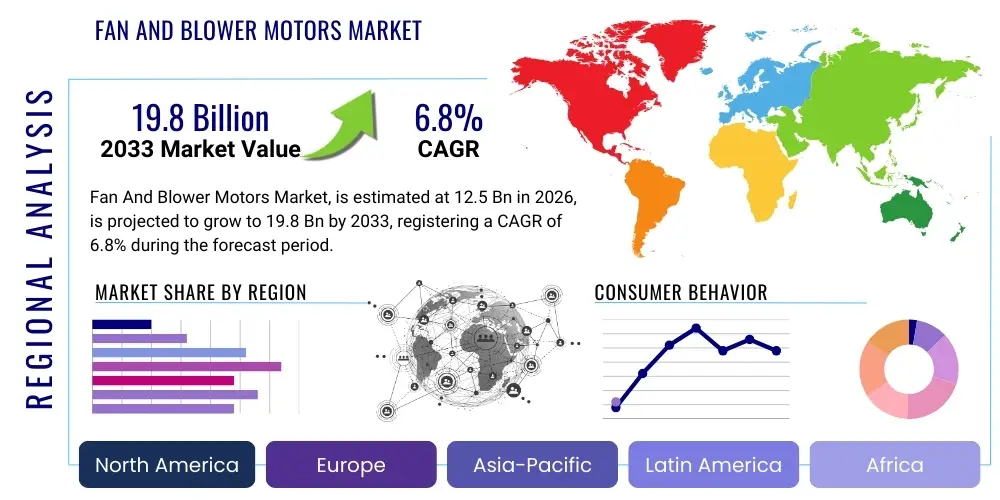

Fan And Blower Motors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442593 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Fan And Blower Motors Market Size

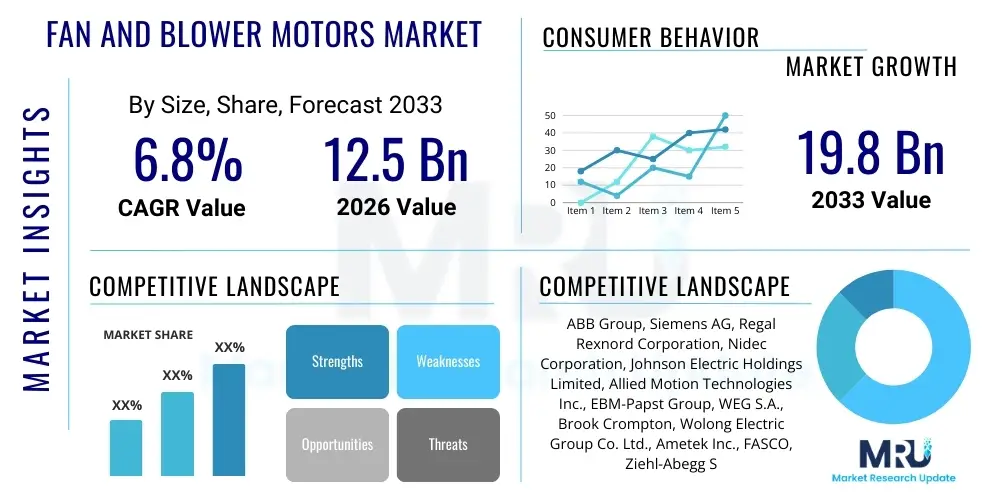

The Fan And Blower Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 12.5 Billion in 2026 and is projected to reach USD 19.8 Billion by the end of the forecast period in 2033.

Fan And Blower Motors Market introduction

The Fan and Blower Motors Market encompasses a diverse range of electric motors specifically engineered to drive fans, blowers, and air-moving equipment across residential, commercial, and industrial settings. These motors are fundamental components in Heating, Ventilation, and Air Conditioning (HVAC) systems, ensuring crucial airflow management for thermal comfort, air quality control, and process cooling. Products range from fractional horsepower motors used in small residential appliances to high-efficiency industrial motors integral to large-scale infrastructure, power generation, and manufacturing operations. The core objective of these products is to provide reliable, efficient, and speed-controlled rotational power necessary for effective air displacement, crucial for maintaining optimal operating environments and machinery performance.

Major applications for fan and blower motors span various sectors, including data centers requiring continuous cooling, automotive systems needing cabin climate control and engine cooling, and complex industrial processes involving fume extraction or pneumatic conveying. Modern fan and blower motors are increasingly characterized by the adoption of Electronically Commutated (EC) technology and Variable Frequency Drives (VFDs). These technologies significantly enhance energy efficiency and precision control, allowing systems to meet stringent global energy consumption regulations, such as those set by regulatory bodies aimed at reducing carbon footprints. The push towards sustainable infrastructure and smart building development is fundamentally driving innovation within this market, emphasizing motor design that prioritizes longevity and reduced total cost of ownership.

Key driving factors stimulating market expansion include rapid urbanization, leading to increased demand for centralized HVAC systems in commercial infrastructure projects globally, particularly across Asia Pacific. Furthermore, the mandatory implementation of energy efficiency standards by governments worldwide necessitates the replacement of older, less efficient motor technologies with high-efficiency alternatives, creating a robust retrofit market. The rising deployment of high-density computing equipment in data centers also places continuous demand on advanced cooling solutions, making powerful and reliable blower motors indispensable for preventing equipment failure. These dynamics collectively position the fan and blower motors market as a critical enabling segment within the broader electromechanical industry.

Fan And Blower Motors Market Executive Summary

The Fan and Blower Motors market is currently undergoing a significant transformation driven by advancements in motor control electronics and stringent global energy efficiency mandates. Business trends emphasize miniaturization, integration of IoT capabilities for remote monitoring and diagnostics, and the aggressive push towards Brushless Direct Current (BLDC) and Electronically Commutated (EC) motor types, which offer superior efficiency compared to traditional AC induction motors. Manufacturers are focusing heavily on developing smart motors that can communicate operational data, enabling predictive maintenance schedules and optimizing system performance dynamically. Furthermore, strategic partnerships between motor manufacturers and HVAC equipment integrators are becoming prevalent to ensure seamless system compatibility and performance guarantees, cementing long-term supply relationships and accelerating product innovation cycles aimed at reducing operational expenditure for end-users.

Regional trends indicate that the Asia Pacific (APAC) region remains the dominant growth engine, fueled by massive infrastructure investment, booming construction activities in residential and commercial sectors, and the rapid expansion of industrial manufacturing bases, particularly in China and India. North America and Europe, characterized by established regulatory frameworks and a strong focus on sustainability, show steady demand driven primarily by replacement cycles, modernization of aging infrastructure, and the widespread adoption of premium, high-efficiency products in response to escalating energy costs. The Middle East and Africa (MEA) are also emerging as key markets, primarily due to large-scale smart city developments and climate control necessities imposed by high regional temperatures, driving demand for powerful and reliable HVAC blower motor solutions designed for extreme operating conditions.

Segmentation trends highlight the increasing prominence of motors based on efficiency standards, with IE4 (Super Premium Efficiency) and EC motors capturing significant market share, especially in high-duty cycle industrial applications. By type, centrifugal blowers and axial fans remain critical, but the distinction lies increasingly in the motor technology applied to them. The HVAC segment continues to dominate application areas, followed closely by the automotive sector, which is rapidly adopting specialized blower motors for Electric Vehicle (EV) battery cooling systems and sophisticated cabin air management. Demand is shifting away from standard single-speed motors toward variable-speed drives, reflecting the industry's need for precise airflow modulation, which translates directly into significant energy savings and improved operational acoustics for both commercial and residential users.

AI Impact Analysis on Fan And Blower Motors Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Fan and Blower Motors Market frequently center on themes of predictive maintenance, optimized energy consumption, and the automation of airflow control systems. Users are keen to understand how AI-driven algorithms can move systems beyond reactive failure detection to proactive component management, predicting motor degradation or bearing failure long before critical breakdown occurs. There is significant concern and expectation around AI's ability to fine-tune Variable Frequency Drives (VFDs) and EC motor speeds dynamically, not just based on temperature set points, but factoring in complex variables like external weather conditions, occupancy levels, and historical performance data, thereby achieving unparalleled energy efficiency. The key themes revolve around achieving true system autonomy, maximizing operational uptime, and reducing lifecycle operational costs through intelligent decision-making capabilities embedded within motor controllers and central building management systems (BMS).

- AI enables highly accurate predictive maintenance models, reducing unexpected motor failure and associated downtime in critical HVAC systems.

- Integration of machine learning algorithms optimizes motor speed and torque based on real-time environmental factors, leading to substantial energy savings beyond traditional VFD control.

- AI facilitates advanced fault diagnostics by analyzing subtle shifts in motor vibration, current draw, and temperature profiles, significantly extending motor service life.

- Implementation of smart, self-learning control systems that dynamically adjust blower performance to maintain optimal air quality and thermal comfort with minimal human intervention.

- AI supports the automated commissioning and recalibration of large arrays of fan and blower systems, ensuring balanced performance and adherence to efficiency protocols across large commercial sites.

DRO & Impact Forces Of Fan And Blower Motors Market

The market trajectory is significantly shaped by a confluence of accelerating drivers, persistent restraints, and untapped opportunities, collectively defining the impact forces. A primary driver is the global commitment to sustainable development, manifested through increasingly stringent governmental regulations mandating high energy efficiency standards (such as IE3 and IE4 motor classes) across commercial and industrial infrastructure, forcing manufacturers and consumers toward premium motor technologies. This regulatory pressure, combined with the substantial operational cost savings realized through high-efficiency Electronically Commutated (EC) and Brushless DC (BLDC) motors, creates a compelling economic argument for widespread adoption and replacement of older technologies. Additionally, the rapid expansion of data centers globally, which require highly reliable, continuous, and precisely controlled cooling solutions, acts as a robust demand driver for advanced blower motor technologies capable of operating efficiently under high-load conditions.

Conversely, the market faces several restraining forces that temper growth rates, including the relatively high initial capital investment required for high-efficiency EC and VFD-driven motor systems compared to standard AC induction motors, which can deter small and medium enterprises (SMEs) in developing regions. Furthermore, the inherent complexity involved in integrating and programming variable speed drives and smart control systems necessitates specialized technical expertise, creating a skills gap in installation and maintenance that can slow adoption. Global supply chain volatility, particularly concerning critical components like rare-earth magnets used in permanent magnet motors and sophisticated semiconductor chips required for motor controllers, poses an ongoing threat, leading to potential price fluctuations and extended lead times for highly specialized products, thereby hindering market expansion initiatives.

Significant opportunities exist in emerging applications, notably the proliferation of Electric Vehicles (EVs), where specialized compact and high-performance blower motors are vital for thermal management of battery packs, power electronics, and sophisticated cabin climate control systems. The development of integrated motor and fan assembly solutions, often incorporating advanced aerodynamics and acoustics, presents an opportunity for manufacturers to offer superior, installation-ready units that reduce system complexity for OEM integrators. Finally, the integration of Industrial Internet of Things (IIoT) capabilities into blower motor systems allows for the development of lucrative subscription-based services centered on performance monitoring, predictive diagnostics, and remote optimization, opening new revenue streams beyond mere hardware sales. These forces necessitate strategic investment in R&D focusing on advanced materials and intelligent control mechanisms to capitalize effectively on evolving market needs.

Segmentation Analysis

The Fan and Blower Motors Market is meticulously segmented based on Motor Type, Product Type, Application, and Efficiency Class, allowing for granular analysis of market dynamics and targeted strategic development. The motor type segmentation distinguishes between standard AC Induction Motors, which remain prevalent in legacy systems, and the rapidly growing DC Brushless, Permanent Magnet Synchronous Motors (PMSM), and Electronically Commutated (EC) motors, which dominate the high-efficiency and variable-speed domains. Product types primarily delineate between Axial Fans, designed for high volume airflow, and Centrifugal Blowers, favored for high pressure applications. Application segmentation provides insight into end-user reliance, with HVAC systems, industrial processes, and automotive sectors representing the largest consumers, each demanding motors tailored to specific operational requirements like temperature resistance or noise reduction. Efficiency class segmentation reflects global mandates, categorizing motors from standard IE1/IE2 to premium IE4/IE5, driving replacement market opportunities.

- By Motor Type: AC Induction Motors, DC Brushless Motors, Electronically Commutated (EC) Motors, Permanent Magnet Synchronous Motors (PMSM).

- By Product Type: Axial Fans, Centrifugal Blowers (Radial, Forward-curved, Backward-inclined), Cross-Flow Blowers.

- By Application: HVAC (Residential, Commercial, Industrial), Automotive (Engine Cooling, Cabin Ventilation, Battery Thermal Management in EVs), Industrial Process Cooling, Electronics Cooling (Data Centers), Medical Equipment.

- By Efficiency Class: Standard Efficiency (IE1), High Efficiency (IE2), Premium Efficiency (IE3), Super Premium Efficiency (IE4).

- By Output Power: Fractional Horsepower (FHP), Integral Horsepower (IHP).

Value Chain Analysis For Fan And Blower Motors Market

The value chain for Fan and Blower Motors begins with upstream activities involving the sourcing of essential raw materials and components, which include copper and aluminum for windings and housing, specialized magnetic materials (e.g., rare earth magnets) for permanent magnet motors, and advanced semiconductors and controllers necessary for VFDs and EC motor operation. Suppliers in this segment, particularly those providing specialized high-performance materials and complex electronic components, hold significant leverage due to the technical specifications and quality requirements mandated by efficiency standards. Manufacturers must engage in rigorous quality control over these input materials, as variations directly impact the motor's ultimate efficiency, durability, and compliance with certifications, necessitating strong relationships with specialized magnet and semiconductor producers to ensure supply stability and cost efficiency, especially in the volatile global market landscape.

Midstream activities encompass the core manufacturing, assembly, and testing of the motors and integrated blower units. This stage involves complex processes such as winding, lamination stacking, rotor balancing, and the precise integration of electronic control boards. Key manufacturers often differentiate themselves here through proprietary motor designs, optimized cooling techniques, and advanced automation in their production lines to maximize consistency and throughput. Rigorous compliance testing for efficiency (e.g., NEMA, IEC standards) and safety (e.g., UL, CE) is mandatory before products enter the distribution phase. The ability of manufacturers to innovate in design—reducing weight, size, and noise while maintaining or increasing efficiency—is paramount to gaining a competitive edge in the highly sophisticated global market for air-moving equipment components.

Downstream activities involve the distribution channel, which is bifurcated into direct and indirect routes. Direct sales are common for Original Equipment Manufacturers (OEMs), where motor producers supply customized units directly to large HVAC system assemblers, automotive manufacturers, or industrial machinery makers under long-term contracts. Indirect distribution relies on an extensive network of industrial distributors, wholesalers, and specialized component suppliers who serve the aftermarket, MRO (Maintenance, Repair, and Operations) segment, and smaller system integrators. Effective channel management, including optimized logistics and strong technical support provided through these distribution partners, is critical for achieving market penetration and ensuring that customers receive timely access to necessary components, including specialized spare parts for high-efficiency motors which require precise replacements.

Fan And Blower Motors Market Potential Customers

Potential customers for Fan and Blower Motors span a wide array of industries fundamentally reliant on managed airflow for core operational functions, primarily driven by the need for thermal control, air quality maintenance, and specific process requirements. The largest buyer segment comprises Original Equipment Manufacturers (OEMs) specializing in Heating, Ventilation, and Air Conditioning (HVAC) systems. These companies integrate millions of motors annually into residential furnaces, commercial air handlers, rooftop units, and dedicated chiller cooling towers. As these OEMs focus intensely on product differentiation through energy star ratings and reduced noise profiles, they prioritize motor manufacturers who can deliver high-efficiency EC motors with quiet, variable-speed operation, often requiring custom specifications to fit compact unit designs and meet stringent building codes globally, especially in smart building deployments.

Another major customer segment involves the operators and builders of large-scale infrastructure, particularly the burgeoning Data Center industry and telecommunication facilities. These customers demand highly reliable, continuous-duty blower motors specifically engineered for cooling mission-critical server racks and associated power electronics, where downtime is financially catastrophic. Motors utilized in this segment must possess superior thermal management capabilities, robust construction to handle continuous operation, and advanced connectivity features for seamless integration into sophisticated Building Management Systems (BMS) that leverage AI for operational optimization. The shift toward immersion cooling and liquid cooling technologies also impacts this sector, requiring specialized pumps and fans, but traditional air cooling remains the dominant requirement for redundancy and primary cooling layers.

Furthermore, the automotive industry represents a high-growth customer segment, particularly driven by the accelerating transition to Electric Vehicles (EVs). Automotive customers require compact, vibration-resistant, and highly efficient blower motors for essential functions such as maintaining precise battery thermal management (BTM) systems, cooling power inverters, and controlling cabin climate with minimal power draw, thereby maximizing driving range. Industrial manufacturing and process customers, including those in mining, chemical processing, and food & beverage, also constitute a stable customer base, requiring ruggedized, explosion-proof, or highly sanitary blower systems for fume extraction, material handling, or sterile environment maintenance. These customers prioritize motor durability, resistance to corrosive environments, and compliance with industry-specific safety standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.5 Billion |

| Market Forecast in 2033 | USD 19.8 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Group, Siemens AG, Regal Rexnord Corporation, Nidec Corporation, Johnson Electric Holdings Limited, Allied Motion Technologies Inc., EBM-Papst Group, WEG S.A., Brook Crompton, Wolong Electric Group Co. Ltd., Ametek Inc., FASCO, Ziehl-Abegg SE, Rotor Electric Co., TECO Electric & Machinery Co., Bosch Rexroth AG, Franklin Electric Co. Inc., Maxon Motor AG, Panasonic Corporation, Toshiba Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fan And Blower Motors Market Key Technology Landscape

The technological evolution within the fan and blower motors market is predominantly centered on maximizing efficiency and controllability through advanced electronics and material science. Electronically Commutated (EC) motor technology represents the current industry benchmark, integrating permanent magnet synchronous motors with sophisticated built-in electronic controllers. This integration allows for precise variable speed operation without the energy losses associated with traditional AC induction motors driven by external VFDs, yielding significant energy savings, particularly under partial load conditions. The use of high-strength rare-earth magnets (like Neodymium) is crucial in EC motors, enabling compact designs with high torque density, although reliance on these materials introduces supply chain vulnerabilities that manufacturers are actively mitigating through research into ferrite or specialized non-magnet-based synchronous reluctance motors (SynRM).

Furthermore, the rapid proliferation of smart control technologies, enabled by embedded microprocessors and communication protocols such as Modbus and BACnet, is redefining the functionality of modern blower motors. These capabilities facilitate integration into Building Management Systems (BMS) and Industrial Internet of Things (IIoT) platforms, allowing operators to monitor motor health parameters, including temperature, vibration, and energy consumption, in real-time. This connectivity supports advanced features like predictive maintenance and automatic fault reporting, dramatically increasing system reliability and reducing lifecycle operational costs. The continuous improvement in power electronics, particularly MOSFET and IGBT switching components, allows for smaller, more efficient motor controllers that manage complex pulse-width modulation (PWM) schemes, resulting in quieter operation and reduced electromagnetic interference (EMI).

Acoustic engineering also forms a crucial part of the technological landscape, especially for motors used in residential HVAC and sensitive commercial environments like hospitals and libraries. Manufacturers are heavily investing in computational fluid dynamics (CFD) analysis to optimize the aerodynamic design of fan blades and scroll housings, ensuring maximum airflow at minimal noise levels. This pursuit of quiet operation often goes hand-in-hand with energy efficiency, as optimized aerodynamics reduce motor load. Additionally, material innovations, such as the use of high-grade composites and specialized coatings, are being employed to enhance motor durability and corrosion resistance, extending the operational life of units deployed in harsh or humid industrial environments. The combined push for efficiency, intelligence, and reduced noise defines the cutting edge of current motor technology development.

Regional Highlights

- North America: Characterized by mature infrastructure and high regulatory pressure for energy efficiency (e.g., Department of Energy mandates). Market growth is primarily driven by the replacement of aging HVAC systems, robust expansion of data centers, and the high penetration rate of premium efficiency (IE3/IE4) and EC motors in commercial buildings seeking LEED certification and reduced operating costs. The US and Canada are leading adopters of smart motor technology for connectivity and optimized performance.

- Europe: Driven by strong governmental commitments to climate goals and stringent efficiency directives (ErP Directive). The region shows high adoption of variable speed drives and EC technology across industrial and commercial segments. Germany and the UK are key markets, leading innovation in thermal management solutions for manufacturing and renewable energy infrastructure, prioritizing systems with low environmental impact and exceptional reliability.

- Asia Pacific (APAC): The largest and fastest-growing market globally, fueled by rapid urbanization, massive infrastructure development, and industrial expansion in China, India, and Southeast Asian nations. Demand is high across all sectors, from affordable residential HVAC units to large-scale industrial blowers. While price sensitivity remains a factor, increasing awareness of energy costs and improving regulatory enforcement are accelerating the transition from standard to high-efficiency motors.

- Latin America: Exhibits steady growth, largely dependent on construction and industrial output in Brazil and Mexico. Market penetration of advanced EC motors is increasing, but AC induction motors still hold a significant share. Demand drivers include industrial modernization projects and the need for reliable cooling solutions in varying climate zones, leading to moderate but consistent growth in commercial applications.

- Middle East and Africa (MEA): Growth is significant due to large-scale construction projects, especially in the Gulf Cooperation Council (GCC) states (UAE, Saudi Arabia), where high ambient temperatures necessitate robust and efficient large-scale HVAC systems. Energy efficiency is becoming increasingly important due to high energy subsidies and a push towards sustainable development in smart cities, creating a niche market for heavy-duty, climate-resistant blower motors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fan And Blower Motors Market.- ABB Group

- Siemens AG

- Regal Rexnord Corporation

- Nidec Corporation

- Johnson Electric Holdings Limited

- Allied Motion Technologies Inc.

- EBM-Papst Group

- WEG S.A.

- Brook Crompton

- Wolong Electric Group Co. Ltd.

- Ametek Inc.

- FASCO

- Ziehl-Abegg SE

- Rotor Electric Co.

- TECO Electric & Machinery Co.

- Bosch Rexroth AG

- Franklin Electric Co. Inc.

- Maxon Motor AG

- Panasonic Corporation

- Toshiba Corporation

Frequently Asked Questions

Analyze common user questions about the Fan And Blower Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driver for adopting EC motors over traditional AC induction motors in the blower market?

The primary driver is superior energy efficiency, especially under partial load conditions. Electronically Commutated (EC) motors significantly reduce energy consumption compared to AC motors, helping commercial and industrial users meet strict global energy mandates and achieve substantial operational cost savings throughout the motor lifecycle.

How is the growth of data centers influencing the demand for fan and blower motors?

Data center expansion necessitates massive, highly reliable, and continuous-duty cooling solutions. This drives demand for specialized, high-performance centrifugal and axial blower motors, often featuring advanced sensor technology and variable speed control, essential for maintaining stable server operating temperatures and preventing costly downtime.

Which geographical region exhibits the highest growth potential for fan and blower motors?

The Asia Pacific (APAC) region is projected to show the highest growth potential, fueled by rapid urbanization, extensive infrastructure investments, and massive industrial expansion, particularly in emerging economies like China and India, increasing the baseline demand for commercial and residential HVAC systems.

What role does predictive maintenance play in the fan and blower motors market?

Predictive maintenance, enabled by IIoT integration and AI algorithms, allows operators to monitor motor vibration, temperature, and current in real-time. This capability predicts potential failures before they occur, maximizing operational uptime, extending the motor's service life, and shifting maintenance from reactive to proactive scheduling, drastically reducing unexpected system breakdowns.

What key challenges restrict the wider adoption of high-efficiency fan and blower motors?

The key challenge is the higher initial capital expenditure required for premium efficiency motors (such as IE4 and EC technologies) compared to standard efficiency units. This cost barrier can be prohibitive for small and medium enterprises, despite the promise of lower long-term operational costs and energy savings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager