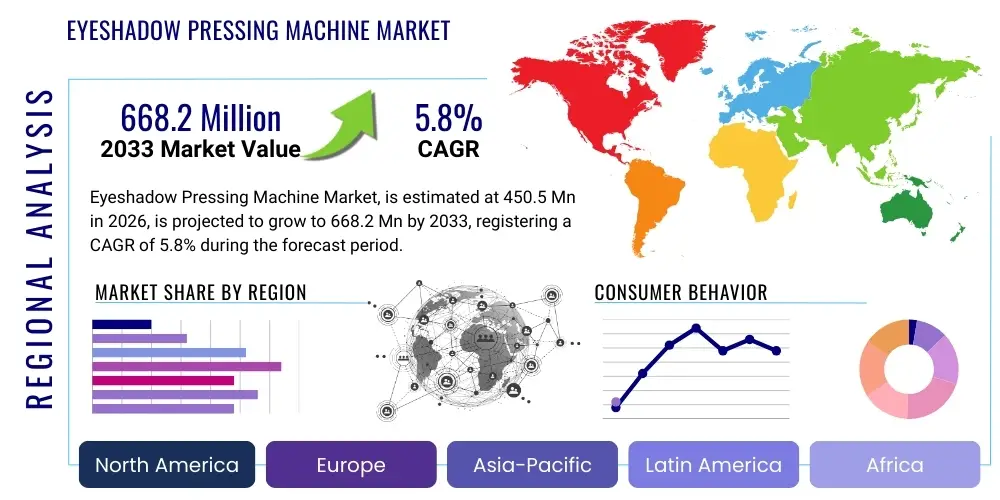

Eyeshadow Pressing Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442211 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Eyeshadow Pressing Machine Market Size

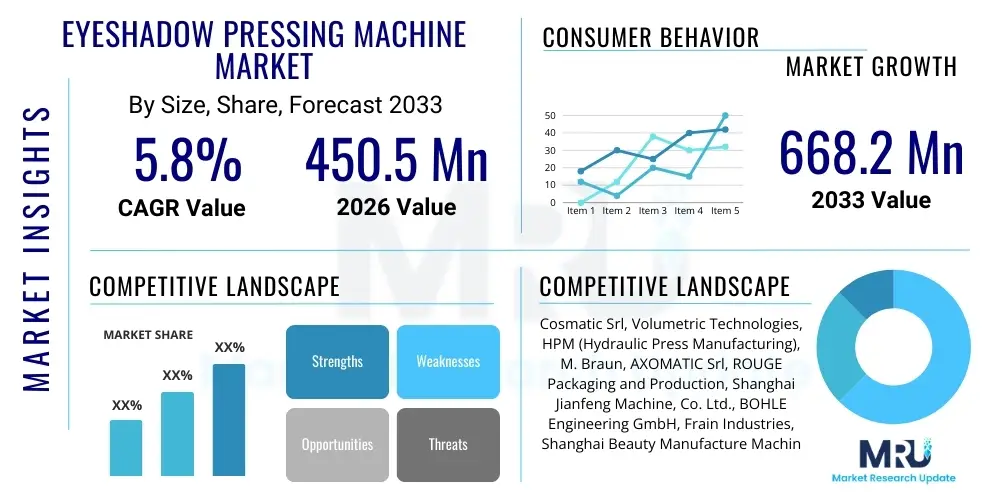

The Eyeshadow Pressing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.2 Million by the end of the forecast period in 2033.

Eyeshadow Pressing Machine Market introduction

The Eyeshadow Pressing Machine Market encompasses industrial equipment specifically designed for the compaction of powdered cosmetic formulations into pans or molds, creating the final consumer product. These machines are crucial components in the high-volume manufacturing of color cosmetics, ensuring consistency in density, texture, and aesthetic presentation across large batches. The primary product scope ranges from semi-automatic, entry-level systems suitable for small-to-mid-sized cosmetic houses, to fully automated, high-speed rotary and linear pressing lines utilized by global beauty conglomerates seeking maximum throughput and minimal human intervention. The efficiency and precision of these machines directly influence the quality, longevity, and color payoff characteristics of the finished eyeshadow product.

Major applications for eyeshadow pressing machines span across various cosmetic production sectors, including traditional baked eyeshadows, dry powder compacts, mineral formulations, and hybrid gel-powder products. These machines are increasingly utilized not only for standard single-color palettes but also for intricate multi-shade, patterned, or embossed designs, requiring highly precise hydraulic or pneumatic control systems. The rapid proliferation of private label manufacturing and the decentralized nature of cosmetic supply chains globally have amplified the demand for flexible, modular pressing solutions that can quickly switch between different pan sizes and formulation types, accommodating fast fashion cycles and seasonal product launches inherent to the beauty industry.

The market growth is fundamentally driven by the robust global expansion of the color cosmetics industry, particularly the accelerating demand for specialized eye makeup products in emerging economies across Asia Pacific and Latin America. Key benefits derived from adopting advanced pressing technology include superior operational efficiency, reduced material wastage, high uniformity of the final product texture, and improved labor productivity, justifying the significant capital investment required. Furthermore, stringent quality control regulations governing cosmetic manufacturing mandate precision, making automated pressing machines an essential tool for compliance and maintaining brand reputation in a highly competitive consumer goods landscape.

Eyeshadow Pressing Machine Market Executive Summary

The Eyeshadow Pressing Machine Market is exhibiting dynamic growth, primarily fueled by shifting consumer preferences towards specialized, high-quality makeup formulations and the relentless pursuit of manufacturing efficiency by leading cosmetic firms. Business trends indicate a strong move toward customization and small-batch production capability, driving manufacturers of pressing equipment to integrate advanced servo motors and programmable logic controllers (PLCs) for quicker setup times and increased versatility. Investment is increasingly concentrated in Asia Pacific, which is rapidly evolving into a major manufacturing hub for both global and regional cosmetic brands, necessitating scaled-up production lines capable of handling immense volumes while maintaining precise quality metrics under competitive pricing pressures. North America and Europe, while mature, emphasize sophisticated automation, traceability features, and compliance with rigorous environmental and safety standards.

Regional trends highlight the dominance of the Asia Pacific (APAC) region in terms of volume consumption, driven by high population density, rising disposable incomes, and the influential K-Beauty and J-Beauty trends which place significant emphasis on innovation in color cosmetics. In contrast, Western markets (North America and Europe) showcase high adoption rates for advanced, integrated pressing systems that feature end-to-end automation, often bundling pressing, destacking, and packaging into a single line. The Middle East and Africa (MEA) region is emerging, spurred by local manufacturing initiatives and expanding beauty retailer presence, demanding reliable and moderately automated machinery solutions. Furthermore, supply chain resilience remains a critical factor, prompting manufacturers to regionalize production facilities to mitigate geopolitical risks and freight volatility, thereby increasing local equipment procurement.

Segmentation trends reveal a clear market preference towards Fully Automatic Eyeshadow Pressing Machines over their semi-automatic counterparts, reflecting the industry’s push for scalability and labor cost reduction. Within the machine type segment, hydraulic presses are seeing sustained demand due to their precision and ability to handle delicate, highly pigmented formulations, while pneumatic systems remain popular for faster, less precise applications or lower capital investment requirements. Furthermore, segmentation based on pressing force and mold size shows that machines capable of handling large-format palettes and innovative product shapes are commanding premium pricing, aligning with consumer demand for differentiated, artistically packaged cosmetics. The private label manufacturing segment is proving to be a highly lucrative end-user vertical, requiring robust, standardized equipment capable of handling diverse client specifications efficiently.

AI Impact Analysis on Eyeshadow Pressing Machine Market

Analysis of common user questions reveals a collective industry concern regarding how Artificial Intelligence (AI) and machine learning (ML) can enhance manufacturing throughput, minimize defects, and optimize formulation parameters within the pressing process. Users frequently inquire about the potential for predictive maintenance capabilities, the role of computer vision systems in real-time quality control, and the integration of smart factory ecosystems utilizing AI for scheduling and resource allocation. The key themes revolve around achieving 'lights-out' manufacturing perfection, reducing the dependency on manual quality checks, and using historical data (e.g., moisture content, particle size distribution) to dynamically adjust pressing force or dwell time to ensure consistent product performance, especially when dealing with slight variances in raw material batches. Expectations center on AI transforming pressing machines from static tools into adaptive, self-optimizing manufacturing assets that guarantee unparalleled product consistency.

- AI-driven predictive maintenance scheduling reduces unexpected downtime by analyzing vibration, temperature, and cycle time anomalies.

- Machine Learning algorithms optimize pressing parameters (force, speed, dwell time) based on real-time feedback from sensors and material properties, minimizing cracking or flaking defects.

- Integrated Computer Vision Systems utilize AI for high-speed, non-destructive inspection of finished pressed products, immediately identifying aesthetic flaws or irregular density distributions.

- Generative Design AI assists in optimizing mold and pan geometries for easier release and improved product integrity during the pressing cycle.

- AI-enhanced resource planning links pressing machine output directly to inventory management and packaging schedules, optimizing the overall manufacturing flow.

- Smart factory integration uses AI dashboards to provide holistic operational visibility, linking pressing line efficiency metrics with overall equipment effectiveness (OEE) targets.

DRO & Impact Forces Of Eyeshadow Pressing Machine Market

The dynamics of the Eyeshadow Pressing Machine Market are shaped by a complex interplay of internal and external forces categorized under Drivers, Restraints, and Opportunities (DRO). Significant market drivers include the burgeoning global demand for specialized color cosmetics, particularly in fast-growing beauty markets like China and India, necessitating rapid scale-up of production capacity. Furthermore, the persistent need for operational precision and defect reduction—critical requirements for premium cosmetic brands—drives investments in highly automated and digitally integrated pressing equipment, ensuring every unit meets stringent quality benchmarks. The shift towards multi-functional makeup products and intricate palette designs also pushes machine manufacturers to innovate hydraulic and control systems capable of handling complex compaction profiles with high repeatability.

However, the market faces notable restraints that temper growth projections. High initial capital investment is a significant barrier, particularly for smaller and emerging cosmetic manufacturers, who often rely on refurbished or semi-automatic alternatives, slowing the adoption of cutting-edge technology. Technical complexity associated with integrating advanced robotic handling systems and sophisticated sensor technology requires highly specialized maintenance personnel, representing a challenge in regions with skill shortages. Moreover, the formulation-sensitive nature of eyeshadow powders—where slight variations in binder percentage or particle geometry require recalibration—can lead to production bottlenecks and efficiency losses if the pressing machines are not inherently flexible and quickly reconfigurable.

Opportunities for market stakeholders primarily lie in developing highly modular and customizable pressing solutions that can cater to the fast-changing demands of contract manufacturers and private label brands. The implementation of IoT and Industry 4.0 principles, particularly focusing on connectivity and remote diagnostics, presents a substantial opportunity for service revenue generation and enhancing customer satisfaction globally. Furthermore, the increasing industry focus on sustainability is creating demand for machines that minimize powder waste and consume less energy, leading to opportunities for green technology innovation in hydraulic systems and energy recovery mechanisms. Addressing the challenge of handling sustainable and mineral-based formulations, which often require unique pressure curves, represents a niche but valuable growth avenue. These forces collectively dictate the strategic decisions of machine manufacturers and the procurement patterns of cosmetic producers.

Segmentation Analysis

The Eyeshadow Pressing Machine Market is systematically segmented based on key criteria including the level of automation, the type of pressing mechanism utilized, and the typical pressing capacity, offering clarity on market structure and demand characteristics. Understanding these segments is crucial for machine suppliers tailoring their offerings and for cosmetic manufacturers selecting appropriate equipment matching their scale of operation and product quality requirements. The shift from manual labor to automated systems, driven by cost efficiency and consistent output quality, is the most defining trend across all geographic segments. Specialized pressing requirements for certain high-end, baked or domed products necessitate specific machine designs, creating distinct sub-markets within the overall landscape. Furthermore, the growing distinction between high-speed mass production lines and flexible, low-volume lines for specialized products shapes the competitive dynamics significantly.

The segmentation by automation level (Semi-Automatic vs. Fully Automatic) provides the clearest indication of capital expenditure and target user base, with Fully Automatic systems dominating due to their lower labor costs and higher throughput capacity, preferred by large multinational companies. Segmentation by pressing mechanism, primarily hydraulic versus pneumatic, reflects the required precision and formulation sensitivity. Hydraulic systems offer superior control over compaction force and dwell time, essential for complex pigment blends, while pneumatic systems offer speed and simplicity, often preferred for lower-cost, high-volume products where extreme precision is secondary. Capacity segmentation, measured in units per hour (UPH), dictates the equipment's suitability for either continuous, large-scale manufacturing or agile, batch-based production catering to custom orders or niche market demands.

These segmentations collectively highlight that the future market growth will be concentrated in high-precision, fully automated hydraulic systems that are equipped with advanced sensors for real-time quality assurance and rapid mold changeover capability. The ability to handle complex product specifications—such as multiple layers of pigment or intricate embossing—without compromising production speed is becoming a critical differentiator across all machine classes. Manufacturers are increasingly prioritizing modular designs that allow end-users to upgrade from semi-automatic to fully automated features incrementally, thereby reducing initial investment risk and enabling scalability within a unified machine platform. The underlying technology advancements in tooling and mold materials also influence segment performance, enhancing durability and reducing maintenance requirements.

- By Automation Type:

- Semi-Automatic Eyeshadow Pressing Machines

- Fully Automatic Eyeshadow Pressing Machines

- By Pressing Mechanism:

- Hydraulic Pressing Machines

- Pneumatic Pressing Machines

- Hybrid Systems (Electro-Hydraulic)

- By Capacity (Units Per Hour - UPH):

- Low Capacity (Below 1000 UPH)

- Medium Capacity (1000 – 5000 UPH)

- High Capacity (Above 5000 UPH)

- By End-User Industry:

- Large-Scale Cosmetic Manufacturers

- Small & Medium Enterprises (SMEs)

- Contract and Private Label Manufacturers

- By Application Type:

- Standard Single Pan Eyeshadows

- Multi-Color Palettes and Kits

- Baked and Specialty Eyeshadows

Value Chain Analysis For Eyeshadow Pressing Machine Market

The value chain for the Eyeshadow Pressing Machine Market begins with upstream activities centered on the procurement and processing of specialized components, encompassing high-precision steel alloys for molds, advanced hydraulic or pneumatic systems, complex electronic control units (PLCs, HMIs), and high-reliability servo motors. Key suppliers in this segment include specialized manufacturers of industrial automation components (e.g., Siemens, Rockwell Automation) and specialized tooling manufacturers crucial for mold accuracy and durability, which directly impacts the quality of the pressed product. This upstream focus requires rigorous quality checks and compliance with international standards for engineering tolerances, as any failure in the core mechanical or electronic components can lead to costly downtime for the cosmetic manufacturer.

The midstream activities involve the machine design, assembly, testing, and system integration conducted by the core Eyeshadow Pressing Machine manufacturers. This stage is characterized by intense Research and Development (R&D) focused on improving speed, reducing footprint, enhancing adaptability for quick product changeovers, and integrating smart features like real-time diagnostics and remote monitoring. Significant value is added through customized engineering solutions, such as adapting pressing kinematics for unique cosmetic formulations (e.g., highly shimmery or baked formulas). Strict internal quality control procedures, involving extensive factory acceptance testing (FAT), are mandatory before the machinery is dispatched to the end-users.

The downstream segment focuses on the distribution, installation, commissioning, and long-term after-sales support. Distribution channels are typically a mix of direct sales teams for major global accounts and specialized industrial machinery distributors or agents for regional markets, especially in APAC and MEA. Indirect channels often provide localized technical expertise and faster response times for maintenance. Post-sale services, including scheduled maintenance, provision of spare parts, software updates, and training for operating personnel, represent a critical source of recurring revenue and a major determinant of customer lifetime value. The efficiency of the downstream support network directly influences the operational continuity and overall equipment effectiveness (OEE) of cosmetic production facilities worldwide.

Eyeshadow Pressing Machine Market Potential Customers

The primary potential customers for Eyeshadow Pressing Machines are entities involved in the production and distribution of color cosmetics, spanning multinational conglomerates, regional private label specialists, and independent beauty startups. Global cosmetic giants such as L'Oréal, Estée Lauder, and Shiseido represent the highest-volume customers, demanding fully integrated, high-speed automated lines that minimize human handling and maximize efficiency across their global manufacturing networks. These customers prioritize reliability, scalability, and seamless integration with existing enterprise resource planning (ERP) systems and sophisticated quality control protocols, justifying investment in premium, customized machinery with integrated robotics for pan loading and unloading.

A rapidly expanding segment of potential customers includes contract manufacturing organizations (CMOs) and private label manufacturers (PLMs), particularly prevalent in China, South Korea, and Italy. These companies require highly flexible, multi-format pressing machines capable of handling small to medium batch sizes efficiently, with rapid changeover capabilities to service a diverse portfolio of client brands ranging from high-street fashion brands to indie beauty labels. Their purchasing decisions are highly sensitive to the machine's versatility, ease of cleaning, and total cost of ownership (TCO), making modular designs with accessible spare parts inventory particularly attractive. The competitive nature of contract manufacturing drives continuous demand for faster and more reliable machinery to maintain profitability.

Emerging and specialized customers include boutique cosmetic laboratories focusing on niche segments such as organic, vegan, or mineral makeup. Although their volume requirements are lower, these customers demand precise, often semi-automatic, or lower-capacity machines that can delicately handle specialized, sometimes abrasive, or challenging powder formulations that require unique pressing profiles to maintain product integrity and safety standards. Furthermore, academic research institutions and specialized material science laboratories occasionally purchase smaller, precision pressing equipment for formulation R&D and pilot batch testing purposes, focusing more on parameter control and data logging capabilities than sheer throughput speed.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cosmatic Srl, Volumetric Technologies, HPM (Hydraulic Press Manufacturing), M. Braun, AXOMATIC Srl, ROUGE Packaging and Production, Shanghai Jianfeng Machine, Co. Ltd., BOHLE Engineering GmbH, Frain Industries, Shanghai Beauty Manufacture Machine Co., Ltd., Co.ma.di.s. Spa, Tecna Srl, Pamasol Willi Mäder AG, Marchesini Group, SmiPack S.p.A., Nanning Yongming Machinery Co., Ltd., JSN Machinery, Vetraco Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Eyeshadow Pressing Machine Market Key Technology Landscape

The technological landscape of the Eyeshadow Pressing Machine market is rapidly evolving, moving away from purely mechanical systems toward sophisticated mechatronic solutions integrating advanced software controls. Key advancements are centered around achieving ultra-precise force control and enhancing machine flexibility for quick changeovers. Modern machines utilize closed-loop servo-hydraulic systems that provide exceptional accuracy and repeatability in applying pressing force, crucial for delicate or multi-layer cosmetic powders, ensuring uniformity and preventing cracking or crumbling. Furthermore, the incorporation of advanced Human-Machine Interfaces (HMIs) with intuitive touchscreen interfaces allows operators to store hundreds of specific product recipes, dramatically reducing setup time and the risk of human error during formulation switches, thus catering directly to the demands of contract manufacturing.

A central technological focus is the integration of Industry 4.0 elements, including Internet of Things (IoT) sensors embedded throughout the pressing mechanism. These sensors continuously monitor critical operational parameters such as hydraulic fluid temperature, vibration levels, cylinder pressure, and cycle time. This data is leveraged for real-time performance monitoring and sophisticated predictive maintenance algorithms, significantly improving Overall Equipment Effectiveness (OEE) by anticipating component failure before costly unscheduled downtime occurs. Data connectivity allows cosmetic manufacturers to remotely monitor global pressing operations and perform troubleshooting, improving efficiency across geographically dispersed production sites and supporting centralized quality assurance strategies.

Furthermore, technology related to powder handling and mold management is undergoing significant innovation. Advanced vacuum systems are now standard, ensuring precise powder dosing into the pans, minimizing waste, and preventing cross-contamination between different colored formulations. Quick-release tooling and modular mold designs, often employing lightweight, high-strength composite materials, facilitate rapid cleaning and product format changeovers, which is vital in the fast-paced beauty industry. Robotics and sophisticated vision systems are being integrated downstream to automate the removal of pressed product, quality inspection, and seamless transfer to the packaging line, further closing the automation loop and ensuring end-to-end efficiency without compromising the integrity of the fragile pressed product.

Regional Highlights

The regional analysis of the Eyeshadow Pressing Machine Market reveals distinct growth trajectories and adoption patterns influenced by local manufacturing intensity, consumer trends, and regulatory frameworks. Asia Pacific (APAC) dominates the market both in terms of production volume and demand, primarily driven by the massive cosmetics consumer bases in China, India, and Southeast Asian nations. The region is characterized by high capital investment in new manufacturing facilities, often focusing on high-capacity, mid-range automated pressing machines to meet fierce competition and high output quotas. South Korea and Japan continue to lead in technological adoption, often serving as pilot markets for the latest innovations in high-precision pressing technology, particularly for intricate, specialty products like baked and bouncy eyeshadow formulations.

North America (NA) and Europe represent mature markets characterized by replacement demand and a strong emphasis on full automation and integration of advanced digital technologies. Manufacturers in these regions prioritize machines that offer exceptional traceability, robust compliance features (e.g., meeting EU safety and hygiene standards), and sophisticated software capabilities for complex supply chain management and inventory control. The market trend here favors premium, high-reliability equipment with lower total cost of ownership over their lifecycle, even if the initial investment is higher. Germany, Italy, and the US are major hubs for machine manufacturing and technology adoption, influencing global quality standards.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging as high-growth regions. LATAM, led by Brazil and Mexico, shows increasing demand for semi-automatic and moderately automated systems as local cosmetic manufacturers expand their capacity to serve regional consumer demands driven by rising middle-class disposable income and increasing Westernization of beauty standards. The MEA region, particularly the UAE and Saudi Arabia, is witnessing a concentrated effort to establish local manufacturing capabilities to diversify economies and reduce reliance on imported goods. This strategic push is creating strong demand for turnkey manufacturing lines, including robust pressing machines, suitable for operation in demanding environmental conditions, requiring dependable after-sales support networks.

- Asia Pacific (APAC): Highest volume market; driven by contract manufacturing growth in China and consumer demand surge in India; strong adoption of high-speed automation.

- North America: Mature market focusing on replacement, integration of Industry 4.0, and high-precision machinery for premium, clean-beauty formulations.

- Europe: Demand driven by stringent regulatory compliance (e.g., CE marking), preference for technologically advanced servo-hydraulic systems, and a high concentration of leading cosmetic brands in Italy and France.

- Latin America (LATAM): Growth propelled by increasing local manufacturing base, focusing on flexible, cost-effective semi-automatic and basic automated systems.

- Middle East and Africa (MEA): Emerging market characterized by new facility setup and demand for robust, easily maintainable machinery to support local production initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Eyeshadow Pressing Machine Market.- Cosmatic Srl

- AXOMATIC Srl

- Volumetric Technologies

- ROUGE Packaging and Production

- HPM (Hydraulic Press Manufacturing)

- Shanghai Jianfeng Machine, Co. Ltd.

- M. Braun

- Co.ma.di.s. Spa

- BOHLE Engineering GmbH

- Tecna Srl

- Frain Industries

- Pamasol Willi Mäder AG

- Marchesini Group

- Shanghai Beauty Manufacture Machine Co., Ltd.

- SmiPack S.p.A.

- Nanning Yongming Machinery Co., Ltd.

- JSN Machinery

- Vetraco Group

- Shandong Sinolion Machinery Co., Ltd.

- Dongguan Vitek Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Eyeshadow Pressing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automatic eyeshadow pressing machines?

The primary driver is the necessity for high production throughput, consistent product quality, and significant reduction in manual labor costs, particularly among large-scale cosmetic manufacturers and contract packaging organizations (CMOs) operating in high-volume markets.

How does the choice between hydraulic and pneumatic pressing mechanisms impact product quality?

Hydraulic pressing mechanisms generally offer superior control over compaction force and dwell time, resulting in higher precision and density consistency, which is crucial for handling complex, highly pigmented, or delicate pressed powder formulations, minimizing cracking and ensuring better color payoff.

What is the average expected lifespan and typical maintenance schedule for a high-capacity pressing machine?

The expected operational lifespan of a high-capacity machine is typically 15 to 20 years with proper maintenance. Standard maintenance involves daily checks, weekly lubrication, and major annual services focused on replacing seals, checking hydraulic fluid quality, and recalibrating sensors and control systems.

Which geographical region holds the largest market share for eyeshadow pressing machine sales and why?

The Asia Pacific (APAC) region currently holds the largest market share, predominantly due to the rapid expansion of domestic and international cosmetic manufacturing bases in countries like China and South Korea, coupled with immense consumer market growth necessitating significant production capacity additions.

How is AI technology specifically improving the efficiency of the eyeshadow pressing process?

AI technology enhances efficiency primarily through predictive maintenance, reducing unscheduled downtime, and by integrating computer vision systems for real-time, non-contact quality control checks, dynamically adjusting pressing parameters to optimize the output and minimize material waste based on formulation input variables.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager