Examination Nitrile Gloves Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441945 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Examination Nitrile Gloves Market Size

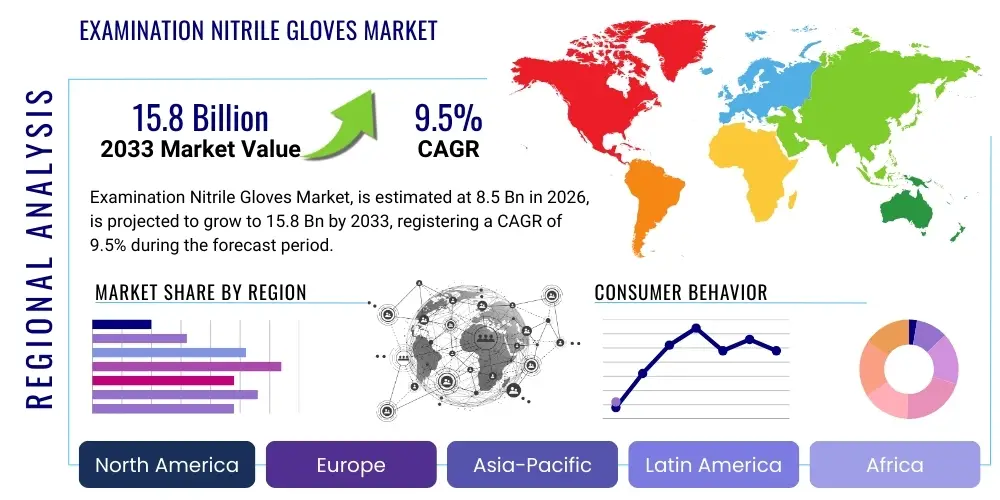

The Examination Nitrile Gloves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at $8.5 Billion in 2026 and is projected to reach $15.8 Billion by the end of the forecast period in 2033.

Examination Nitrile Gloves Market introduction

The Examination Nitrile Gloves Market encompasses the manufacturing, distribution, and sale of synthetic rubber gloves specifically designed for non-surgical medical procedures, laboratory work, and general examination purposes. These gloves are manufactured from acrylonitrile butadiene rubber (NBR), providing superior resistance to punctures, abrasions, and a wide range of chemicals compared to traditional latex alternatives. The primary driver for the market shift toward nitrile is the escalating prevalence of Type I latex hypersensitivity reactions among healthcare professionals and patients globally, necessitating the adoption of latex-free personal protective equipment (PPE). Nitrile gloves are characterized by their barrier protection capabilities, ensuring compliance with stringent infection control protocols mandated by global health organizations.

Product complexity in this sector revolves around enhancing elasticity, tactile sensitivity, and grip, often achieved through advanced polymer formulations and surface treatments such as chlorination or polymer coatings. Major applications span across hospitals, outpatient facilities, dental clinics, diagnostic laboratories, and pharmaceutical manufacturing settings where cross-contamination risk is paramount. The benefits derived from nitrile gloves include dependable barrier integrity, a prolonged shelf life compared to latex, and exceptional comfort when designed with features like textured fingertips or low-modulus formulations. These attributes position nitrile gloves as the preferred standard in clinical environments where consistent performance and patient safety are non-negotiable requirements, thereby continuously fueling market expansion.

Driving factors sustaining the market momentum include intensified awareness regarding healthcare-associated infections (HAIs), substantial increases in global healthcare expenditure, and evolving regulatory mandates that standardize glove quality (e.g., ASTM D6319 and ISO 13485 compliance). Furthermore, lessons learned from recent global pandemics have cemented the necessity for robust national PPE stockpiling and decentralized manufacturing, leading to significant capital investments in production capacity expansion, particularly across established manufacturing hubs in Southeast Asia. This expansion is essential to meet the burgeoning, structurally higher demand from both established and emerging economies prioritizing enhanced public health infrastructure and worker safety standards across clinical and non-clinical settings.

Examination Nitrile Gloves Market Executive Summary

The Examination Nitrile Gloves Market is currently characterized by intense consolidation among established manufacturers seeking to leverage economies of scale and control raw material procurement, particularly NBR latex feedstock. Business trends indicate a strong focus on automation and vertical integration to mitigate supply chain volatility experienced in recent years. Manufacturers are heavily investing in accelerator-free and low-dermatitis potential glove technology to address occupational health concerns among long-term users, marking a pivotal shift toward specialized, high-margin products. Furthermore, sustainability initiatives, including the development of biodegradable nitrile alternatives and the reduction of packaging waste, are gaining traction, driven by corporate social responsibility commitments and consumer preference, though full-scale adoption remains constrained by cost and performance requirements.

Regionally, the market exhibits a dual dynamic: Asia Pacific (APAC) firmly maintains its dominance in manufacturing volume, benefiting from lower operating costs and governmental incentives, thereby serving as the global production engine. Conversely, North America and Europe remain the principal consumption centers, characterized by high per-capita healthcare spending, stringent regulatory frameworks (such as the EU Medical Device Regulation), and high awareness levels regarding infection prevention. Emerging markets in Latin America and the Middle East & Africa (MEA) are demonstrating rapid growth, fueled by infrastructural development and increasing penetration of standardized healthcare practices. These regions represent critical future growth vectors as they transition from relying on multi-use or non-medical grade PPE to disposable, high-quality examination gloves.

Segment trends confirm the overwhelming market preference for powder-free nitrile gloves, largely driven by regulatory action aimed at reducing lung inflammation risks associated with glove powder exposure. In terms of usage, the Ambulatory Surgical Centers (ASCs) and physician offices segment is experiencing above-average growth, reflecting the global trend toward decentralization of minor surgical procedures. Innovations within the segment include thinner-gauge gloves that maintain barrier protection while offering enhanced tactile sensitivity for precision tasks, a feature highly valued in specialized fields such as dentistry and laboratory analysis. The strategic prioritization of high-quality, specialized segments over generic, low-cost alternatives is defining the competitive landscape.

AI Impact Analysis on Examination Nitrile Gloves Market

User inquiries regarding AI's influence in the Examination Nitrile Gloves Market primarily center on three themes: enhancing manufacturing quality control, optimizing complex global supply chains, and improving demand forecasting capabilities following periods of extreme volatility. Consumers and industry stakeholders are keen to understand how AI can ensure consistent compliance with rigorous standards (e.g., AQL levels) without human intervention, thereby reducing batch rejection rates. A major concern revolves around the application of machine vision systems, powered by deep learning algorithms, to detect microscopic defects in high-speed dipping lines, which are often missed by traditional inspection methods. Furthermore, there is significant interest in using predictive analytics to manage NBR feedstock procurement, a notoriously volatile commodity, and to anticipate regional shortages or surpluses, thereby stabilizing pricing structures and ensuring continuous availability of essential PPE.

The integration of Artificial Intelligence fundamentally transforms the operational efficiency of large-scale glove manufacturing facilities. By analyzing real-time data collected from sensors positioned along the dipping, leaching, vulcanization, and stripping lines, AI systems can dynamically adjust parameters such as temperature, coagulation fluid concentration, and drying times. This level of precision optimization reduces material waste, minimizes energy consumption, and significantly improves the consistency of the final product’s physical properties, including tensile strength and modulus. For manufacturers operating dozens of production lines across multiple geographically dispersed sites, AI provides the necessary tooling for centralized performance benchmarking and remote diagnostics, ensuring global operational parity and rapid problem identification, which is vital for maintaining high throughput.

Beyond the factory floor, AI's application in logistics management promises substantial economic benefits. Machine learning models process vast datasets encompassing historical sales, global epidemiological trends, public health announcements, shipping capacity, and port congestion reports to generate highly accurate forecasts for regional demand spikes and troughs. This predictive capability allows distributors and healthcare providers to implement just-in-time inventory management strategies, reducing capital tied up in excessive stock while simultaneously preventing critical supply gaps. Ultimately, AI fosters a more resilient, responsive, and data-driven supply ecosystem for examination nitrile gloves, mitigating the severe disruptive effects caused by unforeseen global events and enhancing overall market stability for healthcare providers worldwide.

- AI-driven machine vision systems detect microscopic defects during manufacturing, ensuring optimal Acceptable Quality Limits (AQL).

- Predictive analytics models forecast volatile NBR raw material pricing and demand fluctuations, optimizing procurement strategy.

- AI enhances manufacturing efficiency by dynamically tuning dipping parameters (temperature, chemical concentration) in real-time.

- Generative modeling supports the development of novel glove formulations, optimizing elasticity and barrier integrity prior to physical testing.

- Automated warehousing and sorting, guided by AI, accelerates distribution and inventory management across global supply chains.

- Chatbots and natural language processing (NLP) assist large-scale buyers in rapidly identifying the appropriate glove type based on procedural requirements and regulatory standards.

DRO & Impact Forces Of Examination Nitrile Gloves Market

The Examination Nitrile Gloves Market is fundamentally driven by stringent regulatory frameworks mandating infection control, coupled with the irreversible shift away from latex due to allergy concerns. Key restraints center on the intense volatility and structural dependence on primary raw materials (Acrylonitrile and Butadiene), leading to significant price fluctuations that challenge cost stability, especially for smaller market players. Opportunities lie primarily in product innovation targeting sustainability, particularly the commercialization of viable biodegradable nitrile alternatives and specialized gloves engineered for specific high-risk environments, such as those resistant to chemotherapy drugs or fentanyl. These forces collectively create a dynamic competitive environment where technological differentiation, regulatory compliance, and supply chain resilience are the critical determinants of market success and long-term viability.

Drivers: Intensifying public and institutional focus on preventing Healthcare-Associated Infections (HAIs) continues to enforce the mandatory use of high-quality disposable gloves across all clinical procedures. Furthermore, the global expansion of healthcare infrastructure, particularly the proliferation of diagnostic centers, ambulatory services, and long-term care facilities in developing nations, significantly increases the baseline consumption volume. The aging global population requiring more frequent medical interventions, alongside rising chronic disease prevalence, ensures a sustained structural demand trajectory. Government mandates supporting PPE stockpiling in key regions also act as a crucial stabilizing driver, particularly post-pandemic, ensuring market resilience even during periods of cyclical demand downturns. The continuous educational outreach regarding the risks of latex allergies further solidifies nitrile’s position as the primary clinical standard.

Restraints: The most significant restraint is the complex and concentrated nature of the NBR supply chain, where geopolitical factors and petrochemical price volatility directly impact manufacturing costs and selling prices, often leading to rapid cost inflation passed onto end-users. Secondly, the market faces saturation in certain mature economies, leading to intense price competition among established players, which pressures profit margins and limits investment in R&D. Furthermore, growing environmental concerns surrounding the disposal of billions of non-biodegradable nitrile gloves are prompting regulatory scrutiny and consumer backlash, representing a long-term challenge that requires expensive material science solutions. Achieving stringent regulatory approvals (e.g., FDA 510(k), CE mark) for new or modified glove designs can be a time-consuming and capital-intensive process, slowing down innovation adoption.

Opportunities: Significant market opportunities exist in the development and scaling of truly sustainable glove solutions, including bio-based materials or accelerated degradation technologies that meet demanding clinical performance standards. Geographic expansion into high-growth emerging economies, where per-capita glove consumption is still low but healthcare access is rapidly improving, offers untapped potential. Specialized product lines, such as anti-microbial gloves, gloves with enhanced tactile properties for microsurgery, or accelerator-free formulations that minimize Type IV allergies, command premium pricing and allow manufacturers to capture high-value niche segments. Moreover, leveraging advanced automation and AI in manufacturing promises cost reduction and quality improvement, offering a competitive advantage to firms willing to invest heavily in smart factory implementation.

Segmentation Analysis

The Examination Nitrile Gloves Market is systematically segmented based on various technical specifications and end-user applications to accurately reflect the diversity of demand and usage patterns across the healthcare spectrum. Primary segmentation relies on the product's finish—powdered or powder-free—with the latter dominating due to health regulations. Further differentiation occurs based on usage modality (medical grade vs. industrial grade, although the focus here is strictly on medical/examination grade), and the specific end-user environment, which dictates required specifications such as thickness, tensile strength, and chemical resistance profiles. Understanding these segmentation nuances is crucial for manufacturers to tailor their production output and marketing strategies toward specific high-value clinical segments requiring specialized protection and sensitivity.

- By Product Type:

- Powdered Nitrile Gloves

- Powder-Free Nitrile Gloves (Dominant Segment)

- By Usage:

- Disposable

- Reusable (Minimal in examination market, primarily specific industrial uses)

- By End-User:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Diagnostic and Imaging Laboratories

- Dental Clinics

- Pharmaceutical and Biotechnology Industries

- Research and Academic Institutions

- By Geography:

- North America (U.S., Canada)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Malaysia, Thailand, Rest of APAC)

- Latin America (Brazil, Mexico, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Examination Nitrile Gloves Market

The value chain for examination nitrile gloves is long, complex, and highly sensitive to external shocks, beginning upstream with the synthesis of key petrochemical raw materials, primarily acrylonitrile and butadiene, which are copolymerized to create NBR latex. The stability of this upstream segment, which involves specialized chemical manufacturers, dictates the overall cost structure and potential supply consistency for the entire industry. Midstream operations involve the core manufacturing processes: compounding the NBR latex, dipping ceramic or glass formers, curing (vulcanization), leaching (to remove residual chemicals), chlorination or polymer coating (for ease of donning), and quality testing (e.g., pinhole detection, tensile testing). Automation and technology integration in the midstream are crucial for maximizing yield and meeting rigorous Acceptable Quality Levels (AQLs).

Downstream activities focus on packaging, sterilization (if required), distribution, and final sales. Distribution channels are highly fragmented, involving large global medical distributors (e.g., McKesson, Owens & Minor), specialized regional medical supply houses, and, increasingly, direct sales to large hospital groups or government purchasing bodies. Direct channels often allow manufacturers better control over branding and pricing, while indirect channels leverage the established logistics networks of global intermediaries to reach thousands of disparate clinical locations efficiently. The intense scrutiny of quality and adherence to regulatory standards (FDA, European Commission) throughout the value chain means that traceability and certification play a paramount role, adding complexity and cost but ensuring product reliability for critical medical applications.

The integration between the upstream raw material suppliers and the high-volume glove manufacturers is becoming increasingly tight, sometimes involving long-term contracts or even captive NBR production to mitigate price risk. Furthermore, the selection of distribution partners is critical; indirect distribution through established global medical supply companies provides broad market penetration but often dilutes profit margins. Conversely, manufacturers that manage direct distribution to major integrated delivery networks (IDNs) can capture greater value. The efficiency of this downstream segment is heavily influenced by logistics technology and warehousing capabilities, especially given the bulky nature of the product, requiring optimization of shipping volumes and storage to manage costs effectively.

Examination Nitrile Gloves Market Potential Customers

The primary consumers and buyers in the Examination Nitrile Gloves Market are diverse institutions within the global healthcare ecosystem, ranging from acute care facilities to specialized outpatient centers and high-security laboratories. Hospitals and integrated delivery networks (IDNs) represent the largest single procurement segment, purchasing high volumes of gloves annually for emergency rooms, general wards, examination rooms, and non-surgical procedures. The purchasing decisions in this segment are often centralized and highly sensitive to factors such as bulk pricing, contractual supply guarantees, and compliance with institutional standardization policies related to latex allergy prevention and infection control protocols.

Following hospitals, Ambulatory Surgical Centers (ASCs) and physician offices constitute a rapidly growing customer base. As more minor procedures shift from inpatient to outpatient settings globally, the demand for single-use, high-quality examination gloves in these decentralized settings escalates dramatically. These smaller entities typically rely on regional distributors for procurement, valuing convenience, reliable smaller-batch delivery, and often seeking specialized, comfort-oriented gloves that cater to practitioner preference and enhanced tactile needs in procedures like minor excisions or injections.

Other vital end-user groups include diagnostic laboratories, blood banks, pharmaceutical and biotechnology companies, and the thriving dental industry. Diagnostic labs require gloves with high chemical resistance and often specific certifications for use with hazardous biological agents or chemical reagents. Pharmaceutical manufacturing requires stringent quality assurance, often demanding gloves produced in controlled environments (cleanroom-compatible), ensuring zero risk of contamination to sensitive drug products. These diverse customer requirements necessitate a highly varied product portfolio from manufacturers, adapting glove thickness, texture, and compounding ingredients to the unique occupational hazards and regulatory environment of each purchasing sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $8.5 Billion |

| Market Forecast in 2033 | $15.8 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Top Glove Corporation Bhd, Hartalega Holdings Berhad, Kossan Rubber Industries Bhd, Supermax Corporation Berhad, Cardinal Health Inc., Medline Industries LP, Ansell Ltd., Semperit AG Holding, Kimberly-Clark Corporation, Dynarex Corporation, Unigloves GmbH, Shield Scientific B.V., Rubberex Corporation Bhd, Adventa Berhad, YTY Industry Sdn Bhd, Riverstone Holdings Limited, Mercator Medical S.A., Safeskin Corporation, WRP Asia Pacific Sdn Bhd, Midas Safety. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Examination Nitrile Gloves Market Key Technology Landscape

The technological landscape of the Examination Nitrile Gloves Market is rapidly evolving, driven by the need to increase efficiency, reduce material usage, and improve user safety profiles. A major technological focus is the advancement in dipping line automation and robotics. Modern dipping lines utilize sophisticated, high-speed robotic arms for formers handling, minimizing human error and enhancing throughput while ensuring ultra-thin, consistent film formation, crucial for maintaining tactile sensitivity without compromising barrier protection. Furthermore, process control technology, often integrated with Internet of Things (IoT) sensors, continuously monitors parameters like coagulation pH and drying oven temperatures, ensuring optimal vulcanization and curing processes that maximize the glove’s physical properties.

Material science innovation centers around the development of accelerator-free nitrile formulations. Traditional nitrile production relies on chemical accelerators (such as zinc dibutyldithiocarbamate, ZDBC) which can leave residues that cause Type IV (delayed-type) allergic reactions in prolonged use. New technology focuses on creating proprietary NBR latex compounds that cure effectively without these accelerators, offering a critical safety advantage and opening access to highly sensitive healthcare environments. Concurrently, efforts are concentrated on achieving 'low modulus' nitrile, allowing the glove to stretch more easily and conform better to the hand, reducing hand fatigue during extended wear—a key purchasing criterion for healthcare workers.

Another significant technological advancement involves surface treatment and coating technologies. Post-processing steps, such as advanced chlorination or the application of proprietary inner polymer coatings (e.g., hydrogel or silicone blends), are engineered to facilitate rapid donning and doffing, particularly when hands are wet or damp. Furthermore, the incorporation of functional additives, such as antimicrobial agents directly into the glove matrix or specific colorants for easy identification of specialized protective capabilities (e.g., purple for chemo-rated, black for fentanyl protection), represent targeted technological applications addressing specific clinical risks. Continuous innovation in testing protocols, including sophisticated computerized leak testing to maintain AQL standards, ensures that gloves meet ever-increasing regulatory demands for protection and reliability.

Regional Highlights

- North America: This region is characterized by high adoption rates, stringent safety regulations (FDA oversight), and elevated healthcare expenditure. The U.S. represents the largest consumer base globally, emphasizing quality, brand loyalty, and specialized performance (e.g., Fentanyl-rated gloves). Demand is stable and driven by institutional purchasing contracts and robust pandemic preparedness strategies implemented post-2020. Market growth here is largely volumetric rather than driven by price sensitivity, focusing on high-quality, accelerator-free products.

- Europe: Growth is moderately strong, primarily governed by the European Union’s Medical Device Regulation (MDR), which imposes rigorous requirements for clinical data, traceability, and certification, driving lower-tier manufacturers out of the market and favoring large, compliant suppliers. Germany, the U.K., and France are key markets, prioritizing environmental compliance and worker safety standards. There is increasing commercial pressure to adopt sustainable or biodegradable alternatives to address waste concerns.

- Asia Pacific (APAC): APAC is the unquestioned global hub for nitrile glove manufacturing, with Malaysia, Thailand, and China dominating production capacity. The region benefits from access to raw materials and competitive labor costs. While serving as the world's factory, domestic consumption in countries like China and India is rapidly accelerating due to improving healthcare infrastructure, rising disposable incomes, and increasing awareness of hygiene protocols, making it the fastest-growing consumption market globally.

- Latin America (LATAM): The LATAM market, led by Brazil and Mexico, exhibits strong growth potential fueled by government initiatives to expand primary healthcare coverage and modernize medical facilities. While price sensitivity is generally higher than in North America, regulatory tightening and increased foreign investment are slowly pushing the market toward higher-quality, standardized nitrile products, away from cheaper, less reliable alternatives.

- Middle East and Africa (MEA): Growth is tied heavily to infrastructure projects, particularly in the GCC countries (Saudi Arabia, UAE) which are investing billions in world-class medical cities and specialist clinics. Demand is characterized by a preference for premium, Western-certified brands. Africa's market remains fragmented but offers significant long-term opportunity as local public health bodies strengthen disease control measures and basic healthcare access improves.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Examination Nitrile Gloves Market.- Top Glove Corporation Bhd

- Hartalega Holdings Berhad

- Kossan Rubber Industries Bhd

- Supermax Corporation Berhad

- Cardinal Health Inc.

- Medline Industries LP

- Ansell Ltd.

- Semperit AG Holding

- Kimberly-Clark Corporation

- Dynarex Corporation

- Unigloves GmbH

- Shield Scientific B.V.

- Rubberex Corporation Bhd

- Adventa Berhad

- YTY Industry Sdn Bhd

- Riverstone Holdings Limited

- Mercator Medical S.A.

- Safeskin Corporation

- WRP Asia Pacific Sdn Bhd

- Midas Safety

Frequently Asked Questions

Analyze common user questions about the Examination Nitrile Gloves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the long-term growth of the Examination Nitrile Gloves Market?

Long-term growth is driven primarily by mandatory infection prevention protocols, the sustained global transition from latex due to allergy concerns, expansion of healthcare services worldwide (especially in emerging economies), and continuous technological advancements improving glove comfort and safety profiles, such as accelerator-free formulations.

How significant is the impact of NBR raw material price volatility on the final glove cost?

NBR (Acrylonitrile Butadiene Rubber) is the single most significant cost component, meaning price volatility in petrochemical feedstock directly translates to fluctuations in final glove prices. Manufacturers often implement hedging strategies or seek long-term supply contracts to mitigate these impacts, but end-user pricing remains highly correlated with NBR costs.

Are biodegradable nitrile gloves commercially viable yet, and do they meet required medical standards?

While significant R&D is invested in developing biodegradable nitrile alternatives, these products are currently a niche market segment. Viability challenges include matching the barrier integrity and physical strength of conventional nitrile at a comparable manufacturing cost. Current biodegradable solutions often require specific landfill conditions to initiate breakdown, and widespread clinical adoption is pending robust, cost-effective scaling and universal regulatory approval.

What is the primary difference between powdered and powder-free nitrile gloves in a clinical setting?

Powdered gloves use cornstarch to ease donning but pose risks of respiratory irritation and act as carriers for latex allergens (if present). Powder-free gloves, treated via chlorination or polymer coating, eliminate these risks, making them the standard choice in virtually all medical and surgical environments to enhance patient and worker safety, mandated by many global health regulatory bodies.

Which geographical region dominates the manufacturing of examination nitrile gloves?

The Asia Pacific (APAC) region, particularly Malaysia, Thailand, and China, overwhelmingly dominates global manufacturing volume. This concentration is due to established infrastructure, competitive operating costs, and strong vertical integration among key regional players, positioning APAC as the essential global supply center.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager