Fingertip Joysticks Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441263 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Fingertip Joysticks Market Size

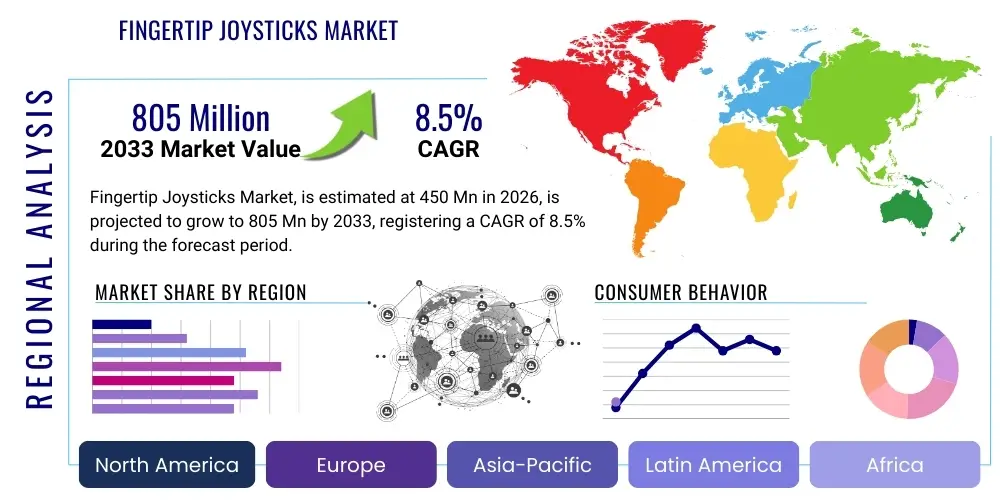

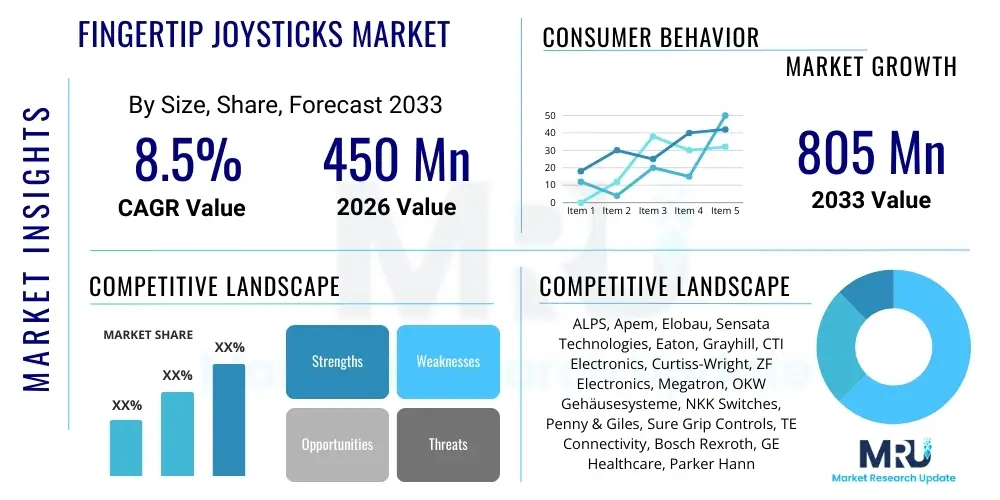

The Fingertip Joysticks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 805 Million by the end of the forecast period in 2033.

Fingertip Joysticks Market introduction

Fingertip joysticks are specialized human-machine interface (HMI) devices designed for high-precision control in applications where space is limited and ergonomic input is crucial. These miniature controllers provide proportional control, translating fine user finger movements into electrical signals for directional or speed manipulation of machinery, systems, or software interfaces. Unlike standard joysticks, fingertip models prioritize miniaturization, high responsiveness, and durability, often incorporating advanced sensing technologies such as Hall effect sensors or force-sensing strain gauges to ensure extended operational life and consistent accuracy. They are fundamentally employed in scenarios demanding nuanced and subtle manipulation, offering a balance between tactile feedback and space-saving design.

The primary applications of fingertip joysticks span across rigorous industrial, medical, and defense sectors. In industrial control, they are integral components in heavy machinery remote controls, complex robotic systems, and precision machine tools where operators require fine tuning capabilities. Medical applications include controlling high-tech surgical robots and motorized wheelchairs, leveraging their smooth operation and reliability. Furthermore, they are extensively utilized in military and aerospace applications, particularly in cockpit controls, drone ground control stations, and surveillance equipment, where robust performance in harsh environments is non-negotiable. The inherent benefits, such as enhanced ergonomic control, space efficiency, and robust construction, position them as critical components for next-generation automated systems.

Market growth is predominantly driven by the accelerating trend of industrial automation globally, which necessitates precise control mechanisms for complex robotic arms and specialized automated vehicles. The continuous miniaturization of electronic components, coupled with increasing demand for highly ergonomic interfaces in demanding environments, further propels adoption. Key drivers also include the rising complexity of surgical procedures requiring robotic assistance and the consistent technological advancements in sensor technology, improving joystick sensitivity and longevity, making them increasingly reliable for critical control functions across diverse high-value industries.

Fingertip Joysticks Market Executive Summary

The global Fingertip Joysticks Market exhibits strong growth momentum, primarily fueled by advancements in precision manufacturing and the widespread integration of automation technologies across key vertical sectors. Business trends highlight strategic partnerships and mergers focused on expanding product portfolios, particularly in force-sensing and non-contact technology domains, aimed at enhancing durability and responsiveness. Leading market participants are investing heavily in R&D to incorporate advanced materials and specialized components that cater to extreme environmental specifications, especially those required by the military and heavy industry sectors. The shift towards IoT-enabled control systems is also driving innovation, compelling manufacturers to develop joysticks with integrated digital communication interfaces, ensuring seamless data transmission and superior diagnostic capabilities for preventative maintenance.

Regionally, the Asia Pacific (APAC) area is emerging as the fastest-growing market, driven by rapid industrialization, large-scale deployment of robotics in manufacturing bases, and significant governmental investments in infrastructure and defense capabilities in countries like China, India, and South Korea. North America remains a crucial market, maintaining leadership in terms of revenue share due to established, high-value end-user industries such as military & aerospace and advanced medical device manufacturing, demanding premium, high-reliability components. Europe demonstrates stable, consistent growth, largely underpinned by stringent regulations promoting ergonomic workplace equipment and the steady adoption of smart factory technologies, particularly in Germany and the Nordic countries, focusing on efficiency and operator safety in sophisticated industrial machinery.

Segment trends reveal that the Force Sensing segment is witnessing the most rapid expansion, favored in applications requiring extremely high sensitivity and minimal physical displacement, thereby reducing wear and tear. Within the application landscape, the Industrial Control sector holds the largest market share, driven by the expanding global fleet of cranes, remote-operated vehicles (ROVs), and specialized construction equipment. However, the Medical Devices segment is projected to show the highest CAGR, primarily due to the increasing adoption of robotic surgery systems and sophisticated patient mobility devices. The transition from purely analog to digital output joysticks, providing cleaner signal integrity and better compatibility with modern computer control systems, represents a significant technological shift impacting overall market structure and product design priorities.

AI Impact Analysis on Fingertip Joysticks Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Fingertip Joysticks market often revolve around how AI can enhance the user experience, improve control precision, and automate aspects of HMI interaction. Key themes include the integration of predictive analytics into joystick systems to anticipate operator intentions or detect potential machine faults based on input patterns, and the use of machine learning algorithms to calibrate control sensitivity dynamically based on task requirements or operator proficiency. Concerns often center on the potential for AI to render certain manual control tasks obsolete, though the consensus suggests that AI will primarily serve as an augmentation layer, refining the control loop rather than replacing the fundamental need for human intervention via precise interfaces like fingertip joysticks. Users also seek to understand how AI-driven haptic feedback mechanisms can provide more intuitive and contextualized tactile warnings or guidance during complex operations.

AI’s influence is profound in optimizing the performance characteristics of fingertip joysticks, particularly in highly dynamic and sensitive applications such as drone operation or surgical robotics. By analyzing historical usage data and real-time operational feedback, AI algorithms can tailor the response curve of the joystick, ensuring maximum precision and reducing operator fatigue. For instance, in teleoperation of complex machinery, AI can filter out human tremor or compensate for external disturbances (like wind gusts on a drone), translating the operator’s intent into smoother, more stable machine movement. This predictive compensation elevates the overall performance and reliability of the HMI system, making fingertip joysticks more effective tools in critical control environments.

Furthermore, AI is instrumental in the diagnostic and maintenance aspects of these precision devices. Machine learning models can monitor the electrical output and mechanical wear patterns of the joysticks, predicting component failure before it occurs. This proactive maintenance capability is particularly valuable in aerospace and military sectors, where component reliability is paramount and downtime is costly. The incorporation of advanced AI processing at the edge, either within the control system or the joystick interface itself, facilitates smarter, context-aware control inputs, paving the way for adaptive interfaces that evolve with the user and the operational environment, thereby future-proofing the fingertip joystick technology against competitive input methods.

- AI integration enhances predictive control algorithms, optimizing output based on operator intent and reducing errors.

- Machine learning facilitates dynamic calibration, adjusting joystick sensitivity based on task complexity and environmental factors.

- AI-driven diagnostics predict mechanical wear and component failure, improving system reliability and reducing maintenance downtime.

- Adaptive haptic feedback, guided by AI, provides contextual sensory cues to the operator, enhancing situational awareness.

- AI supports the development of sophisticated human-machine collaboration systems, ensuring seamless interaction between human input and automated systems.

DRO & Impact Forces Of Fingertip Joysticks Market

The Fingertip Joysticks Market dynamics are shaped by a complex interplay of factors spanning technological advancements, regulatory pressures, and market demand fluctuations across specialized vertical industries. Key drivers include the global push for greater automation and precision in manufacturing and logistics, which mandates robust, reliable, and compact control interfaces. Restraints typically involve the high initial cost associated with specialized, high-precision components (especially force-sensing models) and the inherent complexity of integrating these controllers into diverse legacy systems. Opportunities are centered on emerging technological fields, notably the development of advanced haptic feedback systems, integration into augmented and virtual reality control applications, and expansion into non-traditional consumer electronics that require ergonomic, fine motor control inputs.

Drivers contributing significantly to market acceleration include the increasing sophistication of medical robotics, which relies heavily on highly sensitive fingertip joysticks for manipulation of surgical instruments with minimal deviation, and the continuous trend of miniaturization across all electronics, enabling joysticks to fit into smaller, handheld control units without sacrificing performance. The growing adoption of unmanned aerial vehicles (UAVs) and ground vehicles (UGVs) in defense, agriculture, and surveillance sectors further escalates demand for precision controllers. Moreover, the enhanced ergonomic design of modern fingertip joysticks, reducing operator strain during long shifts, is a substantial selling point in industrial and heavy equipment applications, conforming to stricter occupational safety standards.

However, the market faces headwinds from various restraints, including intense competition from alternative, often lower-cost input solutions, such as advanced touchscreens and voice command systems, which are increasingly adopted in less mission-critical applications. Furthermore, the reliance on highly specialized components and the relatively complex supply chain for high-grade sensors can lead to production bottlenecks and higher manufacturing costs, limiting mass-market penetration. Standardization across different industrial protocols also remains a challenge, as compatibility issues can complicate system integration for Original Equipment Manufacturers (OEMs). The key impact forces driving strategic decisions within the market include the need for enhanced environmental sealing and robustness (IP ratings) to withstand extreme temperatures, moisture, and vibration, particularly for defense and outdoor industrial machinery, coupled with the pressure to continuously innovate sensor technology to offer higher resolution and accuracy.

Segmentation Analysis

The Fingertip Joysticks Market is meticulously segmented based on key criteria including the type of sensing technology, the primary application area, and the end-user profile, allowing for a focused analysis of specific demand drivers and competitive landscapes within each niche. Understanding these segmentations is critical for market participants to tailor their product offerings, sales strategies, and R&D efforts towards sectors exhibiting the highest growth potential or requiring specialized technical compliance. For instance, the distinction between analog and digital output segments reflects the evolution of control system technology, where digital solutions offer enhanced noise immunity and precision, increasingly preferred in modern networked industrial environments, while analog systems retain relevance in certain legacy or cost-sensitive applications.

Segmentation by application clearly delineates the differing demands of various industries. The Industrial Control segment, for example, demands extreme durability, longevity, and high ingress protection (IP) ratings, whereas the Medical Devices segment places a premium on ergonomic design, sterile compatibility, and ultra-fine control resolution. This variance in requirements necessitates specialized design and manufacturing processes for each application category, influencing pricing structures and competitive positioning. Furthermore, the geographic segmentation reflects substantial differences in regulatory standards and technological maturity, with advanced economies primarily focusing on high-end specialized units (e.g., surgical robotics) and emerging economies driving volume demand for standard industrial control units.

The detailed market segmentation aids companies in identifying lucrative untapped markets, such as the growing demand for specialized controllers in Virtual Reality (VR) and Augmented Reality (AR) systems that require subtle haptic feedback and fingertip precision. By focusing on high-growth segments, such as force-sensing technology within military and aerospace applications, companies can allocate resources effectively to gain a competitive advantage. The granular nature of this analysis also informs supply chain strategies, ensuring that manufacturers can efficiently manage the procurement of specialized sensors and materials required for specific product variants, aligning production with projected demand across diverse vertical markets.

- By Type

- Analog Fingertip Joysticks

- Digital Fingertip Joysticks

- Force Sensing Fingertip Joysticks

- By Output Signal

- CAN Bus

- USB

- PWM

- RS232/RS485

- By Application

- Industrial Control Equipment (Cranes, Forklifts, ROVs)

- Medical Devices (Surgical Robots, Wheelchairs)

- Military & Aerospace (Cockpit Controls, UAV Ground Stations)

- Gaming and Simulation

- By End-User

- Original Equipment Manufacturers (OEMs)

- Aftermarket and System Integrators

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Fingertip Joysticks Market

The value chain for the Fingertip Joysticks Market is structured around specialized expertise, starting with upstream suppliers who provide critical high-technology components, progressing through complex manufacturing and assembly, and culminating in highly specific distribution channels targeting industrial system integrators and specialized OEMs. Upstream activities involve the sourcing of critical materials such as specialized plastics, metals, and, most importantly, high-precision sensors (e.g., Hall effect sensors, strain gauges). The performance and cost of the final product are highly dependent on the quality and miniaturization capabilities offered by these component suppliers. Manufacturers often establish long-term relationships with sensor providers to ensure a stable supply of components meeting stringent quality and environmental standards necessary for defense and medical applications.

Midstream activities encompass the core manufacturing processes, including precision machining, electronic assembly, and rigorous quality assurance testing, particularly for ingress protection and operational lifespan. This stage involves the integration of the electronic components with mechanical housing and the calibration of the joystick’s output signal to meet precise customer specifications. Major manufacturers invest heavily in automated assembly and calibration lines to maintain consistency and high volumes while catering to custom orders. Downstream activities focus on reaching the end-user, primarily through direct sales to large OEMs (like medical robotics manufacturers or heavy equipment builders) or via specialized, technically proficient distributors and system integrators who add value through installation, configuration, and after-sales support.

The distribution channel is generally bifurcated into direct and indirect routes. Direct sales are predominant for high-volume, custom orders from major OEMs in highly regulated industries, allowing manufacturers to maintain tight control over product specifications and client relationships. Indirect sales utilize specialized distributors and resellers who possess deep technical knowledge of HMI components and serve smaller system integrators and aftermarket users. E-commerce platforms are growing, especially for standard industrial replacement parts, but highly specialized units still rely heavily on direct or technical distributor channels due to the complexity of the pre-sale technical consultation required. The efficiency of the downstream network, particularly in providing rapid support and spare parts, is a crucial determinant of market success and customer retention.

Fingertip Joysticks Market Potential Customers

Potential customers for fingertip joysticks are diverse yet primarily concentrated within high-value sectors that prioritize precision control, reliability, and compact design. The largest segment of buyers consists of Original Equipment Manufacturers (OEMs) specializing in industrial and heavy machinery, including manufacturers of tower cranes, container handling equipment, mining vehicles, and specialized construction equipment. These OEMs integrate the joysticks directly into their control panels and remote interfaces, demanding high durability, extreme temperature resistance, and compliance with specific industrial safety standards (e.g., SIL ratings). The purchasing decision for this group is heavily influenced by the joystick’s Mean Time Between Failures (MTBF) and its ability to withstand continuous, rigorous use in harsh environments.

Another critical customer group comprises manufacturers of advanced medical devices, notably producers of surgical robotics, diagnostic imaging systems, and advanced patient mobility solutions like motorized wheelchairs. These buyers require joysticks that offer extremely high fidelity, smooth operation, and ergonomic design suitable for prolonged surgical procedures or patient navigation. For medical applications, compliance with sterilization standards and meticulous quality control is paramount. The defense and aerospace sectors constitute a powerful segment, with customers including military contractors and government agencies procuring joysticks for critical applications such as unmanned aerial vehicle (UAV) ground control stations, aircraft cockpit auxiliary controls, and complex radar systems, where failure is not an option and demanding MIL-SPEC compliance is mandatory.

Furthermore, system integrators and smaller engineering firms that specialize in retrofitting or customizing industrial control systems form a significant portion of the aftermarket demand. These customers purchase joysticks for upgrading older machinery or building bespoke control interfaces for unique industrial tasks. Finally, simulation and gaming equipment manufacturers, particularly those creating high-end professional flight or heavy machinery simulators used for training, represent a smaller but growing segment demanding ultra-realistic tactile feedback and precision tracking, often utilizing force-sensing technology to replicate real-world operational feel accurately. The focus across all potential customers remains centered on reliability, precision, and the total cost of ownership over the component’s lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 805 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ALPS, Apem, Elobau, Sensata Technologies, Eaton, Grayhill, CTI Electronics, Curtiss-Wright, ZF Electronics, Megatron, OKW Gehäusesysteme, NKK Switches, Penny & Giles, Sure Grip Controls, TE Connectivity, Bosch Rexroth, GE Healthcare, Parker Hannifin, TT Electronics, Danfoss. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fingertip Joysticks Market Key Technology Landscape

The technological evolution of fingertip joysticks is centered on achieving enhanced precision, greater reliability, and expanded functional integration, moving far beyond basic resistive or potentiometric mechanisms. Modern fingertip joysticks heavily rely on non-contact sensing technologies, predominantly Hall Effect sensors, which measure movement using magnetic fields rather than physical contact. This shift significantly reduces mechanical wear and tear, dramatically extending the operational lifespan of the joystick, a critical requirement for high-duty cycle industrial and defense applications. Advanced technology also focuses on miniaturization techniques, allowing manufacturers to pack sophisticated electronics and sensor arrays into extremely small form factors, facilitating integration into portable and compact control interfaces without compromising accuracy or ergonomic stability.

Another major technological pillar is the rise of Force Sensing Joysticks (FSJs), which utilize strain gauge technology to measure the force applied by the operator’s finger rather than measuring physical displacement. FSJs offer zero movement, making them highly resistant to vibration and shock, ideal for harsh environments, and providing exceptional control resolution due to the absence of mechanical play. Furthermore, the electronic interface technology is evolving rapidly, moving towards standardized industrial communication protocols such as CAN bus (Controller Area Network) and Ethernet. Integrating these digital outputs directly into the joystick assembly allows for real-time data exchange, improved noise immunity, complex diagnostics, and seamless integration into sophisticated networked control systems prevalent in automated factories and advanced medical equipment.

The material science employed in joystick manufacturing is also a key area of innovation, focusing on ruggedized polymer and metal alloys that provide superior chemical resistance, thermal stability, and sealing capabilities to achieve high Ingress Protection (IP) ratings (e.g., IP67 or IP68). The incorporation of haptic technology, enabling the joystick to provide programmable tactile feedback to the operator, represents a significant technological advancement. This haptic integration, often controlled by sophisticated microprocessors, enhances user engagement and safety by communicating critical status alerts or operational boundaries directly through touch. Overall, the technology landscape is characterized by a strong push toward smart, durable, and highly integrated control solutions capable of meeting the stringent performance demands of mission-critical applications.

Regional Highlights

North America holds a commanding position in the Fingertip Joysticks Market, primarily driven by substantial government expenditure in the defense and aerospace sectors and a highly advanced medical device manufacturing industry. The demand here is skewed towards premium, highly customized products that comply with rigorous military specifications (MIL-SPEC) and stringent medical regulatory standards (e.g., FDA requirements). Key applications include sophisticated surgical robots, unmanned aerial vehicle (UAV) ground control systems, and high-fidelity flight simulators. The region benefits from a strong presence of key technology developers and system integrators who emphasize technological superiority and localized production to maintain high-quality control and supply chain resilience. The trend of automation in high-cost labor sectors also fuels consistent demand for precision industrial controllers.

Europe represents a mature and stable market, characterized by robust adoption in the industrial automation, maritime, and construction equipment manufacturing sectors, particularly in Germany, the UK, and Nordic countries. The focus in Europe is heavily placed on ergonomic design, operator safety, and compliance with high environmental standards, driving demand for joysticks with superior sealing (IP ratings) and long operational life. The region’s strong manufacturing base, especially in automotive and machinery, necessitates reliable HMI components for both factory floor robotics and remote control units for heavy equipment. Furthermore, European space agencies and defense contractors contribute to consistent, though specialized, demand for high-reliability components, often integrating advanced CAN bus communication protocols for networked machine control.

Asia Pacific (APAC) is projected to witness the highest growth rate during the forecast period, powered by rapid industrialization, large-scale infrastructure projects, and increasing automation in emerging economies like China, India, and Southeast Asia. The region’s growth is volume-driven, fueled by the massive deployment of industrial robotics, expansion of the construction sector utilizing modern cranes and heavy vehicles, and significant investment in domestic defense modernization programs. While price sensitivity is higher in some sub-regions, the growing commitment to quality and adoption of high-precision manufacturing processes are accelerating the transition from standard input devices to advanced fingertip joysticks. Japan and South Korea remain key hubs for advanced technology adoption, particularly in medical robotics and complex industrial control systems, setting the benchmark for regional technological standards.

Latin America (LATAM) and the Middle East & Africa (MEA) regions currently hold smaller market shares but offer significant future growth potential. In LATAM, market expansion is tied to the modernization of infrastructure, mining, and oil & gas industries, driving the need for remote operational control equipment. In MEA, particularly the GCC countries, large defense procurement programs and significant investment in smart city infrastructure and high-tech medical facilities are creating specialized pockets of demand for high-end fingertip joysticks. However, these regions often rely heavily on imports and face challenges related to establishing robust local technical support networks and managing complex logistical chains, which can sometimes slow the adoption rate compared to fully industrialized economies.

- North America: Dominant market share due to strong military and medical device sectors, high demand for MIL-SPEC components.

- Europe: Stable growth driven by industrial automation, stringent safety standards, and sophisticated machinery manufacturing.

- Asia Pacific (APAC): Fastest growing region, fueled by rapid industrialization, expansion of manufacturing robotics, and infrastructure development.

- Latin America: Growth tied to modernization of mining, oil & gas, and infrastructure projects, focusing on remote control applications.

- Middle East & Africa (MEA): Specialized demand arising from defense modernization and investment in advanced healthcare facilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fingertip Joysticks Market.- ALPS Electric Co. Ltd.

- Apem SAS

- Elobau Sensor Technology Inc.

- Sensata Technologies Holding plc

- Eaton Corporation plc

- Grayhill Inc.

- CTI Electronics LLC

- Curtiss-Wright Corporation

- ZF Electronics (Cherry)

- Megatron Elektronik GmbH & Co. KG

- OKW Gehäusesysteme GmbH

- NKK Switches Co. Ltd.

- Penny & Giles (A Curtiss-Wright Brand)

- Sure Grip Controls Inc.

- TE Connectivity Ltd.

- Bosch Rexroth AG

- Danfoss A/S

- TT Electronics plc

- Hengstler GmbH

- Saetco Controls

Frequently Asked Questions

Analyze common user questions about the Fingertip Joysticks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of Hall Effect fingertip joysticks over older potentiometer-based models?

The primary advantage of Hall Effect fingertip joysticks is their non-contact operation, which eliminates mechanical wear on the sensing elements. This results in significantly longer operational lifespan, greater reliability, and consistent precision over millions of cycles, making them ideal for high-duty cycle industrial and medical applications.

Which application segment drives the highest demand for specialized fingertip joysticks?

The Industrial Control Equipment segment currently drives the largest volume of demand, requiring joysticks with high environmental protection (IP ratings) and rugged construction for use in heavy machinery and remote-operated vehicles (ROVs). However, the Medical Devices segment demands the highest precision and resolution, leading to the highest average selling prices for specialized units.

How is Artificial Intelligence impacting the design and functionality of fingertip joysticks?

AI is being integrated to enhance predictive control capabilities, allowing the joystick system to dynamically adjust sensitivity and filter out human tremor or operational noise. AI also aids in developing advanced haptic feedback systems, providing context-aware tactile alerts to the operator for improved safety and control accuracy.

What are the key differences between displacement joysticks and force sensing joysticks (FSJs)?

Displacement joysticks measure physical movement of the stick handle, while Force Sensing Joysticks (FSJs) measure the magnitude and direction of the force applied by the finger, typically remaining stationary. FSJs are favored in applications requiring high resistance to shock and vibration, offering extremely fine control resolution with zero moving parts, enhancing durability.

Why is the Asia Pacific region projected to exhibit the fastest growth in the Fingertip Joysticks Market?

The APAC region is experiencing accelerated growth due to widespread adoption of industrial automation and robotics in large-scale manufacturing operations, coupled with significant governmental investments in modernizing infrastructure and expanding defense capabilities, creating high volume demand for precision HMI components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager