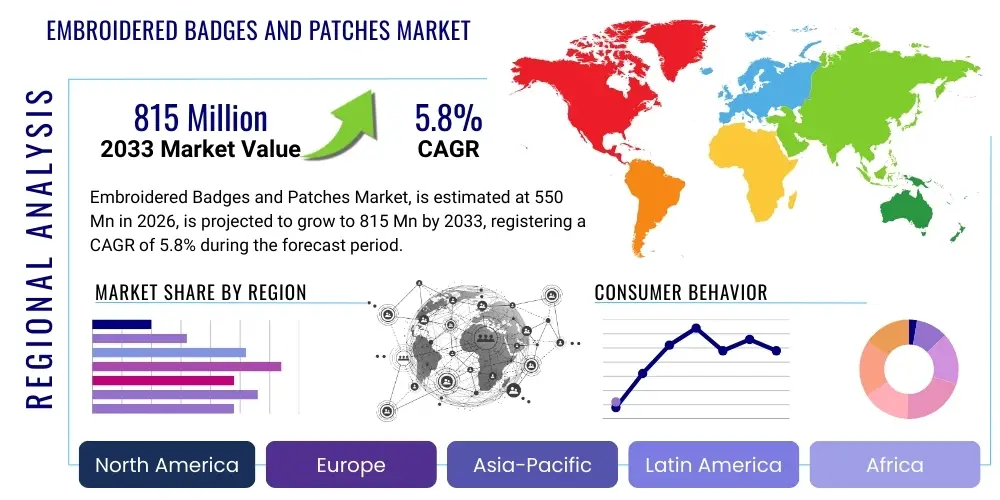

Embroidered Badges and Patches Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443480 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Embroidered Badges and Patches Market Size

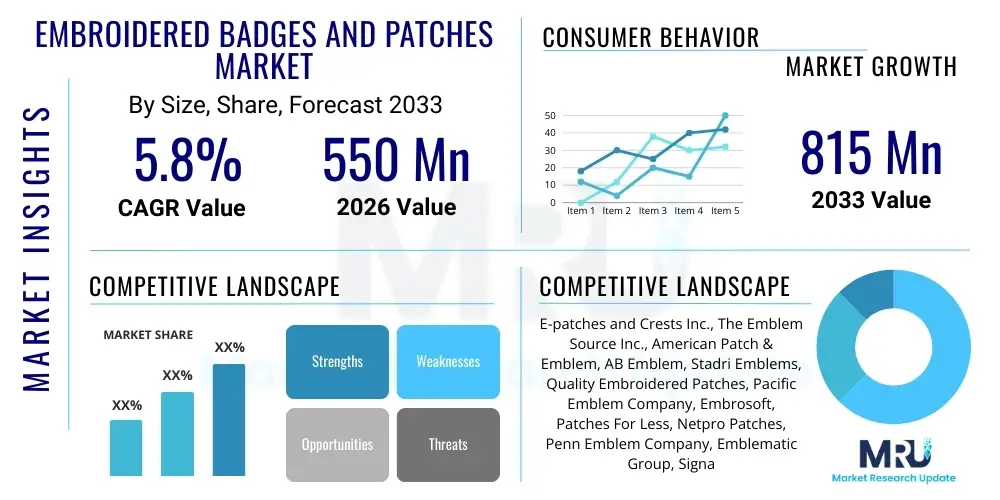

The Embroidered Badges and Patches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $550 Million USD in 2026 and is projected to reach $815 Million USD by the end of the forecast period in 2033. This consistent expansion is primarily driven by the increasing demand for personalized apparel decoration, robust corporate branding initiatives across diverse industries, and the enduring popularity of embroidered items within the fashion and collector communities. The resilience of this market lies in its versatility, catering to high-volume commercial orders as well as niche, custom artisanal requests.

Market expansion is significantly bolstered by advancements in automated embroidery machinery and digitization software, which have lowered production costs and increased the speed of complex designs. These technological improvements enable manufacturers to handle mass customization efficiently, a critical factor in serving fast-fashion cycles and rapid corporate re-branding efforts. Furthermore, the rising awareness and adoption of sustainable materials, such as recycled polyester threads and organic cotton backings, are opening new segments and appealing to environmentally conscious consumers and organizations, further fueling revenue growth throughout the forecast period.

Geographically, the Asia Pacific region is anticipated to demonstrate the most accelerated growth rate, attributed to the presence of large manufacturing hubs, growing domestic apparel consumption, and the increasing outsourcing of uniform and promotional goods production to countries like China, India, and Vietnam. Meanwhile, established markets in North America and Europe continue to drive innovation in design aesthetics and premium patch materials, focusing on high-quality, durable products for military, law enforcement, and high-end fashion applications, thereby maintaining strong market value contribution.

Embroidered Badges and Patches Market introduction

The Embroidered Badges and Patches Market encompasses the production, distribution, and sale of decorative fabric pieces created using needle and thread to form intricate designs, logos, or text, which are subsequently attached to garments, accessories, or other textile substrates. These products serve multiple critical functions, including brand identification (corporate logos, sports teams), personalization (custom names, artwork), occupational recognition (military insignia, emergency services badges), and artistic expression (fashion detailing, collecting). The market’s foundation rests on high-precision embroidery techniques, utilizing materials such as rayon, polyester, cotton, and specialty metallic threads, affixed using sew-on, iron-on (heat-seal), or hook-and-loop (Velcro) backings.

Major applications span institutional sectors, including armed forces, scouting organizations, police departments, and fire services, where standardized identification is paramount. Commercially, they are indispensable for corporate uniforms, promotional merchandise, sportswear, and private label fashion lines, offering a tactile and premium aesthetic compared to printed alternatives. Key benefits driving market demand include durability, wash resistance, superior visual texture, and the ability to convey a sense of heritage or quality craftsmanship. Driving factors primarily revolve around the global emphasis on brand visibility, the continued growth of the global uniform sector, and the booming trend of DIY and personalization in consumer goods, encouraging the purchase of standalone patches for customizing existing items.

Embroidered Badges and Patches Market Executive Summary

The global Embroidered Badges and Patches Market is experiencing dynamic growth characterized by evolving manufacturing automation, shifting consumer demands for customization, and regional divergence in application focus. Current business trends highlight a strong movement towards ‘on-demand’ manufacturing models facilitated by efficient digital design integration and streamlined supply chains, allowing smaller businesses and individual creators to enter the market with custom products. Furthermore, strategic partnerships between large embroidery houses and promotional product distributors are cementing market reach into high-volume corporate accounts, ensuring stable foundational demand alongside the volatility of seasonal fashion trends.

Regional trends indicate North America and Europe maintaining leadership in technological adoption and premium product manufacturing, especially catering to specialized sectors such as aviation, space programs, and luxury fashion brands that require stringent quality standards and unique materials. Conversely, the Asia Pacific region dominates in terms of sheer production volume and cost efficiency, attracting significant foreign investment for large-scale uniform and apparel decoration contracts. Emerging markets in Latin America and the Middle East & Africa are demonstrating nascent but rapid growth, particularly driven by increasing investments in institutional sectors, including government agencies, security forces, and rapid retail expansion demanding localized branding solutions.

Segment trends reveal that the 'Application' segment, particularly Corporate and Uniforms, remains the largest revenue contributor, offering stable, recurring demand. However, the fastest growth is observed within the 'Backing Type' segment for Heat-Applied (Iron-On) patches, favored by consumers for ease of use and personalization. Material innovation is also a key segment driver, with patches utilizing specialized glow-in-the-dark threads or 3D puff embroidery techniques gaining significant traction in sportswear and novelty applications, diversifying the overall market landscape and providing opportunities for higher margin sales.

AI Impact Analysis on Embroidered Badges and Patches Market

Common user questions regarding AI’s impact on the Embroidered Badges and Patches Market often center on automation potential, intellectual property risks related to design generation, and the speed of customization. Users frequently inquire if AI can fully automate the digitization process (turning artwork into stitch files), how generative AI might affect the need for human designers, and whether AI-driven quality control systems can eliminate defects in mass production. The key themes summarized from these inquiries reveal an expectation that AI will significantly streamline the pre-production phase, accelerate personalization options for end-users, and potentially compress lead times and costs, though concerns about maintaining artistic integrity and managing workforce transition remain prominent within the manufacturing sector.

The integration of Artificial Intelligence primarily revolutionizes the design and manufacturing workflow. AI-powered algorithms are increasingly used to optimize stitch counts and thread paths, ensuring the most efficient and aesthetically pleasing embroidery outcome while reducing material wastage and machine run time. Furthermore, AI assists in trend forecasting, analyzing vast amounts of fashion data and consumer preferences to predict popular colors, motifs, and patch shapes, providing manufacturers a critical competitive edge in stocking and designing marketable products ahead of seasonal demand. This shift towards smart manufacturing ensures higher throughput and reduced manual intervention in complex digitization tasks.

Beyond design optimization, AI is crucial in quality assurance. Vision systems utilizing machine learning models are being deployed on production lines to automatically detect minor flaws, such as skipped stitches, incorrect color sequencing, or misalignment, far more effectively and rapidly than human inspectors. This results in superior finished goods quality, reduced rework rates, and increased customer satisfaction, particularly vital in high-stakes applications like military or medical identification badges where zero tolerance for errors is standard. These comprehensive AI deployments position the market for enhanced scalability and precision in the coming years.

- AI-driven optimization of stitch density and thread color mapping, reducing design digitization time by up to 40%.

- Predictive maintenance analytics for industrial embroidery machines, minimizing downtime and maximizing operational efficiency.

- Generative AI tools assisting in rapid concept creation and mockup generation based on textual prompts or uploaded images.

- Automated defect detection and quality control using machine vision systems on high-speed production lines.

- Enhanced supply chain management through AI forecasting of raw material (thread, fabric) demand.

- Personalized marketing and recommendation engines for custom patch customers based on purchase history and design trends.

DRO & Impact Forces Of Embroidered Badges and Patches Market

The Embroidered Badges and Patches Market is influenced by a powerful interplay of Drivers, Restraints, and Opportunities (DRO), collectively shaping its trajectory. The primary driver is the pervasive need for corporate and organizational identity, which mandates standardized and durable branded apparel. This core demand is consistently supported by the opportunity presented by the democratization of design software and production technology, enabling small businesses and individual consumers to easily order highly customized, low-volume batches. Conversely, the market faces significant restraints, chiefly volatility in raw material prices (polyester and rayon threads) and intense competition from alternative decoration methods such as printed patches or direct-to-garment (DTG) printing, which often offer lower entry costs and faster setup times.

Impact forces acting on the market structure include the increasing demand for sustainable manufacturing practices, forcing companies to invest in eco-friendly threads and chemical-free backings, thereby influencing pricing structures and material sourcing. The accelerating global trend of personalization—driven by social media influence and niche cultural movements—acts as a powerful reinforcing driver, expanding the consumer base beyond traditional institutional buyers. Furthermore, international trade policies and tariffs significantly impact the cost structure for manufacturers relying on cross-border supply chains, particularly affecting the competitive landscape between Asian and Western producers.

The strongest opportunities lie in expanding applications within emerging sectors, such as professional gaming (eSports merchandise), sophisticated medical device manufacturing requiring specialized cleanroom apparel identification, and the burgeoning market for collectible and art-focused patches sold through online marketplaces. Companies that successfully leverage advanced automation (like multi-head embroidery machines and robotics) while simultaneously addressing the consumer desire for eco-conscious products are poised for disproportionate growth. The ability to pivot quickly to micro-trends while maintaining high-quality output defines successful navigation of these market forces.

Segmentation Analysis

The Embroidered Badges and Patches Market is comprehensively segmented based on three primary attributes: Material, Backing Type, and Application. Analyzing these segments provides strategic insights into consumer preferences, technological adaptation rates, and high-growth end-user sectors. Material segmentation is crucial as it determines durability, texture, and cost, with polyester threads remaining dominant due to their resilience and vibrant color retention, while specialty materials like metallic threads command premium pricing in luxury or tactical gear applications. Backing Type segmentation reflects ease of application for the end-user, with Iron-On (Heat-Seal) patches showing the fastest consumer adoption due to convenience, contrasting with the permanence required for Sew-On and Hook-and-Loop (Velcro) patches favored by military and outdoor industries.

The Application segment offers the deepest insight into market demand drivers. Corporate & Uniforms consistently holds the largest market share, driven by rigid organizational requirements for professional identity and safety compliance across industries like healthcare, transportation, and service sectors. Conversely, the Fashion & Retail segment, though more cyclical, offers rapid growth opportunities fueled by collaboration with designers and the quick adoption of aesthetic trends. The institutional and government segment, encompassing military and public services, is characterized by highly stable, large-volume, and non-negotiable quality contracts, providing a reliable revenue stream for specialized suppliers.

- By Material:

- Polyester Threads

- Rayon Threads

- Cotton Threads

- Metallic & Specialty Threads (e.g., UV reactive, Glow-in-the-dark)

- Eco-friendly/Recycled Threads

- By Backing Type:

- Sew-On Backing

- Iron-On (Heat-Seal) Backing

- Adhesive Backing (Peel and Stick)

- Hook-and-Loop (Velcro) Backing

- By Application:

- Corporate & Uniforms (Including industrial, service, and office wear)

- Military, Law Enforcement, and Emergency Services

- Sports Teams & Organizations

- Fashion & Retail (Including merchandise and private labels)

- Institutional (Scouting, Schools, Non-profits)

- Collector & Hobbyist (Personalized use)

- By End-Use Industry:

- Apparel and Textile Manufacturing

- Promotional Products

- Government and Defense

- Retail and E-commerce

- By Product Type:

- Standard Embroidered Patches

- Chenille Patches (High pile, often used in varsity letters)

- 3D Puff Patches

- Woven Badges (Often used interchangeably)

Value Chain Analysis For Embroidered Badges and Patches Market

The value chain for the Embroidered Badges and Patches Market begins with upstream suppliers providing critical raw materials, primarily specialized threads (polyester, rayon, cotton), base fabrics (felt, twill), and various backing adhesives or hook-and-loop components. This upstream phase is characterized by high sensitivity to petrochemical pricing, which affects synthetic thread costs, and requires rigorous quality control, especially for color fastness and tensile strength. Key considerations here include securing stable, high-quality, and increasingly sustainable thread sourcing, as environmental mandates push manufacturers away from traditional synthetic dyes and materials. Supplier relationships are critical for maintaining competitive manufacturing costs and ensuring compliance with international textile standards.

The middle segment of the value chain involves the manufacturing process, which includes design digitization (converting artwork into machine-readable embroidery files), setup, production using multi-head industrial embroidery machines, and finishing (heat cutting, border finishing, and application of backing). Manufacturers act as value-add centers, leveraging advanced technology and skilled labor to achieve complex, multi-color, and durable designs. Efficiency in this stage is heavily reliant on machine utilization rates, minimizing defects, and optimizing logistics for both small-batch custom orders and large-scale bulk contracts. Investments in computerized automation and sophisticated quality control systems are essential for competitive differentiation.

Downstream analysis focuses on distribution channels and end-user engagement. The distribution channel is diversified, spanning direct sales to large institutional clients (military, large corporations), wholesale distribution through promotional product companies, and increasingly, direct-to-consumer (D2C) sales facilitated by e-commerce platforms and online customizers. Direct channels offer higher margins and greater control over the customer experience, particularly important for personalization services. Indirect channels, primarily through distributors and resellers, are vital for market penetration into varied geographical locations and accessing specialized industry buyers. The efficiency of final application methods (e.g., heat press performance for iron-on patches) also constitutes a key part of the downstream value proposition.

Embroidered Badges and Patches Market Potential Customers

Potential customers for embroidered badges and patches are exceptionally diverse, ranging from high-security government agencies to individual fashion enthusiasts seeking unique self-expression. The largest volume buyers include global corporations requiring standardized branding across employee uniforms, promotional merchandise, and safety gear, where durability and consistency are paramount. Institutional buyers, such as the Department of Defense, various police forces, and fire departments across the world, represent crucial, long-term contractual customers demanding superior quality, precise specifications, and robust production traceability for their insignia and identification badges. These segments prioritize compliance and longevity over cost optimization.

The promotional products industry constitutes another major customer segment, purchasing patches in bulk for marketing campaigns, event giveaways, and branded apparel lines. These distributors act as intermediaries, servicing thousands of small to medium-sized businesses (SMBs) across retail, hospitality, and event management sectors. Furthermore, the retail sector, specifically apparel manufacturers and fashion brands, are increasingly utilizing embroidered patches as high-end embellishments to elevate perceived product value, drive limited-edition sales, and tap into retro or vintage aesthetics popular among younger consumer demographics, often demanding creative designs like 3D puff and chenille patches.

A rapidly expanding segment involves individual consumers, small-scale designers, and online entrepreneurs utilizing the market for personalized projects. Driven by platforms like Etsy and Print-on-Demand services, these buyers value ease of ordering, quick turnaround times for low quantities, and accessible design tools. These customers typically favor Iron-On or Adhesive backings for ease of application. Serving this personalized market requires manufacturers to invest heavily in user-friendly online interfaces and efficient, digitized production workflows capable of handling high variability in order specifications without compromising profitability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million USD |

| Market Forecast in 2033 | $815 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | E-patches and Crests Inc., The Emblem Source Inc., American Patch & Emblem, AB Emblem, Stadri Emblems, Quality Embroidered Patches, Pacific Emblem Company, Embrosoft, Patches For Less, Netpro Patches, Penn Emblem Company, Emblematic Group, Signature Patches, Custom Embroidered Patches, UltraPatches |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Embroidered Badges and Patches Market Key Technology Landscape

The manufacturing landscape for embroidered badges and patches is rapidly evolving, driven by the need for increased precision, speed, and design complexity. Central to this evolution is the reliance on high-speed, multi-head computer numerical control (CNC) embroidery machines, such as those produced by specialized firms like Tajima and Barudan. These machines utilize advanced servo motor technology to execute intricate stitch patterns simultaneously across multiple production units, dramatically improving throughput and minimizing human error. The continuous technological upgrade cycle for these machines, focusing on higher stitch counts per minute (SPM) and larger embroidery fields, ensures scalability for both small, complex designs and massive bulk orders, maintaining the quality required by institutional clients.

Equally critical is the technological ecosystem surrounding the machinery, primarily design digitization software (e.g., Wilcom, Pulse). These software solutions are fundamental, enabling designers to convert standard vector artwork into detailed stitch files, optimizing needle movements, thread tension, and color sequencing. Recent advancements in this software incorporate AI-assisted features that automatically suggest optimal stitch angles and densities based on the chosen material, significantly reducing the time spent on manual file preparation. This digitization capability is the cornerstone of the market's ability to offer rapid, highly accurate custom patch services at competitive prices.

Furthermore, post-embroidery finishing technologies are becoming increasingly specialized. Laser cutting and ultrasonic welding are replacing traditional manual or die cutting methods for patch borders, offering cleaner, sealed edges that prevent fraying and provide a premium finish. This technology is particularly important for complex, custom shapes that require extreme precision. For the application of backing, automated heat-seal coating equipment ensures uniform and durable adhesion properties for iron-on patches, meeting the rigorous demands of the consumer market for easy and reliable home application, further solidifying the technological advantage of modern manufacturers over traditional methods.

Regional Highlights

The global distribution and consumption patterns of embroidered badges and patches demonstrate distinct regional characteristics shaped by economic development, industrial focus, and local cultural appreciation for decorated textiles. North America is a major revenue hub, characterized by high disposable income and significant expenditure on corporate branding, sports merchandise (NFL, NBA, NHL), and large, well-funded military and emergency services sectors. The market here is defined by demand for premium quality, often requiring patches with specialized features like infrared reflectivity or high-denier thread counts for tactical applications. Innovation in patch aesthetics, particularly 3D and intricate detailing, originates strongly from this region.

Asia Pacific (APAC) stands out as the global manufacturing powerhouse, hosting the majority of the world's large-scale embroidery operations, primarily centered in China, Vietnam, and India. This region benefits from lower operating costs and established textile supply chains, driving cost-competitive production for global exports, particularly for the high-volume corporate uniform and fast-fashion industries. While dominating in production volume, APAC is also rapidly growing in domestic consumption, fueled by expanding middle classes, burgeoning retail sectors, and increasing regional military modernization programs that require large volumes of standardized identification badges, projecting the highest CAGR during the forecast period.

Europe represents a mature market focusing heavily on aesthetic quality, ethical sourcing, and compliance with stringent environmental regulations (REACH). Key drivers include luxury fashion houses utilizing high-end embroidery for embellishment, and a robust institutional sector (EU military cooperation, national railways, postal services). The European market exhibits strong growth in the specialized/niche segment, particularly for vintage-style patches and sustainable or organic thread utilization, catering to a sophisticated consumer base willing to pay a premium for ethical and quality craftsmanship. Latin America and MEA are emerging markets, primarily driven by government investment in security forces and rapid urbanization fueling demand for service sector uniforms and promotional items.

- North America: Leading market for high-quality, specialized (tactical/military) patches and strong corporate uniform demand. Focus on rapid customization platforms.

- Asia Pacific (APAC): Dominant manufacturing center; highest growth potential driven by manufacturing scale and rapidly expanding domestic apparel markets in China and India.

- Europe: High emphasis on sustainable materials, ethical production, and luxury fashion applications; mature market with steady demand from institutional bodies.

- Latin America (LATAM): Growth driven by expanding local industries, standardization of corporate uniforms, and rising consumer interest in personalized accessories.

- Middle East & Africa (MEA): Market expansion linked to increased defense spending, infrastructural development, and growing tourism requiring branded merchandise.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Embroidered Badges and Patches Market.- E-patches and Crests Inc.

- The Emblem Source Inc.

- American Patch & Emblem

- AB Emblem

- Stadri Emblems

- Quality Embroidered Patches

- Pacific Emblem Company

- Embrosoft

- Patches For Less

- Netpro Patches

- Penn Emblem Company

- Emblematic Group

- Signature Patches

- Custom Embroidered Patches

- UltraPatches

- PinProsPlus

- The Patch Factory

- Houston Embroidery Service

- Woven Labels UK

Frequently Asked Questions

Analyze common user questions about the Embroidered Badges and Patches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Embroidered Patches Market?

The primary factor driving market growth is the soaring global demand for personalization and customization in apparel and accessories, coupled with the persistent need for durable, high-visibility corporate and institutional identification badges that offer superior quality compared to printed alternatives.

Which backing type is most popular for consumer-grade embroidered patches?

The Iron-On (Heat-Seal) backing type is highly popular among consumer and retail segments due to its ease of application, requiring only a standard household iron or heat press, making it ideal for non-professional application on jackets, bags, and casual wear.

How is technology impacting the cost and production speed of custom embroidered badges?

Technological advancements, including high-speed multi-head CNC embroidery machines and AI-enhanced design digitization software, are significantly reducing labor costs and production lead times, allowing manufacturers to efficiently handle small, highly customized orders without drastically increasing the per-unit price.

Which geographical region holds the largest production capacity for embroidered badges and why?

The Asia Pacific (APAC) region, particularly countries like China, India, and Vietnam, holds the largest production capacity, attributed to lower operational costs, abundant skilled labor, established textile supply chains, and large-scale manufacturing infrastructure catering to global export demands.

What are the main sustainable material innovations being adopted in patch manufacturing?

Key sustainable material innovations include the use of recycled polyester threads derived from plastic bottles, organic cotton twill backings, and the implementation of eco-friendly dyeing processes that reduce water consumption and eliminate harmful chemical residues, appealing to environmentally conscious brands and consumers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager