Electrosurgical Cutting Forcep Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441244 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Electrosurgical Cutting Forcep Market Size

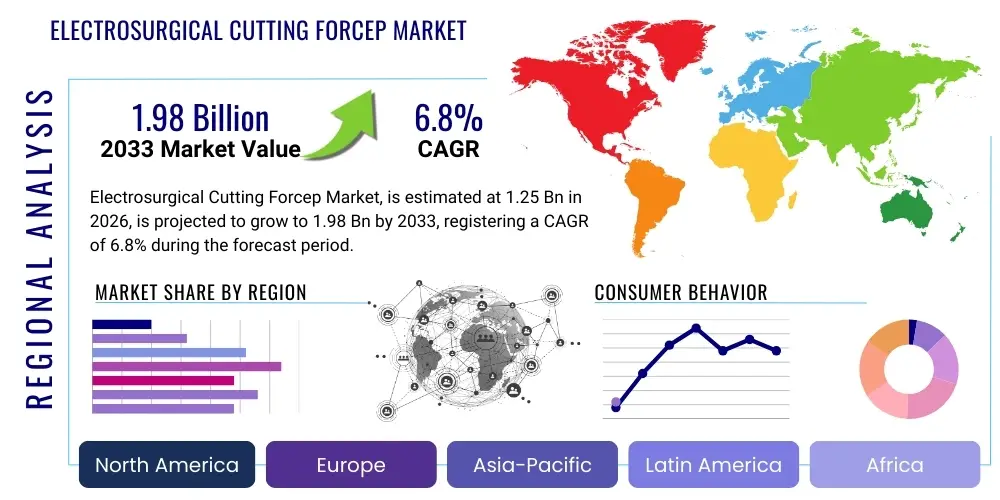

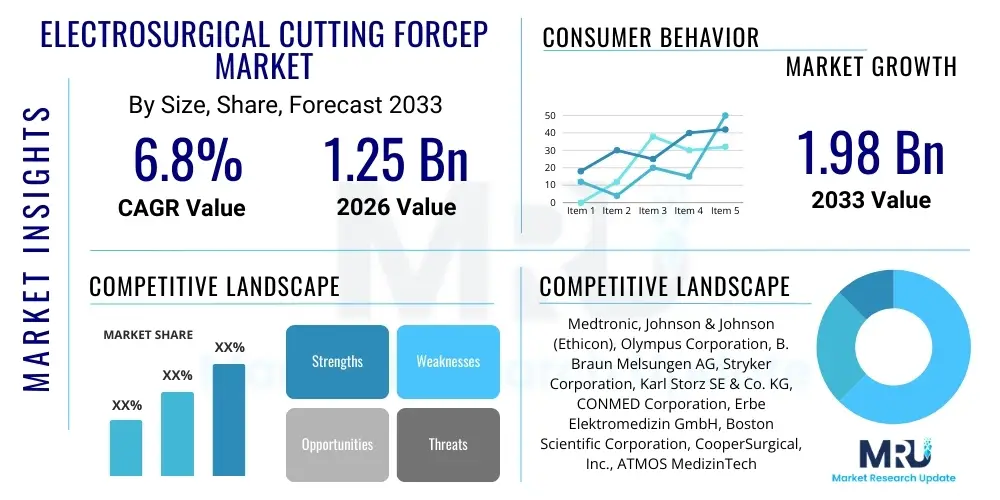

The Electrosurgical Cutting Forcep Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033.

Electrosurgical Cutting Forcep Market introduction

The Electrosurgical Cutting Forcep Market encompasses specialized surgical instruments designed to apply high-frequency electrical currents directly to tissue, enabling simultaneous cutting, dissection, and coagulation during various surgical procedures. These devices are critical components of modern operating theaters, offering enhanced precision and minimizing blood loss compared to traditional mechanical scalpels. The primary function involves utilizing monopolar or bipolar energy configurations to generate localized heat, which vaporizes cellular water and achieves the desired surgical effect. The increasing global preference for minimally invasive surgical (MIS) techniques across specialties such as general surgery, gynecology, and urology serves as the foundational demand driver for these advanced forceps.

Product sophistication is continuously improving, focusing on integrating features that enhance safety and operational efficiency. Modern electrosurgical cutting forceps feature advanced insulation materials, ergonomic designs, and integrated suction or irrigation capabilities. These technological advancements ensure precise energy delivery, reducing the risk of adjacent tissue damage and improving patient outcomes. Key applications span high-volume procedures including laparoscopic cholecystectomy, colon resections, and complex oncological surgeries. The inherent benefits, such as reduced operating time, faster patient recovery, and decreased risk of infection associated with electrosurgery, solidify the market position of these instruments within the global healthcare landscape.

Major market driving factors include the rising prevalence of chronic diseases requiring surgical intervention, particularly cardiovascular and gastrointestinal disorders, coupled with the rapid growth of the elderly population globally who often necessitate surgical care. Furthermore, substantial investments in healthcare infrastructure in emerging economies and the increasing adoption of automated and robotic-assisted surgical systems—which require compatible, high-precision electrosurgical tools—are significantly propelling market expansion. The shift towards disposable electrosurgical tools, ensuring sterility and consistency, also contributes substantially to the overall market growth trajectory.

Electrosurgical Cutting Forcep Market Executive Summary

The Electrosurgical Cutting Forcep Market is characterized by robust innovation focused on enhancing surgical precision and safety, particularly within the minimally invasive segment. Business trends indicate a strong move toward disposable devices, driven by concerns over cross-contamination and the increasing complexity of reprocessing reusable instruments. Key manufacturers are aggressively investing in Research and Development (R&D) to develop smart forceps integrated with feedback mechanisms that monitor tissue impedance and temperature, allowing for automated energy adjustment. Strategic mergers and acquisitions are common, aimed at consolidating market share and expanding specialized product portfolios, especially in the bipolar energy segment which offers superior localized control and safety profiles compared to traditional monopolar systems.

Regionally, North America maintains market dominance due to early adoption of advanced surgical technologies, high healthcare expenditure, and the presence of leading market players. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by improving access to advanced healthcare, rapidly expanding hospital infrastructure in countries like China and India, and increasing medical tourism. European markets show stable growth, heavily influenced by stringent medical device regulations (suchably the MDR), which drive manufacturers to maintain high standards of quality and clinical evidence. Latin America and the Middle East & Africa (MEA) offer nascent growth opportunities, contingent upon greater healthcare penetration and economic stability.

Segment trends highlight the bipolar electrosurgical cutting forceps as the fastest-growing category, largely due to their enhanced safety profile, making them preferred in critical procedures like neurosurgery and pediatric surgery. Among end-users, Ambulatory Surgical Centers (ASCs) are gaining prominence, driven by the shift of lower-acuity procedures from inpatient settings to cost-effective outpatient facilities. The application segment continues to be dominated by general surgery and gynecology, although specialized fields such as cosmetic and bariatric surgery are demanding specialized, finely calibrated electrosurgical tools. These trends collectively underscore a market moving towards greater specialization, safety, and integration with advanced surgical platforms.

AI Impact Analysis on Electrosurgical Cutting Forcep Market

Common user questions regarding AI's impact on the Electrosurgical Cutting Forcep Market center on how artificial intelligence can improve surgical precision, reduce thermal damage risk, and automate energy delivery settings during procedures. Users are keenly interested in the potential for AI algorithms to analyze real-time tissue properties—such as impedance, density, and perfusion—and dynamically adjust the forcep's energy output to achieve optimal cutting or coagulation with minimal collateral damage. Concerns also revolve around the cost implications of integrating AI sensors and processors into existing electrosurgical generators and handpieces, and the regulatory hurdles associated with deploying AI-driven decision support systems in critical surgical environments. Users expect AI integration to transition electrosurgery from a manual skill-dependent process to a highly standardized, predictable, and data-driven procedure.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is beginning to revolutionize the functionality of electrosurgical cutting forceps, moving beyond simple power output controls. AI systems are being developed to interpret live sensor data from the forcep tip, identifying tissue type and boundaries with higher accuracy than human perception alone. This capability significantly reduces the incidence of thermal spread and ensures more effective tissue sealing in vessel ligation. For instance, ML models trained on vast amounts of surgical video and energy delivery data can predict optimal energy application duration and intensity, thus preventing electrode overheating and ensuring consistently reliable surgical outcomes, particularly in complex laparoscopic environments where visibility is constrained.

Furthermore, AI plays a crucial role in surgical planning and training. Preoperative imaging data can be fed into ML models to create predictive simulations of how different tissues will react to electrosurgical energy, allowing surgeons to pre-program customized energy delivery profiles for specific patients. Post-procedure, AI algorithms can analyze the energy usage logs and patient outcomes, providing valuable feedback for quality improvement, surgeon training, and refining future device performance. This predictive maintenance and continuous improvement loop ensures that electrosurgical forceps systems operate at peak efficiency and safety throughout their operational lifecycle, optimizing resource utilization within hospitals and ASCs.

- AI-driven real-time tissue impedance monitoring for automated energy adjustment.

- Predictive modeling to minimize thermal spread and ensure precise coagulation.

- Integration of ML algorithms for optimizing surgical cutting parameters based on tissue density.

- AI-enhanced robotic compatibility, allowing for finer control during automated procedures.

- Automated failure detection and predictive maintenance warnings for electrosurgical generators.

- Data logging and analysis for improved surgeon training and standardization of surgical techniques.

DRO & Impact Forces Of Electrosurgical Cutting Forcep Market

The Electrosurgical Cutting Forcep Market expansion is primarily driven by the increasing global demand for Minimally Invasive Surgery (MIS), which inherently relies on precise electrosurgical tools to manage tissue cutting and hemostasis through small ports. The continuous growth in the geriatric population, which requires frequent surgeries for age-related conditions, further fuels demand. However, the market faces significant restraints, chiefly the high initial cost of advanced electrosurgical generators and disposable accessories, which particularly limits adoption in resource-constrained settings. Stringent regulatory approval processes, requiring extensive clinical trials and documentation, also slow down the introduction of innovative products. Opportunities abound in integrating these forceps with advanced robotic platforms and developing specialized, energy-efficient tools for niche markets like cosmetic and ambulatory surgery. The inherent safety risks associated with electrosurgery, such as unintended burns or electromagnetic interference with other medical devices, constitute a major impact force necessitating continuous innovation in insulation and feedback technology.

Drivers: The widespread adoption of laparoscopic procedures across general surgery, gynecology, and bariatrics is a paramount driver. These procedures necessitate precise cutting and sealing capabilities that only specialized electrosurgical forceps can reliably provide within a confined space. Moreover, technological progress, including the shift from traditional radiofrequency methods to advanced ultrasonic and hybrid energy systems, enhances the forcep's efficacy and reduces smoke plume production, improving visibility for the surgeon. Government initiatives in developed countries aimed at reducing hospital stays and promoting quicker patient recovery indirectly bolster the demand for highly efficient MIS tools, including advanced cutting forceps. The focus on single-use devices, eliminating reprocessing costs and sterilization concerns, also serves as a strong economic and safety-driven catalyst for market expansion, particularly in high-volume surgical centers.

Restraints: One major constraint is the steep learning curve associated with operating high-powered electrosurgical equipment; improper use can lead to catastrophic intraoperative injuries, driving up medical malpractice insurance premiums and fostering reluctance among less experienced surgical staff. Furthermore, the market is highly competitive and fragmented, leading to intense pricing pressure on standard monopolar forceps, which can negatively affect profit margins for smaller manufacturers. The disposal of single-use electrosurgical devices also presents an environmental challenge and cost burden, creating friction between healthcare sustainability goals and clinical safety preferences for disposables. Overcoming these restraints requires extensive surgeon training programs and developing more cost-effective, environmentally sustainable disposable materials.

Opportunities: Significant market opportunities exist in emerging economies, where healthcare infrastructure investment is rapidly increasing, facilitating the adoption of modern surgical technologies. Customization and specialization represent another key opportunity; developing forceps tailored for specific tissue characteristics, such as liver tissue or highly vascularized organs, allows manufacturers to capture niche, high-value segments. The increasing trend of combining electrosurgery with advanced imaging techniques, such as fluorescent guidance systems, offers potential for smarter, more precise cutting tools. Additionally, developing integrated systems that seamlessly interface electrosurgical forceps with robotic arms and augmented reality guidance platforms will unlock substantial growth within the robotic surgery segment, currently one of the fastest-expanding areas of surgical technology.

Segmentation Analysis

The Electrosurgical Cutting Forcep market is analyzed across several critical dimensions, primarily segmented by product type (Monopolar and Bipolar), application (General Surgery, Gynecology, Urology, Cardiovascular, etc.), and end-user (Hospitals, Ambulatory Surgical Centers, and Specialty Clinics). This segmentation helps identify specific market dynamics, consumer preferences, and technological adoption rates within different healthcare settings. The market exhibits a clear preference shift toward Bipolar forceps, driven by their safety profile which minimizes stray energy and reduces the need for a grounding pad, thereby increasing patient safety, particularly in procedures involving sensitive organs or patients with pacemakers. Segmentation by application demonstrates that general surgery and gynecology currently account for the largest market share due to the high volume of procedures performed globally that require precise cutting and coagulation.

Within the product segmentation, Monopolar devices remain essential, particularly in high-volume, cost-sensitive procedures, and for large area dissection, offering powerful cutting capability. However, Bipolar forceps are seeing accelerating growth due to technological enhancements providing superior hemostasis and precision in delicate surgeries. End-user analysis reveals that hospitals, particularly large teaching and tertiary care facilities, are the primary purchasers, driven by their capacity to handle complex procedures and high patient volumes. Nonetheless, the rapid establishment and expansion of Ambulatory Surgical Centers (ASCs) globally are expected to significantly alter the distribution landscape, as these centers increasingly adopt specialized, lower-cost, high-efficiency instruments suitable for outpatient settings, driving demand for single-use devices.

Further granular segmentation by energy source or tip design is also important, differentiating between hook electrodes, needle electrodes, and specialized tissue grasping tips that integrate cutting functionality. This level of detail allows manufacturers to tailor their marketing and product development strategies to specific clinical needs. For example, the market for specialized forceps used in endoscopic and robotic procedures is growing substantially faster than the market for conventional open surgery tools. Understanding these granular trends is crucial for strategic market positioning and identifying underserved clinical requirements globally.

- Product Type:

- Monopolar Electrosurgical Cutting Forceps

- Bipolar Electrosurgical Cutting Forceps

- Application:

- General Surgery

- Gynecology

- Urology

- Cardiovascular Surgery

- Neurosurgery

- Others (Ophthalmic, Plastic, and Cosmetic Surgery)

- End-User:

- Hospitals

- Ambulatory Surgical Centers (ASCs)

- Specialty Clinics and Research Institutes

Value Chain Analysis For Electrosurgical Cutting Forcep Market

The value chain for the Electrosurgical Cutting Forcep Market begins with the sourcing of specialized raw materials, primarily medical-grade stainless steel, high-performance polymers for insulation, and sophisticated electronic components for generators and feedback systems. Upstream activities involve meticulous material procurement and component manufacturing, focusing heavily on quality control to meet stringent biocompatibility and sterilization standards. Suppliers of high-grade insulation and precision machining services are crucial nodes in this early stage. Manufacturing then focuses on assembly, sterile packaging, and rigorous testing, ensuring the forceps comply with international standards like ISO 13485 and FDA regulations. Efficiency in manufacturing is paramount, especially for high-volume disposable products, where scaling production while maintaining cost-effectiveness is key to competitive pricing.

The downstream component involves complex distribution and sales strategies. Direct sales models are often employed for large hospital systems and teaching institutions, allowing manufacturers to maintain direct relationships, provide specialized training, and manage post-sale service for the expensive generator units. Conversely, indirect distribution channels, involving regional medical device distributors and wholesalers, are vital for reaching smaller clinics, ASCs, and international markets. These distributors manage local logistics, inventory, and regulatory requirements specific to their regions. A successful distribution network must ensure timely delivery of both reusable forceps, which require reprocessing support, and disposable instruments, which require reliable, high-volume supply.

The final crucial link in the value chain is the post-sales engagement and feedback loop involving end-users—surgeons, nurses, and hospital procurement departments. This feedback is essential for continuous product improvement, especially concerning ergonomics, efficacy (cutting/sealing performance), and ease of use. Companies that effectively integrate this end-user intelligence back into their R&D processes gain a significant competitive advantage. The increasing influence of Group Purchasing Organizations (GPOs) in North America also impacts pricing and procurement decisions, centralizing buying power and influencing which manufacturers gain entry into major healthcare networks, thereby shaping the competitive dynamics within the downstream segment.

Electrosurgical Cutting Forcep Market Potential Customers

Potential customers for Electrosurgical Cutting Forceps are predominantly professional healthcare organizations that perform invasive and minimally invasive surgical procedures requiring controlled tissue cutting and hemostasis. Hospitals, specifically large tertiary care hospitals and academic medical centers, represent the largest customer segment due to their comprehensive surgical capabilities, high patient inflow, and capacity to invest in advanced, high-cost electrosurgical systems and compatible forceps. These institutions require a wide array of forcep types to cater to diverse surgical specialties, including cardiothoracic, neurosurgery, and complex oncology procedures. Procurement decisions in this segment are often driven by clinical validation, product reliability, and comprehensive service agreements, including specialized training for surgical staff.

Ambulatory Surgical Centers (ASCs) constitute the fastest-growing customer base, particularly in developed healthcare systems focused on cost containment and procedural efficiency. ASCs specialize in outpatient procedures (e.g., orthopedic, gastroenterology, basic gynecology), demanding high-quality, often single-use electrosurgical forceps that minimize setup time and sterilization costs. Their purchasing strategy heavily favors bundled purchasing agreements and products that are proven to reduce operating time and enhance quick patient turnover. The proliferation of these centers, driven by favorable reimbursement policies and patient preference for outpatient care, makes them a crucial target demographic for manufacturers focused on disposable product lines and streamlined inventory management solutions.

Specialty clinics, particularly those focused on urology, endoscopy, and plastic and cosmetic surgery, form the third significant customer segment. These clinics require highly specialized and sometimes miniaturized electrosurgical cutting forceps tailored for specific, delicate procedures. For example, dermatological clinics utilize fine-tip electrosurgical needles for precise lesion removal, while urology clinics require specific configurations for transurethral procedures. Procurement in these niche segments is highly influenced by physician preference and the need for tools that offer unparalleled precision and aesthetic outcomes, often leading to acceptance of higher price points for specialized, technologically superior devices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Medtronic, Johnson & Johnson (Ethicon), Olympus Corporation, B. Braun Melsungen AG, Stryker Corporation, Karl Storz SE & Co. KG, CONMED Corporation, Erbe Elektromedizin GmbH, Boston Scientific Corporation, CooperSurgical, Inc., ATMOS MedizinTechnik GmbH & Co. KG, Applied Medical Resources Corporation, KLS Martin Group, Richard Wolf GmbH, Kirwan Surgical Products, Inc., Symmetry Surgical Inc., Apyx Medical Corporation, Utah Medical Products, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrosurgical Cutting Forcep Market Key Technology Landscape

The Electrosurgical Cutting Forcep Market technology landscape is rapidly advancing, moving beyond basic high-frequency current application to sophisticated energy management and instrument design. A key technological innovation is the development of advanced vessel sealing systems, which integrate bipolar energy with optimized pressure sensors to ensure reliable and permanent vessel occlusion up to 7mm in diameter. These systems minimize the need for mechanical ligatures, reducing foreign body implantation and improving procedural efficiency. Another significant trend involves the integration of high-definition camera systems and illumination within the forcep handle itself, particularly crucial for visualizing target tissues and ensuring precise placement during complex endoscopic or robotic procedures where articulation is key. Manufacturers are increasingly prioritizing specialized insulation coatings, such as PTFE or proprietary ceramics, to enhance safety by preventing capacitive coupling and accidental burns outside the active tip, a common risk with monopolar instruments.

Furthermore, the focus is shifting towards 'smart' electrosurgical units (ESUs) that utilize microprocessors and proprietary algorithms to monitor tissue impedance and adjust power output automatically—often referred to as 'feedback controlled' systems. This ensures consistent thermal effect regardless of variations in tissue hydration or density, leading to repeatable and safer surgical outcomes. These smart systems are critical for optimal performance of cutting forceps, maximizing the cutting speed while ensuring adequate coagulation. The advent of hybrid energy devices, which combine radiofrequency (RF) and ultrasonic energy into a single instrument platform, also represents a major technological leap, offering surgeons the versatility to switch between fast cutting and superior hemostasis without changing instruments, thereby improving workflow and reducing operative time significantly.

In terms of physical design, the market is witnessing continuous improvements in ergonomics and material science, especially regarding single-use disposable forceps. New materials are being engineered to provide strength comparable to reusable instruments while remaining cost-effective for mass production and easily disposable. The trend toward developing smaller, more flexible forceps compatible with smaller surgical ports (e.g., 3mm or 5mm ports) is being driven by the demand for ultra-minimally invasive surgery, which minimizes scarring and accelerates recovery. Compatibility standards, ensuring seamless integration between various manufacturers’ forceps and third-party generators and robotic systems, remain a crucial technical focus area for ensuring widespread adoption and reducing friction in the operating room environment.

Regional Highlights

North America currently holds the largest share of the Electrosurgical Cutting Forcep Market, primarily due to the established and highly advanced healthcare infrastructure, high per capita healthcare spending, and swift adoption of sophisticated surgical technologies, including robotic-assisted and high-definition laparoscopic equipment. The presence of major global market leaders and favorable reimbursement policies for complex surgical procedures further contribute to this dominance. High awareness among surgical professionals regarding the benefits of advanced bipolar and smart electrosurgical systems drives consistent demand for technologically superior, often premium-priced, cutting forceps. The U.S. remains the core hub for R&D and innovation in surgical devices, setting the pace for global product standards and clinical adoption protocols.

Europe represents the second-largest market, characterized by stringent regulatory environments, particularly post-MDR implementation, which emphasizes device safety and clinical evidence. Western European countries like Germany, France, and the UK are strong markets owing to well-funded public healthcare systems and a focus on high-quality medical devices. Market growth in Europe is steady, driven by the aging population and the replacement cycles of older electrosurgical generators. The Nordic countries, in particular, show high penetration rates for minimally invasive techniques, favoring specialized, high-precision cutting tools used in outpatient settings. Economic variations across Eastern Europe, however, necessitate offering a mix of premium and cost-effective product lines.

The Asia Pacific (APAC) region is projected to be the fastest-growing market globally, experiencing rapid expansion driven by massive investments in public and private hospital infrastructure, particularly in countries such as China, India, and South Korea. Rising disposable incomes, increasing awareness regarding advanced surgical techniques, and the burgeoning medical tourism sector accelerate the adoption of modern electrosurgical equipment. While price sensitivity remains a factor, the sheer volume of surgical procedures performed across these densely populated countries provides substantial growth opportunities. Manufacturers are focusing on establishing local production facilities and distribution networks in APAC to overcome logistical hurdles and address region-specific cost constraints effectively, positioning this region as the future engine of market expansion.

- North America: Dominance due to high expenditure on healthcare, robust technological adoption, and extensive robotic surgery integration. Key focus on disposable, high-precision bipolar systems.

- Europe: Stable growth driven by an aging population and mandatory device replacement cycles; highly influenced by stringent EU Medical Device Regulation (MDR). Strong presence of key regional manufacturers.

- Asia Pacific (APAC): Highest CAGR expected, fueled by infrastructure development, rising surgical volumes, and increasing penetration of MIS techniques in emerging economies like China and India.

- Latin America (LATAM): Emerging market characterized by increasing healthcare access and gradual technology upgrades, though constrained by economic instability and reliance on imports.

- Middle East & Africa (MEA): Growth concentrated in affluent GCC countries (e.g., UAE, Saudi Arabia) driven by government initiatives to establish world-class medical facilities and high prevalence of lifestyle-related diseases requiring surgery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrosurgical Cutting Forcep Market.- Medtronic plc

- Johnson & Johnson (Ethicon, Inc.)

- Olympus Corporation

- B. Braun Melsungen AG

- Stryker Corporation

- Karl Storz SE & Co. KG

- CONMED Corporation

- Erbe Elektromedizin GmbH

- Boston Scientific Corporation

- CooperSurgical, Inc.

- ATMOS MedizinTechnik GmbH & Co. KG

- Applied Medical Resources Corporation

- KLS Martin Group

- Richard Wolf GmbH

- Kirwan Surgical Products, Inc.

- Symmetry Surgical Inc.

- Apyx Medical Corporation

- Utah Medical Products, Inc.

- Aesthetic & Medical Technologies, Inc. (A&MT)

- SurgRx, Inc. (now part of Johnson & Johnson)

Frequently Asked Questions

Analyze common user questions about the Electrosurgical Cutting Forcep market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Monopolar and Bipolar Electrosurgical Cutting Forceps?

Monopolar forceps require a grounding pad to complete the circuit, offering broader tissue effects but posing a higher risk of unintended burns. Bipolar forceps complete the circuit between the two tips of the instrument, localizing the current, which provides greater safety and precision, particularly in wet fields or near sensitive anatomical structures.

Which application segment drives the highest demand for Electrosurgical Cutting Forceps?

The General Surgery segment, encompassing high-volume procedures such as laparoscopic cholecystectomy, hernia repair, and abdominal surgeries, currently accounts for the largest market share due to the ubiquitous need for precise cutting, dissection, and hemostasis during these common operations worldwide.

How is technological advancement impacting the safety profile of these devices?

Technological advancement is improving safety through integrated feedback control systems that automatically modulate energy output based on real-time tissue impedance, advanced insulation materials to prevent stray currents, and ergonomic designs that reduce surgeon fatigue and improve handling precision.

What are the main factors restraining the market growth in emerging economies?

The primary restraints include the high initial investment cost of sophisticated electrosurgical generators, challenges related to establishing reliable maintenance and service infrastructure, and budget constraints within public healthcare systems limiting the widespread adoption of expensive disposable instruments.

Are reusable or disposable Electrosurgical Cutting Forceps dominating the market?

While reusable forceps have been historically dominant, the market trend is rapidly shifting towards disposable (single-use) forceps, driven by increasing concerns over cross-contamination (e.g., prion diseases), the rising costs and complexity of instrument reprocessing, and mandates for sterility assurance in complex MIS procedures.

The Electrosurgical Cutting Forcep Market stands at a critical juncture, characterized by accelerating innovation and strategic segmentation driven by the global imperative for safer, more effective surgical outcomes. Manufacturers are focused intensely on merging energy delivery systems with smart technologies, aiming to produce instruments that are not only capable of precise cutting and coagulation but also offer integrated intelligence for real-time surgical decision support. The shift towards robotic surgery further mandates the development of specialized, high-articulation forceps that are fully compatible with complex automated platforms, ensuring minimal thermal spread and maximal efficacy during robotic procedures. This technological convergence promises to redefine the standards of electrosurgery, particularly in highly sensitive and anatomically challenging surgical fields. The geopolitical and economic landscape influences market distribution, compelling leading companies to localize manufacturing and customize product offerings to meet diverse regulatory and pricing demands across continents, especially in high-growth regions like Asia Pacific and the Middle East.

Furthermore, sustainability and environmental responsibility are becoming increasingly important variables in product design. While disposable instruments offer clear safety advantages, the environmental impact of plastic and electronic waste is prompting R&D into biodegradable or easily recyclable materials for single-use devices. This focus on green manufacturing and supply chain efficiency represents a long-term strategic challenge and opportunity. The competitive intensity remains high, pushing companies to differentiate their products not only on performance metrics but also on comprehensive service agreements, training modules, and strong clinical evidence supporting improved patient recovery and reduced operative complications. Future market success will largely hinge on successful navigation of strict regulatory pathways and demonstrating clear value proposition to hospital administrators concerned with cost-benefit ratios.

In summary, the market's trajectory is firmly upward, underpinned by irreversible trends such as the demographic shift towards an older population requiring more surgical interventions, and the universal shift towards less invasive surgical methods. Bipolar technology continues to gain ground, marginalizing traditional monopolar applications in non-critical areas. The integration of AI for predictive modeling and automated energy management is set to be the defining technological differentiator in the latter half of the forecast period. Strategic growth will be unlocked through targeted expansion into emerging markets, alongside continued penetration within the burgeoning global network of Ambulatory Surgical Centers (ASCs), necessitating agile manufacturing and tailored product portfolios focused on efficiency and cost optimization for outpatient environments.

The Electrosurgical Cutting Forcep Market analysis underscores a dynamic environment where regulatory compliance, technological sophistication, and surgical workflow integration are paramount to achieving sustainable growth and market leadership. The sustained investment in research aimed at minimizing energy hazards and maximizing tissue sealing reliability reflects the industry's commitment to enhancing patient safety. Specialized training programs for surgeons on the use of advanced electrosurgical systems are also crucial for ensuring proper utilization and mitigating surgical risks, effectively translating product innovation into positive clinical outcomes. This comprehensive approach, encompassing technical excellence, safety assurance, and clinical education, is vital for long-term penetration in established and emerging healthcare markets globally, securing the projected CAGR through 2033.

Specifically concerning product lifecycle management, leading companies are increasingly focusing on modular design for their electrosurgical systems. This allows for easier upgrades to generators to incorporate new AI algorithms or connectivity features without requiring hospitals to replace the entire capital equipment base. This approach offers cost flexibility to end-users and promotes faster adoption of the latest technological enhancements in forcep performance. The development of standardized data protocols for communication between different surgical devices (such as electrosurgical generators, insufflators, and robotic platforms) is another area of active development, facilitating the creation of truly integrated operating rooms (ORs). Standardization efforts reduce complexity for OR staff and enhance the overall efficiency of surgical procedures involving electrosurgical cutting forceps.

Finally, the growing specialization in surgical subfields demands a corresponding specialization in forcep design. For instance, instruments designed for pediatric surgery require extreme miniaturization and precision to operate within small anatomical spaces, demanding unique material and energy delivery solutions. Similarly, instruments used in bariatric surgery must handle significant layers of fat and specialized tissue, requiring higher power settings and enhanced sealing capabilities. This push towards clinical specialization ensures that market growth is not only volumetric but also value-driven, targeting high-margin, niche surgical segments with purpose-built electrosurgical cutting forceps that offer unparalleled clinical advantages over general-purpose instruments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager