Fiber Optic Rotary Joints Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440805 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Fiber Optic Rotary Joints Market Size

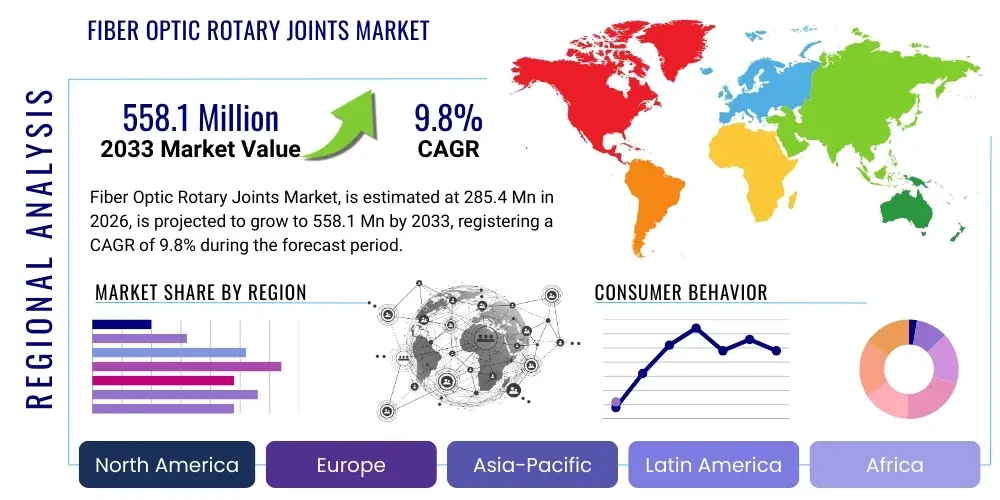

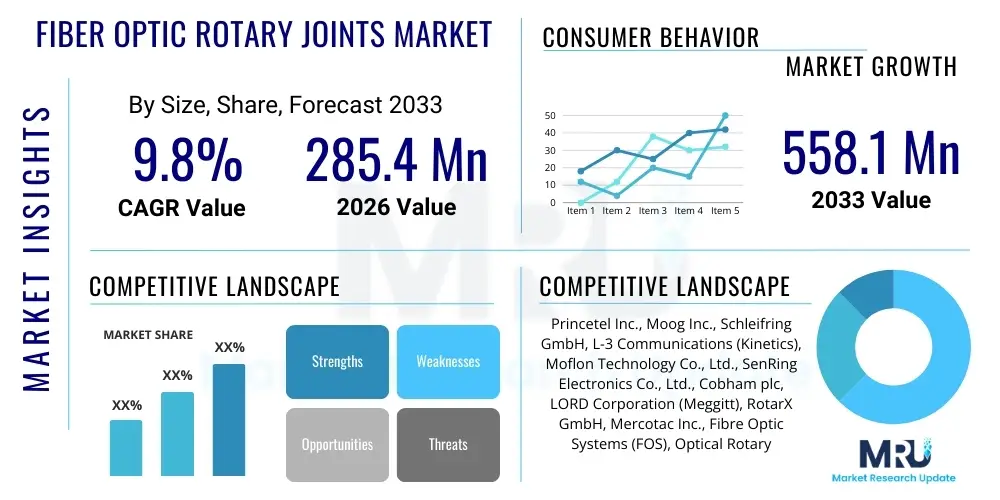

The Fiber Optic Rotary Joints Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 285.4 Million in 2026 and is projected to reach USD 558.1 Million by the end of the forecast period in 2033. This growth is primarily driven by the escalating demand for high-bandwidth, reliable data transmission in a multitude of industrial, defense, and medical applications where continuous rotation of components is essential. The increasing complexity of modern machinery, coupled with the miniaturization trend in optical communication components, further propels this market expansion.

Fiber Optic Rotary Joints Market introduction

Fiber Optic Rotary Joints (FORJs) are sophisticated electromechanical devices designed to transmit optical signals across a rotating interface, enabling continuous, high-speed, and low-loss data transfer without twisting optical fibers. These critical components are indispensable in systems requiring simultaneous power and data transmission while undergoing continuous rotation, offering superior signal integrity compared to traditional electrical slip rings. Their fundamental operating principle relies on precisely aligning optical fibers across a rotating junction, ensuring minimal attenuation and back reflection, thus preserving the quality of the optical signal.

Major applications for FORJs span a wide array of industries, including defense and aerospace for radar systems, gimbals, and remotely operated vehicles; medical devices such as CT scanners and surgical instruments; industrial automation for robotics, wind turbines, and material handling equipment; and renewable energy for solar trackers and marine-based systems. The unique ability of FORJs to handle multiple optical channels, different fiber types (single-mode and multi-mode), and various wavelengths makes them highly versatile and adaptable to diverse operational requirements. Their robust construction and capability to withstand harsh environmental conditions further solidify their position as essential components in demanding applications.

The primary benefits of utilizing FORJs include significantly increased data bandwidth, electromagnetic interference (EMI) immunity, extended service life due to non-contact operation, and reduced system complexity by eliminating the need for signal conversion. Key driving factors propelling the market include the global surge in demand for automation and robotics across manufacturing sectors, the rapid expansion of renewable energy infrastructure, particularly offshore wind farms, and continuous advancements in defense and surveillance technologies requiring high-definition data transmission. Furthermore, the growing adoption of fiber optics in medical imaging and therapeutic devices contributes substantially to market growth, underscoring the indispensable role of FORJs in facilitating cutting-edge technological progress.

Fiber Optic Rotary Joints Market Executive Summary

The Fiber Optic Rotary Joints market is witnessing robust growth, propelled by the increasing integration of automation, advanced sensor technologies, and high-bandwidth communication systems across diverse industries. Business trends indicate a strong focus on product miniaturization, multi-channel capabilities, and the development of hybrid FORJs that combine optical and electrical transmission. Manufacturers are strategically investing in research and development to enhance product reliability, extend operational lifetimes, and reduce overall cost, aiming to broaden application horizons and penetrate emerging markets. Furthermore, customization remains a critical differentiator, with companies offering bespoke solutions tailored to specific client requirements, especially in defense, medical, and high-precision industrial sectors. Strategic partnerships and collaborations between FORJ manufacturers and system integrators are also becoming prevalent, facilitating integrated solutions and expanding market reach.

Regional trends reveal North America and Europe as dominant forces, driven by established defense industries, advanced manufacturing bases, and significant investments in renewable energy. However, the Asia Pacific region is rapidly emerging as a high-growth market, attributed to escalating industrialization, burgeoning automation sectors in countries like China, Japan, and South Korea, and substantial government initiatives supporting technological advancements. Latin America, the Middle East, and Africa are also showing promising potential, albeit at a slower pace, as infrastructure development and adoption of modern industrial practices gain momentum. Each region presents unique market dynamics, influenced by local regulatory frameworks, technological adoption rates, and economic conditions, necessitating localized market strategies for sustained growth.

Segmentation trends highlight the increasing demand for multi-channel FORJs, driven by complex systems requiring simultaneous transmission of multiple data streams, such as advanced robotics and sophisticated surveillance equipment. Single-mode FORJs are gaining traction due to their ability to support longer distances and higher bandwidths, particularly in telecommunications and high-definition video applications, while multi-mode FORJs continue to be essential in industrial and shorter-range applications. Application-wise, defense and aerospace, industrial automation, and renewable energy sectors remain the largest consumers, with medical and marine applications exhibiting significant growth. The continuous evolution of these end-use sectors, driven by technological innovations and expanding operational requirements, will continue to shape the demand patterns for various FORJ types, emphasizing the market's dynamic and responsive nature to technological shifts.

AI Impact Analysis on Fiber Optic Rotary Joints Market

Common user questions regarding AI's impact on the Fiber Optic Rotary Joints market often revolve around its potential to enhance FORJ design and manufacturing, improve predictive maintenance, and drive new application demands. Users are keen to understand if AI can optimize material selection for better performance and durability, streamline assembly processes for increased precision, and develop intelligent monitoring systems for FORJs to predict failures before they occur. There's also significant interest in how AI-powered autonomous systems, robotics, and smart infrastructure will amplify the need for reliable, high-bandwidth data transmission across rotating interfaces, thereby creating new market opportunities for advanced FORJs. Concerns often include the complexity of integrating AI into existing manufacturing workflows and the data security implications of AI-driven monitoring.

- AI-driven optimization in FORJ design can lead to enhanced performance, reduced signal loss, and extended operational lifespan through advanced material simulation and structural analysis.

- Predictive maintenance for FORJs, enabled by AI algorithms analyzing operational data, can anticipate potential failures, minimize downtime, and reduce maintenance costs for critical applications.

- Increased adoption of AI-powered autonomous systems and robotics across industries will generate a higher demand for sophisticated multi-channel FORJs capable of handling vast amounts of real-time data from sensors and control systems.

- AI can facilitate more efficient quality control and anomaly detection during the manufacturing process of FORJs, improving production yields and ensuring higher product consistency.

- The development of smart factories and Industry 4.0 initiatives, heavily reliant on AI for operational intelligence, will necessitate robust and reliable fiber optic communication links for rotating machinery, thus expanding the FORJ market.

- AI-enabled sensor fusion in defense and surveillance applications, requiring real-time processing of high-definition video and radar data, will drive the demand for high-bandwidth, low-latency FORJs.

DRO & Impact Forces Of Fiber Optic Rotary Joints Market

The Fiber Optic Rotary Joints market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form its Impact Forces. A primary driver is the accelerating global adoption of automation and robotics across manufacturing, logistics, and healthcare sectors, which inherently require continuous, high-speed data transfer across rotating axes. The burgeoning demand for high-bandwidth communication in defense, surveillance, and aerospace applications, coupled with the rapid expansion of renewable energy infrastructure such as wind turbines and solar trackers, further propels market growth. The inherent benefits of FORJs, including EMI immunity, high data rates, and long operational life, make them indispensable in these critical applications, substituting traditional electrical slip rings where high performance and reliability are paramount. Advancements in fiber optic technology, leading to smaller, more efficient, and multi-channel FORJs, also serve as a strong market impetus.

Conversely, the market faces several significant restraints that could impede its growth trajectory. The relatively high initial cost of FORJ systems compared to conventional electrical slip rings can be a barrier to adoption for cost-sensitive applications, particularly in developing economies. Technical complexities associated with the precision manufacturing and stringent environmental sealing requirements of FORJs also present challenges, leading to higher production costs and potentially limiting market entry for new players. Furthermore, the limited awareness and understanding of FORJ technology among potential end-users in certain traditional industrial sectors can hinder market penetration. The reliance on highly specialized manufacturing processes and a skilled workforce also poses a constraint, making scalability and rapid production increases more challenging.

Despite these restraints, numerous opportunities are emerging that promise to fuel future market expansion. The miniaturization of FORJs opens new avenues in compact medical devices, wearables, and advanced drone technology, where space and weight are critical considerations. The development of hybrid FORJs, which integrate both optical and electrical transmission capabilities, offers a versatile solution for systems requiring both power and data, thereby expanding their applicability. Furthermore, the increasing investment in smart cities, IoT infrastructure, and underwater communication systems presents untapped potential for FORJ deployment. Emerging applications in entertainment, simulation, and virtual reality also offer niche but high-growth opportunities. Continuous research and development into new materials and manufacturing techniques to improve performance, reduce cost, and enhance durability will unlock further market prospects, solidifying the long-term growth potential of the Fiber Optic Rotary Joints market.

Segmentation Analysis

The Fiber Optic Rotary Joints market is comprehensively segmented across various parameters, including channel type, fiber type, application, and end-user industry. This segmentation provides a granular view of market dynamics, allowing for a detailed analysis of demand patterns, technological preferences, and regional consumption trends. Understanding these segments is crucial for manufacturers to tailor their product offerings, for suppliers to optimize their distribution channels, and for investors to identify high-growth areas within this specialized market. The intricate nature of FORJ technology necessitates a multi-faceted approach to market analysis, reflecting the diverse requirements of its end-use sectors.

- By Channel Type:

- Single-Channel FORJ

- Multi-Channel FORJ

- By Fiber Type:

- Single-Mode Fiber Optic Rotary Joint

- Multi-Mode Fiber Optic Rotary Joint

- By Application:

- Defense & Aerospace

- Industrial Automation (Robotics, Material Handling, Packaging)

- Renewable Energy (Wind Turbines, Solar Trackers)

- Medical & Healthcare (CT Scanners, Surgical Equipment)

- Marine & Subsea (ROVs, AUVs, Offshore Oil & Gas)

- Telecommunications & Broadcast

- Oil & Gas Exploration

- Test & Measurement

- Others (Entertainment, Simulation, etc.)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Fiber Optic Rotary Joints Market

The value chain for the Fiber Optic Rotary Joints market is characterized by several critical stages, beginning with upstream raw material suppliers and extending through manufacturing, assembly, and downstream distribution to end-users. Upstream analysis involves the procurement of highly specialized optical fibers, precision mechanical components (such as bearings, housings, and connectors), and advanced optical alignment components. Suppliers in this segment must meet stringent quality standards and often provide customized materials to ensure the high precision and reliability required for FORJ performance. This stage is crucial as the quality of raw materials directly impacts the optical and mechanical integrity of the final product, influencing factors such as signal loss, rotational accuracy, and operational lifespan.

The midstream segment comprises the core manufacturing and assembly processes. This highly technical phase involves precise machining of mechanical parts, integration of optical components with sub-micron accuracy, and specialized bonding techniques to ensure robust and stable optical pathways. Manufacturers leverage advanced engineering capabilities, including CAD/CAM, optical alignment systems, and cleanroom environments, to produce FORJs that meet exact specifications for multi-channel, single-mode, or multi-mode applications. Quality control and testing are paramount at this stage to verify optical performance, rotational dynamics, and environmental durability before products move further down the chain. The expertise and proprietary technologies developed in this segment are key differentiators among market players.

Downstream analysis encompasses the distribution channels, which can be direct or indirect, leading to the end-users. Direct sales are common for specialized, high-value, and custom-engineered FORJs, where manufacturers engage directly with large defense contractors, industrial automation integrators, or medical device OEMs. This approach allows for closer collaboration, technical support, and tailored solutions. Indirect channels involve distributors, value-added resellers, and system integrators who serve a broader customer base, including smaller businesses or those requiring standard FORJ products. These intermediaries often provide local inventory, technical support, and integration services, expanding market reach. Effective distribution strategies are vital to ensure timely delivery and efficient market penetration, especially given the global nature of the end-user industries that rely on FORJ technology.

Fiber Optic Rotary Joints Market Potential Customers

The potential customers for Fiber Optic Rotary Joints are diverse and span across multiple high-tech and industrial sectors, primarily comprising organizations that require the reliable transmission of high-bandwidth optical signals across rotating interfaces. These end-users typically operate sophisticated machinery and systems where traditional electrical slip rings are inadequate due to bandwidth limitations, EMI susceptibility, or specific environmental demands. Key customers include original equipment manufacturers (OEMs) of complex machinery, system integrators developing advanced solutions, and research institutions pushing the boundaries of technology. Their common need is robust, high-performance data transfer in dynamic environments, making FORJs an essential component in their operational success.

Within the defense and aerospace sector, major customers include government defense agencies, aerospace manufacturers, and contractors specializing in radar systems, missile guidance, remotely operated vehicles (ROVs), unmanned aerial vehicles (UAVs), and gimbals for cameras and sensors. These entities demand FORJs with extreme reliability, shock resistance, and performance in harsh conditions. In the industrial automation domain, potential customers are robotics manufacturers, producers of automated guided vehicles (AGVs), material handling system integrators, and companies involved in automated inspection and assembly lines. These customers seek FORJs to facilitate continuous communication between stationary and rotating parts in complex robotic arms and production machinery, enhancing efficiency and operational precision.

Other significant customer segments include renewable energy companies, particularly developers and operators of wind turbines and solar trackers, who utilize FORJs for transmitting control signals and data from rotating components. The medical and healthcare industry also represents a growing customer base, with manufacturers of advanced medical imaging equipment such as CT scanners, MRI systems, and surgical robots requiring high-precision FORJs for real-time data transmission. Additionally, marine and subsea exploration companies, telecommunications infrastructure developers, and specialized test and measurement equipment manufacturers form important customer groups, all relying on the superior capabilities of Fiber Optic Rotary Joints to ensure seamless and high-integrity data flow in their respective applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.4 Million |

| Market Forecast in 2033 | USD 558.1 Million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Princetel Inc., Moog Inc., Schleifring GmbH, L-3 Communications (Kinetics), Moflon Technology Co., Ltd., SenRing Electronics Co., Ltd., Cobham plc, LORD Corporation (Meggitt), RotarX GmbH, Mercotac Inc., Fibre Optic Systems (FOS), Optical Rotary Joints (ORJ), Diamond SA, SPINNER GmbH, Shanghai DaHe Electronics Technology Co., Ltd., JINPAT Electronics, Foring Transmisson, Advanced Fiber Products, Ltd., Shenzhen Greatview Optical Co., Ltd., Shanghai OMNISAFE Opto-Electronic Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fiber Optic Rotary Joints Market Key Technology Landscape

The Fiber Optic Rotary Joints market is underpinned by a sophisticated technology landscape, continually evolving to meet increasing demands for higher performance, greater reliability, and expanded functionality. Core technologies primarily revolve around precision optical alignment, robust mechanical design, and advanced materials science. Optical alignment technology, crucial for minimizing signal loss and back reflection, often involves specialized lenses, prisms, or mirrors that precisely direct light across the rotational interface. This requires ultra-high precision manufacturing techniques, typically within cleanroom environments, to ensure that the optical path remains stable and aligned even under continuous rotation and varying environmental conditions, often leveraging automated optical assembly systems for consistency and accuracy.

Mechanical design technology focuses on ensuring durability, smooth rotation, and resistance to environmental factors such as vibration, shock, temperature fluctuations, and moisture. This includes the selection of high-grade bearings (e.g., precision ball bearings or air bearings for ultra-smooth operation), robust housing materials, and advanced sealing mechanisms to protect sensitive optical components. The design must also accommodate various rotational speeds and torque requirements, from slow, precise movements to high-speed continuous rotation. Furthermore, miniaturization techniques are becoming increasingly vital, allowing FORJs to be integrated into compact systems without compromising performance, often requiring micro-machining and advanced fabrication methods to achieve small footprints.

The development of multi-channel and hybrid FORJs represents another significant technological advancement. Multi-channel FORJs utilize sophisticated optical multiplexing or multiple discrete optical paths to transmit several independent data streams simultaneously, crucial for complex systems like advanced robotics or high-definition surveillance. Hybrid FORJs integrate both optical and electrical slip rings into a single unit, providing a versatile solution for applications requiring simultaneous power, data, and signal transmission, often involving complex integration challenges and electromagnetic compatibility considerations. Ongoing research into new optical materials, advanced fiber types (e.g., polarization-maintaining fibers), and non-contact optical coupling methods continues to push the boundaries of FORJ capabilities, aiming for even lower insertion loss, higher bandwidths, and extended operational lifespans to support the next generation of interconnected and automated systems.

Regional Highlights

- North America: A mature market driven by significant defense spending, robust industrial automation sectors, and early adoption of advanced medical technologies. The presence of key market players and substantial R&D investments in optical communication further solidify its leading position.

- Europe: Characterized by strong growth in renewable energy (especially offshore wind), advanced manufacturing, and a prominent aerospace industry. Strict regulatory standards and a focus on high-quality, durable components fuel demand for premium FORJ solutions.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization, massive investments in infrastructure development, and the burgeoning electronics and automotive sectors. China, Japan, and South Korea are key contributors, with increasing adoption of robotics and automation.

- Latin America: An emerging market with growing investments in oil and gas exploration, mining, and renewable energy projects. Demand for FORJs is gradually increasing as countries upgrade their industrial infrastructure and adopt modern technologies.

- Middle East & Africa (MEA): Shows promising growth potential, particularly in defense, oil & gas, and renewable energy sectors. Infrastructure development projects and diversification efforts away from traditional industries are driving the adoption of advanced industrial components like FORJs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fiber Optic Rotary Joints Market.- Princetel Inc.

- Moog Inc.

- Schleifring GmbH

- L-3 Communications (Kinetics)

- Moflon Technology Co., Ltd.

- SenRing Electronics Co., Ltd.

- Cobham plc

- LORD Corporation (Meggitt)

- RotarX GmbH

- Mercotac Inc.

- Fibre Optic Systems (FOS)

- Optical Rotary Joints (ORJ)

- Diamond SA

- SPINNER GmbH

- Shanghai DaHe Electronics Technology Co., Ltd.

- JINPAT Electronics

- Foring Transmisson

- Advanced Fiber Products, Ltd.

- Shenzhen Greatview Optical Co., Ltd.

- Shanghai OMNISAFE Opto-Electronic Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Fiber Optic Rotary Joints market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Fiber Optic Rotary Joint (FORJ)?

A Fiber Optic Rotary Joint (FORJ) is an electromechanical device that transmits optical signals across a rotating interface, allowing continuous, high-speed, and low-loss data transfer without twisting optical fibers. It ensures signal integrity in systems requiring both rotation and high-bandwidth communication.

What are the main applications of FORJs?

FORJs are primarily used in defense and aerospace (radar, gimbals, ROVs), industrial automation (robotics, wind turbines), medical devices (CT scanners, surgical instruments), marine and subsea systems, and telecommunications for reliable data transmission during continuous rotation.

What is the difference between single-mode and multi-mode FORJs?

Single-mode FORJs are designed for single-mode fibers, offering higher bandwidth and longer transmission distances, typically used in telecommunications and high-definition sensing. Multi-mode FORJs are for multi-mode fibers, suitable for shorter distances and industrial applications with larger core diameters.

How do FORJs enhance system performance compared to electrical slip rings?

FORJs offer superior performance by providing significantly higher data bandwidth, complete immunity to electromagnetic interference (EMI), reduced signal loss, and extended operational lifespan due to non-contact optical transmission, making them ideal for high-precision and data-intensive applications.

What factors are driving the growth of the FORJ market?

Key drivers include the global expansion of industrial automation and robotics, increasing demand for high-bandwidth communication in defense and aerospace, growth in renewable energy infrastructure (wind turbines), and advancements in medical imaging and surgical technologies requiring continuous data transfer.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager