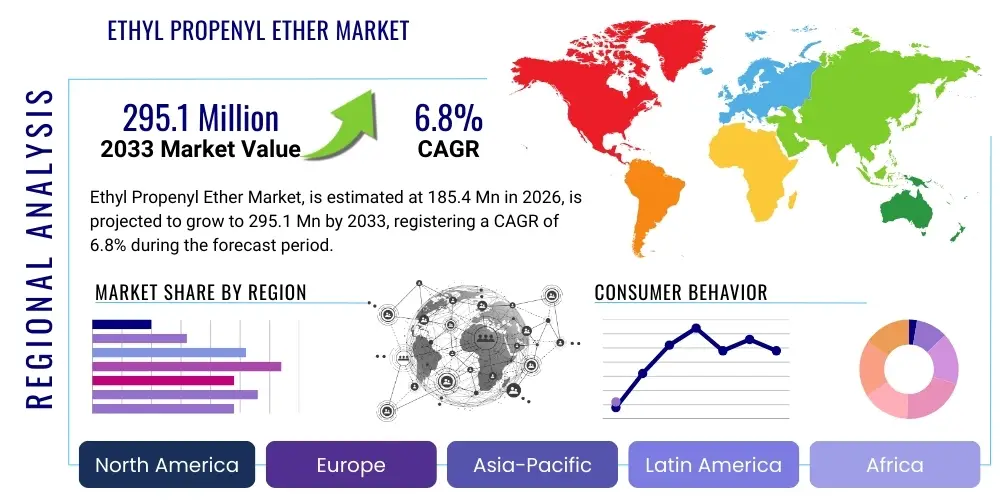

Ethyl Propenyl Ether Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441763 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Ethyl Propenyl Ether Market Size

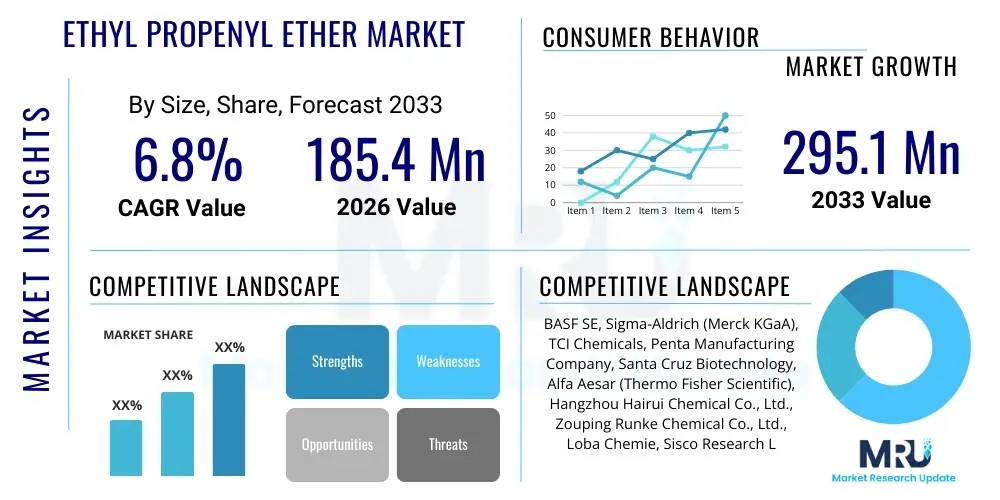

The Ethyl Propenyl Ether Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 185.4 Million in 2026 and is projected to reach USD 295.1 Million by the end of the forecast period in 2033.

Ethyl Propenyl Ether Market introduction

The Ethyl Propenyl Ether (EPE) market encompasses the global production, distribution, and consumption of this colorless, volatile liquid recognized chemically as 1-ethoxypropene. EPE serves predominantly as a highly reactive chemical intermediate, characterized by its vinyl ether functionality which makes it crucial in various sophisticated synthetic pathways. Its primary role is in the introduction of an ethoxypropyl group into organic molecules, facilitating the production of specialty chemicals that require high purity and specific structural characteristics. The versatility of EPE allows it to be utilized in polymerization processes, where it contributes to the development of unique copolymers and specialty resins valued for their specific thermal, mechanical, or chemical resistance properties. Demand for EPE is highly correlated with the performance of end-user industries such as pharmaceuticals, advanced materials, and high-performance coatings.

Product description highlights EPE’s significance as a building block chemical. It is synthesized typically through the reaction of ethanol with propyne or other suitable precursors under controlled catalytic conditions, demanding stringent quality control due to its reactivity and potential for side reactions. Major applications include its use in the synthesis of specialized fragrances and flavors, where its unique structure imparts desirable aromatic profiles. Furthermore, in the pharmaceutical sector, EPE acts as a key intermediate for synthesizing complex therapeutic agents, protecting groups, and chiral auxiliaries, enabling complex multi-step syntheses critical for drug development. The high purity required for these applications dictates the market dynamics, favoring manufacturers capable of consistent, high-grade production.

The market is primarily driven by the escalating demand for high-solids and radiation-curable coatings, where EPE derivatives enhance cross-linking density and cure speed. Furthermore, the expansion of the fine chemicals sector, particularly in emerging economies, significantly contributes to market traction. The benefits associated with EPE include its efficiency in facilitating high-yield reactions and its contribution to creating highly stable and specialized end products. Driving factors involve technological advancements in synthetic chemistry leading to more cost-effective production methods, coupled with the increasing regulatory push towards higher performance and lower Volatile Organic Compound (VOC) content in industrial coatings and adhesives. These factors collectively underscore EPE’s irreplaceable role in modern chemical manufacturing.

Ethyl Propenyl Ether Market Executive Summary

The Ethyl Propenyl Ether market is experiencing robust growth fueled by accelerated demand from the specialty polymer and advanced pharmaceutical intermediate sectors. Current business trends indicate a shift towards sustainable synthesis routes, with key players investing heavily in optimizing catalytic processes to improve yield and reduce environmental impact. Pricing stability is maintained by a delicate balance between supply chain dependencies on key raw materials (like propylene and ethanol) and the high value-add nature of the final EPE derivatives. Strategic partnerships between EPE producers and downstream pharmaceutical companies are becoming common, ensuring a secure supply of high-purity material required for complex drug synthesis. Market fragmentation is moderate, dominated by a few large chemical manufacturers who leverage economies of scale and sophisticated purification techniques, while smaller players focus on niche, high-margin applications such as isotopic labeling or custom synthesis for research purposes.

Regionally, the market dynamics are heavily skewed towards Asia Pacific (APAC), which serves both as a major production hub, primarily China and India, and a rapidly expanding consumption center driven by burgeoning infrastructure and manufacturing sectors, especially in coatings and adhesives. North America and Europe maintain strong demand for high-end applications, particularly pharmaceuticals and specialty polymers, characterized by stringent quality requirements and a focus on innovation. Regional trends also reflect varying regulatory pressures regarding chemical handling and environmental standards, influencing manufacturing site selections and operational costs globally. The Middle East and Africa (MEA) and Latin America are emerging markets, showing potential growth linked to expanding industrial bases and increasing foreign direct investment in chemical processing facilities.

Segment trends emphasize the dominance of the Pharmaceutical Grade EPE segment due to its high required purity and premium pricing, despite lower volume consumption compared to Industrial Grade EPE. By application, Polymer Synthesis remains the largest segment, driven by the increasing use of EPE in forming specialized monomers for high-performance elastomers and plastics utilized in automotive and aerospace industries. In terms of technology, continuous flow chemistry methods are gaining traction over traditional batch processing, promising enhanced safety, improved energy efficiency, and tighter control over reaction parameters, directly impacting the cost structure and quality consistency across segments. This technological migration is set to redefine competitive advantages over the forecast period, pushing innovation in material handling and purification sciences.

AI Impact Analysis on Ethyl Propenyl Ether Market

Common user questions regarding AI's influence on the Ethyl Propenyl Ether market frequently revolve around its potential to optimize synthesis pathways, predict material properties, and streamline supply chain management. Users are concerned about whether AI-driven catalysis design can accelerate the discovery of novel, more efficient methods for EPE production, especially those minimizing hazardous byproducts or maximizing atom efficiency. Key themes include the implementation of machine learning for quality control, predicting the reactivity and stability of EPE derivatives under various polymerization conditions, and utilizing predictive analytics to forecast demand fluctuations in pharmaceutical and specialty chemical end-markets. Expectations are high regarding AI’s ability to reduce time-to-market for new EPE-based products and enhance the precision of high-purity chemical manufacturing processes.

- AI-driven optimization of catalytic systems for EPE synthesis, leading to higher yields and reduced energy consumption.

- Predictive maintenance schedules for production equipment, minimizing downtime and ensuring continuous supply chain reliability.

- Machine learning algorithms applied to high-throughput screening for identifying novel polymerization co-monomers utilizing EPE.

- Enhanced quality control through real-time spectroscopic data analysis, ensuring high purity levels required for pharmaceutical grades.

- Supply chain risk assessment and dynamic inventory management based on AI forecasting of fluctuating demand from end-user industries.

- Simulation of chemical reactions to predict product stability and reactivity profiles under varying industrial conditions, accelerating R&D cycles.

DRO & Impact Forces Of Ethyl Propenyl Ether Market

The Ethyl Propenyl Ether market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO). Key drivers include the exponential growth in demand for high-performance coatings and specialty adhesives that utilize EPE derivatives for enhanced cross-linking capabilities, coupled with the relentless expansion of the global pharmaceutical industry requiring high-purity intermediates for complex organic synthesis. Restraints primarily involve the high volatility and flammability of EPE, necessitating strict safety and handling protocols, which adds significantly to operational costs. Furthermore, the availability of alternative vinyl ether derivatives, although often less reactive or more expensive, poses a competitive constraint. Opportunities lie significantly in developing bio-based or sustainable synthesis routes for EPE, catering to the increasing global focus on green chemistry, and exploring novel applications in advanced materials, such as flexible electronics and specialized elastomers where EPE’s unique reactivity can be leveraged.

Impact forces stemming from technological progress are profound. Advances in continuous flow chemistry, for instance, are revolutionizing EPE manufacturing, improving safety, consistency, and scalability, thereby lowering the unit cost and boosting global supply capabilities. Regulatory impact forces, particularly those relating to industrial emissions and chemical exposure (like REACH in Europe), necessitate continuous investment in safer manufacturing infrastructure but also create a barrier to entry for smaller, less compliant producers. Economic impact forces, notably global GDP growth and investment in infrastructure (which directly correlates with coatings and adhesives demand), provide underlying stability to market expansion. Competitive intensity remains high, primarily focused on purity specifications and pricing strategies, especially in high-volume industrial segments, pushing manufacturers to constantly innovate their purification and supply chain logistics to maintain profitability and market share in this specialized chemical segment.

Segmentation Analysis

The Ethyl Propenyl Ether market is comprehensively segmented based on Purity Grade, Application, and End-Use Industry, providing a granular view of market dynamics and consumer preferences across different tiers of the chemical spectrum. Purity Grade segmentation differentiates between Industrial Grade EPE, utilized in large-volume applications like general-purpose coatings and bulk chemical synthesis where 95-98% purity is acceptable, and High Purity/Pharmaceutical Grade EPE, which demands 99.5% or higher purity for sensitive applications such as drug synthesis and electronic chemical formulation. Application segmentation dissects the primary use cases, including Polymer Synthesis (monomers/co-monomers), Chemical Intermediate (for other complex molecules), and Specialty Chemicals (fragrances, flavors, and performance additives). End-Use Industry analysis maps consumption across key sectors like Pharmaceuticals, Coatings and Adhesives, Automotive, and Electronics, illustrating the diverse utility and dependency on EPE across modern manufacturing.

- Purity Grade:

- Industrial Grade

- High Purity/Pharmaceutical Grade

- Application:

- Polymer Synthesis (Specialty Monomers)

- Chemical Intermediates (Drug Synthesis, Chiral Auxiliaries)

- Specialty Chemicals (Fragrances, Flavors)

- End-Use Industry:

- Pharmaceuticals

- Coatings, Adhesives, and Sealants (CAS)

- Automotive and Transportation

- Electronics and Semiconductors

- Fine Chemicals and Agrochemicals

Value Chain Analysis For Ethyl Propenyl Ether Market

The value chain for Ethyl Propenyl Ether begins with upstream analysis focusing on raw material procurement, primarily ethanol and propylene derivatives, sourced from the petrochemical industry. Stability in the supply of these foundational components significantly impacts the manufacturing cost of EPE. Key activities at the manufacturing stage include sophisticated chemical synthesis utilizing specialized catalysts and energy-intensive distillation and purification processes to achieve the required high purity standards, particularly crucial for pharmaceutical applications. Due to the hazardous nature and required purity, manufacturing requires highly specialized infrastructure and technical expertise, often creating high barriers to entry.

The distribution channel analysis involves both direct and indirect sales models. Direct distribution is favored for large-volume industrial buyers and specialized pharmaceutical companies requiring customized specifications and just-in-time delivery protocols, fostering closer relationships between producer and end-user. Indirect channels involve chemical distributors and specialized brokers who manage inventory, logistics, and smaller orders for diverse downstream users, offering crucial market penetration, especially in geographically dispersed or less-developed regions. The handling of EPE mandates adherence to strict international transport regulations (e.g., IMO, ADR), increasing logistical complexity and associated costs.

Downstream analysis centers on the transformation of EPE into final value-added products. This includes high-performance coating formulators who utilize EPE derivatives to enhance resin properties, and pharmaceutical companies integrating EPE as a precursor in Active Pharmaceutical Ingredient (API) synthesis. The value addition at this stage is substantial, as EPE enables the creation of proprietary, high-performance materials or complex, life-saving drugs. The efficiency and reliability of the EPE supply directly affect the downstream users' ability to meet their production targets and maintain competitive pricing in their respective end markets.

Ethyl Propenyl Ether Market Potential Customers

Potential customers for Ethyl Propenyl Ether are predominantly specialized chemical processors, formulators, and manufacturers across high-value industrial sectors requiring specific chemical building blocks. The pharmaceutical industry constitutes a premier customer base, utilizing high-purity EPE as a chiral auxiliary or a reactive protecting group in complex, multi-step synthesis of small molecule drugs, demanding rigorous quality assurance and traceability from suppliers. Another significant customer segment includes manufacturers of high-performance industrial and architectural coatings and adhesives, where EPE derivatives are integrated into UV-curable and high-solids formulations to improve durability, adhesion, and rapid curing times, making them essential for high-speed production lines in the automotive and construction sectors.

The fine chemical and agrochemical industries also represent key buyers, purchasing EPE for the synthesis of specialized intermediates used in producing advanced crop protection agents, flavors, and fragrances, where its distinct chemical structure provides unique functionalization capabilities. Furthermore, the electronics sector, particularly those involved in producing photoresists and specialty polymers for semiconductor fabrication, utilizes ultra-high purity EPE derivatives, though in lower volumes, demanding the strictest purity specifications. These diverse customer groups emphasize different priorities: Pharmaceuticals prioritize purity and regulatory compliance; Coatings prioritize volume and consistent reactivity; and Electronics prioritize trace impurity control and specialized packaging.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.4 Million |

| Market Forecast in 2033 | USD 295.1 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Sigma-Aldrich (Merck KGaA), TCI Chemicals, Penta Manufacturing Company, Santa Cruz Biotechnology, Alfa Aesar (Thermo Fisher Scientific), Hangzhou Hairui Chemical Co., Ltd., Zouping Runke Chemical Co., Ltd., Loba Chemie, Sisco Research Laboratories Pvt. Ltd., Tokyo Chemical Industry Co., Ltd., SynQuest Laboratories, Inc., Advanced Chemical Technology Inc., J&K Scientific Ltd., Clearsynth. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ethyl Propenyl Ether Market Key Technology Landscape

The technology landscape governing the Ethyl Propenyl Ether market is defined by advancements in synthesis methodologies and rigorous purification techniques essential for meeting high-purity requirements, especially in pharmaceutical and electronics applications. Traditionally, EPE production relied on batch processing involving acid catalysis of ethanol and propene derivatives; however, modern trends emphasize flow chemistry techniques. Continuous flow reactors offer significant advantages, including enhanced control over reaction temperature and pressure, which mitigates the risk of polymerization side reactions and improves overall yield and selectivity. This technological shift is pivotal as it allows manufacturers to produce EPE more safely, efficiently, and at a consistently higher quality, directly addressing the safety restraints associated with handling highly volatile vinyl ethers.

Furthermore, separation and purification technologies are critical differentiators in the competitive landscape. High-efficiency distillation columns, coupled with advanced chromatographic methods (especially simulated moving bed chromatography), are employed to remove trace impurities, unreacted starting materials, and isomeric byproducts, ensuring the EPE meets pharmaceutical grade specifications (often >99.5%). Innovations in catalyst technology, specifically the development of solid acid catalysts or metal-organic frameworks (MOFs), are being explored to facilitate greener synthesis routes, reducing reliance on corrosive or hard-to-handle liquid acids and enabling easier catalyst recycling, thereby aligning with broader sustainability goals within the chemical industry.

Digital technologies, particularly sophisticated process control systems utilizing sensors and automation, play an increasing role in optimizing the entire production line. These systems monitor reaction parameters in real-time, allowing for immediate adjustments to maintain optimal conditions, which is crucial for maximizing throughput and minimizing waste. The implementation of Quality by Design (QbD) principles, facilitated by these digital tools, ensures that product quality attributes are consistently met, reducing batch-to-batch variation. This integrated technological approach—from advanced catalysis to automated purification and process control—is instrumental in enabling manufacturers to scale production while maintaining the strict quality standards demanded by the premium end-use sectors of the Ethyl Propenyl Ether market.

Regional Highlights

- Asia Pacific (APAC): APAC dominates both the production and consumption of EPE, driven primarily by high investments in infrastructure, robust growth in the automotive sector, and the relocation of chemical manufacturing bases, particularly to China and India. The region benefits from lower operating costs and rapidly expanding domestic markets for coatings, adhesives, and generics pharmaceuticals. China, in particular, is a major consumption hub for Industrial Grade EPE, while increasing pharmaceutical R&D activities in India bolster the demand for High Purity Grade material.

- North America: Characterized by high-value consumption and stringent quality requirements, North America is a crucial market, especially for pharmaceutical intermediates and highly specialized polymer applications (aerospace, high-tech electronics). Demand growth is stable, driven by continuous innovation in specialty chemicals and a strong emphasis on domestic drug manufacturing resilience, requiring reliable, high-specification EPE supply.

- Europe: The European market is highly regulated (REACH compliance heavily influences production), focusing on sustainable chemistry and high-performance applications. Consumption is significant in the coatings and adhesives sector, particularly for green building materials and UV-curable systems. European manufacturers focus on technical excellence and high-purity products, often serving niche markets within fine chemicals and pharmaceutical research.

- Latin America (LATAM): LATAM is an emerging market for EPE, with growth tied to industrialization and urban development, driving demand for coatings and construction chemicals. Brazil and Mexico are the primary markets, exhibiting potential expansion as local manufacturing capabilities increase and foreign investments stimulate downstream industrial growth, necessitating consistent imports of chemical intermediates like EPE.

- Middle East and Africa (MEA): Growth in MEA is primarily linked to large-scale infrastructure projects, particularly in the GCC countries, stimulating the demand for high-performance protective coatings. The region relies heavily on imports but is strategically positioned to develop localized chemical hubs in the long term, supported by access to petrochemical feedstocks, which could influence future EPE production capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ethyl Propenyl Ether Market.- BASF SE

- Sigma-Aldrich (Merck KGaA)

- TCI Chemicals

- Penta Manufacturing Company

- Santa Cruz Biotechnology

- Alfa Aesar (Thermo Fisher Scientific)

- Hangzhou Hairui Chemical Co., Ltd.

- Zouping Runke Chemical Co., Ltd.

- Loba Chemie

- Sisco Research Laboratories Pvt. Ltd.

- Tokyo Chemical Industry Co., Ltd.

- SynQuest Laboratories, Inc.

- Advanced Chemical Technology Inc.

- J&K Scientific Ltd.

- Clearsynth

- Parchem Fine & Specialty Chemicals

- Matrix Scientific

- Chem-Impex International Inc.

- Wuhan Pharmadule Science & Technology Co., Ltd.

- Acros Organics (Fisher Scientific)

Frequently Asked Questions

Analyze common user questions about the Ethyl Propenyl Ether market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth in the Ethyl Propenyl Ether market?

The market is primarily driven by escalating demand from the specialty chemicals sector, particularly for high-performance UV-curable coatings and adhesives, and the pharmaceutical industry, where high-purity EPE is essential for synthesizing complex active pharmaceutical ingredients (APIs).

Which geographical region holds the largest market share for Ethyl Propenyl Ether?

Asia Pacific (APAC), led by manufacturing expansion in China and India, currently holds the largest market share due to its significant contribution to both global production and robust consumption across industrial and pharmaceutical applications.

What is the key difference between Industrial Grade and Pharmaceutical Grade EPE?

The critical difference lies in purity; Pharmaceutical Grade EPE requires purity levels exceeding 99.5% with stringent control over trace impurities to ensure safety and efficacy in drug synthesis, whereas Industrial Grade EPE typically meets a 95-98% purity standard for bulk industrial uses.

How does the volatility of Ethyl Propenyl Ether affect its commercialization?

EPE’s high volatility and flammability necessitate advanced safety protocols, specialized storage, and highly controlled transportation logistics, which inherently increase operational and handling costs, acting as a major restraint on market accessibility.

What role does technology play in mitigating production challenges for EPE?

Advanced technologies like continuous flow chemistry and high-efficiency purification (chromatography) are crucial; they enhance safety, improve reaction control, reduce waste, and consistently achieve the ultra-high purity required for premium market segments like pharmaceuticals and electronics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager