Fire Blanket Sales Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442719 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Fire Blanket Sales Market Size

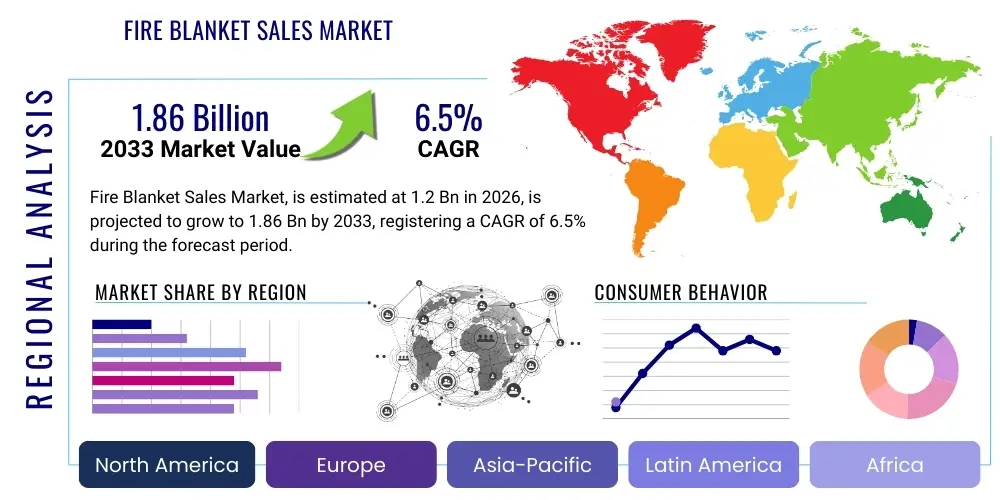

The Fire Blanket Sales Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.86 Billion by the end of the forecast period in 2033. This steady expansion is driven primarily by increasingly stringent fire safety regulations across commercial and residential sectors globally, coupled with a heightened public awareness regarding proactive fire suppression tools, especially in high-risk areas like kitchens and workshops. The stability of fiberglass as the primary raw material, offering excellent thermal insulation and non-combustible properties, ensures consistent market availability and reliability.

Market expansion is also heavily influenced by regulatory bodies such as the International Organization for Standardization (ISO) and regional bodies like the European Committee for Standardization (CEN), which mandate the installation of approved fire safety equipment in new construction and renovations. Developing nations, undergoing rapid urbanization and industrialization, present significant untapped opportunities for manufacturers, particularly for large industrial-grade fire blankets used in heavy machinery and welding applications. The relatively low cost and zero maintenance requirement, compared to traditional fire extinguishers, make fire blankets an attractive secondary safety option for various end-users.

Fire Blanket Sales Market introduction

The Fire Blanket Sales Market encompasses the manufacturing, distribution, and sale of specialized flexible sheets designed to smother small incipient fires by cutting off the oxygen supply. Fire blankets are typically constructed from fire-resistant materials, predominantly woven fiberglass treated with chemical coatings like silicone or vermiculite, enabling them to withstand extremely high temperatures, often exceeding 500°C. These essential safety products are characterized by their ease of use, non-toxic nature, and portability, making them ideal for rapid deployment in emergency situations without requiring training or creating residue, unlike foam or powder extinguishers.

Major applications of fire blankets span diverse sectors, including domestic settings (primarily kitchens, targeting cooking oil fires), industrial environments (laboratories, welding workshops, boiler rooms), commercial premises (restaurants, hotels, offices), and specialized transport (marine vessels and automotive workshops). The market’s resilience stems from its core benefit: providing a crucial, immediate response tool for Class F fires (cooking oils) and certain Class A fires (solids), where traditional water-based methods are ineffective or dangerous. The driving factors propelling market growth include stricter enforcement of fire safety codes, increased consumer education regarding kitchen safety, and the continuous need for reliable, simple fire suppression solutions in dense urban areas and manufacturing centers.

The product description highlights a safety device stored in a quick-release container, ensuring immediate access when a small fire erupts. The fire blanket acts as a thermal barrier, preventing the spread of flames and protecting individuals during evacuation or suppression attempts. Benefits include zero maintenance, unlimited shelf life (if undamaged), chemical-free operation, and effectiveness against various fire classes. The increasing regulatory framework, especially in mature economies of North America and Europe, mandating readily available fire safety equipment in residential rental properties and commercial kitchens, remains the fundamental engine for sustained market growth.

Fire Blanket Sales Market Executive Summary

The Fire Blanket Sales Market is poised for substantial growth, reflecting broader global trends towards enhanced occupational and domestic safety standards. Business trends indicate a strong move by manufacturers toward material innovation, focusing on producing blankets capable of higher thermal resistance and enhanced durability, particularly appealing to the heavy industry and automotive sectors. Supply chain optimization remains a key focus, driven by the need to efficiently source high-quality, standardized fiberglass materials while meeting varied international certification requirements (such as CE marking and EN 1869 standards). Furthermore, digitalization in distribution, leveraging e-commerce and specialized industrial marketplaces, is streamlining the procurement process for both B2B and B2C segments.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, primarily fueled by rapid infrastructure development, increased industrial activity, and the implementation of modern building codes in populous nations like China and India. Conversely, North America and Europe represent mature markets characterized by replacement sales and high regulatory compliance, leading to stable, high-value demand for certified, premium products. These established regions are seeing increased demand for larger, specialized industrial blankets (e.g., welding blankets) that protect equipment and surrounding areas from sparks and heat, differentiating the industrial segment from the high-volume domestic market.

Segment trends emphasize the dominance of the Woven Fiberglass type due to its cost-effectiveness and proven performance. However, there is notable growth in the treated cotton segment, favored in applications requiring lighter weight or non-itchy materials, though less suited for extremely high temperatures. Application-wise, the Kitchen/Domestic segment accounts for the largest volume sales, driven by necessity and high fire incidence rates related to cooking. Simultaneously, the Industrial segment is witnessing the highest value growth, propelled by complex safety requirements in manufacturing, petrochemicals, and energy sectors. Segmentation analysis confirms a dual market strategy: high volume penetration in residential settings and high-value specialization in industrial and commercial sectors.

AI Impact Analysis on Fire Blanket Sales Market

User queries regarding AI's impact on the Fire Blanket Sales Market predominantly revolve around how smart technology influences the prevention, detection, and mitigation stages of fire events, and whether AI renders simple, manual devices obsolete. Key themes identified include the integration of fire blankets into smart home safety ecosystems, the use of AI in optimizing supply chain logistics for faster market response, and the role of machine learning in quality control during manufacturing. Concerns center on predictive maintenance models potentially reducing the need for emergency response tools, while expectations focus on AI systems dynamically identifying the most appropriate fire suppression tool (including recommending fire blankets) based on early detection data, thereby increasing targeted sales.

AI's primary influence is not on the product itself—as a passive safety item, its design remains fundamentally simple—but on the surrounding ecosystem and operational efficiencies. In manufacturing, AI-powered computer vision systems can inspect the weaving quality and chemical treatments of fiberglass cloth with higher precision than human inspectors, ensuring all blankets meet stringent thermal resistance standards, thus improving brand trust and reducing liability risks. Furthermore, predictive analytics, utilizing historical fire data and demographic information, can enable retailers and distributors to forecast demand more accurately across different geographical micro-markets, reducing inventory carrying costs and stockouts, particularly during peak seasons or regulatory shifts.

Moreover, the integration of AI within smart building management systems (BMS) and smart kitchen appliances indirectly drives fire blanket sales. If an AI system detects an early stage thermal anomaly (e.g., overheating oil on a stove) before a full alarm is triggered, it can send localized alerts that remind residents of the immediate availability and proper use of nearby fire safety tools, effectively boosting awareness and reinforcing the necessity of owning a fire blanket. This synergy between advanced detection systems and passive suppression tools ensures that even basic safety products remain relevant and highly accessible in modern, digitized environments.

- AI-driven supply chain optimization enhances inventory management and reduces time-to-market for certified blankets.

- Machine learning algorithms improve manufacturing Quality Assurance (QA) by detecting minute flaws in material weaving and chemical treatments.

- Integration into Smart Home Safety Ecosystems (SHSE) allows AI to recommend fire blanket deployment based on detected fire class (e.g., cooking oil fires).

- Predictive safety modeling helps insurance and regulatory bodies mandate fire blanket presence in high-risk zones, increasing institutional sales.

- AI-powered user interfaces in commercial settings provide tailored training videos on fire blanket usage, improving adoption rates and effectiveness.

DRO & Impact Forces Of Fire Blanket Sales Market

The dynamics of the Fire Blanket Sales Market are shaped by a complex interplay of regulatory drivers, economic restraints, and technological opportunities, culminating in significant impact forces. Key drivers include the global harmonization of safety standards, such as the increasing adoption of the European standard EN 1869, which sets a benchmark for performance and quality, compelling manufacturers to adhere to high specifications and increasing consumer trust. The high incidence rate of kitchen fires globally, often linked to unattended cooking or faulty appliances, continuously reinforces the necessity for accessible, simple suppression tools like fire blankets, particularly in residential and restaurant settings. Furthermore, ongoing Occupational Safety and Health Administration (OSHA) compliance requirements in industrial environments mandate specific fire mitigation tools, driving B2B sales.

Conversely, the market faces restraints primarily related to a lack of pervasive consumer awareness in developing regions, where fire safety education may be rudimentary, leading to reliance on outdated methods or complete absence of safety equipment. Additionally, the increasing technological sophistication and miniaturization of advanced fire extinguishing systems (e.g., automatic aerosol or clean agent systems) pose a competitive challenge, often preferred in high-value industrial settings due to their automated operation. The primary opportunity lies in expanding into emerging economies through subsidized safety programs and leveraging advancements in material science to develop multi-purpose blankets with superior temperature ratings and lighter weights, opening doors into specialized fields like motorsports and aerospace.

The impact forces are substantial, driven by legislative mandates and the resultant consumer behavior shift. The regulatory force compels mandatory purchases and replacements, providing market stability. Economic forces, particularly the low cost of the product, ensure high penetration potential, acting as a crucial entry point for basic fire safety in budget-constrained markets. The impact of societal awareness, amplified through public safety campaigns and insurance company endorsements, translates directly into residential sales growth. The confluence of these factors ensures that while advanced technologies exist, the fire blanket maintains its status as an indispensable, immediate-response safety device due to its inherent simplicity and reliability against specific fire classes.

Segmentation Analysis

The Fire Blanket Sales Market is systematically segmented based on Product Type, Size, Application, and Distribution Channel, allowing for detailed market targeting and product customization. Analyzing these segments provides crucial insights into market penetration rates and growth trajectories across different end-user groups. The segmentation confirms that the market operates under a dual structure: high volume, standardized products catering to the residential sector, and low volume, high specification products serving specialized industrial needs. Understanding the interplay between material selection and required temperature rating is paramount for manufacturers defining their competitive strategy.

The application segmentation is particularly critical, as it defines the necessary material composition and required size. Kitchen/Domestic use typically requires smaller, highly visible blankets adhering strictly to specific standards (like EN 1869) for oil and fat fires. Conversely, Industrial applications demand larger, thicker blankets, often utilizing specialized coatings like ceramic fibers or high-silica materials, designed to withstand welding sparks, grinding debris, and prolonged exposure to high radiant heat. This differentiation underscores the variance in price points and manufacturer specialization needed to service the market effectively across its diverse operational environments.

- By Product Type:

- Woven Fiberglass

- Silicone Coated Fiberglass

- Ceramic Fiber Blankets

- Treated Cotton/Wool Blankets (Lower Temp)

- Others (e.g., high-silica textiles)

- By Size:

- Small (1.0m x 1.0m, 1.2m x 1.2m)

- Medium (1.2m x 1.8m, 1.5m x 1.5m)

- Large/Industrial (1.8m x 1.8m, 2.0m x 3.0m, and custom sizes)

- By Application:

- Kitchen/Domestic Use

- Industrial & Manufacturing (Welding, Boiler Rooms)

- Automotive & Transportation

- Commercial Buildings (Hotels, Restaurants, Offices)

- Laboratories & Educational Institutions

- By Distribution Channel:

- Online Retail (E-commerce Platforms)

- Offline Retail (Supermarkets, Hardware Stores)

- Industrial Supply & Safety Equipment Distributors (B2B)

- Direct Sales (Government/Military Contracts)

Value Chain Analysis For Fire Blanket Sales Market

The value chain for the Fire Blanket Sales Market begins with the Upstream Analysis, which focuses heavily on the procurement of specialized raw materials. The primary material is high-quality, high-tensile fiberglass yarn, which requires meticulous manufacturing to ensure uniform weave and heat resistance. Other crucial inputs include specialized chemical coatings—such as silicone, vermiculite, or polyurethane—that enhance the blanket's fire resistance, durability, and ergonomic properties (reducing skin irritation). Raw material suppliers often operate in highly specialized chemical and textile markets, requiring manufacturers to maintain rigorous quality control over inputs to meet mandated international standards like EN 1869, which is a major cost driver in the upstream stage.

The Midstream stage involves manufacturing and processing. This includes weaving the raw yarn into dense fabric, applying fire-retardant chemical treatments, cutting, stitching, and packaging the final product into quick-release casings. Efficiency in manufacturing processes, particularly automation in weaving and coating, is critical for maintaining competitive pricing, especially for high-volume domestic market segments. Distribution Channel analysis reveals a robust split between direct and indirect sales. Industrial-grade, customized blankets are often sold through specialized Industrial Supply distributors (B2B), offering technical support and integration services. Conversely, the smaller, standardized domestic blankets rely heavily on high-volume Indirect distribution channels, primarily Offline Retail (hardware stores and supermarkets) and rapidly growing Online Retail platforms (e-commerce), which require efficient logistics and strong branding.

The Downstream Analysis involves marketing, sales, and post-sale interaction with the End-Users. For B2C sales, the focus is on visibility, clear instructions, and ensuring the product is easily accessible alongside other household safety equipment. For B2B sales, the emphasis shifts to certification compliance, bulk purchasing agreements, and reliability. Given the product's safety function, quality assurance and compliance documentation are paramount throughout the entire value chain, directly influencing brand reputation and market acceptance across all geographical regions.

Fire Blanket Sales Market Potential Customers

Potential customers for fire blankets are broadly categorized into three major segments: residential users, commercial enterprises, and industrial facilities, each driven by distinct needs and regulatory requirements. Residential end-users represent the largest volume segment, primarily driven by safety consciousness concerning kitchen fires, which are the most common cause of domestic fire incidents. Homeowners and tenants prioritize ease of use, compact design, and compliance with local safety recommendations. The purchase decision here is often spontaneous or driven by retail promotions and safety campaigns.

Commercial enterprises, including restaurants, hotels, schools, and hospitals, represent a high-value segment where procurement is mandatory based on stringent fire codes (e.g., NFPA standards). Professional kitchens are high-priority buyers due to the constant risk of Class F fires (deep fat fryers). These customers require durable, certified blankets (typically 1.2m x 1.8m or larger) and often engage in bulk purchasing through B2B channels, demanding verifiable product certification and longevity. Compliance documentation and adherence to local health and safety regulations are key determinants in the purchasing process for this segment.

Industrial facilities, such as welding shops, automotive repair garages, chemical processing plants, and heavy manufacturing sites, demand the most specialized and robust blankets. These End-Users require large, high-temperature blankets, often categorized as welding blankets or curtains, designed to protect equipment and personnel from intense heat, sparks, and molten metal splatter. The purchasing criteria here are primarily defined by the specific operational environment, maximum temperature resistance (often requiring silica or ceramic fiber materials), and industrial durability, often sourced directly from specialized industrial distributors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.86 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MGM Safety, F.M. Industry, Jactone Products Ltd., TYCO International PLC, Honeywell International Inc., First Alert, Rescom, Fire Safety USA, Eurofeu, Bristol Uniforms Ltd., SafePro Group, KRM Fire Safety, G&T Industries, Foshan Weijun Fire Equipment Co. Ltd., Ningbo Yilin Safety Equipment Co. Ltd., RAE Systems, Inc., Xtra Lite Fire Protection, FlameStop, Reliance Protectron Inc., Premier Safety |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fire Blanket Sales Market Key Technology Landscape

The core technology underpinning the Fire Blanket Sales Market revolves around advanced textile engineering and specialized material science. While the basic concept of smothering a fire remains simple, modern market competition is centered on improving the thermal performance, durability, and user safety of the fire-resistant textiles. Key technological advancements focus on the composition of the fabric itself, moving beyond standard fiberglass to include materials like high-silica fiber, which offers superior continuous operating temperatures (up to 1000°C), making them essential for heavy-duty industrial applications such as foundries or extreme temperature laboratories. The chemical composition of the coating is equally critical; silicone coatings provide excellent flexibility and resistance to chemical corrosion, while vermiculite treatments enhance abrasion resistance and insulation properties, ensuring the blanket remains effective even after rough handling.

Another crucial technological aspect is the adherence to rigorous international standardization, primarily EN 1869 in Europe and similar specifications globally. Manufacturers invest heavily in testing protocols and production techniques to ensure consistent product performance that meets these benchmarks, specifically regarding the material’s ability to withstand flames without burning, melting, or dripping, and the functionality of the quick-release mechanism. Packaging technology is also evolving, with quick-draw pouches and wall-mounted containers designed for maximum visibility and instantaneous access. These containers are often designed to protect the blanket from environmental degradation (e.g., moisture, UV light) to ensure long-term readiness, reflecting an incremental, yet vital, technological improvement in deployment and maintenance.

Furthermore, the integration of smart textiles represents an emerging technological landscape, though still nascent in mass-market fire blankets. Research is focused on incorporating subtle indicators or low-power sensors within the blanket’s casing or fabric edges. These sensors could signal when the blanket has reached its shelf life, detect damage to the material, or even transmit an alert to a connected safety system upon deployment. This potential move toward 'smart' passive safety equipment aims to address concerns about the maintenance and readiness of fire safety gear, particularly in large commercial or industrial settings where oversight is critical. However, cost remains a barrier for integrating such high-tech features into the typically low-cost, high-volume domestic market segment.

Regional Highlights

The market dynamics of fire blanket sales exhibit significant regional variations influenced by regulatory maturity, industrial concentration, and consumer safety awareness levels.

- North America: This region is characterized by high regulatory enforcement, particularly in the United States and Canada, driven by NFPA standards and local building codes that mandate specific fire suppression equipment in commercial kitchens, multi-unit dwellings, and industrial sites. The market is mature, emphasizing replacement sales and demand for specialized industrial welding blankets. Key countries like the U.S. maintain high average selling prices due to strong preference for domestically manufactured or certified premium imported products.

- Europe: Europe represents a highly standardized market, with the EN 1869 standard acting as a universal benchmark for domestic fire blankets. This region shows robust, stable growth driven by high consumer awareness, widespread adoption in residential and small commercial settings, and proactive legislative mandates across member states requiring safety equipment in rental properties and vehicles. Germany, the UK, and France are key contributors, focusing on quality and sustainability in manufacturing.

- Asia Pacific (APAC): APAC is forecast to be the fastest-growing region, driven by rapid urbanization, massive infrastructure projects, and the gradual adoption of international safety standards, especially in emerging economies like China, India, and Southeast Asian nations. The region benefits from both high-volume manufacturing capabilities and surging domestic demand. Growth is propelled by increased commercial construction (hotels, restaurants) and burgeoning industrial activity requiring specialized, large-scale protection solutions.

- Latin America (LATAM): Growth in LATAM is more sporadic, heavily influenced by localized economic conditions and inconsistent regulatory enforcement. The market is price-sensitive, with demand primarily centered in industrial hubs (Brazil, Mexico) and high-density urban areas. Opportunities exist through government initiatives aimed at improving public safety standards and expanding access to basic safety equipment.

- Middle East and Africa (MEA): The MEA market is largely driven by massive oil & gas projects and infrastructure investments in the Gulf Cooperation Council (GCC) countries, creating high demand for specialized, high-temperature industrial fire blankets. Africa remains a nascent market, focused predominantly on essential commercial and basic residential applications, reliant heavily on imports and gradual regulatory modernization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fire Blanket Sales Market.- MGM Safety

- F.M. Industry

- Jactone Products Ltd.

- TYCO International PLC (Part of Johnson Controls)

- Honeywell International Inc.

- First Alert (A brand of Resideo Technologies, Inc.)

- Rescom

- Fire Safety USA

- Eurofeu

- Bristol Uniforms Ltd.

- SafePro Group

- KRM Fire Safety

- G&T Industries

- Foshan Weijun Fire Equipment Co. Ltd.

- Ningbo Yilin Safety Equipment Co. Ltd.

- RAE Systems, Inc.

- Xtra Lite Fire Protection

- FlameStop

- Reliance Protectron Inc.

- Premier Safety

Frequently Asked Questions

Analyze common user questions about the Fire Blanket Sales market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used in modern fire blankets and why?

The primary material is woven fiberglass fabric, often coated with silicone or vermiculite. Fiberglass is chosen for its non-combustible properties, high heat resistance (typically over 550°C), and low cost, ensuring the blanket smothers fires effectively by forming an airtight, thermal barrier.

Are fire blankets regulated, and what is the main certification standard?

Yes, fire blankets are highly regulated, especially in Europe and North America. The key international standard is EN 1869, which specifies the material, construction, and performance requirements necessary for fire blankets used for extinguishing small fires, particularly cooking oil fires.

How often should a fire blanket be replaced or inspected?

A fire blanket should be inspected regularly (usually annually in commercial settings) for any signs of damage, rips, or chemical deterioration, and to ensure the quick-release casing is functional. Unlike extinguishers, fire blankets do not have an expiry date but must be replaced immediately after a single use, even if the fire appeared minor.

Is the market shifting toward industrial applications, and what is driving this trend?

While the residential segment holds the highest volume, the industrial segment is experiencing faster value growth. This shift is driven by increasing complexity in manufacturing, requiring specialized, higher-temperature resistant materials (like silica fiber) for welding, machinery protection, and adherence to stringent occupational safety regulations.

Can a fire blanket be used on electrical fires?

Yes, a fire blanket can be used on small electrical fires (Class E/C) provided the electricity supply is safely disconnected first. The blanket works by starving the fire of oxygen, a principle effective across most small fire classes, though specialized electrical extinguishers are often preferred where power cannot be immediately cut.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager