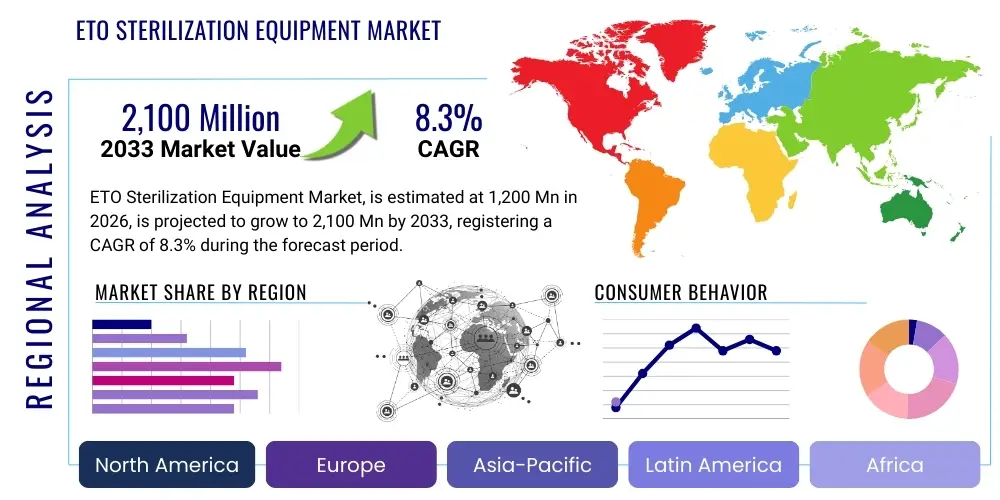

ETO Sterilization Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441222 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

ETO Sterilization Equipment Market Size

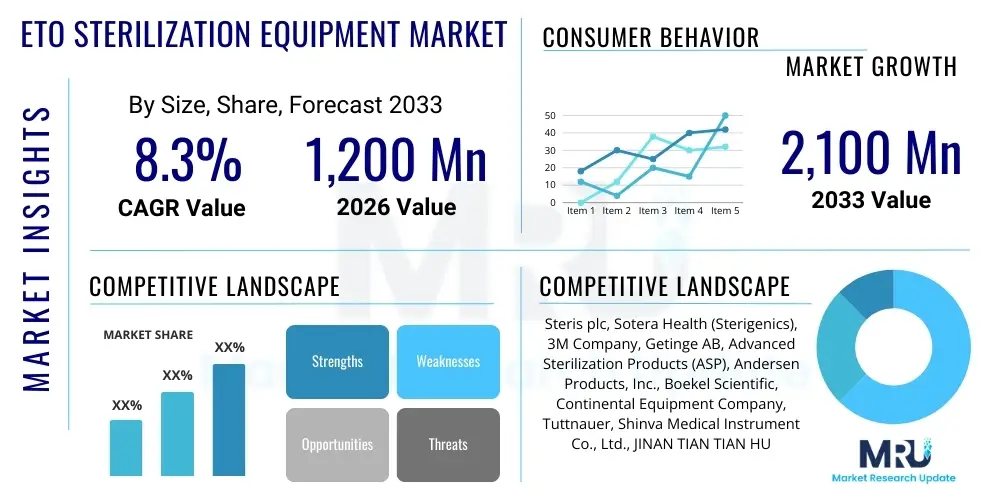

The ETO Sterilization Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.3% between 2026 and 2033. The market is estimated at USD 1,200 Million in 2026 and is projected to reach USD 2,100 Million by the end of the forecast period in 2033.

ETO Sterilization Equipment Market introduction

The Ethylene Oxide (ETO) Sterilization Equipment Market encompasses sophisticated devices and systems utilized primarily in the healthcare and medical device manufacturing industries to sterilize heat- and moisture-sensitive products. ETO gas is highly effective for sterilizing complex devices, including those incorporating plastics, electronics, and delicate components that cannot withstand high-temperature steam sterilization methods. The equipment ranges from small tabletop sterilizers used in clinics to large-scale industrial chambers integrated into automated manufacturing lines. The core function of these systems involves exposing medical devices to ETO gas under controlled conditions of vacuum, temperature, humidity, and exposure time to eliminate microorganisms, thereby ensuring patient safety and regulatory compliance.

Major applications of ETO sterilization technology include the terminal sterilization of single-use medical devices such as syringes, surgical kits, catheters, wound dressings, and implantable devices (e.g., pacemakers, orthopedic implants). The unparalleled material compatibility of ETO makes it indispensable for devices made of polymers like PVC, polyethylene, and polyurethane, which dominate the disposable medical supply sector. The continued global demand for complex, minimally invasive surgical instruments and disposable protective equipment, especially post-pandemic, has solidified ETO's role despite increasing regulatory scrutiny regarding its environmental and occupational health risks. Manufacturers are consistently focusing on advanced aeration cycles and lower-dose ETO usage to mitigate these concerns.

Key benefits driving market adoption include the high efficacy (achieving high Sterility Assurance Levels, or SALs), cost-effectiveness for large batches, and compatibility with a vast range of materials. Driving factors for market expansion are fundamentally linked to the aging global population requiring more surgical interventions, the rapid expansion of the medical device manufacturing sector in emerging economies, and stringent international standards (like ISO 13485 and ISO 11135) mandating certified sterilization processes. Furthermore, continuous technological advancements, such as the development of hybrid sterilization units combining ETO with other modalities, and improved monitoring and validation software, are enhancing the safety profile and efficiency of the equipment, fueling sustained market growth.

ETO Sterilization Equipment Market Executive Summary

The ETO Sterilization Equipment Market is characterized by robust growth, primarily propelled by the escalating complexity of disposable medical devices and stringent global health regulations. Business trends indicate a strong focus on automation and integration, with market leaders investing heavily in large-capacity industrial sterilizers featuring advanced environmental control systems to minimize ETO emissions and improve worker safety. Consolidation among sterilization service providers (Contract Sterilization Organizations or CMOs/CSOs) is a notable trend, influencing equipment procurement, as these providers require scalable, high-throughput systems to serve diverse medical device manufacturers efficiently. Furthermore, there is a distinct business pivot toward retrofitting existing equipment with advanced monitoring software for enhanced process validation and digital record-keeping, ensuring compliance with evolving FDA and EMA guidelines.

Regionally, North America and Europe maintain dominance due to established healthcare infrastructure, stringent regulatory environments demanding high SALs, and a concentration of major medical device manufacturers. However, the Asia Pacific (APAC) region is emerging as the fastest-growing market. This acceleration is attributed to massive investments in healthcare infrastructure in countries like China and India, the shifting of global manufacturing bases to Southeast Asia, and increasing accessibility to advanced medical technologies. Regulatory bodies in APAC are gradually harmonizing their sterilization standards with international norms, creating a significant demand for compliant, state-of-the-art ETO equipment. Conversely, North American markets face challenges related to increased regulatory pressure on ETO plant emissions, prompting investment in alternative, albeit less universally compatible, low-temperature sterilization methods.

In terms of segment trends, large-scale industrial sterilizers (above 10 cubic meters) are expected to command the highest market share, driven by the mass production needs of global medical device giants. By end-user, the hospital and clinical segment shows steady growth, particularly for lower-volume chamber sterilizers used for reprocessing certain specialized items. However, the medical device manufacturing segment, including CSOs, is projected to exhibit the highest CAGR, primarily because ETO remains the mandatory terminal sterilization method for approximately half of all disposable medical devices. Technological advancements within the segment focus on minimizing cycle times and enhancing residual ETO removal efficiency through improved purge and aeration phases, directly responding to efficiency demands and safety standards across all user verticals.

AI Impact Analysis on ETO Sterilization Equipment Market

User inquiries regarding AI's influence on the ETO Sterilization market predominantly revolve around three critical areas: predictive maintenance, optimization of sterilization cycles, and regulatory compliance assurance. Users seek to understand how AI algorithms can predict equipment failure based on real-time operational data (temperature fluctuations, pressure variance, gas concentration monitoring), thereby minimizing downtime which is critical for high-volume sterilization services. A second major theme focuses on leveraging machine learning to analyze historical sterilization parameters, enabling dynamic adjustments to preconditioning and aeration phases to achieve target SALs while reducing exposure time or gas consumption, enhancing both throughput and environmental safety. Finally, users anticipate AI playing a significant role in automating and analyzing complex validation reports and ensuring that digital sterilization records meet strict global audit requirements without manual oversight, streamlining the burdensome compliance process associated with ETO.

The practical application of AI in this niche market is currently focused on integrating advanced data analytics platforms with physical sterilizer hardware. AI tools can analyze hundreds of data points collected during a sterilization batch—including humidity, vacuum depth, temperature uniformity, and ETO dispersion—to identify anomalies that might compromise sterility or waste energy. This move towards intelligent process control allows manufacturers and sterilization service providers to move beyond static, predetermined cycles toward adaptive processing. Such systems not only improve the consistency of the sterilization outcome but also aid in energy conservation and prolong the lifespan of the equipment components, representing a crucial step in modernizing a traditional, chemical-intensive process.

- Enhanced Predictive Maintenance: AI models analyze sensor data to forecast potential component failures (valves, pumps) before they occur, maximizing equipment uptime.

- Sterilization Cycle Optimization: Machine learning algorithms fine-tune temperature, humidity, and ETO concentration based on load characteristics, shortening cycle times while ensuring SAL compliance.

- Automated Compliance and Validation: AI assists in the real-time review and generation of batch records, flagging deviations instantly and simplifying regulatory audits (AEO objective).

- Improved ETO Residue Monitoring: Advanced analytics correlate process parameters with post-sterilization residual ETO levels, leading to safer device release.

- Supply Chain Integration: AI-driven insights optimize scheduling for contract sterilization, matching equipment availability with manufacturing throughput demands.

DRO & Impact Forces Of ETO Sterilization Equipment Market

The ETO Sterilization Equipment Market is profoundly influenced by a complex interplay of demand drivers (D), regulatory restraints (R), technological opportunities (O), and powerful external impact forces. The primary drivers include the inherent material compatibility of ETO sterilization, essential for sterilizing temperature-sensitive, complex medical devices, coupled with the rising volume of single-use, disposable medical products driven by global infection control initiatives and expanding elective surgical procedures. However, the market faces severe restraints centered around the recognized toxicity and potential carcinogenicity of Ethylene Oxide, leading to increasingly stringent air emission standards imposed by regulatory bodies like the EPA in the US and similar environmental agencies worldwide. These environmental pressures necessitate high capital investment in abatement technologies and advanced monitoring systems, increasing the total cost of ownership for ETO equipment users.

Significant opportunities exist in two key areas: first, the vast potential for market penetration in developing economies, which are rapidly building up their medical device manufacturing capacity and require standardized, high-quality sterilization solutions. Second, the technological opportunity to integrate advanced process control and digitalization offers a pathway to mitigate regulatory risks. Developing closed-loop ETO systems, implementing advanced gas scrubbing technology (abatement systems), and utilizing smart sensors for precise cycle control allows manufacturers to maintain the efficacy of ETO while dramatically reducing occupational exposure and environmental impact, thereby addressing major restraints head-on. The development of modular, smaller-scale ETO units for decentralized use in specialty clinics also presents a niche growth avenue.

Impact forces currently shaping the competitive landscape are dominated by regulatory shifts and sustainability mandates. The global push for reducing industrial pollutants places immense pressure on existing ETO facilities, compelling operational upgrades or relocation, affecting profitability and investment cycles. Furthermore, the rising awareness and preference for alternative sterilization modalities, such as hydrogen peroxide gas plasma and vaporized peracetic acid, act as a competitive force, particularly for low-volume applications, although ETO maintains its irreplaceable position for high-volume, complex devices. Successful market players are those who can navigate the regulatory maze by offering systems that not only comply with current safety standards but are future-proofed against anticipated stricter environmental controls, making safety and compliance a core differentiator rather than just a requirement.

Segmentation Analysis

The ETO Sterilization Equipment Market is segmented based on product type, capacity, end-user, and regional geography, providing detailed insights into demand patterns across various industry verticals. Product type segmentation distinguishes between dedicated ETO sterilizers and hybrid systems, where dedicated units remain the workhorse for high-volume terminal sterilization services. Capacity segmentation is crucial, differentiating between industrial-scale sterilizers (typically over 10 cubic meters, used by contract sterilizers and large device manufacturers) and small to medium-scale sterilizers (below 10 cubic meters, favored by hospitals and smaller research laboratories). These segmentations allow stakeholders to tailor strategies based on the operational scale and specific throughput needs of target customers.

The end-user classification highlights the distinct demands of Medical Device Manufacturers (MDMs) versus Contract Sterilization Organizations (CSOs) and Hospitals. MDMs and CSOs represent the largest and fastest-growing segment, requiring automation, traceability, and extreme efficiency due to high-volume output requirements. Hospitals, while still utilizing ETO for specific reusable instruments that cannot tolerate other methods, often prioritize user safety features, ease of use, and quick turnaround for smaller batches. Analyzing segment trends reveals that the CSO segment is accelerating due to the increasing tendency of MDMs to outsource sterilization processes to specialized third-party providers, driven by capital expenditure avoidance and regulatory compliance complexity.

Geographically, market segmentation provides critical context regarding regulatory hurdles and growth potential. The market is regionally divided into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. APAC is characterized by high growth fueled by manufacturing expansion, while North America is defined by technological leadership but constrained by stringent environmental regulations. Understanding the capacity mix demanded within each region—for instance, the heavy demand for industrial capacity in established manufacturing hubs versus the need for compact, cost-effective units in developing markets—is essential for accurate forecasting and strategic market penetration.

- Product Type:

- Dedicated ETO Sterilizers

- Hybrid Sterilization Systems (e.g., ETO/Steam combination)

- Capacity:

- Small Scale (Under 5 m³)

- Medium Scale (5 m³ – 10 m³)

- Large Scale/Industrial (Above 10 m³)

- End User:

- Medical Device Manufacturers (MDMs)

- Contract Sterilization Organizations (CSOs/CMOs)

- Hospitals and Clinics

- Pharmaceutical and Biotechnology Companies

- Research and Academic Institutions

- Geography:

- North America (U.S., Canada)

- Europe (Germany, U.K., France)

- Asia Pacific (China, Japan, India)

- Latin America (Brazil, Mexico)

- Middle East & Africa (GCC Countries, South Africa)

Value Chain Analysis For ETO Sterilization Equipment Market

The ETO Sterilization Equipment value chain begins with the upstream suppliers responsible for raw materials and highly specialized components. This includes manufacturers of high-grade stainless steel (for the sterilization chamber itself), precision pumps, vacuum systems, sophisticated pressure and temperature sensors, and advanced control system hardware (PLCs and HMI interfaces). The quality and durability of these upstream components are paramount, as ETO sterilization requires extremely accurate control over a highly toxic gas within pressurized environments. Suppliers of ETO gas (typically a mixture with inert gases like CO2 or nitrogen) also constitute a crucial upstream segment, where supply stability and adherence to purity standards are non-negotiable for equipment operation and process validation.

The core of the value chain involves the equipment manufacturers who design, assemble, and validate the ETO sterilizers. This stage adds significant value through intellectual property, engineering expertise, software development for process control, and compliance certification (e.g., meeting ASME pressure vessel standards and ISO 11135). Downstream activities encompass the sterilization service provision itself. This is segmented into direct use by large Medical Device Manufacturers (MDMs) operating their own in-house facilities, and indirect use via Contract Sterilization Organizations (CSOs). The rise of CSOs as specialized service intermediaries adds considerable value by providing scalable, compliant sterilization capacity to smaller and medium-sized MDMs, who cannot justify the substantial capital outlay and regulatory burden of owning and operating their own ETO facilities.

The distribution channel is predominantly direct, especially for large, custom-built industrial sterilizers, where the equipment manufacturer directly engages with the end-user (CSOs/MDMs) for installation, validation, and long-term maintenance contracts. Indirect channels are more common for smaller laboratory or clinical units, often involving specialized medical equipment distributors who handle sales, regional support, and consumables supply (like ETO cartridges). Given the high degree of technical complexity and regulatory involvement, the aftermarket segment—including maintenance, calibration, validation services, and consumables (gas, filters)—constitutes a highly profitable and essential part of the downstream value chain, ensuring equipment performance and regulatory compliance throughout the equipment lifecycle.

ETO Sterilization Equipment Market Potential Customers

The primary and most dominant segment of potential customers for ETO sterilization equipment are large-scale Contract Sterilization Organizations (CSOs) and global Medical Device Manufacturers (MDMs). CSOs, such as Sterigenics (Sotera Health), Steris, and Cantel Medical, require high-throughput, industrial-capacity sterilizers (typically 10 cubic meters and above) capable of processing millions of units annually. Their procurement decisions are driven by total cost of ownership, scalability, automation integration, and crucially, advanced abatement technology to manage emissions and regulatory risk. MDMs, particularly those producing temperature-sensitive, high-volume disposables like surgical drapes, catheters, or customized procedure packs, rely on ETO sterilization for terminal sterility assurance, making them consistent buyers of advanced, reliable equipment that can integrate seamlessly into their production logistics.

A secondary, yet significant, customer base comprises hospitals, clinics, and centralized sterile processing departments (CSPD). While many hospitals have shifted towards hydrogen peroxide or steam sterilization for routine instruments, ETO remains essential for heat-sensitive, specialized medical devices that require reprocessing, such as flexible endoscopes, specific optics, and delicate monitoring sensors. These institutions typically purchase smaller-scale, user-friendly tabletop or cabinet sterilizers that emphasize short cycle times, ease of validation, and maximum operator safety, particularly focusing on cartridge-based ETO systems which simplify gas handling and exposure management compared to bulk tanks.

Emerging potential customers include pharmaceutical and biotechnology firms, particularly those developing combination products (drug-device mixtures) or sterile components used in biologics manufacturing, which require low-temperature, non-pyrogenic sterilization methods. Furthermore, research and academic institutions performing material science studies, medical prototyping, and infectious disease research represent a consistent, albeit smaller, market for mid-sized, flexible ETO units. As the complexity of medical devices continues to increase, the necessity for robust sterilization validation across all these user groups ensures continued, differentiated demand for ETO equipment optimized for diverse operational environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,200 Million |

| Market Forecast in 2033 | USD 2,100 Million |

| Growth Rate | 8.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Steris plc, Sotera Health (Sterigenics), 3M Company, Getinge AB, Advanced Sterilization Products (ASP), Andersen Products, Inc., Boekel Scientific, Continental Equipment Company, Tuttnauer, Shinva Medical Instrument Co., Ltd., JINAN TIAN TIAN HUPU MEDICAL INSTRUMENTS CO., LTD., Cisa Production Srl, Celitron Medical Technologies, E-BEAM Services, Inc., BGS Beta-Gamma-Service GmbH & Co. KG, Noxilizer, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

ETO Sterilization Equipment Market Key Technology Landscape

The technological landscape of the ETO sterilization equipment market is centered on enhancing safety, improving process control, and mitigating environmental risk while maintaining sterilization efficacy (SAL 10-6). A core focus involves the sophisticated integration of programmable logic controllers (PLCs) and Human-Machine Interfaces (HMIs) for precise, automated control over the complex cycle phases: preconditioning (temperature and humidity control), gas injection, exposure time, and crucial post-sterilization aeration. Modern sterilizers utilize advanced vacuum technologies to ensure rapid and uniform gas penetration and quick ETO removal, significantly reducing cycle times and minimizing residual ETO levels on the sterilized products. The integration of high-resolution sensors for real-time monitoring of gas concentration, moisture, and temperature uniformity across the load is standard, providing the necessary data for validation and regulatory audits.

A primary area of innovation focuses on abatement technology, which is technologically critical due to stringent environmental regulations. Current ETO sterilizers are increasingly paired with advanced gas scrubbing and emission control systems, such as catalytic converters or wet scrubbers, designed to break down residual ETO gas before it is released into the atmosphere. The technological differentiator lies in the efficiency (up to 99.9% destruction rate) and long-term operating cost of these abatement systems, which constitute a significant portion of the total equipment investment. Furthermore, manufacturers are developing "micro-dose" or "cartridge-based" ETO systems that use smaller, pre-measured quantities of ETO or ETO blends (often diluted with CO2 or nitrogen), enhancing safety and reducing overall emissions compared to older, bulk-tank systems.

Digital transformation, driven by Industry 4.0 principles, is also reshaping the equipment landscape. New generations of sterilizers are being built with integrated connectivity features, enabling remote diagnostics, cloud-based data logging, and sophisticated digital twin models for optimizing performance. This technological shift facilitates predictive maintenance, improves process validation through comprehensive data transparency, and supports the trend toward outsourced data management and regulatory compliance services. The move towards highly validated, software-driven equipment ensures that the sterilization process is not only effective but also fully traceable and auditable, meeting the increasingly demanding requirements of global healthcare regulatory bodies across both industrial and clinical settings.

Regional Highlights

- North America (U.S. and Canada): This region holds the largest market share, characterized by a highly developed healthcare system, a concentration of leading medical device manufacturers (MDMs), and extremely strict regulatory oversight (FDA, EPA). Market growth here is largely driven by replacement cycles for existing equipment and the mandatory adoption of costly, high-efficiency abatement systems to comply with new emission standards. The focus is on technologically advanced, fully automated industrial units that minimize environmental impact.

- Europe (Germany, U.K., France): Europe is a mature market exhibiting robust demand, heavily influenced by EU regulations (e.g., MDR) and ISO standards. Germany and France are key industrial centers. The market is defined by a strong emphasis on validation and quality assurance (compliance with ISO 11135), leading to high demand for equipment with sophisticated monitoring and control systems. Market expansion is moderate, driven by medical device innovation and pharmaceutical growth.

- Asia Pacific (APAC) (China, Japan, India, Southeast Asia): APAC is the fastest-growing region globally. Growth is fueled by massive infrastructure investment, expanding local medical device manufacturing hubs (especially in China and India), and rising demand for sterile single-use devices. While the initial adoption of ETO equipment may involve older, cost-effective models, regulatory harmonization and foreign investment are increasingly driving demand for industrial-scale, compliant, state-of-the-art sterilizers, positioning it as the primary engine for future capacity growth.

- Latin America (LATAM) (Brazil, Mexico): This region shows steady growth, primarily focused on improving local healthcare access and strengthening domestic manufacturing capabilities. Demand is mixed, involving both small-to-medium hospital-grade units and growing industrial capacity needed to serve regional medical device supply chains. Market adoption is sensitive to economic volatility and reliant on imported equipment and technologies.

- Middle East and Africa (MEA): MEA represents a developing market segment. Growth is sporadic but concentrated in high-income Gulf Cooperation Council (GCC) countries investing heavily in modern healthcare infrastructure and specialty hospitals. The need for advanced ETO equipment is driven by efforts to reduce reliance on imported sterile devices and establish local sterilization service centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the ETO Sterilization Equipment Market.- Steris plc

- Sotera Health (Sterigenics)

- Getinge AB

- Advanced Sterilization Products (ASP)

- Andersen Products, Inc.

- Tuttnauer

- Continental Equipment Company

- 3M Company

- Boekel Scientific

- JINAN TIAN TIAN HUPU MEDICAL INSTRUMENTS CO., LTD.

- Shinva Medical Instrument Co., Ltd.

- Cisa Production Srl

- Celitron Medical Technologies

- E-BEAM Services, Inc.

- BGS Beta-Gamma-Service GmbH & Co. KG

- Noxilizer, Inc.

- Sterilization Services, Inc.

- I-MED Pharma Inc.

- Belimed AG

- Meditool Medizintechnik GmbH

Frequently Asked Questions

Analyze common user questions about the ETO Sterilization Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for ETO sterilization equipment?

The primary driver is the need to sterilize complex, heat- and moisture-sensitive medical devices, such as catheters, electronic implants, and specialized surgical kits, which cannot withstand traditional high-temperature steam sterilization methods. ETO offers high material compatibility and sterilization assurance (AEO objective).

How are environmental regulations impacting the ETO sterilization equipment market?

Strict environmental regulations, particularly concerning Ethylene Oxide emissions (EPA standards), are forcing facilities to invest significantly in costly, high-efficiency abatement and gas scrubbing technology. This shifts market demand towards equipment with integrated, closed-loop ETO handling and advanced emission control systems, increasing the overall cost of ownership.

Which geographical region is showing the highest growth rate for ETO sterilization equipment?

The Asia Pacific (APAC) region, particularly China and India, is exhibiting the highest Compound Annual Growth Rate (CAGR). This growth is attributed to rapid expansion of the local medical device manufacturing sector, large-scale healthcare infrastructure development, and increasing harmonization of regional sterilization standards.

What are the main alternatives to ETO sterilization?

The main alternatives include low-temperature methods such as Hydrogen Peroxide Gas Plasma/Vapor, Nitrogen Dioxide (NO2) sterilization, and Vaporized Peracetic Acid. However, none of these alternatives currently possess the same broad material compatibility and depth of penetration as ETO for high-volume, complex medical device loads.

What role does AI or digitalization play in modern ETO sterilization?

AI is being implemented for predictive maintenance, optimizing sterilization cycle parameters (temperature, humidity, time) to enhance efficiency, and automating the process validation and digital record-keeping required for stringent regulatory compliance (AEO and GEO optimization for audit trails).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- ETO Sterilization Equipment Market Size Report By Type (Medical Consumable, Medical Equipment), By Application (Injection Molding, Printing, Assembly Syringes and Needles, Blister Packing, Ethylene Oxide Sterilization), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- ETO Sterilization Equipment Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Medical Consumable, Medical Equipment), By Application (Injection Molding, Printing, Assembly Syringes and Needles, Blister Packing, Ethylene Oxide Sterilization), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager