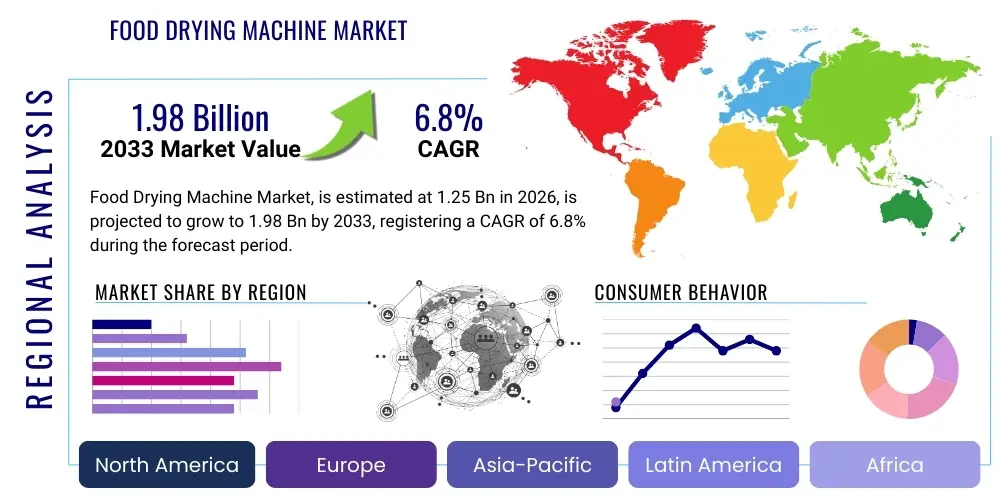

Food Drying Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442815 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Food Drying Machine Market Size

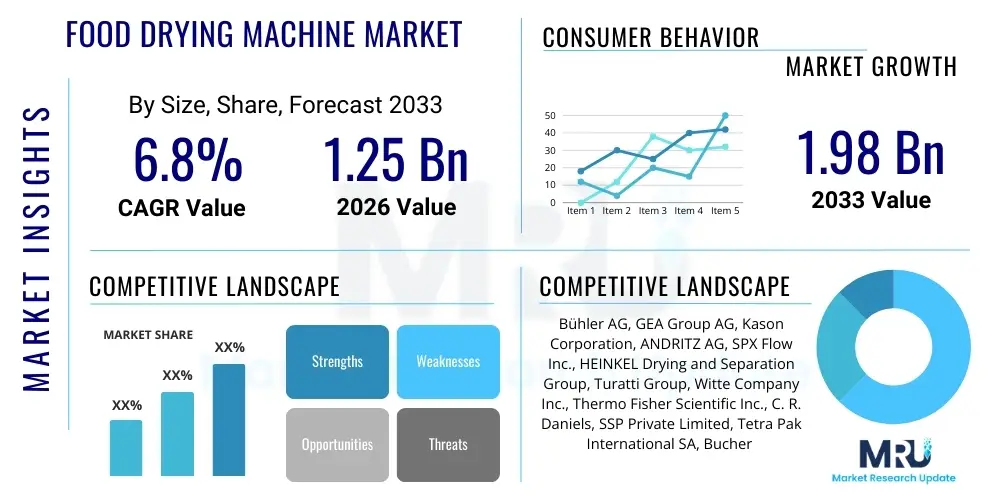

The Food Drying Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating global demand for processed, shelf-stable food products, coupled with increasing investments in commercial food processing infrastructure across emerging economies. The technological shift towards more energy-efficient and scalable drying technologies is also playing a crucial role in enabling higher capacity utilization and lowering operational costs for manufacturers.

Food Drying Machine Market introduction

The Food Drying Machine Market encompasses equipment utilized for removing moisture content from various food items, including fruits, vegetables, grains, spices, meats, and seafood, thereby extending their shelf life and preserving their nutritional value and flavor profiles. These machines operate based on principles such as convection, conduction, radiation, and freeze-drying, ranging from small-scale domestic dehydrators to massive industrial continuous drying systems like tunnel dryers, spray dryers, and vacuum dryers. The primary function of these specialized machines is crucial in ensuring food security by minimizing spoilage and enabling efficient global distribution of agricultural produce, especially in regions with volatile climate conditions.

Major applications for food drying machines span across diverse sectors, including the creation of ready-to-eat snacks, ingredients for baking and confectionery, powdered food products (like instant coffee and milk powder), and pet food manufacturing. The benefits derived from employing these sophisticated drying technologies are manifold, centering on significant reduction in transportation weight and volume, superior preservation of sensitive nutrients compared to other preservation methods like canning, and the capability to process seasonal harvests year-round. Furthermore, the ability to create new product textures and formats, such as crispy dried fruit slices or finely milled spice powders, opens up significant avenues for product innovation in the consumer packaged goods (CPG) industry.

The principal driving factors propelling market growth include the burgeoning consumer preference for natural and healthy food alternatives, where dried foods often require minimal or no artificial preservatives due to their low moisture activity. Secondly, stringent food safety regulations globally necessitate controlled and sanitary processing environments, which modern industrial dryers are designed to provide. Lastly, the rapid globalization of supply chains means that producers need reliable methods to stabilize perishable goods for long-distance transit, making high-efficiency drying machines indispensable components of the modern food logistics ecosystem.

Food Drying Machine Market Executive Summary

The Food Drying Machine Market is characterized by robust business trends focusing heavily on sustainability and operational efficiency, prompting manufacturers to invest significantly in advanced heat pump technology and solar-assisted drying systems to reduce energy consumption and operational expenditure. Key business strategies observed include strategic mergers and acquisitions among equipment providers to consolidate technological expertise, particularly in sophisticated techniques such as microwave vacuum drying and osmotic dehydration pretreatment. Furthermore, the integration of automation and IoT-enabled monitoring systems into industrial drying equipment is becoming standard, facilitating predictive maintenance and optimal process control, which are critical for high-volume processors managing narrow profit margins.

Geographically, Asia Pacific (APAC) stands out as the predominant market driver, primarily due to the vast agricultural output of countries like China, India, and Southeast Asian nations, necessitating large-scale processing equipment to handle increasing volumes of fruits, vegetables, and aquatic products. North America and Europe, while being mature markets, exhibit high adoption rates of advanced, specialized drying equipment for high-value applications, such as pharmaceutical-grade ingredients and premium snack foods, driven by rigorous quality standards and a strong focus on energy recovery systems. Regional trends also show Latin America and the Middle East accelerating investments in drying technology as part of broader initiatives to diversify their processed food industries and enhance domestic food security capabilities.

In terms of segmentation trends, the Vacuum Drying segment is witnessing accelerated growth due to its ability to process heat-sensitive materials with minimal degradation, making it ideal for nutraceuticals and high-end spices. Concurrently, the Fruits and Vegetables application segment remains the largest volume consumer of drying machinery, fueled by the global demand for dried fruit snacks and vegetable powders used in ready meals. The trend within the capacity segment is leaning towards high-capacity industrial systems (above 5,000 kg/batch) as major food corporations seek economies of scale, although the proliferation of small and medium enterprises (SMEs) is simultaneously bolstering the demand for mid-range, modular drying solutions tailored for specific product lines and flexible operation.

AI Impact Analysis on Food Drying Machine Market

Common user inquiries concerning AI’s role in the Food Drying Machine Market often revolve around optimizing energy usage, ensuring consistent product quality, and enabling predictive maintenance schedules. Users frequently ask how AI-driven sensors can monitor moisture content in real-time to adjust drying parameters automatically, minimizing energy waste due to over-drying or under-drying, which directly impacts profitability. There is also significant interest in using machine learning algorithms to analyze historical batch data, predicting equipment failure before it occurs, and identifying optimal drying profiles for novel food matrices. The prevailing expectation is that AI integration will transform drying from a process reliant on fixed recipes and operator experience into a dynamic, highly precise, and self-optimizing operation, leading to superior yield consistency and substantial cost reductions in power consumption and labor.

- AI algorithms enable precise, real-time control of temperature, humidity, and airflow, optimizing energy consumption by up to 15-20%.

- Machine learning facilitates predictive quality control by analyzing spectral data and imaging during the drying cycle, ensuring uniform moisture levels and color retention.

- AI-powered monitoring systems predict mechanical failures in blowers, heating elements, and conveyor systems, significantly reducing unplanned downtime and maintenance costs.

- Deep learning models analyze vast process data to create optimal, product-specific drying recipes automatically, enhancing throughput and yield for diverse food items.

- Chatbots and conversational AI tools provide immediate operational support and diagnostic assistance to machine operators, improving troubleshooting efficiency.

DRO & Impact Forces Of Food Drying Machine Market

The dynamics of the Food Drying Machine Market are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively constituting the market’s impact forces. The central driving force is the imperative for extended food shelf life coupled with the massive expansion of the global processed food industry, necessitating scalable preservation technologies. Conversely, high initial capital investment required for sophisticated industrial dryers, especially those utilizing energy-intensive technologies like freeze drying, acts as a primary restraint, particularly for smaller enterprises. Significant opportunities lie in the development and proliferation of cost-effective, sustainable drying solutions, such as solar dryers and hybrid systems, which address both energy efficiency concerns and accessibility challenges in developing regions. These impact forces shape manufacturers' investment strategies, technology roadmaps, and ultimately, the market penetration rate of advanced drying equipment across various geographical sectors.

Drivers: A paramount driver is the rising global population and the resulting demand for food security, which mandates effective post-harvest loss reduction, achievable through efficient drying techniques. The shift in consumer dietary habits towards convenience and healthy snacking options, such as dried fruits, vegetables, and meat jerky, substantially bolsters demand for high-quality, controlled atmosphere drying machines. Furthermore, government initiatives aimed at modernizing agricultural infrastructure, particularly in APAC and African nations, often include subsidies or incentives for adopting processing equipment, accelerating the procurement of industrial-scale food dryers. The expansion of international trade standards also favors dried products due to their reduced risk of microbial contamination compared to fresh produce, driving processors to invest in certified drying equipment that meets export requirements.

Restraints: The most prominent restraint is the exceptionally high energy consumption associated with traditional hot air and tunnel drying systems, leading to substantial operating expenses and contributing to environmental footprints. This energy dependence makes processors vulnerable to fluctuating energy prices. Another critical challenge is maintaining the organoleptic and nutritional integrity of certain heat-sensitive food products; excessive heat can degrade vitamins, color, and flavor, pushing processors towards more expensive, specialized methods like freeze-drying, which further increases capital expenditure. Additionally, the lack of skilled labor capable of operating and maintaining advanced computerized drying systems in some developing markets poses an infrastructural barrier to full technological adoption and optimal utilization.

Opportunities: Substantial market opportunities exist in the development and commercialization of hybrid drying technologies that integrate multiple techniques, such as microwave-vacuum drying combined with air drying, offering a balance between speed, quality preservation, and energy efficiency. The burgeoning demand for organic and functional food ingredients, which require gentle processing methods to retain bio-active compounds, opens up niche markets for low-temperature and osmotic dehydration systems. Moreover, the growth of the pet food and animal feed sectors, particularly in specialized high-protein dried components, presents a stable, high-volume application area for large-scale drying machinery. Finally, implementing comprehensive IoT and AI solutions offers equipment manufacturers an opportunity to provide value-added services focused on predictive optimization and remote diagnostics, creating recurring revenue streams and improving customer retention.

Impact Forces: The combined effect of these factors creates a strong positive momentum towards market growth, primarily influenced by technological advancements that mitigate the primary restraint—high energy consumption. The market's trajectory is increasingly shaped by regulatory compliance requirements related to food safety and environmental sustainability. These regulatory forces act as catalysts, compelling processors to phase out older, inefficient equipment in favor of state-of-the-art systems that offer superior control, traceability, and lower carbon intensity, ensuring that efficiency and compliance remain central to purchasing decisions.

Segmentation Analysis

The Food Drying Machine Market is meticulously segmented across several critical dimensions, including the type of drying technology employed, the capacity of the machinery, the specific application or end-product being processed, and the mode of operation (batch versus continuous). This detailed segmentation provides essential insights for equipment manufacturers to tailor their product offerings, sales strategies, and service models to the highly diverse needs of the global food processing industry. The analysis reveals distinct preferences among large multinational corporations for continuous, high-capacity systems leveraging vacuum or spray drying, whereas smaller specialized producers often prioritize batch-type freeze dryers for high-value ingredients. Understanding these segmentation nuances is crucial for accurate market forecasting and competitive positioning within this capital-intensive sector.

- By Type: Tunnel Dryers, Cabinet Dryers, Spray Dryers, Fluidized Bed Dryers, Freeze Dryers, Drum Dryers, Microwave Vacuum Dryers, Rotary Dryers, Dehydrators.

- By Operation: Batch Dryers, Continuous Dryers.

- By Capacity: Small Capacity (Up to 100 kg/batch), Medium Capacity (100 kg/batch - 5000 kg/batch), Large Capacity (Above 5000 kg/batch).

- By Application: Fruits and Vegetables, Dairy Products, Cereals and Grains, Seafood and Meat, Nuts and Seeds, Spices and Condiments, Pharmaceuticals and Nutraceuticals.

- By End User: Commercial Food Processors, Food Service (Hotels, Restaurants), Residential Users.

Value Chain Analysis For Food Drying Machine Market

The value chain for the Food Drying Machine Market begins with the upstream activities centered on raw material procurement, which includes sourcing high-grade stainless steel, heat exchangers, high-precision sensors, complex automation software, and robust energy components like heat pumps and burners. The quality and availability of these specialized components directly influence the manufacturing costs and the final performance specifications of the drying equipment. Key upstream challenges involve managing global supply chain volatility for specialized microprocessors and high-performance alloys required for corrosive environments, making strategic supplier partnerships critical for maintaining consistent production throughput and quality control in the manufacturing phase.

The midstream phase focuses on the design, engineering, and manufacturing of the drying systems, where specialized expertise in thermal engineering, fluid dynamics, and sanitary design is paramount. This stage involves complex assembly, stringent quality assurance testing, and customization to meet specific food industry requirements, such as adherence to FDA and European Union food contact material standards. Distribution channel dynamics are bifurcated into direct sales for large-scale, highly customized industrial systems, which involve direct negotiation, installation, and long-term service contracts between the manufacturer and the food processor, and indirect channels relying on authorized distributors and system integrators for standardized or smaller capacity machines.

Downstream activities encompass installation, commissioning, after-sales service, and technical support, which form a significant component of the overall value proposition, especially for sophisticated equipment like freeze dryers and microwave systems. Direct distribution ensures personalized service and faster response times for complex machinery, while indirect channels provide broader market reach and localized support, particularly in emerging markets where equipment maintenance is often handled by regional service partners. The successful operation of the value chain is increasingly reliant on digital service offerings, including remote diagnostics and software updates, which lock customers into long-term relationships with the equipment provider.

Food Drying Machine Market Potential Customers

Potential customers for food drying machines are broadly segmented across various scales and industries, with large commercial food processors representing the primary end-users due to their need for high-volume, continuous operation capabilities. These entities include multinational corporations specializing in processed snacks, breakfast cereals, powdered dairy products (like whey protein and milk powder), and instant beverage mixes. Their procurement decisions are heavily influenced by factors such as throughput capacity, energy efficiency ratings, compliance with international food safety standards (HACCP, ISO 22000), and the total cost of ownership over a typical 10-15 year lifecycle.

The second major category comprises specialized producers focusing on high-value, niche products, such as organic dried fruits, functional ingredients, nutraceutical compounds, and high-end artisanal spice blends. These buyers often prioritize vacuum drying or freeze-drying technologies to maintain maximum nutritional value and pristine product appearance, despite the higher initial investment. Their market requirements demand precise control over temperature and pressure profiles to preserve sensitive compounds, making technological sophistication a non-negotiable purchasing criterion, often relying on European or North American manufacturers known for precision engineering.

Furthermore, agricultural cooperatives and farming organizations, particularly in countries with significant seasonal harvests and inadequate storage infrastructure, are emerging as key buyers for medium-scale batch dryers, often focusing on solar-assisted or hybrid models to improve post-harvest management and reduce waste. Finally, the growing market for specialized pet food and animal feed ingredients requires substantial drying capabilities for meat by-products and protein meals, making pet food manufacturers a rapidly expanding customer segment seeking reliable, high-capacity rotary and drum drying systems designed for continuous, heavy-duty operation and hygiene adherence.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bühler AG, GEA Group AG, Kason Corporation, ANDRITZ AG, SPX Flow Inc., HEINKEL Drying and Separation Group, Turatti Group, Witte Company Inc., Thermo Fisher Scientific Inc., C. R. Daniels, SSP Private Limited, Tetra Pak International SA, Bucher Unipektin, PFEIFFER Vacuum GmbH, Okawara MFG. Co. Ltd., Drying Technology Inc., H. C. Edmisten Company, Finetec Co., Ltd., ZIEL s.r.o., DeLonghi Appliances S.r.l. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Drying Machine Market Key Technology Landscape

The Food Drying Machine Market is undergoing a rapid technological evolution, moving away from conventional energy-intensive hot air drying toward sophisticated, hybrid systems designed for superior product quality and operational efficiency. A core focus of current innovation is the optimization of heat recovery systems, such as advanced heat pump dryers, which utilize closed-loop systems to recycle heat and dehumidify air, dramatically reducing specific energy consumption per kilogram of water removed. Furthermore, advancements in infrared radiation and radio frequency (RF) drying are gaining traction, offering faster drying kinetics by applying heat volumetrically rather than relying solely on surface conduction, which is particularly beneficial for products requiring minimal exposure to high temperatures to preserve color and nutrients.

Vacuum drying technology, including Microwave Vacuum Drying (MVD), represents another critical segment of innovation, allowing food processors to dry sensitive products like probiotics, certain herbs, and exotic fruits at significantly lower temperatures. By reducing the pressure inside the drying chamber, the boiling point of water is lowered, accelerating the removal of moisture while minimizing thermal damage and oxidation. Manufacturers are also integrating advanced sensor technologies, including near-infrared (NIR) spectroscopy and moisture analyzers, directly into the drying chambers. These sensors provide continuous, non-invasive data on moisture content and temperature gradients, feeding real-time information to centralized Programmable Logic Controllers (PLCs) and AI management systems, ensuring stringent adherence to quality specifications.

The rise of digital manufacturing and Industry 4.0 principles has cemented the importance of automation and connectivity in modern food drying machinery. Contemporary industrial dryers are equipped with comprehensive IoT platforms that facilitate remote monitoring, enable detailed data logging for compliance and optimization purposes, and support predictive maintenance protocols. This technological shift not only improves machine uptime and reduces maintenance costs but also provides granular data traceability, which is increasingly essential for meeting global food safety regulations and ensuring consumer trust in the processed product. The continuous development of modular and scalable drying units also allows producers to expand capacity incrementally without needing complete system overhauls.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to maintain its position as the fastest-growing and largest market for food drying machines, largely driven by the sheer scale of agricultural production in countries such as China, India, and Vietnam, where the need to process vast quantities of rice, spices, fruits, and tea leaves is paramount. Government policies focusing on reducing post-harvest losses and promoting value-addition in agricultural produce strongly incentivize investments in industrial drying infrastructure. The rapid expansion of the middle class and growing demand for convenience foods and packaged snacks further fuel the procurement of continuous drying systems, especially spray dryers for dairy and instant food powders, and large tunnel dryers for staple crops.

- North America: North America represents a mature, high-value market characterized by high regulatory standards and a strong focus on automation and high-efficiency equipment. Demand here is dominated by sophisticated technologies, particularly freeze dryers for premium health foods and nutraceuticals, and microwave vacuum dryers for high-end snack products. The region prioritizes systems with low energy footprints and integrated quality control systems, driven by high labor costs and rigorous consumer expectations regarding product quality and traceability. Investment is highly focused on modernizing existing facilities to incorporate IoT capabilities and superior energy recovery systems.

- Europe: The European market demonstrates robust demand, propelled by strict EU regulations governing food safety, environmental sustainability, and energy efficiency. European processors are leaders in adopting specialized drying techniques for high-end applications like infant formula, specialized dairy proteins, and pharmaceutical ingredients. The region shows a significant preference for heat pump and closed-loop drying systems to comply with carbon footprint reduction goals. Germany, Italy, and the Netherlands are key manufacturing and consumption hubs, focusing on precision-engineered, customizable batch and continuous dryers.

- Latin America (LATAM): LATAM is an emerging market experiencing significant growth, primarily in agricultural processing for export. Countries like Brazil, Argentina, and Mexico are investing in drying machinery to process coffee, cacao, tropical fruits, and beef products efficiently. Market adoption is currently focused on mid-range, cost-effective industrial dryers, but there is a growing trend toward more advanced systems as processors aim to meet international quality standards for global export markets. Infrastructure development and regional trade agreements are key factors driving the increased adoption rates across the food processing sector in this region.

- Middle East and Africa (MEA): Growth in the MEA region is accelerating, particularly due to government diversification efforts away from oil economies and increased focus on domestic food production and processing capabilities, aiming for greater food self-sufficiency. Investment is notable in large-scale grain drying facilities and specialized equipment for date and spice processing. While price sensitivity remains a factor, the increasing emphasis on modernizing storage and processing facilities to combat high climate-related food spoilage rates provides a strong, long-term driver for the installation of industrial drying technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Drying Machine Market.- Bühler AG

- GEA Group AG

- Kason Corporation

- ANDRITZ AG

- SPX Flow Inc.

- HEINKEL Drying and Separation Group

- Turatti Group

- Witte Company Inc.

- Thermo Fisher Scientific Inc.

- C. R. Daniels

- SSP Private Limited

- Tetra Pak International SA

- Bucher Unipektin

- PFEIFFER Vacuum GmbH

- Okawara MFG. Co. Ltd.

- Drying Technology Inc.

- H. C. Edmisten Company

- Finetec Co., Ltd.

- ZIEL s.r.o.

- DeLonghi Appliances S.r.l.

Frequently Asked Questions

Analyze common user questions about the Food Drying Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Food Drying Machine Market through 2033?

The Food Drying Machine Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by increasing global demand for processed foods and technological innovations focused on energy efficiency.

Which drying technology segment is expected to show the highest growth in the coming years?

The Freeze Dryers and Microwave Vacuum Dryers segments are anticipated to demonstrate the fastest growth due to their ability to process high-value, heat-sensitive ingredients (like nutraceuticals and coffee) while preserving maximum nutritional integrity and quality, meeting consumer demand for premium products.

What are the primary factors restraining the adoption of industrial food drying machines?

The main restraints include the high initial capital investment required for industrial-scale machinery, especially sophisticated freeze-drying systems, and the historically high operational energy consumption associated with conventional hot air drying methods.

How is AI impacting the operational efficiency of food drying equipment?

AI integration is significantly improving operational efficiency by enabling real-time moisture monitoring, predictive quality control, and automated adjustments to drying parameters, which results in optimized energy usage and reduced incidence of product spoilage or over-drying.

Which geographical region holds the largest market share for Food Drying Machines?

The Asia Pacific (APAC) region currently holds the largest market share, fueled by massive agricultural output, rapid industrialization of food processing, and governmental support for reducing post-harvest losses in major economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager