Flatback Paper Tapes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440965 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Flatback Paper Tapes Market Size

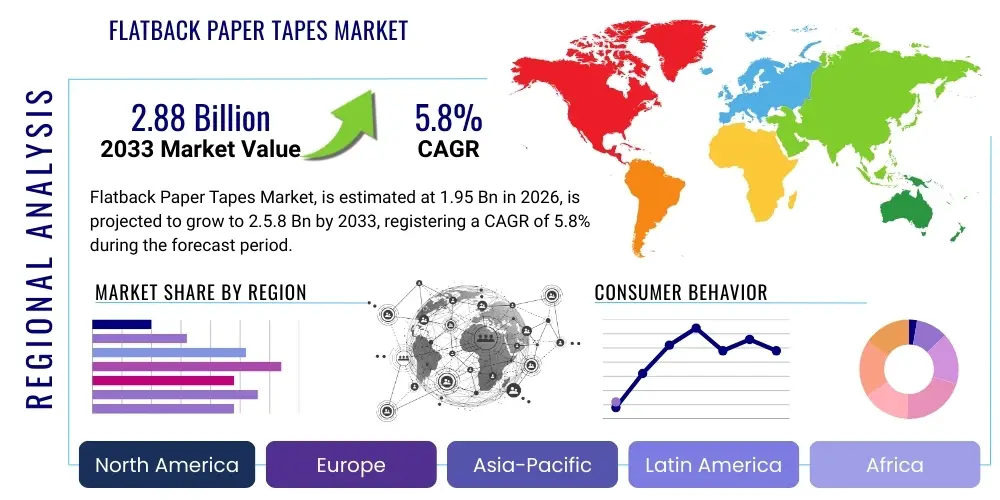

The Flatback Paper Tapes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.95 Billion in 2026 and is projected to reach $2.88 Billion by the end of the forecast period in 2033.

Flatback Paper Tapes Market introduction

The Flatback Paper Tapes Market encompasses specialized adhesive products characterized by a smooth, saturated paper backing that offers high tensile strength, resistance to curling, and excellent conformability. These tapes are distinct from conventional masking tapes due to their greater durability and ability to provide a clean, sharp paint line or a reliable, tear-resistant packaging seal. The backing is typically treated with release agents to ensure easy unwind, making them suitable for high-speed, automated application processes across various industrial environments.

Flatback paper tapes serve critical functions across diverse end-use sectors, including high-temperature automotive paint masking, general industrial packaging, robust carton sealing, splicing in paper mills, and intricate graphic arts applications. Their key benefits include high adhesion strength without leaving residue upon removal (for specific types), excellent dimensional stability, and their inherent sustainability advantage as a paper-based product compared to plastic alternatives. Furthermore, their smooth surface facilitates printing and labeling, enhancing their utility in branding and identification processes.

Driving factors for this market primarily include the burgeoning e-commerce sector, which necessitates high-performance, eco-friendly packaging solutions; the increasing sophistication of industrial masking requirements, particularly in automotive and aerospace finishing; and the general industry shift toward sustainable and recyclable materials. The versatility and consistent performance attributes of flatback tapes position them as indispensable components in manufacturing and logistics operations globally.

Flatback Paper Tapes Market Executive Summary

The Flatback Paper Tapes Market is characterized by robust growth fueled primarily by the sustainability mandates driving packaging material choices and the demanding requirements of industrial processing applications. Key business trends include aggressive investment in adhesive technology, focusing on solvent-free formulations and specialized acrylic systems that offer enhanced temperature and UV resistance. Manufacturers are also prioritizing automated application systems, where the consistent strength and reliable unwinding properties of flatback tapes are essential for maximizing throughput and reducing operational downtime in high-volume environments.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, driven by massive expansion in manufacturing and infrastructure development, particularly in China and India, alongside significant growth in the e-commerce supply chain. North America and Europe, while mature markets, are experiencing demand shifts towards premium, high-performance flatback tapes used in specialized applications like high-end automotive refinishing and sustainable food packaging. Strict environmental regulations in these regions also necessitate the adoption of recyclable paper-based solutions, further boosting market penetration.

Segment trends reveal that the Rubber-based adhesive segment continues to dominate due to its cost-effectiveness and strong initial tack, widely utilized in general packaging and bundling. However, the Acrylic-based segment is projected to exhibit the fastest CAGR, driven by its superior resistance to extreme temperatures, moisture, and UV exposure, making it crucial for automotive masking and outdoor construction applications. In terms of application, packaging and bundling remain the largest segment, but specialized applications like splicing and graphic arts require tapes with extremely precise specifications, commanding higher margins and driving product innovation.

AI Impact Analysis on Flatback Paper Tapes Market

Common user questions regarding AI's impact on the Flatback Paper Tapes Market typically revolve around operational efficiency, quality control, and supply chain optimization rather than direct product transformation. Users are keenly interested in how AI can minimize waste during high-speed application, optimize inventory management based on real-time industrial demand fluctuations, and enhance the consistency of adhesive coating processes. Key themes include the implementation of predictive maintenance for taping machinery, automated defect detection in finished tape rolls, and intelligent forecasting of raw material prices (paper pulp and specialized adhesives). Expectations center on AI driving down operational costs and improving the overall quality consistency of tapes used in automated assembly lines, ensuring that the tapes meet the exacting standards required for applications like high-precision automotive painting and heavy-duty industrial sealing.

- AI-driven predictive maintenance optimizes flatback tape application machinery, reducing unplanned downtime and enhancing throughput efficiency.

- Machine Vision systems utilize AI for real-time quality control, automatically detecting imperfections, inconsistencies in adhesive coating, and defects in the paper backing during manufacturing.

- AI algorithms enhance inventory management by accurately forecasting demand fluctuations across diverse end-use sectors (e.g., construction vs. e-commerce packaging).

- Generative AI tools assist in simulating new adhesive formulations and backing materials, accelerating the R&D cycle for specialized flatback tapes (e.g., UV-resistant or temperature-stable versions).

- AI integration into supply chain logistics optimizes the sourcing of raw materials, particularly sustainable paper pulp, ensuring cost-effective and environmentally compliant production.

- Automated pricing and competitive analysis, powered by AI, help manufacturers strategically position specialized flatback tape products within competitive industrial and consumer markets.

DRO & Impact Forces Of Flatback Paper Tapes Market

The dynamics of the Flatback Paper Tapes Market are profoundly influenced by a complex interplay of driving forces and inherent constraints. Primary drivers include the global push for sustainable packaging alternatives, where flatback paper tapes offer a recyclable and biodegradable advantage over plastic film tapes. Rapid growth in industries requiring precision masking, such as automotive painting and electronics assembly, also mandates the use of high-quality, residue-free flatback solutions. Simultaneously, the market faces restraints, chiefly volatile raw material costs, particularly fluctuations in paper pulp and chemical adhesive prices, which impact production margins. The competitive threat from advanced plastic film tapes, which sometimes offer superior moisture barrier properties, also limits expansion in specific applications. Opportunities arise from developing niche tapes with enhanced functional characteristics, such as extreme temperature resistance, and expanding penetration into emerging markets through improved distribution channels. These forces collectively shape the competitive landscape and strategic direction for key market players.

Segmentation Analysis

The Flatback Paper Tapes Market is structurally diverse, segmented primarily based on the adhesive composition, the tape's physical thickness, the intended application, and the specific end-use industry. Understanding these segments is crucial for manufacturers to tailor product specifications and market penetration strategies. The adhesive type—Rubber, Acrylic, or Silicone—determines the tape's performance characteristics, such as tack level, temperature tolerance, and removability. Application segmentation highlights the versatility of flatback tapes, ranging from high-volume, general-purpose carton sealing to specialized, high-precision masking and splicing tasks, each requiring unique strength and adhesion profiles. Thickness variations cater to light-duty labeling versus heavy-duty strapping needs. The end-use industry segmentation provides insight into major demand centers, such as the consistent, high-volume requirements of the automotive sector contrasted with the seasonal and project-based demands of the construction and DIY segments.

- By Adhesive Type

- Rubber-based Adhesive

- Acrylic-based Adhesive

- Silicone-based Adhesive

- By Thickness

- Standard Thickness (<= 6 mils)

- Heavy-duty Thickness (> 6 mils)

- By Application

- Packaging and Bundling

- Masking and Surface Protection (Industrial and Automotive)

- Splicing and Core Starting (Paper and Film Industries)

- Labeling and Graphics Arts

- By End-Use Industry

- Automotive (Refinishing and Assembly)

- Construction and Infrastructure

- General Manufacturing and Fabrication

- Electronics and Electrical

- Paper and Printing

- Arts, Crafts, and DIY

- Logistics and E-commerce

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Flatback Paper Tapes Market

The value chain for the Flatback Paper Tapes Market begins with upstream activities involving raw material procurement, primarily focusing on saturated paper backing, various adhesives (natural rubber, synthetic polymers, acrylics), and release agents. Suppliers of high-quality, sustainable paper pulp and specialized chemical additives wield significant influence over manufacturing costs and final product quality. The midstream manufacturing phase involves sophisticated coating and slitting processes, where technological expertise in applying consistent, solvent-free adhesives is a key differentiator. Effective manufacturing minimizes defects and optimizes roll consistency, crucial for automated application systems used by end-users.

Downstream activities center around distribution and market reach. The distribution channel is multifaceted, comprising direct sales to large industrial users (e.g., major automotive plants), specialized industrial distributors, and general retail channels for DIY and office supplies. Direct distribution allows for tailored product consultation and bulk purchasing efficiency, while indirect channels leverage the extensive reach of regional distributors to serve small and medium enterprises (SMEs) and specialized niche markets. E-commerce platforms are increasingly vital, especially for smaller businesses seeking sustainable packaging solutions, demanding robust fulfillment capabilities from manufacturers and distributors.

Efficient logistics and strategic partnerships between manufacturers and large industrial distributors (e.g., MRO providers) are paramount for ensuring timely supply and maintaining product integrity. The inherent technicality of certain flatback tapes, such as those used for high-temperature powder coating, necessitates strong technical support and application expertise within the sales and distribution network. This integrated approach ensures product specification matches end-user process requirements, optimizing the overall value delivered through the supply chain.

Flatback Paper Tapes Market Potential Customers

Potential customers for flatback paper tapes are diverse, spanning virtually every industrial and commercial sector that requires reliable sealing, masking, bonding, or identification. The largest segment of buyers includes logistics and e-commerce companies seeking reliable, eco-friendly carton sealing tapes that maintain integrity during transit while offering easy recyclability. Major automotive manufacturers and their Tier 1 suppliers represent a high-value customer base, utilizing specialized flatback tapes for precision masking during multi-stage painting processes, where clean removal and temperature resistance are non-negotiable performance attributes. The construction industry uses them for window sealing, stucco mask, and general surface protection.

Beyond these industrial giants, significant demand originates from the paper and printing industries, where flatback tapes are essential for web splicing—connecting new paper rolls during high-speed production without stopping the machinery. Furthermore, general manufacturing facilities, encompassing everything from furniture making to electronics assembly, rely on these tapes for bundling, holding components, and interim masking procedures. The arts and crafts, as well as the professional graphic design sectors, utilize precision flatback tapes for crisp line creation and mounting applications.

The consistent need across these disparate sectors emphasizes the product's fundamental utility. Buyers prioritize technical performance metrics such as tensile strength, shear resistance, temperature stability, and residue-free removal, depending on the specific application. For sustainability-conscious buyers, particularly in Europe and North America, the environmental profile and recyclability certification of the tape are increasingly critical purchasing criteria, making certified eco-friendly flatback tapes highly attractive.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.95 Billion |

| Market Forecast in 2033 | $2.88 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M, Tesa SE, Shurtape Technologies, Berry Global, Intertape Polymer Group (IPG), Nitto Denko, Saint-Gobain, Lohmann GmbH & Co. KG, Adhesives Research Inc., Scapa Group, Mactac (A Lintec Company), PPM Industries, Advance Tapes International, Orafol Europe GmbH, Tape Rite Co., Cantech, Sicad Group, Vibac Group, ProTapes & Specialties, Jiaxing Bofeisi Adhesive Products. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flatback Paper Tapes Market Key Technology Landscape

The technological landscape of the Flatback Paper Tapes Market is centered around optimizing adhesive chemistry, improving paper backing saturation, and enhancing coating application methods to achieve superior performance characteristics. A critical focus area is the transition from solvent-based adhesives to environmentally safer alternatives, such primarily water-based acrylics and hot-melt rubber formulations. This shift is driven by stringent environmental regulations and the need for VOC reduction in manufacturing processes. Innovations in hot-melt technology are particularly relevant, offering rapid setting times and high shear strength, crucial for high-speed automated packaging lines.

Furthermore, technology is rapidly evolving in the paper treatment phase. Manufacturers are employing advanced saturation techniques to enhance the tensile strength, tear resistance, and dimensional stability of the paper backing, ensuring it withstands aggressive industrial handling and high-temperature curing cycles common in automotive processes. This saturation often involves specialized latex or polymer treatments that allow the tape to adhere aggressively yet still unwind smoothly and resist edge curl, which is a key performance metric for automated machinery.

A third significant technological development involves precision coating systems, such as gravure and slot-die coating, which ensure extremely uniform adhesive thickness. This consistency is vital for applications requiring residue-free removal (masking) or guaranteed permanent bonding (splicing). Manufacturers are also integrating smart manufacturing techniques, including sensors and data analytics, to monitor the coating and drying processes in real-time, significantly reducing material waste and ensuring batch-to-batch consistency, thereby maintaining the quality required for demanding industrial applications.

Regional Highlights

The global Flatback Paper Tapes Market exhibits distinct characteristics across major geographical regions, influenced by localized industrial output, regulatory frameworks, and sustainability preferences.

- Asia Pacific (APAC)

- APAC is the fastest-growing region, dominated by high manufacturing output and rapid expansion of e-commerce logistics, particularly in China, India, and Southeast Asian nations.

- Demand is driven by general packaging and high-volume industrial use, with increasing adoption of advanced flatback tapes in the region's burgeoning automotive assembly and electronics manufacturing sectors.

- Lower labor costs and proximity to raw material sources support competitive production, making APAC a major global hub for flatback tape manufacturing and consumption.

- North America

- North America is a mature market characterized by high consumer awareness regarding sustainable packaging, leading to strong demand for recyclable paper tapes in retail and logistics.

- The region maintains significant demand for high-performance, specialized flatback tapes in the aerospace, automotive repair (aftermarket), and high-end construction industries, where performance specifications are critical.

- Stringent environmental compliance mandates prompt early adoption of solvent-free and VOC-compliant adhesive technologies.

- Europe

- Europe is a key market driven by exceptionally rigorous sustainability goals and EU regulations promoting circular economy principles, making flatback paper tapes highly desirable over plastic alternatives.

- Germany, France, and the UK are primary consumers, with strong uptake in specialized industrial masking, particularly in premium automotive manufacturing and industrial coating applications.

- Innovation in adhesive research, focusing on bio-based and biodegradable components, often originates in this region, setting high standards for performance and environmental profile.

- Latin America (LATAM)

- Growth in LATAM is linked to infrastructure development and increasing international trade, boosting the need for robust packaging and bundling solutions in countries like Brazil and Mexico.

- The market relies heavily on imports of specialized tapes but shows growing local manufacturing capacity for general-purpose applications.

- Middle East and Africa (MEA)

- The MEA market is expanding, driven by large-scale construction projects and diversification away from oil, particularly in the UAE and Saudi Arabia.

- Demand is emerging for flatback tapes used in general fabrication, maintenance, repair, and operations (MRO), often requiring tapes capable of withstanding high ambient temperatures prevalent in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flatback Paper Tapes Market.- 3M

- Tesa SE

- Shurtape Technologies

- Berry Global

- Intertape Polymer Group (IPG)

- Nitto Denko

- Saint-Gobain

- Lohmann GmbH & Co. KG

- Adhesives Research Inc.

- Scapa Group

- Mactac (A Lintec Company)

- PPM Industries

- Advance Tapes International

- Orafol Europe GmbH

- Tape Rite Co.

- Cantech

- Sicad Group

- Vibac Group

- ProTapes & Specialties

- Jiaxing Bofeisi Adhesive Products

Frequently Asked Questions

Analyze common user questions about the Flatback Paper Tapes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of flatback paper tape over traditional plastic tapes?

Flatback paper tapes offer superior tensile strength, excellent conformability, high resistance to tearing, and are generally recognized as a more sustainable, recyclable, and biodegradable packaging alternative compared to conventional plastic film tapes.

Which adhesive type is best suited for high-temperature industrial masking applications?

Silicone-based and high-performance Acrylic-based flatback tapes are optimally suited for high-temperature industrial masking, such as automotive painting or powder coating, due to their superior heat resistance and ability to remove cleanly without residue after curing cycles.

How is the growth of the e-commerce sector impacting the Flatback Paper Tapes Market?

The e-commerce boom is a major driver, generating immense demand for flatback tapes as preferred carton sealing solutions due to their eco-friendly profile, strong hold, and the ability to be easily processed through automated packaging and fulfillment systems.

What key factors determine the price volatility of flatback paper tapes?

Price volatility is primarily determined by fluctuations in the cost of critical raw materials, specifically saturated paper pulp, which is tied to forestry markets, and the chemical input costs for specialized synthetic rubber and acrylic adhesives.

Which geographic region currently dominates the consumption of flatback paper tapes?

While North America and Europe lead in high-value specialized segments, the Asia Pacific (APAC) region currently dominates the global consumption volume due to its vast manufacturing base, intensive industrial activity, and expansive logistics and packaging sector growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager