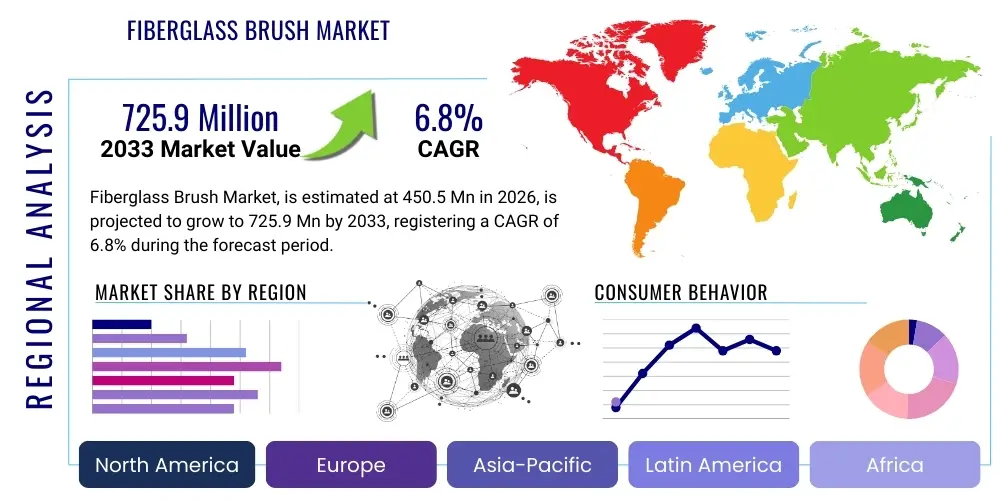

Fiberglass Brush Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443453 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Fiberglass Brush Market Size

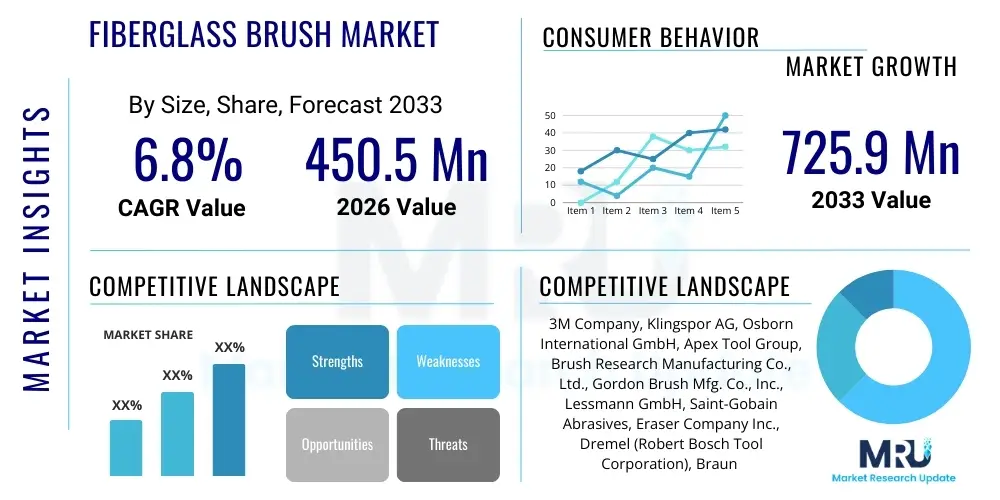

The Fiberglass Brush Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 725.9 Million by the end of the forecast period in 2033.

Fiberglass Brush Market introduction

The Fiberglass Brush Market encompasses specialized abrasive tools manufactured using fine strands of glass fiber, bundled or mounted onto various holders such as pens, wheels, or handheld formats. These instruments are highly valued across numerous industries due to their unique ability to provide highly controlled, non-scratch, and non-contaminating abrasive action, distinguishing them from traditional metal wire brushes. Fiberglass brushes excel in tasks requiring precision, such as surface preparation, residue removal from sensitive materials, and detailed cleaning of intricate components where aggressive abrasion is detrimental. Their primary function revolves around light deburring, cleaning solder flux from printed circuit boards (PCBs), removing corrosion and oxidation layers, and preparing small areas for specialized bonding or finishing operations.

Major applications of fiberglass brushes span across the electronics manufacturing sector, particularly in PCB repair and rework, where the necessity for precision cleaning without substrate damage is paramount. Furthermore, they are extensively utilized in automotive restoration for detailed rust removal in crevices, jewelry manufacturing for delicate polishing and cleaning, and in aerospace maintenance for non-destructive testing preparation. The core benefit these brushes offer lies in their fine abrasive capability, allowing technicians to achieve high surface purity and preparation standards crucial for subsequent processes like soldering, coating, or inspection. This gentle yet effective abrasion profile is instrumental in maintaining the integrity of highly sensitive materials, driving their adoption across high-reliability applications.

Key driving factors propelling the market include the exponential growth in the global electronics industry, characterized by miniaturization and increasing complexity of PCBs, demanding superior tools for rework and maintenance. The stringent quality standards in critical sectors like aerospace and medical device manufacturing necessitate tools capable of achieving extremely high surface cleanliness without cross-contamination. Moreover, the increasing adoption of fiberglass brushes in niche applications, such as detailed art conservation and restoration, further contributes to market momentum. Continuous product innovation focusing on ergonomic design and integration into automated systems also fuels demand, expanding their utility beyond traditional manual operations into semi-automated production lines.

Fiberglass Brush Market Executive Summary

The Fiberglass Brush Market is characterized by robust expansion driven primarily by technological advancements in electronics manufacturing and the growing demand for precision cleaning tools across high-value industrial segments. Current business trends indicate a strong shift toward specialized, application-specific brushes, such as pen-style brushes optimized for intricate PCB rework and larger wheel-style brushes tailored for industrial surface preparation. Manufacturers are focusing on enhancing the abrasive resilience and longevity of the fiberglass filaments while also developing environmentally compliant resin binders. Strategic alliances between brush manufacturers and equipment integrators are becoming prevalent, aiming to incorporate fiberglass brush systems into automated cleaning and deburring machinery, thus addressing the labor-intensive nature of manual processes and boosting productivity in high-throughput environments.

Regionally, the Asia Pacific (APAC) market maintains dominance and exhibits the fastest growth trajectory, predominantly due to the region’s massive electronics and automotive manufacturing base, particularly in countries like China, South Korea, and Taiwan. North America and Europe, characterized by established aerospace, medical device, and high-reliability industrial sectors, represent significant revenue contributors, driven by stringent quality control requirements demanding precision surface treatment tools. These mature markets focus heavily on high-specification, premium fiberglass brush variants designed for critical applications. Emerging markets in Latin America and the Middle East & Africa are showing increasing potential, spurred by infrastructural development and burgeoning local electronics assembly capabilities, although market penetration remains lower compared to established industrial zones.

Segmentation analysis highlights the Application segment, particularly the Electronics and Electrical segment, as the primary revenue generator, reflecting the indispensable role of these brushes in semiconductor and circuit board production. Within the Type segmentation, the pen-style fiberglass brush is experiencing high demand due to its unparalleled suitability for localized and highly precise work, contrasting with the high volume usage of wheel-style brushes in broader industrial settings. End-user trends show continuous expansion in the Industrial segment, which includes general maintenance, fabrication, and machinery operations, alongside specialized growth within the DIY and restoration markets where enthusiasts require precise tools for detailed finishes. The overall market trajectory suggests sustained, high-growth potential anchored by continuous innovation and diversification into new materials and critical industrial processes.

AI Impact Analysis on Fiberglass Brush Market

User queries regarding AI's impact on the Fiberglass Brush Market often center on themes of automation in surface preparation, quality control integration, and predictive maintenance of brushing systems. Consumers and industry professionals frequently ask how Artificial Intelligence and Machine Learning (ML) can optimize the usage life of fiberglass filaments, precisely control the contact pressure during automated cleaning processes, and integrate visual inspection systems to assess surface cleanliness instantly post-brushing. The primary concerns revolve around the integration costs of intelligent systems and whether AI can truly replicate the nuanced dexterity required for highly sensitive rework operations, such as fine removal of oxidation layers without damaging micro-components. Expectations are high regarding AI's ability to minimize human error, standardize surface preparation quality across mass production lines, and provide data-driven insights into material degradation and process optimization.

While fiberglass brushes are physical consumables, the value chain surrounding their application is becoming increasingly digitized and optimized using AI/ML methodologies. The immediate impact is less on the brush itself and more on the machinery that utilizes it. AI-powered robotics are being developed to execute repetitive and high-precision brushing tasks, ensuring consistent force application and path planning, which directly maximizes brush efficiency and component yield. Furthermore, predictive analytics models leverage sensor data—such as torque, vibration, and temperature—to forecast the optimal replacement time for fiberglass brushes, moving away from reactive maintenance and reducing unplanned downtime in critical manufacturing environments, particularly in aerospace component cleaning and electronics assembly.

This technological integration fosters higher demand for consistent, high-quality brush supplies compatible with automated systems, necessitating tighter manufacturing tolerances for brush geometry and density. AI also plays a crucial role in enhancing product development by simulating wear patterns and testing new filament composite materials under various operating conditions, drastically reducing the physical prototyping phase. Manufacturers are thus adapting by creating 'smart brushes' or associated sensor packages that provide real-time operational feedback, enabling true closed-loop optimization of the surface treatment process, leading to superior quality control and improved cost-effectiveness for end-users relying on high-volume or ultra-precision applications.

- AI-driven Robotic Integration: Enables precise, automated brushing for consistent surface finish and standardized quality in electronics and automotive sectors.

- Predictive Maintenance: ML algorithms analyze real-time usage data (pressure, speed, vibration) to forecast fiberglass brush wear, optimizing replacement schedules and reducing downtime.

- Quality Control (QC): AI-powered vision systems rapidly inspect surfaces post-brushing, ensuring removal of contaminants and compliance with micro-level cleanliness standards.

- Process Optimization: AI fine-tunes operational parameters (speed, trajectory, contact angle) to maximize brush lifespan and minimize damage to delicate substrates like PCBs.

- Manufacturing Enhancement: AI/ML simulates material performance, accelerating the development of specialized, more durable fiberglass filament compositions.

DRO & Impact Forces Of Fiberglass Brush Market

The dynamics of the Fiberglass Brush Market are shaped by a complex interplay of internal and external forces, summarized through the Drivers, Restraints, and Opportunities (DRO). The primary driving force is the relentless demand from the electronics sector for superior tools for cleaning and reworking delicate Printed Circuit Boards (PCBs), where fiberglass brushes offer a unique balance of cleaning efficacy and low substrate damage potential. This driver is amplified by the global trend toward miniaturization, necessitating finer and more controlled abrasive processes. Conversely, the market faces constraints related to the inherent fragility of fiberglass filaments, leading to concerns regarding particle shedding and potential contamination in ultra-clean environments, which mandates careful procedural adherence and disposal protocols. Opportunities are abundant in the development of specialized, non-shedding brush materials and expansion into high-growth applications such as battery manufacturing and advanced material surface preparation, enabling market players to capture significant value by innovating product delivery and material composition.

Drivers: The increasing complexity of modern industrial maintenance, repair, and overhaul (MRO) activities necessitates highly specialized tools that can perform non-destructive surface treatments. Fiberglass brushes are essential in sectors like aerospace MRO for tasks such as cleaning turbine blades before Non-Destructive Testing (NDT) or removing light corrosion without altering critical tolerances. Furthermore, the burgeoning demand for vintage restoration across automotive and antique markets provides a robust, albeit niche, consumer base that values the meticulous and controlled abrasion offered by fiberglass pen brushes. The adoption rate is also positively influenced by standardization efforts in quality assurance processes within high-reliability industries, where consistency in surface preparation is a non-negotiable requirement for regulatory compliance and product reliability. These factors collectively push manufacturers towards higher volume production and product diversity.

Restraints: Significant restraints include the health and safety concerns associated with handling shed fiberglass particles, which can be respiratory or skin irritants, requiring users to employ stringent Personal Protective Equipment (PPE) and adequate ventilation. This regulatory burden and the associated operational costs sometimes steer smaller users toward alternative, less effective, but perceived safer cleaning methods. Additionally, the relatively short service life of certain fiberglass brush variants, particularly those subjected to high rotational speeds or aggressive usage, results in frequent replacement cycles, which can be perceived as high operational expenditure compared to durable wire brushes for less sensitive applications. Finally, market fragmentation and the proliferation of low-quality, inexpensive imports compromise both pricing stability and end-user trust in the performance consistency of the product category, particularly impacting brand perception in developing regions.

Opportunities: Opportunities lie in penetrating emerging industrial sectors that prioritize precision surface treatment, such as the electric vehicle (EV) battery manufacturing ecosystem, where precise cleaning of connecting surfaces and busbars is critical for weld integrity and long-term performance. Developing automated, enclosed brushing systems that mitigate the particle shedding risk presents a major innovation pathway, opening doors to integration in cleanroom environments. Furthermore, R&D focused on producing fiberglass composite filaments with enhanced flexibility, reduced shedding, and improved chemical resistance will allow manufacturers to differentiate their offerings and command premium pricing. Geographic expansion into under-penetrated industrial clusters in Southeast Asia and Africa, coupled with strategic partnerships with major industrial distributors, offers substantial growth avenues. The transition toward sustainable and bio-degradable components within the brush structure, excluding the fiberglass itself, also presents a lucrative pathway for eco-conscious market positioning.

Segmentation Analysis

The Fiberglass Brush Market is comprehensively segmented based on Type, Application, and End-Use, reflecting the diverse requirements across the industrial landscape. The segmentation by Type delineates between pen-style, wheel-style, and handheld brushes, each catering to distinct operational needs—from intricate, localized rework (pen-style) to broad industrial cleaning (wheel-style). Application segmentation highlights the critical role of these brushes in electronics, automotive, aerospace, and jewelry sectors, demonstrating their versatility across materials and precision levels. The End-Use segmentation further categorizes demand into industrial, commercial, and DIY segments, correlating product specifications with user expertise and volume usage. Detailed analysis of these segments is crucial for identifying high-growth pockets and tailoring marketing strategies to specific user demands, optimizing product portfolio management and distribution channels across varying industrial supply chains globally.

The functional diversity inherent in the Type segment is paramount to market success. Pen-style brushes, often retractable and highly portable, are indispensable tools for electronic technicians requiring pinpoint accuracy for cleaning solder flux residues or removing minute scratches on sensitive components. Their small diameter and ergonomic design facilitate meticulous control, essential for high-precision tasks that cannot be accomplished with larger tools. Conversely, wheel-style brushes, designed for mounting on bench grinders or automated machinery, target high-volume applications such as industrial deburring of small metal parts or rapid surface preparation over larger areas, prioritizing speed and uniformity of abrasion over intricate detail. The differentiation between these types allows manufacturers to capture demand across the entire spectrum of required abrasion levels and operational scales, from laboratory settings to heavy manufacturing floors.

Growth in the Application segment is largely dominated by the Electronics industry, which continuously drives innovation in brush characteristics, demanding finer filaments and enhanced non-contaminating properties suitable for cleanroom environments. However, the Automotive segment, particularly in high-end classic car restoration and specialized electric vehicle maintenance, shows significant growth potential as fiberglass brushes are favored for cleaning intricate wiring harnesses and preparing surfaces for advanced coating applications. The interplay between Type and Application segments determines pricing power and market share; for instance, specialized, non-contaminating pen brushes designed for aerospace applications command significantly higher margins than general-purpose wheel brushes used for general fabrication maintenance. Understanding these cross-segment dynamics is essential for strategic market positioning and capital investment in manufacturing capabilities.

- By Type:

- Pen-style Fiberglass Brushes (Retractable and Fixed)

- Wheel-style Fiberglass Brushes (Mandrel Mounted and Arbor Hole)

- Handheld/Block Fiberglass Brushes

- Fiberglass Brush Inserts and Refills

- By Application:

- Electronics Manufacturing and Rework (PCB Cleaning, Flux Removal)

- Automotive Maintenance and Restoration (Rust Removal, Detail Cleaning)

- Aerospace and Defense (Component Cleaning, NDT Preparation)

- Jewelry and Watchmaking (Polishing, Oxidation Removal)

- Industrial Maintenance and Repair (MRO)

- Art Conservation and Restoration

- By End-Use:

- Industrial (Heavy Manufacturing, Fabrication, Assembly Lines)

- Commercial (Repair Shops, Specialized Service Providers)

- DIY and Consumer Use (Hobbyists, Restoration Enthusiasts)

Value Chain Analysis For Fiberglass Brush Market

The Value Chain for the Fiberglass Brush Market begins with the upstream sourcing and processing of raw materials, primarily focusing on high-quality glass fibers, various binding resins, and handle materials (plastic, metal, wood). Upstream efficiency is critical, as the purity and consistency of the glass fiber strands directly dictate the final brush performance, abrasion characteristics, and resistance to shedding. Key suppliers in this stage are specialized chemical and glass fiber manufacturers who provide the basic filament bundles, often requiring customization in diameter and density. Manufacturers must establish stable, reliable relationships with these suppliers to ensure a consistent inflow of specialized materials compliant with industry standards, minimizing volatility in production costs and maintaining product quality essential for precision applications like electronics rework.

Midstream activities involve the core manufacturing processes: bundling, cutting, shaping, and mounting the fiberglass filaments into the final brush product forms (pen, wheel, or block). This stage requires specialized machinery for precise filament placement and curing of the resin binders, which ensure the durability and integrity of the brush structure. Quality control checkpoints are rigorous, especially for pen-style brushes, focusing on the concentricity and consistent protrusion length of the bristles. Distribution channels then move the finished goods downstream. The market relies on a multi-tiered distribution network encompassing direct sales to large industrial users (especially aerospace and electronics giants), partnerships with global industrial distributors (e.g., Grainger, Fastenal), and engagement with specialized electronics and jewelry supply retailers. E-commerce platforms are increasingly vital, serving the fragmented DIY and small commercial repair segments globally, necessitating efficient logistics and inventory management.

The downstream analysis focuses on the end-users and the service support provided post-sale. For large industrial clients, technical support regarding optimal usage parameters, safety protocols (due to particle shedding risks), and waste disposal compliance is crucial, adding value beyond the physical product. Direct sales channels often facilitate this high-level technical consultation. In contrast, the consumer and small commercial segments rely heavily on product availability through indirect channels and clear usage instructions provided via packaging and online resources. The increasing complexity of applications, especially in micro-electronics, requires continuous feedback loops from end-users to the manufacturers to drive product refinement, ensuring that fiberglass brush specifications evolve in tandem with industrial requirements, maintaining relevance and competitive edge in specialized cleaning and surface preparation tasks.

Fiberglass Brush Market Potential Customers

Potential customers for the Fiberglass Brush Market are diverse, spanning multiple high-tech industrial sectors, specialized repair operations, and consumer segments focused on detailed restoration. The primary and highest-value customers reside in the Electronics Manufacturing Services (EMS) industry, including OEMs and repair facilities focused on Printed Circuit Boards (PCBs). These entities utilize fiberglass brushes extensively for cleaning solder flux residue, removing oxidation from component pads prior to soldering, and performing intricate rework and repair of micro-components. Their purchasing decisions are driven by brush consistency, minimal particle shedding characteristics, and compatibility with cleanroom protocols, leading them to favor high-specification, premium pen-style brushes that offer precise control necessary for modern, high-density PCBs.

Another significant customer segment is the Automotive industry, particularly those involved in engine rebuilding, chassis restoration, and specialized electrical system maintenance. Fiberglass brushes are essential tools for detail work such as cleaning spark plug threads, removing light rust from metal components in confined spaces, or preparing battery terminals for welding and connections in Electric Vehicles (EVs). These customers seek brushes offering high durability and effective, yet non-destructive, abrasion. Similarly, the Aerospace and Defense sector represents a high-value, albeit volume-constrained, customer base. Companies in this sector use brushes for preparing critical components for Non-Destructive Testing (NDT), removing corrosion on aircraft skin, and cleaning precision machined parts, where material integrity must be preserved at all costs, demanding brushes with verifiable quality assurance and material composition specifications.

Beyond heavy industry, niche markets provide substantial revenue streams. Jewelry and watch repair professionals utilize extremely fine fiberglass brushes for cleaning intricate mechanisms and polishing precious metals without harsh chemicals. Furthermore, the large global market of hobbyists, model makers, and antique restoration specialists forms the DIY/Consumer end-user segment. These buyers, typically sourcing through retail hardware stores or e-commerce platforms, require versatile, easy-to-use, and affordable handheld brushes for detailed cleaning, crafting, and small-scale restoration projects. Catering to this fragmented market requires robust retail distribution and focused marketing on ease of use and versatility, complementing the technical focus applied to the high-volume industrial buyer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 725.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Klingspor AG, Osborn International GmbH, Apex Tool Group, Brush Research Manufacturing Co., Ltd., Gordon Brush Mfg. Co., Inc., Lessmann GmbH, Saint-Gobain Abrasives, Eraser Company Inc., Dremel (Robert Bosch Tool Corporation), Braun Corporation, Merit Abrasives, PFERD INC., Abtex Corporation, Weiler Abrasives Group, Tanis Inc., Schaefer Brush Manufacturing, Cratex Manufacturing Co., Inc., Spiral Brushes Inc., Power-Pipe Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fiberglass Brush Market Key Technology Landscape

The technology landscape of the Fiberglass Brush Market is primarily centered around material science advancements and precision manufacturing techniques required to produce high-performance filaments and robust brush structures. Key technological focus areas include developing ultra-fine fiberglass filaments with enhanced uniformity and reduced fragility to minimize shedding, a critical requirement for controlled environments. Furthermore, manufacturers are investing in research to optimize the resin binder formulations used to encapsulate the filaments, aiming to improve chemical resistance, thermal stability, and overall structural integrity, thereby extending the brush's operational lifespan under harsh industrial conditions. Automation technologies in the manufacturing process, such as precision CNC bundling and laser-guided cutting, ensure highly consistent brush geometry and filament density, which are essential for repeatable results in automated end-user applications like robotic cleaning systems.

Beyond the material composition, a significant technological driver is the integration of fiberglass brushes into advanced power tool systems and semi-automated machinery. This involves engineering brush designs compatible with high-speed rotary tools while maintaining minimal vibration and ensuring secure mounting mechanisms, particularly for wheel-style variants used in industrial deburring. The retraction mechanism technology in pen-style brushes is also a continuous focus for innovation, ensuring smooth, precise extension and retraction of the filaments, crucial for delicate hand rework tasks. This mechanism often incorporates sophisticated springs and locking collars that prevent accidental filament withdrawal or over-extension, directly impacting the user control and lifespan of the precision tool, catering to the exacting standards of micro-electronics technicians who rely on tactile feedback for damage prevention.

Future technology is expected to converge with sustainability and sensor integration. Research is being conducted on composite brush head materials that may incorporate recycled or biodegradable components to address environmental concerns associated with disposable plastics. Furthermore, technological advancements are enabling the embedding of micro-sensors within brush holders or robotic end-effectors. These sensors monitor parameters like applied force, rotational speed, and friction heat in real-time. This integration facilitates data collection necessary for AI-driven process optimization, allowing industrial users to achieve unprecedented levels of precision and quality control, thereby transforming the fiberglass brush from a simple consumable tool into a component of an intelligent surface preparation system. This technological evolution underscores the market's shift toward high-value, data-enabled solutions.

Regional Highlights

The Fiberglass Brush Market exhibits significant regional disparities in demand and growth drivers, heavily influenced by local industrial specialization and manufacturing capacity.

- Asia Pacific (APAC): APAC is the dominant market region and is projected to maintain the highest growth rate throughout the forecast period. This dominance is intrinsically linked to the region’s status as the global manufacturing hub for electronics, automotive components, and general industrial fabrication. Countries like China, South Korea, Taiwan, and Vietnam have burgeoning electronics assembly and repair markets that heavily rely on fiberglass brushes for PCB rework and quality control. Government initiatives supporting local manufacturing and massive foreign direct investment in high-tech assembly lines further cement APAC’s leading position, driving massive volume consumption of both pen-style and industrial wheel-style brushes.

- North America: North America represents a mature, high-value market characterized by stringent quality standards in aerospace, medical devices, and high-reliability defense manufacturing. Demand here is driven less by volume and more by the necessity for highly specialized, premium fiberglass brushes that meet exacting specifications for non-destructive surface preparation. The robust MRO (Maintenance, Repair, and Overhaul) sector in the US, particularly for aircraft and complex machinery, is a primary consumer. Furthermore, a strong culture of DIY and classic restoration contributes substantially to the consumer segment, ensuring stable demand across both professional and retail channels.

- Europe: Europe holds a strong position, fueled by its advanced automotive industry (especially Germany and Italy) and precision engineering sectors. Strict environmental and occupational safety regulations in the EU compel end-users to seek out high-quality brushes that minimize particle shedding and adhere to rigorous health standards, favoring reputable brands and certified products. The demand is concentrated in Western European nations with established industrial bases, emphasizing high-precision applications in micro-mechanics, tool and die cleaning, and advanced material surface treatment prior to coating or inspection.

- Latin America, Middle East, and Africa (LAMEA): These regions currently hold smaller market shares but offer long-term growth potential. Demand is gradually increasing due to infrastructural development, growing regional electronics assembly operations (e.g., in Mexico and Brazil), and investments in oil & gas and mining sectors requiring robust MRO tools. Market penetration in MEA is largely concentrated in industrialized zones, driven by foreign construction and maintenance contracts. As industrialization accelerates, particularly in South Africa and the UAE, the adoption of fiberglass brushes for precision cleaning and maintenance will expand significantly.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fiberglass Brush Market.- 3M Company

- Klingspor AG

- Osborn International GmbH

- Apex Tool Group

- Brush Research Manufacturing Co., Ltd.

- Gordon Brush Mfg. Co., Inc.

- Lessmann GmbH

- Saint-Gobain Abrasives

- Eraser Company Inc.

- Dremel (Robert Bosch Tool Corporation)

- Braun Corporation

- Merit Abrasives

- PFERD INC.

- Abtex Corporation

- Weiler Abrasives Group

- Tanis Inc.

- Schaefer Brush Manufacturing

- Cratex Manufacturing Co., Inc.

- Spiral Brushes Inc.

- Power-Pipe Inc.

Frequently Asked Questions

Analyze common user questions about the Fiberglass Brush market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of fiberglass brushes in modern electronics manufacturing?

Fiberglass brushes are essential in electronics for precision rework and cleaning, primarily used to meticulously remove solder flux residue from Printed Circuit Boards (PCBs) and to strip thin layers of oxidation from component pads before soldering. Their non-metallic and controlled abrasive nature prevents damage to delicate circuits and micro-components, ensuring surface preparation integrity critical for high-reliability assemblies.

How do fiberglass brushes differ from standard wire or nylon brushes?

Fiberglass brushes utilize extremely fine, controlled glass fiber filaments that provide a much finer and less aggressive abrasive action compared to metal wire brushes, which can scratch sensitive surfaces. Unlike softer nylon brushes, fiberglass offers sufficient rigidity to remove stubborn residue like baked-on flux or light corrosion while minimizing substrate material removal. They are specialized for high-precision, non-contaminating surface preparation.

What safety precautions are necessary when using fiberglass brushes?

Due to the nature of the fiberglass filaments, which can shed micro-particles, users must always wear appropriate Personal Protective Equipment (PPE), including safety glasses and gloves, and preferably use respiratory protection, especially during high-speed applications. Operations should ideally be conducted in well-ventilated areas or utilizing localized dust extraction systems to mitigate exposure to airborne glass particles and prevent skin irritation or inhalation risks.

Which types of fiberglass brushes are most demanded by professional repair technicians?

Professional repair technicians, particularly in electronics and jewelry, exhibit the highest demand for pen-style (retractable) fiberglass brushes. These brushes offer exceptional control and accuracy, allowing technicians to target very small, localized areas for cleaning, polishing, or corrosion removal without affecting surrounding components. Their portability and ergonomic design are key factors driving adoption in field service and bench repair operations.

Is the Fiberglass Brush Market expected to integrate with automation technology?

Yes, the market is increasingly integrating with automation. Industrial wheel-style fiberglass brushes are being incorporated into CNC and robotic deburring/cleaning cells, utilizing AI/ML to optimize contact pressure and speed for standardized quality output. This automation minimizes human error, ensures consistency, and allows fiberglass brushes to perform critical surface preparation tasks in high-throughput manufacturing environments like automotive and aerospace assembly lines.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager