Flexible Fuel Tank Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443188 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Flexible Fuel Tank Market Size

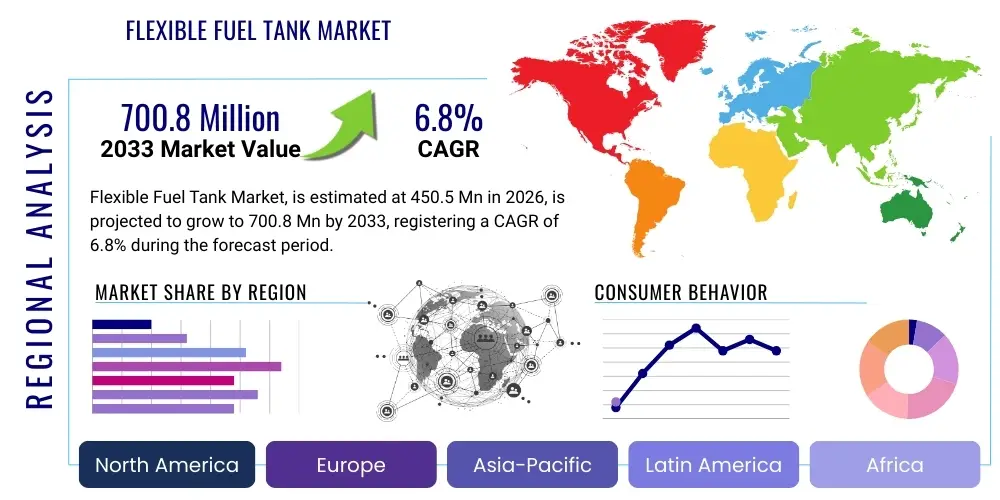

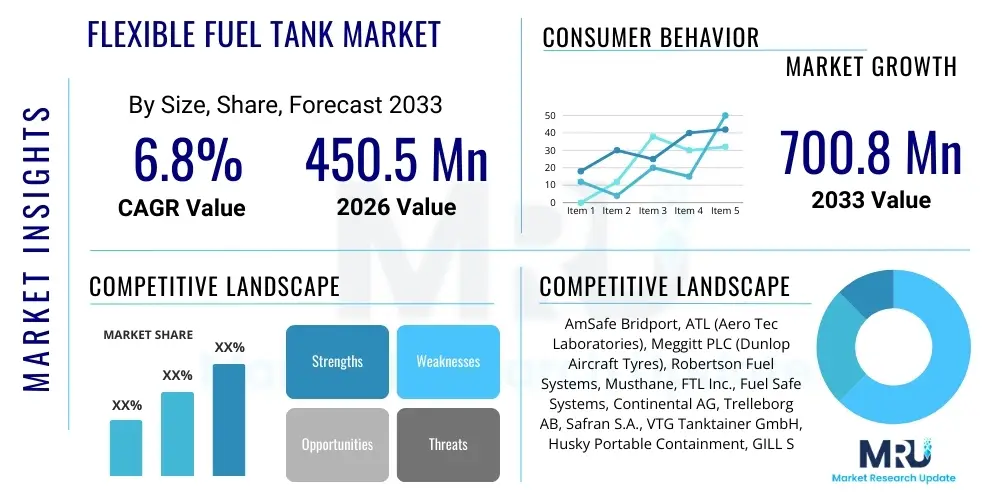

The Flexible Fuel Tank Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $450.5 Million in 2026 and is projected to reach $700.8 Million by the end of the forecast period in 2033.

Flexible Fuel Tank Market introduction

The Flexible Fuel Tank Market encompasses highly specialized fluid storage solutions designed for environments where traditional rigid tanks are impractical due to space constraints, dynamic movement, or stringent safety requirements regarding impact and explosion mitigation. These tanks, often referred to as fuel bladders or cells, are typically constructed from robust, lightweight, and chemical-resistant elastomers and composite fabrics, such as high-performance synthetic rubbers (e.g., Nitrile, Neoprene) reinforced with materials like Kevlar or ballistic nylon. This advanced material composition grants the tanks superior flexibility, crash resistance, and resistance to hydro-dynamic forces, making them essential components in high-stress applications.

Major applications of flexible fuel tanks span critical sectors including military and defense (ground vehicles, aircraft, temporary storage), aerospace (UAVs, light aircraft, emergency buoyancy), motorsports (Formula 1, NASCAR, endurance racing), and humanitarian aid/disaster relief (portable water and fuel storage). These tanks offer significant advantages over rigid counterparts, notably their ability to conform to complex vehicle geometries, collapse when empty to save space, and dramatically reduce the risk of catastrophic fuel leakage or ignition upon impact. The inherent lightweight nature of these systems contributes directly to enhanced vehicle performance and fuel efficiency, positioning them as a critical technology in weight-sensitive industries.

The market growth is primarily driven by escalating global defense modernization efforts, particularly the demand for self-sealing and crash-resistant fuel systems in military aircraft and ground combat vehicles. Furthermore, the stringent safety regulations imposed by international motorsports governing bodies (such as the FIA) mandating specialized fuel bladders to minimize fire risk during high-speed collisions strongly underpin demand. The continuous proliferation of unmanned aerial vehicles (UAVs) and drones, which prioritize maximum payload and minimum weight, also serves as a key accelerator for flexible, custom-fit fuel cell solutions.

Flexible Fuel Tank Market Executive Summary

The Flexible Fuel Tank Market is characterized by intense specialization, driven primarily by technological advancements in material science focusing on enhanced durability, reduced weight, and superior fire suppression capabilities. Business trends indicate a strong move toward integration of advanced elastomeric layers, often incorporating self-sealing properties derived from specialized internal coatings or gels, responding directly to military specifications for survivability. Key manufacturers are focusing on securing long-term contracts with defense primes and top-tier motorsports organizations, which often involve bespoke design and rigorous certification processes. The competitive landscape is moderately concentrated, emphasizing quality assurance (e.g., FAA, military standard compliance) over mass production, leading to high barriers to entry for new competitors who lack the necessary regulatory approvals and material expertise.

Regionally, North America maintains market dominance, primarily attributable to substantial defense spending, the presence of major aerospace manufacturers, and a thriving motorsports culture that mandates high-specification flexible fuel cells. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth trajectory, propelled by increasing indigenous defense manufacturing in countries like China and India, coupled with rapid urbanization driving demand for flexible, temporary industrial liquid storage solutions. European market stability is ensured by established aerospace programs and its central role in high-profile motorsports leagues, where regulatory requirements for safety drive consistent component upgrades and replacements. The specialized nature of production means supply chains are highly dependent on proprietary material formulations and specialized vulcanization/fabrication equipment.

Segment trends reveal that the Defense & Aerospace application segment holds the largest market share, prioritizing tanks with extreme environmental tolerance and advanced ballistic protection capabilities. Concurrently, the increasing capacity segment (tanks above 500 liters) is expanding rapidly due to demand from long-range military transports and large industrial storage applications. Material innovation is trending toward PTFE (Polytetrafluoroethylene) liners, which offer superior resistance to aggressive modern fuels and bio-fuels, enhancing the operational lifespan and maintenance cycle of the tanks. The ongoing shift toward lighter, more fuel-efficient vehicles across all application sectors ensures sustained innovation in material composites to achieve maximum strength-to-weight ratios without compromising structural integrity.

AI Impact Analysis on Flexible Fuel Tank Market

User inquiries regarding AI's influence on the Flexible Fuel Tank Market frequently center on optimizing material failure prediction, enhancing complex manufacturing processes like vulcanization and seam sealing, and streamlining the highly regulated supply chain. Users express expectations that AI-driven analytics will drastically reduce material waste during production and improve the consistency of quality assurance testing, particularly for tanks destined for high-stakes environments like military aviation or space applications. Common concerns involve the initial capital expenditure required to implement complex machine learning models for non-rigid material analysis and ensuring that AI-optimized designs still meet the fundamental physical performance requirements set by bodies like the FAA or DoD. The key themes revolve around achieving predictive maintenance, automating complex design iterations for custom geometries, and using computer vision for high-fidelity defect detection far beyond human capabilities.

AI is strategically integrated into the material science aspect of flexible fuel tank production. Machine learning algorithms analyze vast datasets comprising stress testing results, chemical exposure histories, and fatigue cycle data for various composite materials (e.g., rubberized fabrics, Kevlar, and specialized coatings). This analysis enables manufacturers to predict precisely how material combinations will behave under extreme operating conditions, such as high-G maneuvers or ballistic impact, leading to the rapid iteration of safer, lighter, and more durable designs. Generative design AI is becoming crucial for optimizing the internal baffling and external shape of the tanks to maximize volume efficiency while mitigating fuel sloshing, a critical factor in motorsports and aerospace stability.

Furthermore, AI-powered computer vision systems are revolutionizing quality control during the manufacturing phase. These systems monitor the precise application of sealants and coatings, identify microscopic flaws in the fabric weaves, and ensure the consistency of the complex vulcanization process, which is vital for the structural integrity of the fuel bladder. In logistics and supply chain management, AI algorithms optimize inventory management for highly specialized, often temperature-sensitive raw materials, predicting procurement needs based on complex long-term defense and aerospace contracts, thereby minimizing lead times and reducing overall operational risks associated with component shortages.

- AI-driven Predictive Failure Analysis (PFA) optimizes material selection for longevity and crash resistance.

- Machine Learning (ML) algorithms streamline complex elastomer curing and vulcanization parameters for superior bond strength.

- Generative design tools enable rapid iteration of custom fuel cell geometries for complex vehicle integration (e.g., UAV wings).

- Computer vision systems enhance quality assurance, detecting microscopic defects in fabric and seam sealing during production.

- Intelligent inventory management systems predict demand spikes for regulated materials, ensuring robust defense supply chain stability.

- Optimization of fuel slosh mitigation through dynamic baffling design modeled by AI simulation.

DRO & Impact Forces Of Flexible Fuel Tank Market

The Flexible Fuel Tank Market is primarily driven by rigorous safety and environmental regulations in high-risk sectors (Defense, Motorsport), alongside inherent advantages such as significant weight reduction and superior impact resistance compared to metallic tanks. However, high initial production costs, complexity in obtaining highly specialized raw materials (advanced polymers and fire-retardant fabrics), and the necessity for lengthy, expensive regulatory certifications (e.g., military MIL-spec standards, FIA approval) act as significant restraints. Opportunities lie in the increasing adoption of flexible tanks for hydrogen storage solutions—requiring specialized liners—and the burgeoning market for commercial and military UAVs, which mandate ultra-lightweight, customizable energy storage systems. These forces converge to create a market characterized by high value, low volume, and technological specialization, where innovation in material science directly dictates market share and profitability.

The primary driver is the pervasive demand for improved safety features across critical applications. In motorsports, the FIA mandate for self-sealing, crash-resistant fuel bladders has standardized the adoption of flexible tanks, minimizing fuel spillage in high-speed accidents. Similarly, defense organizations worldwide prioritize crew survivability, necessitating flexible tanks that are self-sealing against small arms fire and capable of withstanding severe impacts without rupture. Conversely, a major restraint is the highly capital-intensive nature of manufacturing. Production requires precise environmental controls, specialized machinery for composite layup and curing, and proprietary formulations of elastomers, resulting in a high unit cost that limits penetration into less demanding commercial vehicle markets.

A critical opportunity impacting future growth involves the transition to alternative fuels. As the aerospace and logistics sectors explore hybrid propulsion systems and hydrogen fuel cells, flexible tank manufacturers are uniquely positioned to develop specialized, lightweight bladders that can safely store cryogenic or high-pressure gases and aggressive chemical compounds. Furthermore, the rapid expansion of the global UAV market, driven by reconnaissance and logistics applications, presents a consistent demand for bespoke, lightweight fuel bladders that can be integrated into unconventional airframe designs. These opportunities necessitate continuous investment in R&D to maintain a technological edge and comply with evolving safety and fuel compatibility standards.

- Drivers (D): Increased global focus on vehicle safety standards and crash resistance; Growing adoption in military and defense for crew survivability; Lightweight advantages enhancing fuel efficiency in aerospace and racing.

- Restraints (R): High manufacturing complexity and stringent quality control requirements; Dependence on specialized, high-cost raw materials (e.g., aramid fibers, proprietary elastomers); Lengthy and costly regulatory and certification processes (e.g., FAA, MIL-STD).

- Opportunities (O): Development of flexible tanks for alternative fuels (Hydrogen, Bio-fuels); Exponential growth in the Unmanned Aerial Vehicle (UAV) market; Expanding industrial applications for temporary and remote fuel/water storage.

- Impact Forces: Regulatory mandates dictate design specifications; Technological advancements in self-sealing and ballistic materials; Geopolitical stability influencing defense spending and procurement cycles.

Segmentation Analysis

The Flexible Fuel Tank Market is comprehensively segmented based on material type, capacity, application, and end-user, reflecting the diverse and specialized requirements of the core industries it serves. Understanding these segments is crucial as material composition and capacity are directly correlated with regulatory compliance and cost structures. For instance, tanks designed for Formula 1 must adhere to strict capacity limits and utilize high-end, certified materials, differentiating them significantly from larger, less impact-resistant tanks used for bulk military fuel storage in remote areas. The technical specifications within each segment drive supplier differentiation, demanding focused expertise in specific manufacturing techniques and material integration.

By Material Type, the market is differentiated between Rubberized Fabric (primarily Nitrile and Neoprene for general flexibility and hydrocarbon resistance) and Composite Materials (incorporating Kevlar, Aramid fibers, or ballistic nylon for superior strength and puncture resistance). Composite materials dominate high-stakes sectors like defense and aerospace due to their superior survivability characteristics, while specialized materials like PTFE liners are gaining traction for compatibility with aggressive, modern synthetic fuels. The capacity segment is bifurcated, ranging from small tanks (under 100 liters) prevalent in small UAVs and lightweight racing vehicles to large tanks (over 500 liters) critical for long-range military logistics and temporary field depots.

The Application segment is critical, determining the regulatory environment and performance criteria. Defense and Aerospace demand the most stringent specifications regarding crashworthiness and self-sealing technology, representing the highest value segment. Motorsports require tanks optimized for high-G forces and rapid refueling, while commercial/industrial applications prioritize durability and cost-effectiveness for bulk fluid transfer. Analyzing these segments provides strategic insights into investment areas, highlighting the growing need for specialized small-capacity tanks driven by drone technology and the enduring high-value nature of the defense sector.

- By Material Type:

- Rubberized Fabric (Nitrile, Neoprene)

- Composite Materials (Kevlar/Aramid Reinforced)

- Specialized Liners (PTFE, Polyurethane)

- By Capacity:

- Small Capacity (Under 100 Liters)

- Medium Capacity (100–500 Liters)

- Large Capacity (Above 500 Liters)

- By Application:

- Defense & Aerospace

- Motorsports (Racing)

- Industrial & Commercial Storage

- Marine & Offshore

- By End-User:

- OEMs (Aircraft/Vehicle Manufacturers)

- Aftermarket & Replacement (Racing Teams, Military Maintenance)

Value Chain Analysis For Flexible Fuel Tank Market

The value chain for flexible fuel tanks is complex and highly specialized, beginning with the sourcing of specialized raw materials. The upstream segment is dominated by chemical companies supplying high-grade synthetic elastomers (e.g., specialized fluoropolymers, proprietary nitrile compounds) and fiber manufacturers providing high-strength reinforcement textiles such as aramid or ballistic nylon. Due to the requirement for specific chemical resistance and fire-retardant properties, the procurement of these raw materials often involves proprietary agreements and lengthy qualification processes. This upstream specialization directly impacts the cost and performance attributes of the final product, creating critical dependency on a limited number of certified material suppliers globally.

The core manufacturing and midstream segment involves sophisticated processes, including composite layup, precision cutting, and highly controlled vulcanization (curing) or RF welding techniques to create durable, leak-proof seams. Quality control is paramount in this stage, often involving advanced non-destructive testing (NDT) such as pressure testing and radiographic inspection to ensure compliance with military or racing safety standards. Specialized fabricators must possess extensive expertise in achieving optimal material bonding, particularly at stress points where the bladder interfaces with metallic hardware (e.g., filler necks, pump housings). The high level of technical skill required restricts market participation to companies with substantial technological maturity and certifications.

The downstream distribution channels are typically direct-to-customer due to the bespoke nature of the products. Direct channels involve manufacturers engaging directly with Defense Prime Contractors, major aerospace OEMs (Original Equipment Manufacturers), and professional Motorsports Teams. Indirect channels, while less common, involve specialized distributors or maintenance, repair, and overhaul (MRO) service providers handling aftermarket replacements or smaller industrial orders. The direct sales model ensures that complex technical requirements and regulatory compliance needs are communicated accurately, facilitating the delivery of custom-engineered solutions crucial for high-performance and safety-critical applications.

Flexible Fuel Tank Market Potential Customers

The primary customers for flexible fuel tanks are concentrated within highly regulated and specialized sectors that prioritize safety, weight reduction, and customization over initial cost. The largest customer segment consists of global defense organizations and their prime contractors (e.g., Lockheed Martin, Boeing Defense, BAE Systems). These entities are consistent high-volume buyers, utilizing flexible tanks in tactical aircraft, helicopters, combat vehicles, and field logistics for their superior crashworthiness and self-sealing capabilities against hostile fire. Procurement cycles in this sector are lengthy and demanding, requiring adherence to strict military standards (MIL-SPEC) and significant testing/qualification phases.

The second major customer group includes global motorsports teams and racing leagues (e.g., Formula 1 teams, NASCAR, endurance racing outfits). These customers require FIA or comparable sanctioning body certified bladders designed to withstand extreme acceleration, deceleration, and impact forces while maintaining fuel stability (slosh mitigation). Their demand is characterized by cyclical replacement driven by regulatory expiry dates and continuous technological upgrades aimed at optimizing vehicle weight and center of gravity. Furthermore, custom-designed tanks are frequently commissioned for specific chassis geometries to maximize internal volume efficiently.

An emerging, high-growth customer base involves Unmanned Aerial Vehicle (UAV) manufacturers and specialized aerospace companies focusing on light aircraft and space exploration logistics. UAVs require extremely lightweight, custom-fit fuel solutions to maximize range and payload capacity, making flexible bladders an ideal choice. The industrial and commercial sector also represents a reliable customer base, particularly entities involved in remote exploration, disaster relief, and bulk fluid transport (such as mining operations or emergency services) where portable, temporary, and durable fluid storage solutions are essential.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450.5 Million |

| Market Forecast in 2033 | $700.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AmSafe Bridport, ATL (Aero Tec Laboratories), Meggitt PLC (Dunlop Aircraft Tyres), Robertson Fuel Systems, Musthane, FTL Inc., Fuel Safe Systems, Continental AG, Trelleborg AB, Safran S.A., VTG Tanktainer GmbH, Husky Portable Containment, GILL Sensors & Controls, GWR Fuel Systems, Kolon Industries Inc., Westamerica, SEI Industries Ltd., Firestone Industrial Products, Custom Metalcraft Inc., F.J. Zipline. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Fuel Tank Market Key Technology Landscape

The technological landscape of the Flexible Fuel Tank Market is rapidly evolving, driven by the need for enhanced safety, reduced weight, and compatibility with next-generation fuels. A primary area of innovation is in the development of advanced composite layering systems, which incorporate highly elastic elastomers, chemical barriers (such as PTFE or ETFE liners), and structural reinforcement materials like aramid or glass fibers. The goal is to create multi-layered systems that are not only resistant to aggressive fuels (including JP-8 jet fuel and high-octane racing fuels) but also offer superior burst strength and flexibility in extreme temperature ranges. Continuous refinement in the cross-linking and vulcanization processes for synthetic rubber compounds is essential to ensure long-term integrity and prevent degradation under cyclic loading, a crucial factor in aerospace applications.

Another crucial technological advancement involves self-sealing and crashworthy design methodologies. Self-sealing technology typically integrates specialized polymeric materials or gels between the tank’s layers that rapidly swell and close upon being punctured by a projectile, significantly mitigating fuel loss and explosion risk—a non-negotiable feature for military platforms. Crashworthy tanks utilize proprietary internal baffling systems and external restraints to ensure the bladder maintains its shape and integrity upon high-impact deceleration. Furthermore, manufacturers are increasingly utilizing advanced Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) software to simulate complex sloshing dynamics and predict stress concentration points, optimizing the tank’s internal structure before physical prototyping, thereby accelerating the design cycle and improving performance.

The integration of monitoring and sensor technologies is also becoming standard practice. Modern flexible fuel cells are often equipped with integrated fuel level sensors, temperature gauges, and sometimes structural health monitoring (SHM) systems embedded within the tank walls. These sensors relay real-time data on fuel mass, thermal conditions, and potential structural fatigue back to vehicle management systems. This technological shift supports predictive maintenance strategies, essential for extending the operational life of high-value assets in defense and aerospace. Furthermore, the development of specialized barrier materials for hydrogen storage (cryogenic or pressurized) is opening up new technological pathways, requiring expertise in vacuum insulation and ultra-low temperature resistance within a flexible, lightweight envelope.

Regional Highlights

- North America: North America holds the largest market share, predominantly driven by the robust defense sector and extensive expenditure on military aircraft and ground vehicle upgrades demanding self-sealing and crash-resistant fuel systems. The region is home to major aerospace OEMs and defense contractors, facilitating close collaboration in the development of custom-engineered fuel bladders adhering to stringent MIL-SPEC standards. Additionally, the dominant presence of high-profile motorsports leagues (NASCAR, IndyCar) guarantees consistent demand for certified racing fuel cells, ensuring continuous technological procurement and aftermarket activity.

- Europe: Europe represents a mature market, strongly supported by a well-established aerospace industry (e.g., Airbus programs) and being the global epicenter for Formula 1 and other elite motorsports. Regulatory frameworks set by the European Aviation Safety Agency (EASA) and the Federation Internationale de l’Automobile (FIA) drive high demand for technologically advanced, safety-critical flexible tanks. Key growth is focused on R&D for next-generation material science to comply with evolving environmental and fuel compatibility standards, particularly regarding bio-fuels and Sustainable Aviation Fuels (SAFs).

- Asia Pacific (APAC): The APAC region is forecast to be the fastest-growing market due to rapid military modernization programs in China, India, and South Korea, leading to increasing indigenous production of aircraft and combat vehicles requiring flexible fuel solutions. The proliferation of commercial and military UAV technology across the region, coupled with rising demand for flexible storage in infrastructure projects and disaster response applications, is accelerating market expansion. Local manufacturers are increasingly focusing on technology transfer and gaining international certifications to meet specialized defense and aerospace procurement needs.

- Latin America & Middle East and Africa (LAMEA): While smaller in volume, these regions show steady growth, primarily driven by defense purchases and the need for remote industrial and mining storage solutions. The Middle East, in particular, exhibits demand linked to high military spending and specialized requirements for flexible storage solutions in extreme desert environments, focusing on resilience to high temperatures and UV exposure. Latin America's growth is tied to local defense fleet upgrades and small-scale commercial aviation needs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Fuel Tank Market.- ATL (Aero Tec Laboratories)

- Meggitt PLC (Dunlop Aircraft Tyres)

- Robertson Fuel Systems

- AmSafe Bridport

- Fuel Safe Systems

- Continental AG

- Trelleborg AB

- Safran S.A.

- Musthane

- FTL Inc.

- VTG Tanktainer GmbH

- Husky Portable Containment

- GILL Sensors & Controls

- GWR Fuel Systems

- Kolon Industries Inc.

- Westamerica

- SEI Industries Ltd.

- Firestone Industrial Products

- Custom Metalcraft Inc.

- F.J. Zipline

Frequently Asked Questions

Analyze common user questions about the Flexible Fuel Tank market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of flexible fuel tanks over traditional rigid tanks?

Flexible fuel tanks offer superior crash resistance, are self-sealing against ballistic threats, weigh significantly less than metallic tanks, and can conform to complex vehicle spaces, collapsing when empty for efficient storage—critical for aerospace and motorsports safety.

Which regulatory bodies dictate the safety standards for flexible fuel tanks?

Key regulatory bodies include the Federal Aviation Administration (FAA) and corresponding international agencies like EASA for aviation, military standards (e.g., MIL-SPEC) for defense applications, and the Federation Internationale de l’Automobile (FIA) for global motorsports.

How is AI influencing the manufacturing process of flexible fuel cells?

AI is employed for predictive failure analysis in materials, optimizing complex vulcanization and bonding processes, and using computer vision systems for highly detailed quality control checks on seam integrity and composite layering, reducing defect rates in critical applications.

What materials are commonly used in the construction of high-performance flexible fuel bladders?

High-performance bladders typically utilize multi-layered composites, including specialized elastomers like Nitrile or Fluoropolymers for chemical resistance, reinforced structural fabrics such as aramid (Kevlar) or ballistic nylon for strength, and PTFE liners for aggressive fuel compatibility.

What is the market outlook for flexible fuel tanks in the UAV and drone sector?

The outlook is exceptionally strong; the rapid expansion of both military and commercial UAVs necessitates ultra-lightweight, customizable fuel storage solutions to maximize flight endurance and payload capacity, making flexible bladders the preferred technology choice for these platforms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager