the consumer and small commercial segments, offering extensive product catalogs and rapid fulfillment.

Electronic Glue Guns Market Potential Customers

Potential customers for electronic glue guns are highly diverse, spanning individual consumers engaged in minor household repairs and crafts, mid-sized commercial entities utilizing the tools for display construction or minor assembly tasks, and large industrial manufacturers requiring high-volume, reliable bonding solutions. The segmentation of end-users highlights distinct product requirements: home users prioritize safety, ease of handling, and affordability, whereas professional industrial users demand durability, high power output, extremely precise temperature control, and compatibility with specialized, often high-viscosity, hot melt adhesives.

The largest industrial consumer segment includes the packaging industry, where electronic glue guns, often integrated into semi-automated or fully automated machinery, are crucial for rapidly sealing cartons and boxes. Other significant industrial users are automotive aftermarket service providers, who use them for non-structural interior repairs, cosmetic enhancements, and cable bundling, valuing quick setting times and portability. Furthermore, the furniture manufacturing sector relies heavily on hot melt adhesives applied via electronic guns for assembly operations, particularly veneering and small component attachment, demanding tools capable of continuous heavy-duty use.

The burgeoning commercial and institutional sector, including educational establishments, theatrical production companies, and retail visual merchandisers, represents a growing customer base. These users require reliable, medium-duty tools that balance performance with safety and portability, often favoring cordless models for flexibility around workspaces. Successful market penetration strategies involve customizing product offerings—for example, offering low-temperature models specifically designed for educational or delicate crafting applications—to precisely match the functional and safety requirements of each distinct customer segment, ensuring maximized market capture and strong brand loyalty.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.0 Million |

| Market Forecast in 2033 | USD 1000.0 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch, Stanley Black & Decker (DeWalt), Ryobi, Dremel (Bosch), Surebonder, AdTech, Pam Fastening, 3M, Makita, Milwaukee Tool, Steinel, WEN, Arrow Fastener, TECBond, Loctite (Henkel), PowerMax, Genesis, Workpro, Tacklife, P&W |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electronic Glue Guns Market Key Technology Landscape

The technological landscape of the Electronic Glue Guns Market is rapidly evolving, driven primarily by innovations in power management, thermal engineering, and material science. The dominant technological shift involves the transition from traditional NiCad or NiMH battery systems to high-efficiency Lithium-Ion (Li-ion) power sources, especially in professional and industrial-grade cordless models. Li-ion technology offers significantly higher energy density, providing longer runtimes and faster recharge capabilities, which is critical for demanding applications where tethered operations are impractical. Manufacturers are leveraging advanced battery management systems (BMS) to enhance safety, extend battery life, and ensure consistent power delivery throughout the discharge cycle, thereby maintaining optimal thermal performance.

Thermal control technology represents another crucial area of innovation. Modern electronic glue guns feature sophisticated Positive Temperature Coefficient (PTC) heating elements coupled with microprocessors that provide precise temperature regulation, often allowing users to select specific temperature profiles tailored to different adhesive formulations (e.g., high-temperature for heavy-duty bonds, low-temperature for delicate materials). Digital temperature displays and feedback loops are becoming standard features in premium models, ensuring the adhesive reaches and maintains its optimal melting point without overheating, which preserves adhesive integrity and prevents nozzle clogging—a common operational challenge.

Furthermore, IoT integration is beginning to penetrate the high-end industrial segment, enabling features such as wireless monitoring of operational metrics, remote diagnostics, and automated calibration. Ergonomic design advancements, including reduced weight distribution, non-drip nozzles utilizing specialized retraction mechanisms, and improved trigger systems for controlled dispensing, also constitute vital technological improvements enhancing user experience and precision. The overall trend is towards creating smarter, safer, and more durable tools capable of handling specialized, high-performance hot melt adhesives designed for complex industrial bonding requirements.

Regional Highlights

Geographic analysis of the Electronic Glue Guns Market reveals varied consumption patterns and growth trajectories influenced by regional industrial development, economic stability, and cultural adoption of DIY practices.

- North America: Characterized by a high demand for premium, cordless professional tools due to advanced infrastructure and high labor costs, driving the need for efficient equipment. The region exhibits high market maturity, with strong penetration in automotive repair and the booming home renovation market. Manufacturers focus heavily on ergonomic design and integration with 18V or 20V battery platforms shared across broader tool ecosystems.

- Europe: A mature market focusing significantly on safety, sustainability, and quality certification (e.g., CE marking). Germany, the UK, and France are key consumers, driven by precision engineering, woodworking, and small-scale manufacturing. There is a strong preference for highly regulated, energy-efficient tools, and growth is moderately steady, supported by robust regulatory frameworks demanding environmentally friendly adhesive solutions.

- Asia Pacific (APAC): Projected as the fastest-growing region, fueled by rapid urbanization, massive infrastructural development, and the establishment of global manufacturing hubs in countries like China, India, and Vietnam. The demand spans from affordable, high-volume consumer models to sophisticated industrial application systems used in packaging and electronics assembly. Economic development is directly correlated with increased spending on consumer tools and industrial automation.

- Latin America (LATAM): Market growth is nascent but promising, particularly in countries like Brazil and Mexico, driven by increasing construction activities and the rising availability of accessible tools through e-commerce channels. Price sensitivity is a major factor, favoring mid-range, versatile tools suitable for light commercial and heavy DIY use.

- Middle East and Africa (MEA): A developing market segment, with demand concentrated in commercial construction projects and facility maintenance in the GCC countries. Adoption rates are lower compared to global averages, but steady growth is anticipated due to diversification efforts and investment in industrial infrastructure, requiring basic, reliable, and durable bonding solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electronic Glue Guns Market.- Bosch

- Stanley Black & Decker (DeWalt)

- Ryobi

- Dremel (Bosch)

- Surebonder

- AdTech

- Pam Fastening

- 3M

- Makita

- Milwaukee Tool

- Steinel

- WEN

- Arrow Fastener

- TECBond

- Loctite (Henkel)

- PowerMax

- Genesis

- Workpro

- Tacklife

- P&W

Frequently Asked Questions

Analyze common user questions about the Electronic Glue Guns market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Cordless Electronic Glue Guns segment?

The primary driver is the significant advancement in Lithium-Ion battery technology, which provides extended runtime, faster recharge cycles, and superior power density compared to older battery types, enhancing user mobility and efficiency, particularly for professional applications requiring high output away from power outlets.

How is temperature control technology changing industrial applications of glue guns?

Advanced digital temperature control using microprocessors and PTC heating elements allows industrial users to precisely tailor the melting temperature to specialty adhesives, ensuring optimal viscosity and bond strength, preventing material degradation, and complying with stringent manufacturing quality standards.

Which geographical region is expected to exhibit the highest Compound Annual Growth Rate (CAGR) in the forecast period?

The Asia Pacific (APAC) region is projected to register the highest CAGR, primarily due to rapid expansion in manufacturing and packaging industries, coupled with increasing consumer adoption of DIY and home improvement tools fueled by rising disposable incomes across key emerging economies.

What are the main restraints hindering the full potential adoption of electronic glue guns in high-demand industrial environments?

Key restraints include the limitations of current battery technology regarding continuous power delivery for heavy, prolonged industrial use without significant downtime for recharging, and intense market competition from highly specialized alternative adhesive technologies such as industrial epoxies and polyurethane foams.

What role does IoT connectivity play in modern electronic glue gun development?

IoT connectivity is being integrated into high-end industrial electronic glue guns to enable remote monitoring of operational parameters like temperature stability, adhesive consumption, and tool diagnostics, facilitating predictive maintenance, asset tracking, and optimizing overall quality control in automated production environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager