Extruded Flat Plastic Mesh Mattress Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443021 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Extruded Flat Plastic Mesh Mattress Market Size

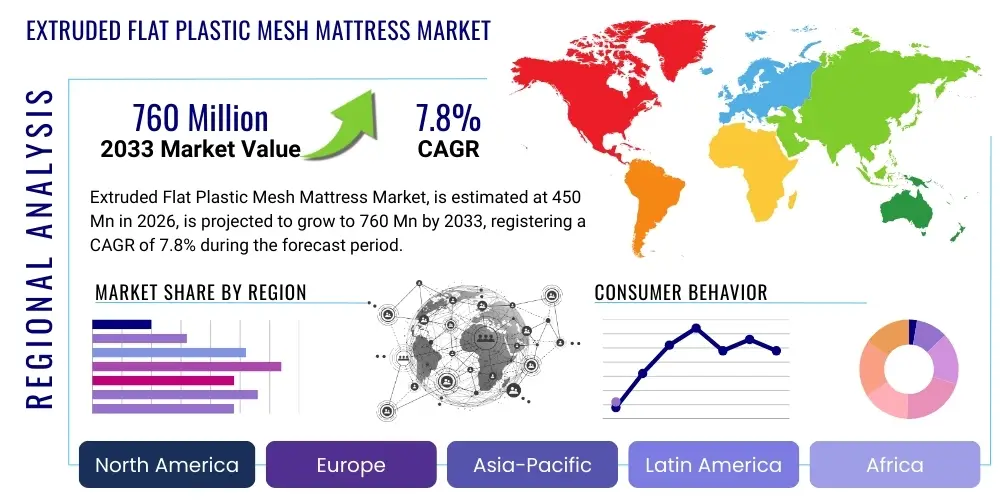

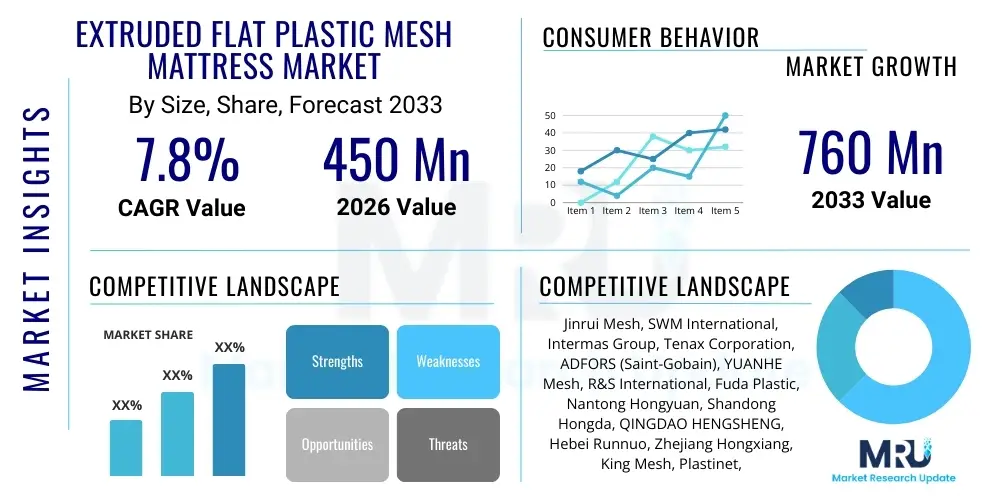

The Extruded Flat Plastic Mesh Mattress Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 760 Million by the end of the forecast period in 2033.

Extruded Flat Plastic Mesh Mattress Market introduction

The Extruded Flat Plastic Mesh Mattress Market encompasses the manufacturing, distribution, and utilization of bedding layers constructed primarily from extruded plastic netting, specifically designed to enhance airflow, moisture management, and structural support within mattress systems. These mesh structures, often made from high-density polyethylene (HDPE), polypropylene (PP), or other durable polymers, serve as core or comfort layers, providing breathability, preventing moisture buildup, and contributing to overall mattress longevity and hygiene. The fundamental product offers an alternative to traditional foam or spring layers, appealing particularly to consumers and manufacturers focused on anti-microbial properties and temperature regulation in bedding. This specialized application addresses critical consumer needs related to sleep quality and health, propelling its integration into modern mattress designs, ranging from standard residential use to specialized medical and institutional applications. The market's evolution is heavily dependent on advancements in polymer extrusion technologies and the increasing consumer preference for environmentally resistant and easily sanitizable sleep surfaces, positioning the extruded mesh as a key material innovation in the bedding sector.

Major applications of extruded flat plastic mesh mattresses span across various sectors, including residential bedding, healthcare facilities (hospitals and clinics), hospitality (hotels and resorts), and institutional settings (dormitories and military bases). In the residential segment, the mesh is often used as a supportive base layer or integrated spacer fabric to maximize ventilation and reduce heat retention, critical factors for comfortable sleep in warm climates or for individuals prone to overheating. Within the healthcare environment, its non-absorbent, easy-to-clean, and hygienic characteristics make it ideal for preventing the proliferation of bacteria and allergens, significantly reducing maintenance complexity and enhancing patient safety. Furthermore, its inherent durability ensures that the product maintains structural integrity over long periods of heavy use, minimizing replacement costs and offering a sustainable solution compared to materials susceptible to degradation or compression over time. The versatility of extrusion techniques allows manufacturers to fine-tune mesh aperture size, thickness, and material composition, tailoring the final product’s firmness and flexibility to specific market demands and regulatory requirements across different geographical regions.

The primary driving factors fueling market growth are intrinsically linked to hygiene consciousness and climate challenges globally. Increased awareness regarding the long-term health benefits associated with sleeping on breathable, mold-resistant surfaces is a major catalyst, particularly in humid or tropical regions where traditional materials struggle with moisture management. Additionally, the industrial shift towards modular and easily recyclable mattress components favors plastic mesh, which simplifies the end-of-life process compared to complex hybrid foams. Regulatory support for fire-retardant and low-VOC (Volatile Organic Compound) materials also indirectly boosts demand, as specialized polymers used in extrusion often meet stringent safety standards more readily. Finally, technological advancements leading to stronger yet lighter mesh materials enhance portability and reduce logistical costs for manufacturers, further improving the economic viability and market penetration of extruded flat plastic mesh mattresses across developing and developed economies.

Extruded Flat Plastic Mesh Mattress Market Executive Summary

The Extruded Flat Plastic Mesh Mattress Market is currently characterized by robust expansion, driven primarily by evolving consumer preferences favoring enhanced hygiene, superior ventilation, and long-term durability in bedding solutions. Key business trends indicate a strong move toward customization and specialization, with manufacturers developing proprietary extrusion patterns and polymer blends to cater to specific applications, such as orthopedic support or extreme temperature regulation. Strategic alliances between polymer suppliers, extrusion technology providers, and major mattress brands are accelerating product innovation and standardizing quality benchmarks across the industry. Furthermore, the market is witnessing significant investment in automated production facilities to achieve economies of scale and meet the burgeoning demand from high-population density regions, particularly across Asia Pacific. This strategic focus on operational efficiency and vertical integration is reshaping competitive dynamics, pushing established players to innovate rapidly while presenting substantial entry barriers for newcomers primarily based on intellectual property surrounding specific mesh geometries and material resilience.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market segment, attributable to high population density, rising disposable incomes, and cultural shifts toward modern bedding solutions that prioritize hygiene in humid climates. China and India, specifically, are experiencing a monumental uptake due to massive construction projects in hospitality and residential sectors, coupled with growing consumer awareness regarding anti-microbial properties. North America and Europe, while mature, demonstrate sustained growth fueled by the premium segment, focusing on high-end, eco-friendly, and technologically integrated smart mattresses where extruded mesh plays a role in internal climate control systems. Regulatory frameworks in these Western markets, emphasizing material safety and sustainable sourcing, are influencing product formulation, steering research and development toward bio-based or recycled polymer usage. Conversely, Latin America and the Middle East & Africa (MEA) are emerging markets, currently focused on cost-effective manufacturing and basic durability, but poised for accelerated growth as urbanization and modern infrastructure development continues, providing new large-scale opportunities for institutional procurement.

Segmentation trends confirm that the product type focusing on high-density polyethylene (HDPE) mesh maintains the largest market share due to its excellent balance of cost-efficiency, rigidity, and resistance to environmental degradation. However, polypropylene (PP) mesh is gaining traction in applications requiring greater flexibility or specific chemical resistance. Application-wise, the residential segment holds the highest volume, driven by mass-market acceptance, but the institutional/healthcare sector offers the highest profit margins due to stringent quality requirements and bulk purchasing contracts. The market’s competitive landscape is defined by vertical integration strategies, where large raw material suppliers are acquiring specialized extrusion firms to gain control over the entire supply chain, ensuring consistent material quality and maximizing profitability. The long-term outlook suggests a sustained shift toward materials engineered for specific climate zones and ergonomic requirements, positioning innovation in mesh structure design as a crucial competitive differentiator for the foreseeable future.

AI Impact Analysis on Extruded Flat Plastic Mesh Mattress Market

User queries regarding the impact of Artificial Intelligence (AI) on the Extruded Flat Plastic Mesh Mattress Market predominantly center around three key themes: optimization of manufacturing processes, development of 'smart' mesh materials, and supply chain efficiency. Users frequently ask how AI can refine the extrusion process to reduce waste and improve the consistency of the mesh pattern (AEO theme: Manufacturing Precision and Sustainability). They are also keenly interested in the potential for integrating sensor technologies directly into the mesh structure, leveraging AI for real-time monitoring of sleep quality, temperature, and moisture levels, transforming the traditional mesh layer into a functional component of a smart mattress system (AEO theme: Smart Bedding Integration). Furthermore, there is significant inquiry into how machine learning algorithms can be applied to predict material sourcing costs and optimize global logistics, especially given the volatility in polymer prices and complex international shipping networks required for bulk mesh distribution. The collective expectation is that AI will not only drive down operational costs but fundamentally enhance the product's functionality and personalized experience, thereby elevating the value proposition of the extruded mesh beyond simple structural support and breathability, moving it toward an integrated sleep data platform.

- AI optimizes polymer mixing ratios and extrusion temperature profiles, minimizing defects and improving mesh tensile strength consistency.

- Machine learning algorithms predict demand fluctuations across regional markets, enabling efficient inventory management and reducing overproduction waste.

- Integrated AI-powered computer vision systems monitor the mesh structure during production, ensuring defect detection far faster than traditional quality control methods.

- AI aids in the development of customized mesh structures by analyzing ergonomic data and recommending specific aperture sizes for personalized firmness profiles.

- Predictive maintenance schedules for extrusion machinery are generated by AI, minimizing costly downtime and maximizing operational longevity.

- Smart mesh integration allows AI to process sensor data on temperature, humidity, and pressure points, providing personalized sleep insights and automatically adjusting micro-climate controls.

DRO & Impact Forces Of Extruded Flat Plastic Mesh Mattress Market

The Extruded Flat Plastic Mesh Mattress Market is governed by a dynamic interplay of factors encapsulated by Drivers, Restraints, and Opportunities (DRO). The primary drivers include the accelerating global demand for durable, anti-allergic, and highly breathable bedding solutions, especially in institutional and hospitality sectors where longevity and ease of cleaning are paramount. This is strongly supported by technological advancements in polymer science, which allow for the production of increasingly fine, yet robust, mesh structures that offer superior ergonomic support without compromising ventilation. These driving forces are fundamentally tied to improving public health standards and the growing investment in modern infrastructure globally. However, the market faces significant restraints, chiefly the relatively higher initial cost compared to conventional low-grade foam solutions, posing a barrier to entry in highly price-sensitive developing markets. Additionally, concerns regarding the environmental impact of plastic use and disposal, despite the long lifecycle of the product, necessitate continuous innovation toward biodegradable or fully recyclable polymers. Overcoming these restraints requires strategic communication regarding the long-term cost-efficiency and hygienic benefits offered by the product, coupled with proactive investment in green manufacturing technologies.

Opportunities for growth are substantial and primarily revolve around geographical expansion into underserved markets, particularly in rapidly urbanizing regions across Africa and Southeast Asia where humidity levels necessitate breathable materials. Product diversification presents another critical opportunity, focusing on developing specialized mesh layers for niche markets such as orthopedic support mattresses, pediatric bedding, and high-performance athletic recovery mattresses. Furthermore, strategic collaboration with interior designers and architects in the commercial real estate sector can establish extruded mesh as a standard component in sustainable and luxury living environments. These opportunities leverage the core strengths of the mesh structure—ventilation and hygiene—and expand its application beyond traditional bedding, maximizing its potential addressable market. Successful market penetration hinges on establishing standardized testing protocols that quantify the superior breathability and durability of the extruded mesh compared to competitive materials, thereby building irrefutable consumer trust and justifying the premium pricing structure.

The impact forces influencing the market are multifaceted, encompassing material volatility, regulatory shifts, and technological disruptions. Material supply chains, particularly the fluctuating costs of raw polymers like HDPE and PP derived from petrochemicals, exert a substantial impact force on manufacturing costs and pricing stability. Regulatory impact forces include stringent new standards related to fire safety (flammability tests) and chemical content (REACH regulations in Europe), which can either restrict non-compliant products or create barriers favoring those manufacturers who invest in certified, high-grade polymers. Lastly, the impact of substitute materials, such as advanced 3D-knitted fabrics or specialized gel-infused foams offering competing cooling benefits, forces continuous technological evolution in mesh design to maintain competitive advantage. Manufacturers must strategically manage these external forces by securing long-term polymer contracts, ensuring proactive regulatory compliance, and consistently introducing patented mesh structures that provide unique, demonstrable performance benefits over substitutes, thereby solidifying market position and mitigating risk.

Segmentation Analysis

The Extruded Flat Plastic Mesh Mattress Market is comprehensively segmented based on material type, mesh structure, application, and distribution channel, providing a clear framework for strategic market targeting and resource allocation. Material segmentation distinguishes between different polymer bases, such as HDPE and PP, each offering distinct properties regarding flexibility, tensile strength, and cost efficiency, directly influencing the final product’s performance characteristics. Structural segmentation focuses on the density and pattern of the mesh, ranging from fine aperture designs optimized for comfort layers to coarse, high-load-bearing structures used as foundational support bases. Analyzing these segments helps stakeholders understand which raw materials and manufacturing processes generate the highest demand and yield the most sustainable growth across varying geographical and economic landscapes. The inherent modularity of the product lends itself well to precise segmentation, allowing for tailored marketing approaches targeting specific end-user requirements, such as high-temperature resistance in industrial applications versus softness and ergonomic contouring in residential sectors.

Application segmentation reveals the crucial end-use environments, separating the high-volume residential market from the high-margin institutional and healthcare sectors. This distinction is vital because the buying criteria, regulatory compliance needs, and average order values differ drastically between these segments. For instance, the healthcare sector demands stringent anti-microbial treatments and fire safety certifications, justifying a higher price point, whereas the residential market is more sensitive to aesthetics, comfort, and retail price points. Distribution channel analysis further refines market understanding, differentiating between direct sales to manufacturers (B2B) versus retail and e-commerce platforms (B2C). The rapid expansion of online sales channels requires specific packaging and logistics strategies optimized for the mesh material's unique physical properties, while traditional B2B channels prioritize bulk supply and long-term contracts. Collectively, these segmentation layers provide a granular view of market dynamics, enabling businesses to identify areas of unmet demand and focus R&D efforts on profitable niches, thereby maximizing overall market penetration efficiency. The segmentation structure reflects the maturity of the industry and its adaptability to diverse global consumer needs.

- Material Type:

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Other Polymers (e.g., PET, Nylon blends)

- Mesh Structure/Format:

- Fine Aperture Mesh (Comfort Layers)

- Coarse Aperture Mesh (Support Bases)

- Bi-Axial Mesh Structures

- Uni-Axial Mesh Structures

- Application:

- Residential Bedding

- Healthcare/Medical Facilities

- Hospitality Sector (Hotels, Resorts)

- Institutional (Dormitories, Military)

- Distribution Channel:

- Direct Sales (B2B to Mattress Manufacturers)

- Wholesalers and Distributors

- E-commerce Platforms

- Retail Channels (Specialty Stores)

Value Chain Analysis For Extruded Flat Plastic Mesh Mattress Market

The Value Chain for the Extruded Flat Plastic Mesh Mattress Market begins with the upstream segment involving raw material sourcing, primarily focusing on the acquisition and processing of petrochemical-derived polymers like HDPE and PP granules. This stage is dominated by large chemical and polymer manufacturers, whose pricing and quality consistency directly impact the profitability of the subsequent manufacturing stages. Following material sourcing, the core manufacturing process involves specialized extrusion and stretching technologies, where polymer pellets are melted, extruded into flat sheets, and then perforated or stretched to create the defined mesh pattern. This highly specialized step requires significant capital investment in machinery and intellectual property regarding mesh design, representing the highest value addition point in the entire chain. Efficient upstream management, including securing stable polymer supplies and optimizing energy use during extrusion, is paramount for maintaining competitive pricing and ensuring the consistent quality required for high-performance bedding components. The sophistication of extrusion technology dictates the final product's characteristics, such as tensile strength, mesh uniformity, and overall dimensional stability.

The distribution channel connects the specialized mesh manufacturers with the downstream mattress assemblers and ultimately, the end consumers. Distribution primarily utilizes both direct and indirect channels. Direct channels involve B2B sales where mesh producers supply large volumes directly to integrated mattress manufacturers who incorporate the mesh layer into their final bedding products. This channel prioritizes customized specifications, long-term contracts, and just-in-time delivery schedules. Indirect channels utilize specialized industrial distributors or wholesalers who maintain inventories and supply smaller or regional mattress producers, offering greater reach but potentially adding margin layers. The selection of distribution method is strategically determined by the manufacturer's size and geographic footprint, focusing heavily on minimizing logistical costs associated with shipping bulky, albeit lightweight, rolls of mesh material. Effective logistics management is a core competency here, ensuring minimal damage and timely delivery to geographically dispersed assembly plants.

Downstream analysis focuses on the final assembly, branding, and retailing of the complete mattress product. Mattress manufacturers integrate the extruded mesh as a support or ventilation layer, often marketing its specific hygienic and cooling properties to the consumer. This stage includes significant value addition through marketing, branding, and customer service. Potential customers, or end-users, interact with the product through various retail formats, ranging from specialized bedding stores to large furniture outlets and rapidly expanding e-commerce platforms. The success at this final stage relies heavily on consumer education regarding the benefits of the mesh layer over traditional materials, requiring effective communication of complex technical advantages in an accessible retail environment. Feedback loops from these downstream channels, capturing consumer preferences regarding firmness, durability, and climate performance, are critical for informing upstream R&D activities and driving iterative product improvements, thus completing the cyclical nature of the value chain and ensuring market alignment.

Extruded Flat Plastic Mesh Mattress Market Potential Customers

The potential customer base for the Extruded Flat Plastic Mesh Mattress Market is diverse and extends far beyond the average residential consumer, encompassing large-scale organizational buyers whose purchasing decisions are driven by durability, hygiene standards, and regulatory compliance. The primary end-users are vertically integrated mattress manufacturing companies, who purchase the mesh in bulk rolls as a key raw material component to enhance the breathability and structural integrity of their branded product lines, often positioning it as a premium feature in their mid-to-high-end offerings. Additionally, institutional procurement agencies represent a significant and consistently growing customer segment. This includes public and private healthcare systems, where the mesh's non-absorbent, easy-to-sanitize properties are essential for preventing cross-contamination and managing patient comfort in long-term care or acute settings. These institutional customers often require large volumes and adherence to strict fire and safety regulations, making quality certifications a non-negotiable purchasing criterion, and emphasizing the importance of robust supplier qualification processes.

Another major segment comprises the global hospitality industry, including major hotel chains, resorts, and extended-stay facilities. For these customers, the longevity and resistance to wear and tear offered by plastic mesh mattresses translate directly into reduced maintenance and replacement cycles, thereby improving operating expenditure efficiency. Hotels prioritize materials that maintain their structural integrity and hygienic standards across thousands of nightly uses and aggressive cleaning cycles. The ability of the extruded mesh to promote air circulation is particularly attractive in the hospitality sector, as it contributes significantly to the perceived comfort and premium quality of the guest experience, mitigating common complaints related to heat retention in traditional mattresses. Strategic targeting of new hotel developments and major refurbishment projects within this sector provides sustained, high-volume opportunities for mesh manufacturers seeking reliable, long-term contractual agreements.

The final, increasingly important segment involves specialized niche buyers, such as manufacturers of outdoor, marine, and specialized medical bedding, including pressure relief systems and adjustable beds. In these applications, the mesh’s inherent resistance to moisture, mold, and mildew makes it irreplaceable, as traditional materials would quickly fail in high-humidity or fluctuating temperature environments. For instance, marine applications require extreme durability against saltwater exposure, a condition where plastic mesh excels. Furthermore, the burgeoning popularity of ergonomic and customizable sleep solutions has created demand from specialty bed manufacturers seeking lightweight, flexible core materials that can integrate seamlessly with complex mechanical adjustments. Successful market penetration into these niche segments requires highly customized product development and technical support, leveraging the mesh's specific material advantages to solve unique performance challenges faced by these specialized end-user/buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 760 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jinrui Mesh, SWM International, Intermas Group, Tenax Corporation, ADFORS (Saint-Gobain), YUANHE Mesh, R&S International, Fuda Plastic, Nantong Hongyuan, Shandong Hongda, QINGDAO HENGSHENG, Hebei Runnuo, Zhejiang Hongxiang, King Mesh, Plastinet, China Netcom, Geogrid Solutions, Polimex, MeshCo, Industrial Netting |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Extruded Flat Plastic Mesh Mattress Market Key Technology Landscape

The technological landscape of the Extruded Flat Plastic Mesh Mattress Market is fundamentally defined by advanced polymer processing and precision extrusion techniques, which are crucial for achieving the desired geometric properties and material strength required for load-bearing and ventilating applications. The core technology involves the flat die extrusion process, followed by either punching, stretching, or molecular orientation to create the netting structure. The newest iterations focus heavily on bi-axial stretching, which significantly enhances the mesh’s tensile strength in both longitudinal and transverse directions, resulting in superior dimensional stability and durability under prolonged compression, vital for mattress cores. Furthermore, manufacturers are increasingly leveraging computer-aided design (CAD) and simulation software to model and test new mesh patterns virtually, allowing for rapid prototyping of structures optimized for specific ergonomic requirements, such as zonal support, before committing to costly physical tooling. Innovation in polymer blending is also prominent, incorporating specialized additives for UV resistance, anti-flammability, and improved anti-microbial performance, enhancing the overall functionality and safety profile of the final mattress component.

Material science innovation constitutes another critical pillar of the technology landscape. While traditional polymers like HDPE and PP remain dominant, the industry is witnessing a concerted shift towards high-performance and sustainable materials. This includes the development of bio-based or recycled plastics that meet stringent performance criteria, addressing growing regulatory pressure and consumer demand for eco-friendly products. Techniques such as nano-additive incorporation are being explored to imbue the mesh surface with enhanced anti-bacterial or phase-change material (PCM) properties, allowing the mesh itself to contribute actively to thermal regulation rather than just passive ventilation. Automation in the manufacturing process is paramount; modern extrusion lines utilize sophisticated sensor arrays and closed-loop control systems to monitor and adjust melt viscosity, die pressure, and stretching speed in real-time. This level of automation minimizes human error, ensures batch-to-batch consistency, and is essential for producing the large volumes needed to serve global markets efficiently, thereby driving down the per-unit cost and improving accessibility.

Looking forward, the integration of smart manufacturing methodologies, often underpinned by IoT and AI, is poised to revolutionize the sector. This involves connecting production machinery to cloud-based analytics platforms to perform predictive maintenance and dynamically adjust production parameters based on raw material variation or immediate quality feedback. Furthermore, the market is exploring integration technologies, focusing on how the plastic mesh can interface effectively with other components, such as memory foams or latex layers, often requiring specialized bonding or thermal welding techniques that maintain the mesh’s inherent breathability. Patented technologies around 'welded joint integrity' and 'mesh fusion' are becoming key competitive differentiators, ensuring that the finished mattress composite provides seamless performance and durability. The continued advancement in high-speed, precision extrusion technology, coupled with smart material science, will maintain the plastic mesh's relevance as a technically superior alternative to less breathable or less durable conventional bedding materials in a global marketplace increasingly prioritizing health and longevity.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to rapid urbanization, massive infrastructure development in residential and hospitality sectors, and a high prevalence of humid climates necessitating breathable bedding. Countries like China, India, and Southeast Asian nations are driving demand due to large-scale procurement for dormitories, hospitals, and burgeoning middle-class consumer spending on premium, hygienic bedding solutions. The region is also a major hub for low-cost, high-volume manufacturing, leading to intense competitive pricing.

- North America: The North American market is characterized by high adoption rates of premium and technological bedding, where extruded mesh is utilized in high-end mattresses for superior climate control and durability features. Growth is stable, driven by consumer demand for luxury sleep products and strict fire safety regulations which often favor the inherent properties of specialized polymers used in mesh production. Innovation focuses on integrating mesh layers into smart beds and optimizing supply chains for quick response to consumer trends.

- Europe: European market growth is steady, heavily influenced by stringent environmental and chemical regulations (like REACH), pushing manufacturers toward sustainable polymers and fully recyclable products. The market emphasizes quality, anti-allergy features, and ergonomic support, particularly in Western European nations. Germany, France, and the UK are key markets, showing strong institutional demand from hospitals and care facilities prioritizing long-term hygiene and low maintenance costs.

- Latin America (LATAM): LATAM is an emerging market with significant growth potential, tied to improving economic conditions and increased investment in housing and tourism infrastructure, especially in Brazil and Mexico. The market is primarily focused on balancing cost-effectiveness with basic durability and ventilation, offering significant opportunities for manufacturers who can establish localized distribution networks and production facilities to mitigate import costs and complex logistics challenges inherent to the region.

- Middle East & Africa (MEA): MEA presents specialized opportunities, particularly in the Middle East due to extreme climate conditions and significant investment in luxury hospitality projects (e.g., UAE, Saudi Arabia). Demand is high for materials offering heat resistance and dust mitigation. The African market, while nascent, is focused on basic, durable, and highly resilient solutions for institutional and low-cost housing projects, reflecting a strong emphasis on product longevity in challenging environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Extruded Flat Plastic Mesh Mattress Market.- Jinrui Mesh

- SWM International

- Intermas Group

- Tenax Corporation

- ADFORS (Saint-Gobain)

- YUANHE Mesh

- R&S International

- Fuda Plastic

- Nantong Hongyuan

- Shandong Hongda

- QINGDAO HENGSHENG

- Hebei Runnuo

- Zhejiang Hongxiang

- King Mesh

- Plastinet

- China Netcom

- Geogrid Solutions

- Polimex

- MeshCo

- Industrial Netting

Frequently Asked Questions

Analyze common user questions about the Extruded Flat Plastic Mesh Mattress market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of using extruded plastic mesh in mattresses?

The primary benefit is superior ventilation and air circulation, which prevents heat retention, minimizes moisture buildup, and significantly inhibits the growth of mold, mildew, and allergens, contributing to a healthier and cooler sleep environment compared to traditional foam bases.

Which material type dominates the Extruded Flat Plastic Mesh Mattress Market?

High-Density Polyethylene (HDPE) currently dominates the market due to its optimal balance of rigidity, durability, resistance to moisture and chemicals, and cost-effectiveness, making it ideal for the core supportive layers of mattress systems.

How is the Extruded Flat Plastic Mesh Mattress Market segmented by application?

The market is primarily segmented into Residential Bedding (largest volume segment), Healthcare/Medical Facilities (high-margin segment focused on hygiene), Hospitality Sector, and Institutional settings, each requiring customized mesh properties.

What are the key technological advancements driving production efficiency?

Key technological advancements include bi-axial stretching techniques for enhanced strength, advanced polymer blending for anti-microbial and fire-retardant properties, and the implementation of AI and IoT systems for real-time monitoring and optimization of the precision extrusion process.

Which geographical region exhibits the fastest growth rate for this market?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, fueled by rapid urbanization, high demand for hygienic bedding in humid climates, and significant governmental investment in infrastructure and healthcare facilities across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager