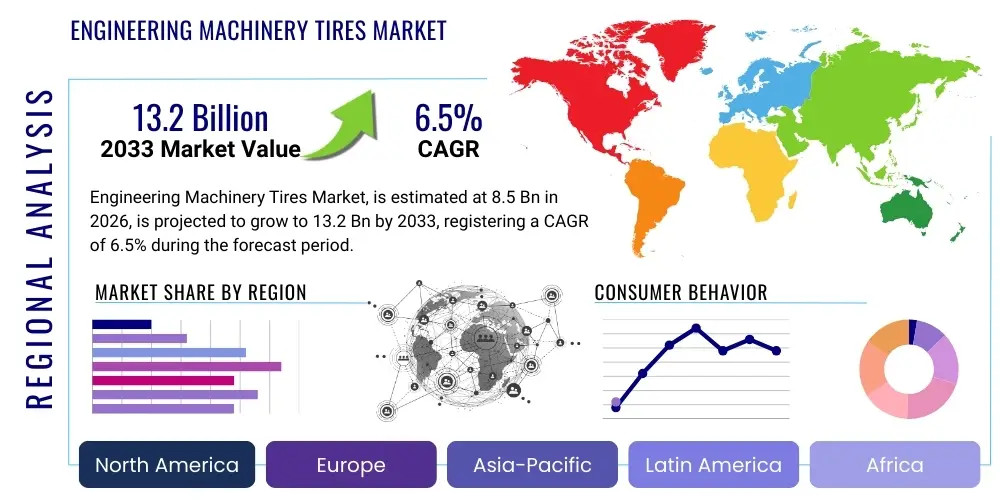

Engineering Machinery Tires Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442702 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Engineering Machinery Tires Market Size

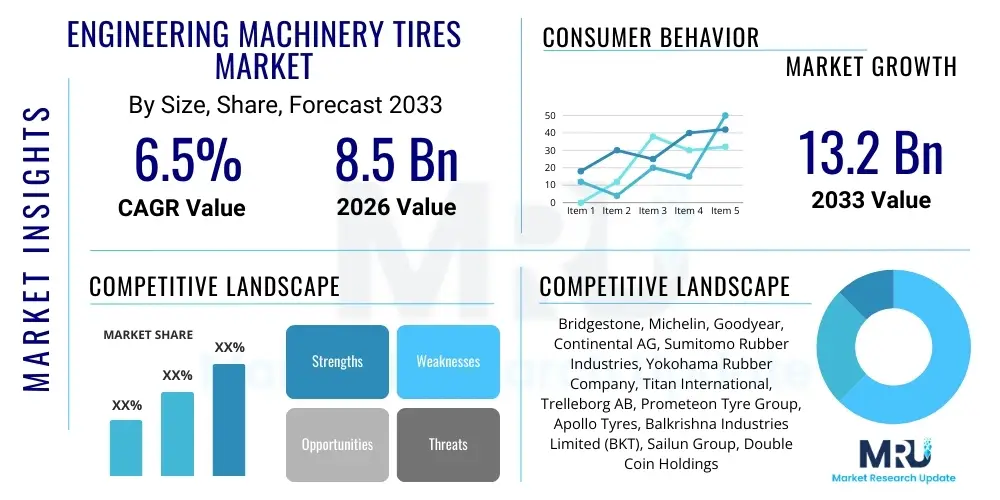

The Engineering Machinery Tires Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 8.5 billion in 2026 and is projected to reach USD 13.2 billion by the end of the forecast period in 2033.

Engineering Machinery Tires Market introduction

The Engineering Machinery Tires Market, often categorized under Off-the-Road (OTR) tires, encompasses specialized heavy-duty tires designed for equipment used in construction, mining, infrastructure development, port handling, and large-scale agricultural operations. These tires are engineered to withstand extreme loads, harsh operating environments—including abrasive surfaces, high temperatures, and puncture risks—and offer superior traction and stability required by heavy machinery such as wheel loaders, bulldozers, dump trucks, excavators, graders, and specialty mining vehicles. Unlike conventional highway tires, OTR tires prioritize durability, longevity, and resistance to impact over speed, utilizing robust casings and specialized rubber compounds. The primary products include Bias tires, traditionally used for low-speed, high-stress applications, and Radial tires, which are gaining prominence due to their improved fuel efficiency, lower heat buildup, and enhanced tread life, making them critical components for optimizing operational efficiency in capital-intensive industries.

Major applications of engineering machinery tires are concentrated heavily in the global infrastructure and resource extraction sectors. Rapid urbanization, coupled with significant governmental investments in roads, railways, ports, and renewable energy projects worldwide, drives consistent demand for construction equipment and, subsequently, their tire replacements. The continuous expansion of global mining activities, particularly in regions rich in iron ore, copper, and coal, mandates durable, high-load tires capable of operating in rugged terrains. Key benefits offered by these specialized tires include minimized downtime due as a result of fewer punctures and failures, improved operational safety through enhanced stability and load-bearing capacity, and ultimately, lower total cost of ownership (TCO) for equipment operators who choose premium, long-lasting products. The market is increasingly influenced by stringent safety regulations and the growing emphasis on sustainability, pushing manufacturers toward the development of advanced materials and retreading solutions to extend tire life cycles.

Driving factors propelling this market forward include macroeconomic trends such as escalating global population leading to heightened demand for residential and commercial infrastructure, coupled with the necessity for modernizing existing infrastructure networks in developed economies. Furthermore, the rising adoption of heavy equipment in developing nations, particularly across Asia Pacific and Latin America, where massive infrastructure projects are underway, contributes substantially to market volume. Technological advancements in tire manufacturing, focusing on integrating sensors for real-time performance monitoring (smart tires), improving cut resistance through synthetic fiber integration, and developing application-specific tread patterns, are crucial for supporting increasingly sophisticated and autonomous machinery. The balance between maintaining robust performance and meeting environmental standards concerning rolling resistance and material sourcing remains a critical strategic challenge for market participants.

Engineering Machinery Tires Market Executive Summary

The Engineering Machinery Tires Market is experiencing transformative growth, underpinned by robust global business trends centered on infrastructure expansion, intensified mining output, and the modernization of construction fleets. A primary business trend observed is the accelerating shift from traditional Bias-ply tires to advanced Radial tires across high-demand applications, driven by end-users seeking better fuel economy and reduced maintenance costs. Furthermore, original equipment manufacturers (OEMs) are increasingly demanding application-specific tire designs tailored for integrated machine performance, thereby creating closer collaborations between tire manufacturers and machinery producers. The market is highly competitive, characterized by strategic mergers, acquisitions, and extensive R&D focused on developing sustainable compounds and smart tire technologies that offer superior durability and operational insights. The aftermarket segment, which accounts for the larger portion of market revenue, is seeing increased penetration of high-quality retreaded tires, addressing both cost efficiency and environmental concerns.

Regional trends indicate that the Asia Pacific (APAC) region currently dominates the market and is projected to maintain the fastest growth rate throughout the forecast period. This dominance is attributed to massive ongoing infrastructure initiatives in countries like China, India, and Southeast Asian nations, coupled with significant investments in resource extraction and urbanization projects. North America and Europe, while being mature markets, show steady growth driven primarily by fleet replacement cycles, the adoption of specialized high-performance tires for complex civil engineering projects, and a strong regulatory push towards safety and environmental standards. The Middle East and Africa (MEA) region is exhibiting robust growth, propelled by large-scale oil and gas exploration, mining projects, and extensive urban development in Gulf Cooperation Council (GCC) countries. Latin America’s market expansion is tied closely to commodity prices influencing mining and agricultural investment cycles.

In terms of segment trends, the Construction segment remains the largest application area, benefitting from global housing and commercial real estate development. However, the Mining segment is the most lucrative in terms of average selling price (ASP) due to the necessity for extremely large and specialized tires (e.g., Ultra Large OTR tires). Technologically, the Radial tire segment is witnessing the highest growth CAGR, gradually eroding the share of Bias tires, although Bias tires retain their niche in specific low-speed, highly abusive environments. The distribution channel is evolving, with OEM sales providing initial high-volume business and the aftermarket segment driving sustained revenue through replacement demand and essential fleet maintenance services. Sustainability is a transversal segment trend, influencing material sourcing and promoting circular economy practices such as advanced tire retreading and recycling technologies across all application types.

AI Impact Analysis on Engineering Machinery Tires Market

User queries regarding the impact of Artificial Intelligence (AI) on the Engineering Machinery Tires Market predominantly revolve around three critical areas: predictive maintenance capabilities, optimization of tire design and material science, and the role of tires in supporting autonomous heavy machinery. Users frequently ask how AI-driven analytics, utilizing data streamed from embedded tire sensors (TPMS, load sensors), can accurately predict potential tire failure before it occurs, minimizing costly unscheduled downtime, which is a major concern in mining and construction operations. Another common theme addresses how machine learning algorithms are being employed in the R&D phase to simulate complex stress factors and optimize rubber compound formulations and tread patterns for maximum longevity and energy efficiency, significantly accelerating the traditionally slow process of tire development. Furthermore, the integration of OTR tires into the ecosystem of autonomous vehicles requires AI to interpret real-time tire performance data to ensure optimal traction, steering responsiveness, and safety protocols for unmanned operations in rugged environments.

The immediate and profound impact of AI is visible in enhancing operational efficiency and safety. AI algorithms process vast datasets related to haul routes, load weights, historical weather conditions, operator behavior, and temperature variations collected via smart tire sensors. This processing capability allows fleet managers to transition from scheduled maintenance to condition-based maintenance, ensuring tires are optimally inflated, rotated, or replaced precisely when necessary, maximizing their lifespan and reducing fuel consumption associated with underinflation. This predictive capability translates directly into significant cost savings for end-users operating large fleets of engineering machinery, establishing AI as a core strategic differentiator for premium tire manufacturers.

In the long term, AI’s influence will extend significantly into the manufacturing and supply chain aspects. Generative AI and deep learning are being leveraged to simulate tire performance under hypothetical extreme conditions, leading to the creation of 'digital twins' of tire products. This allows engineers to rapidly iterate on design changes, optimizing geometric structures and material mixes to achieve desired performance metrics—such as improved cut resistance or reduced rolling resistance—without extensive physical prototyping. Furthermore, AI-driven logistics optimization is enhancing supply chain resilience, forecasting replacement demand across various regions based on infrastructure project cycles and commodity price fluctuations, ensuring that specialized OTR tires are available precisely where and when required, thereby streamlining the highly complex global distribution network.

- AI enables predictive tire maintenance via sensor data analysis, reducing unplanned equipment downtime.

- Machine learning optimizes rubber compound formulation and tread geometry for enhanced durability and fuel efficiency.

- Real-time tire performance data is integrated with autonomous equipment navigation systems to ensure optimal traction and safety.

- AI-driven simulation accelerates the R&D cycle for new OTR tire models and application-specific designs.

- Fleet management systems utilize AI for dynamic load balancing and route optimization based on tire stress prediction.

- AI algorithms enhance quality control in the manufacturing process by analyzing high-resolution scans of finished tires for defects.

DRO & Impact Forces Of Engineering Machinery Tires Market

The Engineering Machinery Tires Market is heavily influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the primary impact forces shaping its trajectory. The dominant Drivers include aggressive global infrastructure spending, driven by governmental stimulus packages aimed at economic recovery and modernization, particularly in emerging economies. The sustained high demand for essential commodities, fueling intensified mining and excavation activities globally, directly translates into a necessity for heavy-duty replacement tires. This is compounded by technological advancements in machinery, leading to larger equipment requiring more specialized, high-load capacity OTR tires. These driving forces exert a significant positive impact force, pushing the market towards higher production volumes and continuous product innovation focused on heavy-duty performance and efficiency.

However, the market faces notable Restraints that temper this growth. Significant volatility in the price of key raw materials, especially natural rubber, synthetic rubber, and petroleum derivatives (carbon black), directly affects manufacturing costs and profitability, creating pricing pressure across the value chain. Moreover, the increasing stringency of global environmental regulations, particularly regarding tire disposal, manufacturing emissions, and the mandated reduction of rolling resistance for improved fuel efficiency, necessitates expensive modifications to manufacturing processes and material sourcing. The relatively long replacement cycle of premium OTR tires, which can often last several years depending on application and terrain, acts as a cyclical restraint on aftermarket sales volume. These restraints collectively create an impact force that focuses manufacturer efforts on cost management, regulatory compliance, and increasing the operational lifespan of their products.

Opportunities within the sector are primarily centered on innovation and diversification. The accelerating development of 'Smart Tires,' equipped with embedded sensors (TPMS, RFID tags), offers a substantial opportunity for manufacturers to transition from product sellers to providers of integrated performance data and maintenance services, creating new revenue streams. The growing emphasis on sustainability and the circular economy presents a lucrative opportunity in the retreading market, where high-quality retreaded OTR tires offer significant cost savings and lower environmental impact compared to new tires. Furthermore, the expansion into niche applications such as automated port handling equipment and specialized forestry machinery offers diversified growth avenues. These opportunities represent a powerful strategic impact force, urging companies to invest heavily in digitalization, material science research, and expanding their service portfolios to capture higher margins and ensure long-term market relevance.

Segmentation Analysis

The Engineering Machinery Tires Market is comprehensively segmented based on three primary dimensions: Type, Application, and Sales Channel, reflecting the diverse requirements and purchasing patterns of end-users across heavy industries. Segmentation by Type differentiates between Bias tires, known for their sidewall strength and stability in stationary or low-speed, high-abuse applications, and Radial tires, which dominate modern, long-distance hauling and demanding conditions due to their superior load distribution, heat dissipation, and reduced rolling resistance. The Application segmentation is crucial as it dictates the specific performance characteristics required (e.g., cut resistance in mining vs. traction in agriculture). Finally, the Sales Channel segmentation highlights the bifurcation between Original Equipment Manufacturer (OEM) sales, driven by new equipment purchases, and the high-volume Aftermarket segment, sustained by replacement demand and maintenance contracts.

The segmentation structure is vital for manufacturers to tailor their product offerings and strategic market approaches. For instance, companies targeting the Mining application segment focus heavily on producing Ultra Large Radial Tires (ULR) with advanced heat resistance technology, requiring immense capital investment and sophisticated R&D. Conversely, companies focused on the Construction sector often target a broader range of medium-sized OTR tires and place greater emphasis on robust distribution networks for rapid aftermarket supply. Understanding the interplay between Type and Application allows for effective pricing strategies, as Radial tires generally command a significant price premium over Bias tires due to their operational efficiencies and technological superiority. This nuanced segmentation reflects the fragmented yet specialized nature of the heavy machinery industry.

Current market trends within these segments show the radialization trend is strongest in the Construction and Mining sectors, driven by the desire to maximize machine uptime and optimize fuel usage. However, the agricultural sector is also rapidly adopting radial flotation tires to minimize soil compaction and improve field efficiency. The aftermarket channel is projected to grow faster than the OEM channel, primarily due to the vast existing fleet of machinery globally and the increasing focus on fleet operational optimization, which includes timely and strategic tire replacement and maintenance services. This requires manufacturers to invest heavily in comprehensive service packages, digital tools for inventory management, and strengthening partnerships with specialized tire dealers and service providers globally.

- By Type:

- Bias

- Radial

- By Application:

- Construction

- Mining

- Industrial (Port Handling, Logistics)

- Agriculture & Forestry

- Others (Military, Waste Management)

- By Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket

- By Equipment Type:

- Loaders and Dozers

- Dump Trucks

- Excavators and Graders

- Specialty Mining Vehicles

- Others (Skidders, Compactors)

Value Chain Analysis For Engineering Machinery Tires Market

The value chain for the Engineering Machinery Tires Market is complex and capital-intensive, starting with the procurement of critical raw materials, moving through highly specialized manufacturing processes, and concluding with sophisticated distribution and service networks. The upstream analysis begins with raw material suppliers, predominantly providers of natural rubber (sourced mainly from Southeast Asia), synthetic rubber (petrochemical derivatives), carbon black (petroleum refinement), reinforcing materials (steel cords, synthetic fabrics), and various chemical additives. Fluctuations in commodity prices and supply chain stability for these materials are key determinants of overall production costs and market competitiveness. Manufacturers often employ sophisticated risk management strategies and establish long-term sourcing contracts to mitigate price volatility, as raw materials account for a substantial proportion of the tire’s manufacturing cost.

The manufacturing stage involves technologically advanced processes, including compounding, molding, and curing, requiring significant investment in heavy machinery and quality control systems to produce OTR tires capable of meeting stringent performance standards. Midstream analysis focuses on the manufacturers (Tier 1 and Tier 2 players) who add value through proprietary design, application-specific tread patterns, and incorporation of advanced technologies like run-flat capabilities or integrated sensors. Efficiency in manufacturing, leveraging automation, and minimizing waste are critical value drivers at this stage. The competitive landscape is characterized by a few global giants who possess the capability to produce the massive, complex Ultra Large OTR tires required by major mining operations.

The downstream segment, encompassing distribution and end-use, is bifurcated into direct and indirect channels. Direct channels involve sales straight to OEMs (Original Equipment Manufacturers) for new machinery fitting and large volume contracts with major mining corporations or national construction fleet operators. Indirect channels, which dominate the aftermarket, rely on extensive networks of specialized dealers, authorized distributors, and service centers that provide installation, maintenance, repair, and retreading services. Effective distribution requires specialized logistics capabilities due to the large size and weight of the products. The proximity of service centers and the availability of high-quality retreading facilities significantly enhance customer value, reduce operational costs for end-users, and strengthen the overall market position of manufacturers who offer comprehensive after-sales support.

Engineering Machinery Tires Market Potential Customers

The primary customers and end-users of engineering machinery tires are large entities that operate fleets of heavy equipment across capital-intensive sectors globally. The largest segment of buyers consists of heavy civil engineering and infrastructure contractors who require tires for wheel loaders, backhoes, motor graders, and articulated dump trucks used in road construction, bridge building, and urban development projects. These customers prioritize durability, reliable supply chains for replacement tires, and tire life warranties, as equipment downtime leads to significant financial losses. Furthermore, governmental agencies managing large-scale public works projects often act as indirect influencers or direct buyers through centralized procurement systems for public fleet maintenance, demanding compliance with specific quality and sustainability standards.

Another crucial group comprises global and regional mining companies, operating open-pit and underground mines for commodities such as coal, iron ore, copper, and precious metals. These buyers utilize the largest and most expensive OTR tires for massive haul trucks (e.g., CAT 797, Komatsu 930E). Their purchasing decisions are driven almost entirely by tire performance under extreme load and hostile abrasive environments, focusing on heat resistance, cut resistance, and maximizing Ton-Kilometer-Per-Hour (TKPH) ratings. For these high-value customers, predictive maintenance services bundled with smart tires are increasingly non-negotiable, offering critical data insights into tire health and optimizing operational cycles. The relationship between tire supplier and mining company is often deeply consultative and long-term.

The agricultural sector, particularly large-scale commercial farming operations in North America, Europe, and Latin America, represents a rapidly growing customer base. Farmers demand specialized radial agricultural tires (R-1W, IF/VF technology) that minimize soil compaction while providing high traction for tractors, combine harvesters, and sprayers. Finally, industrial logistics and port operators constitute a niche but high-volume customer segment, requiring specialized solid or cushion OTR tires for forklifts, straddle carriers, and rubber-tired gantry cranes (RTGs), where stability, puncture resistance, and extended operational hours on paved surfaces are paramount. For all end-users, the transition towards autonomous or semi-autonomous machinery is making the tire a crucial data-generating component, requiring integration with the overall equipment management system.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 billion |

| Market Forecast in 2033 | USD 13.2 billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bridgestone, Michelin, Goodyear, Continental AG, Sumitomo Rubber Industries, Yokohama Rubber Company, Titan International, Trelleborg AB, Prometeon Tyre Group, Apollo Tyres, Balkrishna Industries Limited (BKT), Sailun Group, Double Coin Holdings, Zhongce Rubber Group Co. Ltd. (ZC Rubber), Prinx Chengshan Tire. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Engineering Machinery Tires Market Key Technology Landscape

The technological landscape of the Engineering Machinery Tires Market is rapidly evolving, moving beyond basic compounding towards advanced material science and digital integration. A central technological focus is the continuous refinement of rubber compounds, incorporating advanced elastomers, specialized polymers, and nano-materials (e.g., graphene, silica derivatives) to drastically enhance tire performance metrics such as cut resistance, tear strength, and rolling resistance. This material innovation is critical, particularly for Ultra Large OTR tires operating in challenging mining environments, where thermal buildup and severe abrasion are persistent challenges. Manufacturers are increasingly utilizing sophisticated computational fluid dynamics (CFD) and finite element analysis (FEA) to simulate tire stress and optimize internal structure, tread patterns, and casing rigidity, ensuring optimal load carrying capacity and extended service life without compromising safety.

Digitalization represents the most significant technological shift, spearheaded by the widespread adoption of smart tire technology. This includes integrating Tire Pressure Monitoring Systems (TPMS) and proprietary sensor chips (Tire Intelligence) directly into the tire structure during manufacturing. These sensors continuously monitor critical parameters—pressure, temperature, load, and internal casing strain—and transmit real-time data to fleet management platforms and operator dashboards. This capability facilitates genuine predictive maintenance, allowing operators to preempt failures, maximize fuel efficiency by ensuring optimal inflation, and crucially, maintain optimal conditions for autonomous operation. The development of advanced analytics platforms to interpret this massive influx of telematics data is a parallel technological advancement driving the service-based revenue models in the industry.

Furthermore, technology focused on extending the life cycle and sustainability of OTR tires is gaining momentum. This includes developing enhanced carcass designs specifically optimized for multiple retreading cycles, reducing the reliance on virgin materials and lowering the TCO for end-users. Innovations in bead wire technology and internal cooling systems (e.g., specialized inner liners that dissipate heat more effectively) are essential for supporting the high speeds and heavy loads associated with modern infrastructure and resource transport vehicles. The industry is also exploring non-pneumatic (airless) tire concepts, although these remain largely nascent but hold potential for eliminating catastrophic failures due to punctures, especially in high-risk industrial environments, representing a long-term transformative technology goal.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market, primarily driven by massive government investments in large-scale infrastructure projects (e.g., China's Belt and Road Initiative, India's National Infrastructure Pipeline, Southeast Asian urban development). The region hosts intense mining and commodity extraction activities, necessitating high demand for both OEM and replacement OTR tires. Favorable regulatory environments supporting manufacturing and urbanization trends underpin sustained market expansion.

- North America: Characterized by a mature market with high technological adoption. Growth is steady, fueled by the replacement demand from large construction and mining fleets utilizing advanced, high-performance radial tires. The focus is heavily on efficiency, safety, and the integration of smart tire technology, supported by substantial defense and specialized infrastructure spending.

- Europe: Europe exhibits moderate, stable growth, highly regulated by stringent environmental and safety standards (e.g., mandatory rolling resistance parameters). The market is driven by the modernization of existing infrastructure and high demand from the industrial and specialized agricultural sectors. Emphasis is placed on sustainability, leading to strong growth in the high-quality retreaded tire segment and demand for energy-efficient radial tires.

- Latin America: Market growth is highly correlated with global commodity prices and mining investment cycles, particularly in Brazil, Chile, and Peru. Infrastructure development, while ongoing, is often subject to economic volatility. The region shows strong potential for growth in the radial tire segment as fleet operators seek operational cost optimization in mining and agricultural applications.

- Middle East and Africa (MEA): This region shows significant future growth potential, fueled by large construction projects in the GCC countries (Vision 2030 initiatives) and increased investment in mining and oil & gas infrastructure across Africa. The demand focuses on extremely durable tires capable of operating in high temperatures and harsh, arid conditions, driving the need for specialized heat-resistant products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Engineering Machinery Tires Market.- Bridgestone Corporation

- Michelin Group

- Goodyear Tire & Rubber Company

- Continental AG

- Sumitomo Rubber Industries, Ltd.

- Yokohama Rubber Company, Ltd.

- Titan International, Inc.

- Trelleborg AB

- Prometeon Tyre Group

- Apollo Tyres Ltd.

- Balkrishna Industries Limited (BKT)

- Sailun Group Co., Ltd.

- Double Coin Holdings Ltd.

- Zhongce Rubber Group Co. Ltd. (ZC Rubber)

- Prinx Chengshan Tire Co., Ltd.

- Pirelli & C. S.p.A.

- Nokian Tyres plc

- MRF Limited

- Triangle Tyre Co., Ltd.

- Maxam Tire International

Frequently Asked Questions

Analyze common user questions about the Engineering Machinery Tires market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Engineering Machinery Tires Market?

The primary driver is sustained global investment in infrastructure development and urbanization projects, particularly across the Asia Pacific region, coupled with consistent high demand for raw material extraction in the global mining sector.

How do Radial tires compare to Bias tires in the OTR segment?

Radial tires offer significantly better fuel efficiency, heat dissipation, and tread life compared to Bias tires. They are rapidly gaining market share in high-speed and long-haul applications, whereas Bias tires remain relevant in low-speed, high-stress environments due to their superior sidewall rigidity and resistance to stationary loading.

Which application segment accounts for the largest share of the Engineering Machinery Tires Market?

The Construction application segment holds the largest market share by volume due to the widespread use of machinery like loaders, graders, and excavators worldwide for residential, commercial, and road infrastructure projects.

What role does smart technology play in the future of Engineering Machinery Tires?

Smart tire technology, involving embedded sensors for real-time data monitoring (pressure, temperature, load), is crucial for enabling predictive maintenance, optimizing fleet efficiency, reducing fuel consumption, and ensuring the safety of increasingly autonomous heavy machinery operations.

What is the significance of the retreading process in this market?

Retreading is highly significant, especially in the Aftermarket segment, as it provides a cost-effective and environmentally friendly alternative to purchasing new tires, extending the lifespan of premium OTR casings and reducing dependence on volatile raw materials, aligning with circular economy principles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager