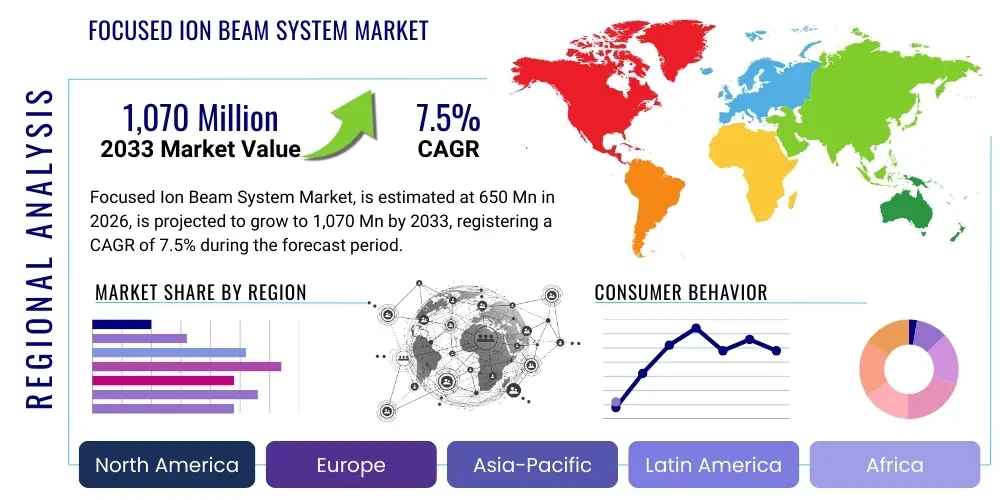

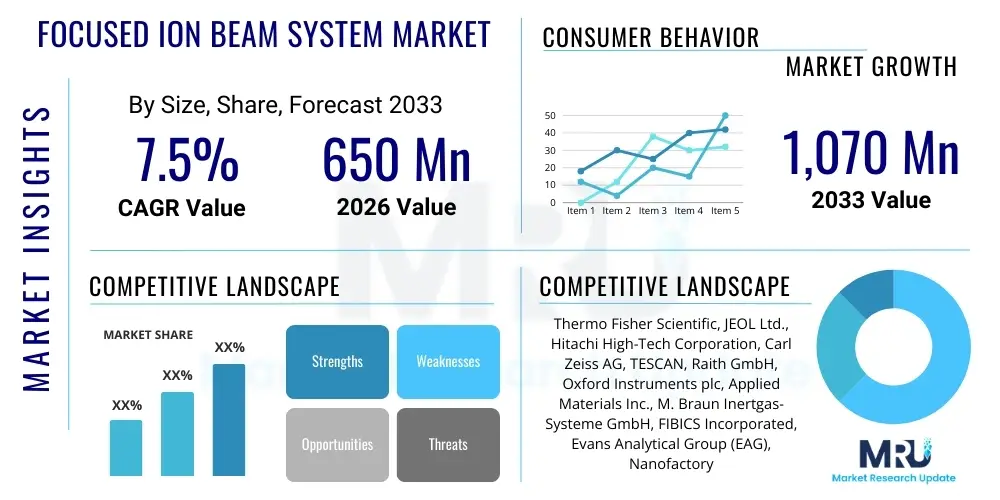

Focused Ion Beam System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442309 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Focused Ion Beam System Market Size

The Focused Ion Beam System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,070 Million by the end of the forecast period in 2033.

Focused Ion Beam System Market introduction

The Focused Ion Beam (FIB) System Market encompasses specialized instrumentation crucial for nanoscale fabrication, imaging, and analysis across various high-technology sectors. FIB systems utilize a finely focused beam of ions, typically gallium (Ga), xenon (Xe), or neon (Ne), accelerated to high kinetic energy, enabling material removal (milling/etching), material deposition, and high-resolution imaging. These systems are foundational tools in semiconductor failure analysis, precise transmission electron microscopy (TEM) sample preparation, and advanced materials modification. The unique capability of FIB to interact simultaneously with scanning electron microscopy (SEM) in a DualBeam configuration has solidified its indispensable role in sophisticated research and industrial quality control, driving efficiency and precision in device development cycles.

The primary applications of FIB systems span circuit modification and debugging in microelectronics, cross-sectional imaging for quality assessment, and the creation of complex three-dimensional nanostructures. The increasing demand for device miniaturization, especially in the context of Moore's Law progression and the advent of 3D stacking architectures (like 3D NAND and FinFETs), directly fuels the adoption of high-performance FIB instruments. Furthermore, the shift towards non-gallium ion sources, such as plasma FIB (PFIB) using xenon, addresses critical challenges related to sample damage and throughput, opening new avenues in large-volume milling and specialized material processing, particularly for energy storage and aerospace components.

Key benefits derived from utilizing Focused Ion Beam technology include unparalleled precision at the nanometer scale, ability to perform in situ modifications, and highly localized material analysis when integrated with detectors like Energy Dispersive X-ray Spectroscopy (EDS) or Electron Backscatter Diffraction (EBSD). Driving factors sustaining the market momentum include robust investments in semiconductor research and fabrication facilities globally, the accelerating complexity of advanced packaging technologies, and expanding applications in biological sciences for cryo-lamella preparation. The convergence of these factors mandates continuous innovation in ion source stability, beam spot size reduction, and software automation, ensuring FIB systems remain at the technological forefront for next-generation material and device characterization.

Focused Ion Beam System Market Executive Summary

The Focused Ion Beam System Market is experiencing a strategic inflection point characterized by rapid technological diversification and intense geographical concentration of demand. Business trends highlight a pronounced shift from traditional Gallium-based sources towards high-throughput Plasma FIB (PFIB) and ultra-high-resolution Gas Field Ion Sources (GFIS), driven primarily by the need for faster processing of large volumes in industrial settings and minimized sample damage in sensitive material studies. Major original equipment manufacturers (OEMs) are focusing on integrating advanced software features, incorporating machine learning algorithms for automated alignment and endpoint detection, thereby addressing the persistent challenge of operational complexity and maximizing tool utilization in high-stakes environments like semiconductor fabs. Partnerships between system providers and software firms specializing in high-dimensional data analysis are defining the competitive landscape, pushing the capabilities of these tools beyond mere milling and imaging into sophisticated metrology platforms.

Regional trends unequivocally position the Asia Pacific (APAC) as the epicenter of market growth, primarily due to the overwhelming concentration of semiconductor manufacturing, packaging, and assembly operations in South Korea, Taiwan, China, and Japan. This region exhibits the highest expenditure on new capital equipment necessary for process control, defect analysis, and yield improvement in leading-edge logic and memory production. North America and Europe, while lagging in sheer production volume, remain critical hubs for advanced fundamental research, materials science innovation, and aerospace/defense applications, driving demand for specialized, ultra-precise FIB systems designed for scientific rather than high-volume industrial use. Strategic government initiatives aimed at bolstering domestic semiconductor supply chains globally, such as the US CHIPS Act and the EU Chips Act, are further stimulating localized investment in FIB infrastructure across these established Western markets.

Segment trends underscore the dominance of the Semiconductor & Electronics segment, which relies heavily on DualBeam systems for failure analysis (FA) and circuit modification. However, the Materials Science sector is exhibiting the fastest growth rate, fueled by research into advanced battery electrodes, catalysts, and high-performance alloys requiring nanoscale structural characterization and TEM lamella preparation. Within the technology segmentation, Plasma FIB systems, utilizing Xenon ions, are projected to capture increasing market share over the forecast period due to their significantly enhanced material removal rates and reduced beam-induced damage compared to conventional sources, making them ideal for high-throughput applications and preparing large-area cross-sections essential for analyzing complex heterogeneous materials.

AI Impact Analysis on Focused Ion Beam System Market

User queries regarding AI's impact on FIB systems center predominantly on automation capabilities, improved data quality, and the reduction of operator dependence, reflecting a strong industry push towards ‘smart’ instrumentation. Key themes include the feasibility of autonomous TEM sample preparation—a highly skill-dependent process—and the ability of AI to interpret complex nanoscale images and diagnostic results faster than human analysts. Users are also concerned about leveraging machine learning for predictive maintenance to minimize costly downtime and optimize beam parameters automatically based on real-time sample feedback. The general expectation is that AI will transform FIB systems from specialized, manually intensive tools into highly efficient, automated instruments capable of handling high-volume, standardized tasks while freeing up experts for novel analytical challenges, thereby improving throughput and consistency across all applications, especially in high-volume production environments.

- AI-driven automation of routine tasks, such as focusing, stigmation, and drift correction, significantly improving operational efficiency and consistency.

- Enhanced image processing and segmentation using deep learning algorithms, enabling faster and more accurate interpretation of complex nanoscale structures and defects.

- Autonomous sample preparation protocols, particularly for difficult tasks like cryo-lamella creation and complex cross-sectioning, reducing reliance on highly specialized human expertise.

- Predictive maintenance schedules and diagnostic tools, utilizing machine learning to analyze system performance data and anticipate potential hardware failures, thereby maximizing uptime.

- Real-time material characterization integration, where AI analyzes FIB milling data simultaneously with EDS/EBSD signals to automatically identify material interfaces and defects during processing.

- Optimization of milling parameters (e.g., beam current, dose) based on sample material characteristics and desired outcome, leading to higher quality results and reduced sample damage.

DRO & Impact Forces Of Focused Ion Beam System Market

The Focused Ion Beam System market dynamics are characterized by robust technological drivers counterbalanced by significant operational constraints, creating complex market forces. A primary driver is the relentless trend of miniaturization in semiconductor manufacturing, demanding increasingly precise tools for failure analysis and modification of devices featuring sub-10 nm nodes and complex 3D integration. This need is further amplified by the growth of advanced packaging technologies like heterogeneous integration and chiplets, where localized structural analysis and modification are essential for yield improvement. Consequently, system manufacturers are compelled to invest heavily in developing cleaner, lower-damage ion sources, such as Xenon PFIBs and Neon FIBs, which cater specifically to these advanced technological requirements, mitigating issues associated with traditional Gallium ion sources. The increasing global R&D expenditure in material science, particularly concerning battery technology, metallurgy, and additive manufacturing, also provides a consistent and diversifying demand base for FIB analysis.

However, the market faces inherent restraints, most notably the exceedingly high initial capital expenditure associated with purchasing and installing advanced DualBeam systems, which can exceed several million USD. This high barrier to entry limits adoption among smaller research institutions and niche industrial players. Furthermore, the operational complexity of FIB systems necessitates highly skilled technical personnel for effective operation, maintenance, and complex application execution, leading to significant ongoing training and labor costs. The issue of sample damage and gallium contamination, although being addressed by newer technologies, still presents a challenge in ultra-sensitive material characterization, sometimes requiring alternative, albeit slower, preparation techniques. These factors collectively temper the overall market growth potential, particularly in price-sensitive emerging economies.

Opportunities for market expansion are substantial and primarily revolve around emerging technological frontiers. The rise of quantum computing research, requiring extremely high-precision nanofabrication of superconducting circuits and qubits, presents a premium niche for ultra-low-current, high-resolution FIB tools. Similarly, advancements in cryo-electron microscopy (Cryo-EM) for biological sciences necessitate the preparation of thin, uncontaminated lamellae (Cryo-lamella), a process uniquely and effectively handled by specialized cryo-FIB systems. The impact forces are further shaped by competitive intensity among the few major global players who dominate the high-end industrial segment, focusing on strategic technological differentiation and expanding service contracts to secure recurring revenue. The integration of FIB into automated workflows, particularly in semiconductor fabs, demonstrates a critical impact force driving future revenue growth through productivity gains and decreased human error.

Segmentation Analysis

The Focused Ion Beam System market is segmented based on ion source type, application, and end-user, providing a granular view of demand distribution across different technological and industrial requirements. Segmentation by ion source type is critical as it defines the tool's primary capabilities, throughput, and suitability for specific materials, with Plasma FIB (PFIB) systems rapidly gaining traction due to superior milling speed and reduced sample contamination compared to legacy Gallium LMIS technology. The application segmentation clearly delineates the market’s primary revenue stream, showing the Semiconductor & Electronics sector as the largest consumer, while the burgeoning Materials Science segment acts as a key driver of technological innovation in ion source development and multi-modal analysis capabilities. Understanding these segments is vital for manufacturers to tailor product development and market penetration strategies effectively.

- By Ion Source Type:

- Liquid Metal Ion Sources (LMIS)

- Gallium (Ga) LMIS

- Other LMIS (e.g., Au, Si)

- Plasma Ion Sources (PFIB)

- Xenon (Xe) PFIB

- Argon (Ar) PFIB

- Gas Field Ion Sources (GFIS)

- Helium (He) GFIS

- Neon (Ne) GFIS

- Liquid Metal Ion Sources (LMIS)

- By Application:

- Semiconductor & Electronics

- Failure Analysis (FA)

- Circuit Editing

- Prototype Manufacturing

- Metrology and Process Control

- Materials Science

- Nanofabrication and Prototyping

- TEM Sample Preparation

- Cross-sectional Imaging

- Metallurgy and Composites Analysis

- Biology & Life Sciences

- Cryo-lamella Preparation

- 3D Reconstruction

- Cell Structure Imaging

- Semiconductor & Electronics

- By End-User:

- Industrial (Semiconductor Fabs, Contract Research Organizations (CROs))

- Academic & Research Institutions

- Government & Defense Laboratories

Value Chain Analysis For Focused Ion Beam System Market

The Focused Ion Beam System market value chain begins with highly specialized upstream suppliers who provide critical components essential for system performance. This includes manufacturers of ultra-high-vacuum (UHV) components, high-precision electron and ion columns, sophisticated detector systems (like EDS, EBSD, STEM detectors), and, most critically, the ion source materials (e.g., high-purity gallium, xenon gas handling systems, or cold field emitter tips). The performance and reliability of the final FIB system are fundamentally dependent on the quality and stability of these core components. Suppliers often work closely with system integrators to ensure compatibility with complex software control systems and advanced safety protocols required for high-energy beam generation.

Midstream activities are dominated by a limited number of global OEMs (Original Equipment Manufacturers) who specialize in system integration, advanced software development, and precision assembly. These companies design the DualBeam architecture, calibrate the intricate beam optics, and develop proprietary software interfaces for controlling milling, imaging, and data acquisition sequences. This stage of the value chain is highly capital-intensive and requires substantial intellectual property protection related to beam steering and source technology. Direct sales and technical support through the OEM’s internal sales force or highly specialized, authorized local distributors characterize the distribution channel, particularly for high-end industrial systems where consultation and custom integration are paramount.

Downstream market activities focus on system installation, extensive operator training, and ongoing post-sales service, which is a significant revenue generator due to the complexity and sensitivity of the equipment. Direct distribution is prevalent for large semiconductor clients who demand immediate technical support and preventative maintenance contracts directly from the OEM to minimize downtime. Indirect distribution channels, often involving regional distributors or specialized application service providers, are more common for serving academic institutions and smaller industrial labs. The end-users—ranging from semiconductor fabs performing daily failure analysis to university labs conducting basic materials research—dictate the configuration and support requirements, making tailored service packages a crucial part of the overall market offering.

Focused Ion Beam System Market Potential Customers

The primary and most lucrative customer segment for Focused Ion Beam systems is the Semiconductor and Microelectronics industry, particularly large integrated device manufacturers (IDMs), pure-play foundries, and outsourced semiconductor assembly and test (OSAT) companies. These entities utilize FIB systems as critical tools for maintaining high yields, performing rapid failure analysis (FA) on defective chips, and conducting precise circuit modifications during the design and validation phases. As device geometries shrink and 3D complexity increases, the reliance on advanced DualBeam systems capable of cross-sectioning and localized elemental analysis within sub-nanometer dimensions becomes absolute, positioning these industrial giants as continuous, high-volume purchasers of the latest generation equipment.

A secondary, yet rapidly expanding, customer base resides within the global ecosystem of Materials Science research and advanced engineering. This includes university research laboratories, national defense laboratories, and specialized industrial R&D centers focusing on fields such as advanced metallurgy, composite materials, nanomaterials, and energy storage (e.g., lithium-ion battery research). These customers prioritize versatility and analytical capability, using FIB for everything from complex TEM sample preparation, which is less destructive than traditional methods, to creating intricate nanostructures for experimental testing. Their demand often drives the market for specialty ion sources, such as Xenon PFIB for large area milling or Neon GFIS for ultra-high-resolution imaging and low-damage patterning.

Furthermore, the emerging market segment of Bio-imaging and Cryo-electron Microscopy (Cryo-EM) labs represents a significant long-term growth opportunity. These institutions rely on specialized Cryo-FIB systems to prepare ultra-thin, vitreous lamellae from frozen biological samples, which are essential for high-resolution structural determination of cellular components and proteins. While currently smaller in volume, this segment is characterized by demanding technical specifications related to cryogenic handling and ultra-precise milling, attracting premium pricing for specialized equipment. Government research labs and third-party contract research organizations (CROs) also constitute stable demand, utilizing FIB systems for specialized forensic, quality control, and R&D services across multiple scientific disciplines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,070 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, JEOL Ltd., Hitachi High-Tech Corporation, Carl Zeiss AG, TESCAN, Raith GmbH, Oxford Instruments plc, Applied Materials Inc., M. Braun Inertgas-Systeme GmbH, FIBICS Incorporated, Evans Analytical Group (EAG), Nanofactory Instruments AB, Delong Instruments, Nion Company, Focused Beam Instruments. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Focused Ion Beam System Market Key Technology Landscape

The technological landscape of the Focused Ion Beam System market is characterized by intense innovation centered on improving beam quality, reducing sample damage, and increasing processing throughput. Traditional systems rely on Liquid Metal Ion Sources (LMIS), primarily Gallium, which offer excellent beam stability and fine focus. However, the high mass of Gallium ions and the resulting implantation and surface damage have necessitated the development of next-generation alternatives. A major ongoing technological advancement is the widespread adoption of Plasma Focused Ion Beam (PFIB) technology, typically using Xenon plasma. PFIB systems boast material removal rates hundreds of times faster than Ga-LMIS, making them indispensable for large-volume milling, rapid cross-sectioning of macro-samples, and high-throughput TEM sample preparation in industrial settings where speed is critical.

Another crucial area of technological differentiation lies in the development of Gas Field Ion Sources (GFIS), such as those using Helium (He) and Neon (Ne). These sources produce extremely small beam spot sizes—often less than 0.5 nm—and deliver significantly lower energy deposition, leading to minimal subsurface damage. Helium and Neon FIB systems are highly valued in critical R&D applications, particularly for ultra-fine patterning in nanofabrication, lithography, and high-resolution imaging where precision outweighs throughput concerns. The integration of these advanced ion sources with Scanning Electron Microscopy (SEM) into sophisticated DualBeam systems remains the market standard, with OEMs continuously refining the coaxial alignment and software control to enable seamless switching between imaging and modification modes at the highest possible resolution.

Furthermore, technological progress is increasingly focused on specialized applications and automation. Cryo-FIB technology, which incorporates a sophisticated cryogenic stage and sample transfer system, is crucial for preserving and analyzing biological and soft matter samples in their native, frozen state, driving demand in life sciences. Automation features, leveraging machine vision and embedded AI, are becoming standard, enabling automated tracking of buried features, endpoint detection during milling, and automated lamella lift-out and grid mounting. This shift towards smart instrumentation reduces operator variability and vastly improves the repeatability and efficiency of complex workflows, ensuring that FIB systems can effectively meet the stringent quality control and high-volume demands of advanced semiconductor manufacturing facilities.

Regional Highlights

- Asia Pacific (APAC): The APAC region commands the largest market share and is projected to exhibit the highest growth rate throughout the forecast period. This dominance is intrinsically linked to its status as the global manufacturing hub for electronics and semiconductors. Countries like China, Taiwan, South Korea, and Japan host the world’s leading foundries and memory manufacturers (e.g., TSMC, Samsung, SK Hynix), necessitating continuous investment in advanced metrology and failure analysis tools, including high-throughput PFIB and DualBeam systems. Government initiatives promoting domestic high-tech manufacturing, coupled with robust infrastructure development, further accelerate the adoption of FIB technology for yield enhancement and defect inspection across 7nm and 5nm technology nodes. The region's vibrant research landscape, particularly in materials science and nanotechnology in countries like Singapore and India, also contributes significantly to the demand for specialized scientific FIB configurations.

- North America: North America represents a mature yet highly innovative market, driven primarily by strong R&D spending, the presence of major aerospace and defense contractors, and leading academic institutions. Demand here is characterized by a focus on cutting-edge applications such as quantum technology nanofabrication, advanced materials development (composites, metallurgy), and specialized biotechnology applications, particularly Cryo-FIB for structural biology. While industrial consumption is substantial (driven by companies like Intel and Micron), the region is a leader in adopting ultra-high-resolution systems (He/Ne GFIS) and integrating AI-driven automation into research workflows. The recent emphasis on semiconductor reshoring, supported by governmental acts, is expected to stimulate increased capital expenditure on analytical tools, boosting the industrial segment's growth significantly over the medium term.

- Europe: Europe holds a strong position, particularly in the academic and industrial materials science segments. Key drivers include rigorous research into advanced energy solutions (battery materials, fuel cells), automotive technology R&D, and substantial investments in European research institutes (e.g., Fraunhofer, Max Planck). European companies are often frontrunners in developing specialized instrumentation and software for complex material characterization. The market here demands high-precision, versatile FIB systems suitable for multi-modal analysis, often integrating specialized detectors like cryo-stages and atom probe tomography (APT) preparation modules. Germany, the UK, and France are the major contributors to market revenue, focusing on precision engineering and complex materials analysis rather than high-volume semiconductor processing found in APAC.

- Latin America, Middle East, and Africa (LAMEA): The LAMEA region currently holds the smallest market share but presents developing opportunities, primarily centered around academic expansion, government-funded research initiatives, and oil and gas sector applications (e.g., analysis of pipeline materials, catalyst characterization). Brazil, Mexico, Saudi Arabia, and South Africa are emerging markets where investments in core research infrastructure are beginning to drive demand for introductory and mid-range DualBeam systems. Growth remains moderate, constrained primarily by limited local technical expertise and substantial reliance on imported high-end capital equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Focused Ion Beam System Market.- Thermo Fisher Scientific

- JEOL Ltd.

- Hitachi High-Tech Corporation

- Carl Zeiss AG

- TESCAN

- Raith GmbH

- Oxford Instruments plc

- Applied Materials Inc.

- M. Braun Inertgas-Systeme GmbH

- FIBICS Incorporated

- Evans Analytical Group (EAG)

- Nanofactory Instruments AB

- Delong Instruments

- Nion Company

- Focused Beam Instruments

Frequently Asked Questions

Analyze common user questions about the Focused Ion Beam System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical difference between Gallium FIB and Plasma FIB?

Gallium Focused Ion Beam (Ga-FIB) systems utilize Liquid Metal Ion Sources (LMIS) to produce high-resolution beams suitable for fine circuit editing but are slow for bulk removal. Plasma FIB (PFIB), typically using Xenon or Argon, uses a plasma source, offering significantly higher beam currents and material removal rates, making it ideal for high-throughput industrial applications and large area cross-sectioning.

How are Focused Ion Beam systems utilized in semiconductor failure analysis?

FIB systems, often operating in a DualBeam configuration with SEM, are crucial for semiconductor failure analysis (FA). They are used to precisely cross-section specific defects or features within a chip for subsurface imaging, to prepare thin lamellae for subsequent high-resolution TEM analysis, and to perform localized circuit modifications (editing) for debugging prototypes.

Which end-user segment drives the highest demand for advanced FIB technology?

The Semiconductor and Electronics industry drives the highest demand, particularly for advanced DualBeam and high-throughput Plasma FIB (PFIB) systems. This segment requires continuous upgrades for defect analysis, quality control, and advanced packaging analysis crucial for maintaining yield in leading-edge fabrication facilities.

What role does AI play in optimizing Focused Ion Beam operations?

AI integration is vital for optimizing FIB operations by enabling automation of complex, repetitive tasks like focusing, alignment, and sample navigation. AI algorithms also enhance image analysis, predict maintenance needs, and allow for autonomous, precise endpoint detection during material milling, significantly improving throughput and data consistency.

What are the key restraints impacting the growth of the FIB system market?

The primary restraints are the high initial capital cost associated with purchasing sophisticated DualBeam systems, which restricts adoption by smaller entities, and the requirement for highly specialized technical expertise necessary to operate and maintain these complex, sensitive instruments effectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager