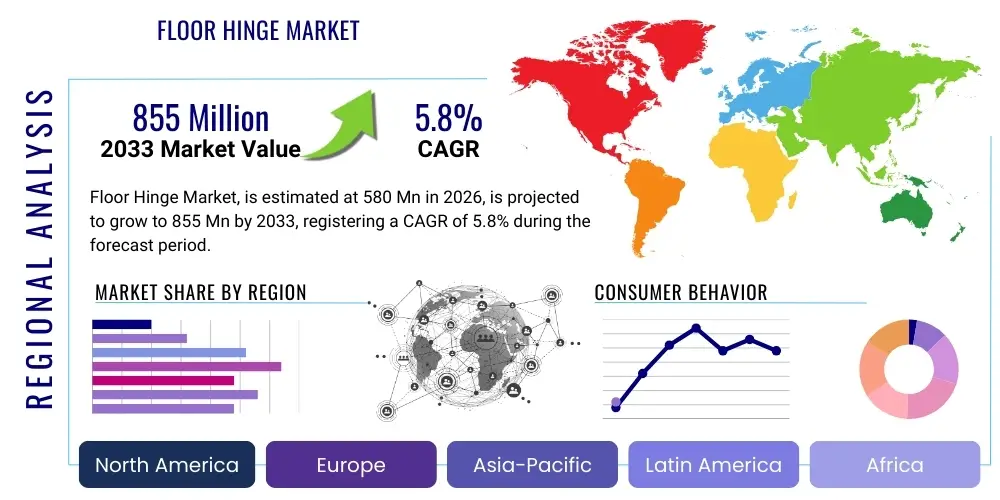

Floor Hinge Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443409 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Floor Hinge Market Size

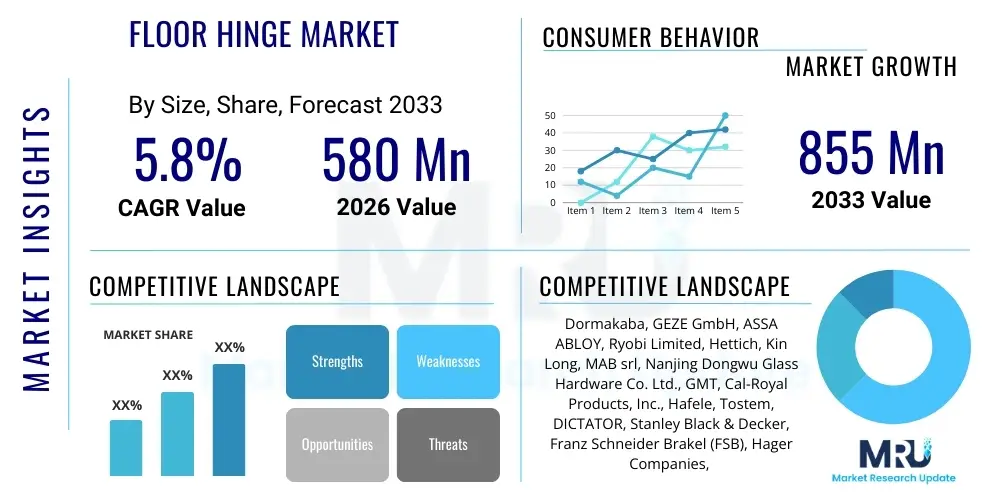

The Floor Hinge Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 580 Million in 2026 and is projected to reach USD 855 Million by the end of the forecast period in 2033. This consistent expansion is predominantly fueled by the global resurgence in commercial infrastructure development, coupled with stringent building codes requiring controlled and safe door closing mechanisms in high-traffic areas such as hospitals, airports, and retail establishments. The increasing aesthetic demands in modern architecture, favoring frameless glass doors, further necessitate the adoption of high-performance, concealed floor hinges, thus driving revenue growth across mature and emerging economies.

The valuation trajectory reflects a growing preference among architects and builders for technologically advanced, heavy-duty floor hinges capable of handling larger and heavier door systems, particularly those made of tempered glass or robust metals. Investments in research and development are concentrating on enhancing the durability, corrosion resistance, and installation efficiency of these mechanisms. While traditional hydraulic floor hinges still dominate volume, the high-value segment is shifting towards electro-hydraulic and smart sensor-integrated solutions that offer synchronized and automated door operation, particularly critical in compliance with accessibility and safety standards.

Floor Hinge Market introduction

The Floor Hinge Market encompasses the manufacturing, distribution, and installation of specialized hardware mechanisms designed to facilitate the controlled opening and closing of doors, predominantly heavy or large architectural doors, by being recessed directly into the floor. These sophisticated mechanisms typically employ hydraulic damping systems to ensure smooth, adjustable closing speeds and holding capabilities, crucial for safety and operational efficiency in commercial and public buildings. Unlike traditional door closers mounted overhead, floor hinges offer a concealed aesthetic, preserving the clean lines of modern design, especially popular with frameless glass applications in retail facades, office lobbies, and public transit hubs. The primary function is to maintain door control under varying conditions, ensuring the door returns reliably to its closed or open position, often supporting both single-action (one-way swing) and double-action (two-way swing) door movements.

Major applications of floor hinges span across the construction sector, including high-end residential complexes, institutional buildings such as universities and government facilities, and critical infrastructure like hospitals and data centers. The benefits associated with using high-quality floor hinges are multifaceted: superior aesthetics due to concealment, exceptional load-bearing capacity, resistance to physical wear and tear, and compliance with fire safety and disability access (ADA/EN) requirements by providing adjustable opening forces and delay actions. The mechanism's ability to support extremely heavy doors (up to several hundred kilograms) is a key differentiator, enabling architectural freedom previously constrained by traditional hardware limitations.

Driving factors propelling this market include rapid urbanization, leading to an increase in high-rise commercial construction activities globally, particularly across the Asia Pacific region. Furthermore, stringent regulatory frameworks related to public safety and accessibility, particularly concerning emergency egress and ease of access for persons with mobility challenges, necessitate the reliable performance offered by modern hydraulic floor hinges. Technological advancements, such as the integration of corrosion-resistant materials and the development of compact, easy-to-install units, are reducing installation time and overall maintenance costs, thereby increasing the overall lifecycle value proposition for end-users and stimulating continuous market demand.

Floor Hinge Market Executive Summary

The Floor Hinge Market is exhibiting robust growth, propelled primarily by expansionary trends in the global construction sector, particularly within commercial and high-end retail infrastructure. Business trends indicate a consolidation among top-tier manufacturers who are focusing intensely on proprietary hydraulic technology and material science innovation to offer products with enhanced longevity and precise adjustability. Key players are also capitalizing on the aesthetic shift towards minimalist design, emphasizing concealed mechanisms that support larger, heavier glass panels. The immediate business future is characterized by a strong demand for products compliant with international safety standards (e.g., CE, UL, ANSI), driving out lower-quality substitutes and establishing a premium market segment for certified, high-performance hinges. Moreover, the integration of BIM (Building Information Modeling) standards in construction project planning is leading to increased specification of high-data, detailed floor hinge models early in the design phase, thus streamlining procurement and favoring manufacturers who provide comprehensive digital product support.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of growth, spurred by massive governmental investment in infrastructural development, rapid commercial urbanization in countries like China and India, and a burgeoning hospitality sector demanding premium architectural finishes. North America and Europe, while representing mature markets, maintain high revenue share due to rigorous renovation cycles, stricter building safety mandates, and a consistent demand for advanced, smart hardware solutions that comply with universal design principles. In these regions, the focus is less on volume growth and more on value creation through specialized products, such as hinges designed for extreme weather conditions or those offering enhanced connectivity for smart building systems. The Middle East and Africa (MEA) region is also emerging as a high-potential zone, driven by large-scale, iconic construction projects requiring bespoke, high-load capacity door hardware.

Segment trends reveal that the double-action floor hinge segment continues to hold the largest market share by volume, due to its versatility and standard use in commercial settings where bidirectional movement is beneficial. However, the fastest growth is observed in the electro-hydraulic/automatic segment, aligning with the broader trend toward automation in smart commercial buildings and increased need for touchless access solutions, particularly emphasized post-pandemic. Material segmentation highlights Stainless Steel as the dominant choice due to its superior corrosion resistance and durability, critical for longevity in diverse climatic environments. The application segmentation clearly demonstrates commercial use (offices, retail, hospitality) as the most lucrative area, commanding the highest average selling prices due to the requirement for heavy-duty, certified products.

AI Impact Analysis on Floor Hinge Market

User queries regarding AI's influence on the Floor Hinge market generally revolve around two major themes: manufacturing efficiency and product intelligence. Common questions include how AI affects the precision engineering of hydraulic components, whether smart hinges can use machine learning for predictive maintenance, and the role of AI in optimizing supply chain and material logistics. Users are keen to understand if AI-driven design tools can accelerate the development of customized hinge solutions for unique architectural needs and if automated quality control systems enhance product reliability beyond traditional manual checks. The overarching expectation is that AI will move the floor hinge from a passive mechanical component to an active, data-generating element within a larger smart building ecosystem, offering enhanced safety, efficiency, and maintenance predictability.

The integration of Artificial Intelligence primarily impacts the floor hinge industry through enhanced operational precision and the creation of intelligent product derivatives. In manufacturing, AI algorithms optimize CNC machining parameters and oversee automated assembly lines, leading to near-zero defect rates for critical hydraulic components, thereby significantly boosting the overall reliability and lifespan of the final product. Furthermore, the application of machine learning in material science allows manufacturers to rapidly model and test new alloys and coatings for superior corrosion and fatigue resistance, accelerating the innovation cycle. This operational improvement directly addresses the core user concern regarding the long-term durability and performance consistency required for certified architectural hardware.

In terms of product innovation, the concept of a 'Smart Hinge' is being realized through AI. These hinges integrate sensors that monitor operational metrics such as usage cycles, force exertion, environmental temperature fluctuations, and hydraulic fluid pressure. AI then analyzes this data to predict potential failure points or maintenance requirements long before a catastrophic failure occurs, enabling proactive servicing. This predictive maintenance capability minimizes downtime and operational expenses for commercial building owners, positioning the floor hinge not just as a piece of hardware, but as a crucial data node contributing to the overall Building Management System (BMS) efficiency. AI also facilitates complex integration with access control systems and synchronizes movement in multi-door installations, optimizing pedestrian flow and security responses.

- AI-driven Predictive Maintenance: Enabling real-time monitoring and forecasting of hydraulic fluid degradation and component wear, minimizing unexpected failures.

- Automated Quality Control: Utilizing vision systems and deep learning algorithms for micron-level defect detection during high-volume manufacturing processes.

- Optimized Design and Simulation: Employing generative design AI tools to quickly prototype and simulate hinge mechanisms for new load requirements and architectural specifications.

- Supply Chain Optimization: Using AI to predict demand fluctuations and manage complex global sourcing of specialized raw materials (e.g., high-grade stainless steel, precision seals).

- Smart Building Integration: Facilitating seamless data exchange between floor hinges and central Building Management Systems (BMS) for enhanced security and energy management.

DRO & Impact Forces Of Floor Hinge Market

The Floor Hinge Market dynamics are characterized by a strong interplay of compelling drivers centered on architectural trends and safety mandates, counterbalanced by inherent restraints related to installation complexity and high initial investment costs. Opportunities are largely dictated by the pervasive trend of smart building integration and market penetration into high-growth developing economies. The primary driving force remains the global shift towards aesthetically minimal yet highly functional door systems, particularly the increased adoption of large, heavy glass doors in commercial spaces, which strictly require the load-bearing capacity and concealed nature offered exclusively by floor hinges. Furthermore, continuous updating and tightening of international standards for accessibility, fire safety, and emergency exit mechanisms globally compel building developers to utilize certified, high-specification hydraulic door control hardware, regardless of initial price sensitivity. This regulatory environment acts as a non-negotiable demand driver.

Key restraints include the relatively complex and time-consuming installation process compared to surface-mounted door closers, requiring precise floor preparation and specialized knowledge, which can increase overall project costs and timelines. Moreover, the initial capital expenditure for premium, heavy-duty floor hinges—especially those with advanced features like electro-hydraulic operation or specialized finishes—is substantially higher. This cost factor often presents a barrier to adoption in budget-constrained residential or smaller commercial projects, leading to the selection of less durable, lower-performance alternatives. Additionally, the maintenance of floor hinges, although infrequent, requires accessing the concealed mechanism, which can be disruptive, necessitating meticulous planning during facility management, a factor that facility managers often weigh when specifying hardware.

Significant opportunities emerge from the convergence of mechanical hardware with IoT (Internet of Things) technology. The development of 'smart floor hinges' that provide real-time status, diagnostics, and remote access control offers a compelling value proposition for large institutional buildings and high-security installations. Geographically, emerging markets in Southeast Asia, Latin America, and certain parts of Africa present vast, untapped potential for mass adoption, driven by rapid urbanization and the adoption of modern building practices. Strategic partnerships between hardware manufacturers and smart building solution providers are creating specialized niches for technologically integrated door systems. Furthermore, market players are actively exploring ways to simplify the installation process through modular designs and installation templates, aiming to mitigate the primary restraint of labor complexity, thereby unlocking wider market acceptance and mitigating negative impact forces.

Segmentation Analysis

The Floor Hinge Market is meticulously segmented based on product type, material composition, application area, and load capacity, reflecting the diverse requirements of the architectural and construction industries. This segmentation is crucial as it dictates material choice, hydraulic complexity, certification requirements, and pricing strategies across the market spectrum. Analyzing these segments helps in understanding the varying demands placed upon the mechanism, ranging from light-duty residential use where aesthetic concealment is paramount, to extreme heavy-duty commercial or industrial applications where structural integrity and sustained high-cycle performance are non-negotiable. The segmentation by application, for instance, highlights the premium pricing power and stricter regulation adherence required in the institutional segment compared to standard residential installations.

The market's performance is heavily weighted toward the double-action hydraulic floor hinge, owing to its universal suitability for high-traffic doorways requiring bidirectional movement, such as those found in shopping malls and transit stations. However, the future growth narrative is increasingly being written by the specialized segments. Material segmentation reveals a strong correlation between performance requirements and material selection; for instance, brass and high-grade stainless steel dominate products specified for high humidity or corrosive environments, ensuring the longevity expected in coastal regions or industrial facilities. Load capacity remains a critical distinguishing factor, directly linked to the physical size and weight of modern architectural door designs, with heavy-duty hinges designed specifically to manage oversized, custom-built pivot doors becoming a high-margin growth area as architects push the boundaries of door design.

Furthermore, the segmentation by product type is increasingly complex with the introduction of electro-hydraulic variants, which are essentially floor hinges integrated with electronic control units for automation, precise speed control, and seamless interface with security systems. While still a niche segment, these high-technology products command significant premiums and are rapidly growing in prominence within smart infrastructure projects and environments requiring touchless or highly regulated access. The underlying segmentation structure provides manufacturers with a clear roadmap for product development, identifying where to focus R&D resources—whether on improving the basic reliability of standard mechanical units or investing heavily in the digital integration capabilities of high-end automated solutions, thereby strategically positioning themselves for future market capture.

- By Product Type:

- Single Action Floor Hinges

- Double Action Floor Hinges

- Electro-Hydraulic Floor Hinges (Automatic)

- By Material:

- Stainless Steel

- Brass

- Aluminum

- Other Alloys

- By Application:

- Commercial (Offices, Retail, Hospitality)

- Residential (High-End & Multi-Family)

- Industrial & Institutional (Hospitals, Airports, Education Facilities)

- By Load Capacity:

- Light Duty (up to 80 kg)

- Medium Duty (81 kg to 150 kg)

- Heavy Duty (151 kg and above)

Value Chain Analysis For Floor Hinge Market

The value chain of the Floor Hinge Market begins fundamentally with upstream activities centered on the procurement and precision processing of specialized raw materials. High-grade materials such as corrosion-resistant stainless steel (e.g., SUS 304, 316), brass alloys for internal components, and specialized polymers for seals and hydraulic fluid are critical inputs. Upstream analysis focuses on securing reliable, high-quality material suppliers who can meet stringent material specifications and certifications required for safety-critical components. Precision engineering, casting, and CNC machining processes transform these raw materials into the highly complex, micron-tolerance internal mechanisms of the hinge, including the spindle, piston, and damping unit. Fluctuations in commodity prices for steel and brass significantly impact manufacturing costs and, subsequently, the final pricing of the hardware. Strategic partnerships with certified material providers are crucial for maintaining quality consistency and achieving cost optimization.

The midstream stage involves the core manufacturing, assembly, and rigorous quality control testing, where floor hinges are assembled, filled with hydraulic oil, and calibrated to meet specified closing forces and delay actions. Certification and compliance testing (e.g., fire rating, cyclic testing, load testing) are integral parts of this stage, adding considerable value and establishing product credibility necessary for market acceptance, particularly in Europe and North America. Manufacturers invest heavily in automated assembly lines and cleanroom environments to minimize contaminants that could compromise the delicate hydraulic systems. This phase also includes the development and integration of electronic components for the growing segment of electro-hydraulic hinges, requiring expertise in both mechanical and electrical engineering.

Downstream activities are dominated by distribution and installation channels. Direct channels involve manufacturers supplying large architectural firms, major construction contractors, or specialized building hardware procurement divisions for high-volume projects. This channel emphasizes technical consultation, customized product specification, and robust after-sales support. Indirect distribution primarily utilizes wholesale hardware distributors, specialized door hardware suppliers, and regional dealers who provide product inventory and services to smaller contractors, installers, and renovation projects. The role of architects and specification writers is paramount in the downstream segment, as they often dictate the brand and model of the hinge during the design phase. Effective engagement and education of the architectural community, along with maintaining a wide network of trained professional installers, are key to market penetration and sustained revenue generation in the highly fragmented end-user market.

Floor Hinge Market Potential Customers

The Floor Hinge Market's potential customers constitute a diverse spectrum of end-users driven by the need for controlled door movement, safety compliance, and aesthetic integration in building structures. The primary end-users are large commercial developers and real estate investment trusts (REITs) engaged in constructing high-rise office towers, large retail shopping centers, and mixed-use complexes. These entities require high-cycle, heavy-duty hinges capable of handling constant traffic and ensuring long-term operational integrity. Facility management companies responsible for the ongoing maintenance and upgrades of existing commercial properties also represent a substantial customer base, driving demand for replacement hinges and modernizing older door systems to meet contemporary safety standards.

A significant customer segment includes the hospitality and leisure sector, encompassing luxury hotels, resorts, and high-end restaurants. In these settings, the concealed nature of the floor hinge is highly valued for preserving sophisticated interior design aesthetics, often accommodating large, elegant glass entrances. The institutional sector, comprising hospitals, universities, libraries, and government buildings, constitutes another core customer group. Their buying decisions are heavily influenced by regulatory requirements, specifically ADA compliance for accessibility and strict fire-safety ratings, leading them to procure premium, certified floor hinge models that guarantee reliable performance under emergency conditions. Furthermore, specialist door and window manufacturers and architectural hardware installers act as intermediary buyers who purchase in bulk from manufacturers to fulfill project-specific requirements.

| Report Attributes | Report Details | |

|---|---|---|

| Market Size in 2026 | USD 580 Million | |

| Market Forecast in 2033 | USD 855 Million | |

| Growth Rate | 5.8% CAGR | |

| Historical Year | 2019 to 2024 | |

| Base Year | 2025 | |

| Forecast Year | 2026 - 2033 | |

| DRO & Impact Forces |

| |

| Segments Covered |

| |

| Key Companies Covered | Dormakaba, GEZE GmbH, ASSA ABLOY, Ryobi Limited, Hettich, Kin Long, MAB srl, Nanjing Dongwu Glass Hardware Co. Ltd., GMT, Cal-Royal Products, Inc., Hafele, Tostem, DICTATOR, Stanley Black & Decker, Franz Schneider Brakel (FSB), Hager Companies, PBB, Inc., Oubao Security Technology, KBB, and VVP Group. | |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) | |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Floor Hinge Market Key Technology Landscape

The technological evolution within the Floor Hinge Market is defined by continuous refinement of hydraulic systems, advancements in material science for corrosion resistance, and the crucial integration of electronic components for automation and control. Modern floor hinges rely heavily on sophisticated hydraulic mechanisms that use specialized damping fluids to ensure precise control over closing speed, latching action, and backcheck function. Key innovations focus on developing highly efficient, thermally stable hydraulic oils that maintain consistent viscosity across wide temperature ranges, ensuring reliable performance in diverse climates, from freezing cold to intense heat. Manufacturers are also prioritizing modular cassette designs which standardize the mechanism within a protective box, simplifying the installation and replacement process and addressing a major historic constraint in the market.

A significant technological shift involves the adoption of electro-hydraulic technology. These advanced hinges incorporate electromagnetic locking and electronic control units that allow for seamless interfacing with access control systems, fire alarms, and Building Management Systems (BMS). This allows for features such as remote locking/unlocking, precise door synchronization in multi-door applications, and integrated safety functions that automatically open or close doors during emergencies. The development of low-power consumption electronics is critical for these systems, ensuring reliability during power outages or when integrated into sustainable, energy-efficient building designs. Furthermore, sensor technology, including optical and magnetic sensors, is increasingly embedded to provide real-time status updates on door position and usage cycles, feeding data back into smart building analytics platforms.

Material technology remains central to performance longevity. The landscape is dominated by the use of high-grade stainless steel (304 and 316) for external cover plates and internal mechanisms, coupled with advanced surface treatments, such as specialized PVD (Physical Vapor Deposition) coatings or electrolytic finishes, to enhance durability against abrasion, corrosion, and environmental degradation, particularly crucial for external applications or those near coastal areas. Research is also focused on developing new sealing materials (elastomers) that can withstand high pressure and continuous flexing over millions of cycles without leakage, ensuring the long-term integrity of the hydraulic reservoir. These material breakthroughs are fundamental to manufacturers offering extended, market-leading warranties, which serves as a major competitive differentiator.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by unparalleled levels of urbanization and commercial infrastructure spending, particularly in China, India, and Southeast Asian nations (e.g., Vietnam, Indonesia). Government initiatives supporting smart city development and massive investments in retail, hospitality, and corporate office spaces necessitate high volumes of durable, reliable door hardware. While cost sensitivity remains a factor, there is increasing demand for certified, medium-to-heavy-duty hinges to comply with rapidly evolving local safety and architectural standards. This region represents both the largest volume market and the primary locus for future capacity expansion by global manufacturers.

- North America: This region is characterized by high average selling prices and a strong preference for certified, technologically advanced products, heavily influenced by strict mandates such as the Americans with Disabilities Act (ADA) and specific fire codes (e.g., UL listings). The market here is mature but driven by robust commercial renovation cycles and a focus on upgrading infrastructure with smart, connected door hardware. Demand for electro-hydraulic hinges and solutions integrated with security access control is particularly strong, positioning North America as a key innovation adoption zone for high-performance and automated floor hinge systems.

- Europe: Europe maintains a significant market share, distinguished by exceptionally stringent safety and quality standards, notably CE marking and compliance with EN norms (e.g., EN 1154 for controlled door closing). The market favors high-quality, long-life products, often with precise aesthetic demands suitable for historic restorations and modern minimalist designs. Germany, the UK, and France are the major consumers, driven by continuous investment in public buildings and a strong focus on energy efficiency and sustainability in construction, leading to sustained demand for premium, highly engineered hydraulic components.

- Middle East and Africa (MEA): Growth in MEA is episodic but high-value, primarily fueled by large-scale, luxury architectural projects in the Gulf Cooperation Council (GCC) countries (e.g., UAE, Saudi Arabia). These projects frequently require bespoke, heavy-duty floor hinges capable of supporting oversized, custom glass and metal doors, often necessitating high levels of corrosion resistance due to the harsh, hot climate. Africa, while nascent, shows potential growth in commercial hubs like South Africa and Nigeria as modern architectural standards are gradually adopted.

- Latin America (LATAM): This region is experiencing moderate growth, spurred by incremental improvements in infrastructure and urbanization in key economies like Brazil and Mexico. The market is competitive and price-sensitive, often favoring reliable, standard hydraulic hinges. However, the commercial and luxury residential segments are increasingly adopting high-specification products to align with international design and safety trends, offering selective opportunities for premium hardware providers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Floor Hinge Market.- Dormakaba

- GEZE GmbH

- ASSA ABLOY

- Ryobi Limited

- Hettich

- Kin Long

- MAB srl

- Nanjing Dongwu Glass Hardware Co. Ltd.

- GMT

- Cal-Royal Products, Inc.

- Hafele

- Tostem

- DICTATOR

- Stanley Black & Decker

- Franz Schneider Brakel (FSB)

- Hager Companies

- PBB, Inc.

- Oubao Security Technology

- KBB

- VVP Group

Frequently Asked Questions

Analyze common user questions about the Floor Hinge market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using a floor hinge over a standard overhead door closer?

The primary advantage of a floor hinge is its concealed installation, which maintains superior aesthetic integrity, particularly for frameless glass doors. It also typically offers higher load-bearing capacity and more precise control over heavy or oversized doors, fulfilling stringent architectural and safety requirements.

Which material segment holds the largest share in the Floor Hinge Market?

Stainless steel is the dominant material segment due to its excellent corrosion resistance, high tensile strength, and long-term durability, making it essential for high-performance, safety-critical applications in diverse environmental conditions, especially coastal or high-humidity areas.

How is the integration of smart technology affecting floor hinge design?

Smart technology integration is leading to the rise of electro-hydraulic hinges equipped with sensors. These devices enable features like predictive maintenance alerts, remote access control synchronization, and precise, automated control over door speed and movement, enhancing safety and building efficiency.

What is the key growth driver for the Floor Hinge Market in the Asia Pacific region?

The key growth driver in the Asia Pacific region is rapid commercial urbanization and substantial investment in new commercial, retail, and hospitality infrastructure projects. This massive volume of new construction demands reliable, modern architectural door hardware on a large scale.

What are the main segments by application in this market?

The market is primarily segmented into Commercial, Residential, and Industrial/Institutional applications. The Commercial segment, encompassing offices, retail, and hospitality, accounts for the largest revenue share due to the requirement for heavy-duty, certified, and aesthetically pleasing door control mechanisms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager