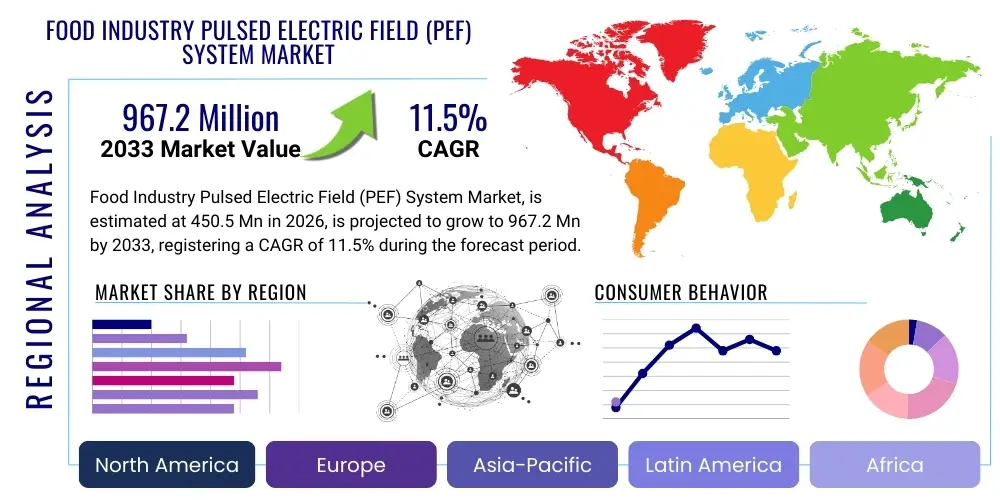

Food Industry Pulsed Electric Field (PEF) System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443002 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Food Industry Pulsed Electric Field (PEF) System Market Size

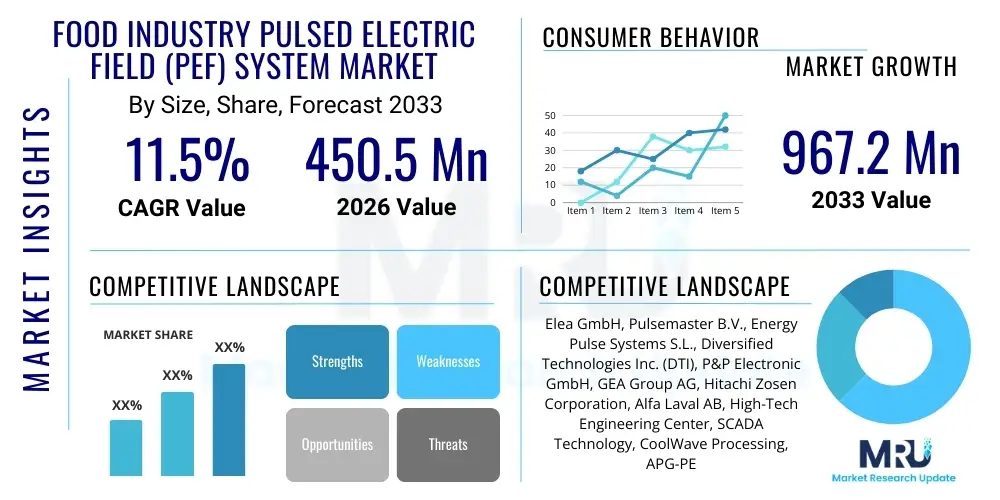

The Food Industry Pulsed Electric Field (PEF) System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 967.2 Million by the end of the forecast period in 2033.

Food Industry Pulsed Electric Field (PEF) System Market introduction

The Pulsed Electric Field (PEF) system market within the food industry encompasses advanced non-thermal processing technology designed primarily for microbial inactivation, enzyme inhibition, and enhancing mass transfer processes in various food matrices. PEF systems apply short bursts of high-voltage electric pulses to liquid or semi-liquid food products situated between two electrodes. This method results in the electroporation of cell membranes—creating temporary or permanent pores—which is highly effective for extending shelf life, retaining nutritional value, and preserving the sensory attributes (flavor, color, texture) of the processed food, contrasting sharply with traditional heat-based treatments that often degrade quality.

Major applications for PEF technology span across several critical sectors, including juice processing where it maximizes yield and preserves fresh characteristics, potato processing for pre-treatment to improve cutting efficiency and reduce oil uptake during frying, and dairy processing for mild pasteurization. The core benefits derived from integrating PEF include significant energy savings due to non-thermal operation, shorter processing times, and enhanced extraction efficiency of valuable intracellular components, such as pigments or sugars, making it a highly attractive sustainable alternative for modern food manufacturers striving for clean label products and operational efficiency.

Key driving factors accelerating the adoption of PEF systems include stringent global regulations concerning food safety and quality, coupled with surging consumer demand for minimally processed and natural-tasting foods. Furthermore, technological advancements leading to more scalable, robust, and energy-efficient PEF equipment are lowering the entry barrier for mid-sized processors. The increasing focus on optimizing raw material utilization and reducing food waste throughout the supply chain solidifies PEF's role as an indispensable technology for future food processing operations, particularly in high-volume, continuous manufacturing environments.

Food Industry Pulsed Electric Field (PEF) System Market Executive Summary

The Food Industry Pulsed Electric Field (PEF) System market is characterized by robust technological innovation and heightened investment across industrialized nations, primarily driven by the imperative to transition towards non-thermal processing methods. Business trends indicate a shift towards modular and scalable PEF systems capable of handling diverse product viscosities and volumes, facilitating greater integration into existing processing lines. Strategic alliances between equipment manufacturers and large multinational food corporations are accelerating commercialization and proving the long-term viability and cost-effectiveness of this technology in mainstream applications, particularly for fruit juices, potato products, and emerging plant-based alternatives.

Regional trends highlight North America and Europe as leading markets, primarily due to rigorous food safety standards, high consumer acceptance of premium, minimally processed goods, and significant research and development funding allocated to novel food technologies. Asia Pacific (APAC) is emerging as the fastest-growing region, stimulated by rapid industrialization of its food processing sector, increasing urbanization leading to demand for packaged foods, and government initiatives promoting sustainable processing practices. However, widespread adoption in developing nations still faces challenges related to high initial capital investment and the necessity for specialized operational training.

Segmentation trends reveal that the liquid food segment, particularly fruit and vegetable juices, dominates the application landscape, leveraging PEF's ability to maintain 'fresh-squeezed' characteristics while ensuring microbial safety. Based on the configuration, continuous flow PEF systems hold the largest market share, suitable for high-throughput commercial operations. Looking forward, the focus is intensifying on solid and semi-solid food applications, such as meat products and dairy cheese preparation, where PEF can enhance texture, improve aging processes, and reduce brine uptake, signaling diversification beyond the traditional beverage domain.

AI Impact Analysis on Food Industry Pulsed Electric Field (PEF) System Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Food Industry Pulsed Electric Field (PEF) System Market often revolve around process optimization, predictive maintenance, and ensuring consistent food quality. Users seek clarity on how AI algorithms can fine-tune PEF parameters (pulse duration, electric field strength, treatment temperature) in real-time to maximize microbial inactivation while minimizing energy consumption and preserving product integrity. There is significant interest in using machine learning (ML) models to predict equipment failure before it occurs, thereby reducing downtime in continuous processing lines. Furthermore, users are keen to understand how AI-driven quality control systems can integrate with PEF units to analyze spectral data or sensor inputs, providing immediate feedback on electroporation effectiveness across batches, addressing key themes of efficiency, precision, and operational reliability.

The integration of AI significantly enhances the operational precision of PEF systems, moving them from static, predetermined settings to dynamically adaptive processing units. Machine learning models analyze vast datasets encompassing raw material variability (e.g., pH, conductivity, temperature), flow rates, and biological targets to autonomously adjust pulse frequency and voltage. This optimization capability ensures maximum lethality against pathogens with the lowest energy expenditure, achieving unparalleled consistency in processing outcomes that traditional control systems cannot match. The enhanced data feedback loops fostered by AI contribute directly to scientific validation and regulatory compliance, addressing concerns about process robustness.

Beyond process control, AI is instrumental in accelerating the development and scaling of new PEF applications. Deep learning algorithms are used in research settings to simulate the effects of electroporation on complex cellular structures found in novel food matrices, such as insect proteins or algae, reducing the need for extensive physical trials. This predictive modeling capability significantly shortens the time-to-market for new clean-label products utilizing PEF technology, positioning AI as a critical enabler for innovation within the non-thermal food processing sector and solidifying PEF's technological advantage over conventional methods.

- AI enables real-time dynamic adjustment of PEF parameters (voltage, pulse width) based on product conductivity and temperature.

- Machine Learning (ML) algorithms optimize energy consumption in PEF processing while maintaining required log reductions of target microorganisms.

- Predictive maintenance schedules for high-voltage components, minimizing unplanned system downtime and maximizing throughput.

- Integration of AI-driven sensors and vision systems for quality verification post-PEF treatment, ensuring uniform cell permeabilization.

- Accelerated research and development through AI simulation of PEF effects on complex food matrices and emerging protein sources.

- Enhanced traceability and documentation by correlating PEF operational data with batch-specific quality attributes using centralized AI platforms.

DRO & Impact Forces Of Food Industry Pulsed Electric Field (PEF) System Market

The Food Industry Pulsed Electric Field (PEF) System Market is propelled by compelling drivers centered on superior food quality and regulatory imperatives, counterbalanced by significant restraints related to capital intensity and product limitations, while substantial opportunities arise from technology diversification and emerging market penetration. The primary impact forces shaping the market trajectory include rapidly evolving consumer preferences favoring minimally processed foods, increasingly strict global food safety regulations mandating sophisticated inactivation methods, and continuous improvements in power electronics reducing equipment footprint and complexity. These forces collectively pressure food manufacturers to modernize processing lines, positioning PEF as a strategic investment rather than a mere operational expense, especially for producers focusing on premium, value-added products with extended shelf life.

Drivers: A paramount driver is the rising consumer demand for products labeled as "fresh," "natural," or "minimally processed," which PEF systems are uniquely positioned to deliver by avoiding high thermal loads. Regulatory bodies in regions like the European Union and North America increasingly favor non-thermal alternatives that maintain higher nutritional integrity, further boosting adoption. Furthermore, the efficiency gains in extraction processes, particularly in potato and sugar beet industries where PEF pre-treatment significantly increases yield and reduces waste, provide a strong economic incentive. The global push for sustainability also favors PEF due to its lower energy consumption compared to traditional heat pasteurization.

Restraints: The primary restraint remains the high initial capital expenditure associated with purchasing and installing sophisticated high-voltage PEF generators and treatment chambers, which can be prohibitive for small and medium-sized enterprises (SMEs). Operational challenges, such as the requirement for highly skilled technical personnel for maintenance and optimization, also hinder widespread adoption. Critically, the applicability of PEF is currently limited mainly to liquid or pumpable foods with specific conductivity ranges; treating non-uniform or highly viscous solid products remains technologically challenging and restricts market scope.

Opportunities: Significant growth opportunities lie in the expansion of PEF applications beyond juices and potatoes into emerging sectors such as wine aging acceleration, improved meat tenderization, decontamination of spices, and enhanced processing of cannabis extracts. Developing cost-effective, modular systems tailored for smaller-scale operations in developing regions presents a substantial market entry opportunity. Furthermore, the convergence of PEF with other non-thermal technologies, such as high-pressure processing (HPP) or membrane filtration, creates powerful hybrid systems capable of addressing complex food matrices and achieving synergistic inactivation effects, opening new avenues for innovation and market expansion.

Segmentation Analysis

The Food Industry Pulsed Electric Field (PEF) System market is systematically segmented based on application type, food type, mode of operation, and treatment capacity, reflecting the diverse operational requirements across the food processing landscape. This structure allows for granular analysis of demand patterns, showing where technological maturity and commercial viability are highest. The dominance of liquid food applications underscores PEF's proven capability in maintaining freshness, while segmentation by operational mode (continuous vs. batch) highlights the preference for high-throughput, continuous systems in established large-scale industrial settings like dairy and juice production.

Analyzing the market by food type is crucial, as it dictates the required electric field strength, pulse duration, and the design of the treatment chamber. While fruit and vegetable products currently generate the highest revenue, the rapid adoption in dairy, seafood, and meat applications signals future diversification and substantial growth potential outside the traditional beverage sector. Segmenting the market by capacity—from laboratory scale systems used in R&D to industrial-scale units—provides insight into the maturity levels of the technology across different end-user types, ranging from academic institutions and small startups to global food giants. The strategic focus is shifting toward developing versatile, adaptable systems that can efficiently handle multiple food types without significant hardware modifications.

- By Application:

- Pasteurization and Sterilization (Microbial Inactivation)

- Extraction Enhancement (Mass Transfer)

- Drying and Freezing Enhancement

- Cutting and Slicing Pre-treatment (e.g., Potatoes, Sugar Beets)

- By Food Type:

- Fruits and Vegetables (Juices, Purees, Smoothies)

- Dairy Products (Milk, Yogurt, Cheese)

- Meat and Seafood Products

- Beverages (Other than Juices, e.g., Beer, Wine)

- Other Food Products (Eggs, Novel Proteins)

- By Mode of Operation:

- Continuous Flow Systems (Industrial Scale)

- Batch Systems (R&D and Pilot Scale)

- By Capacity:

- Laboratory/Pilot Scale (Less than 100 L/hr)

- Medium Scale (100 L/hr to 1000 L/hr)

- Industrial Scale (Above 1000 L/hr)

Value Chain Analysis For Food Industry Pulsed Electric Field (PEF) System Market

The value chain for the Food Industry PEF System market begins with upstream component manufacturing, primarily involving specialized suppliers of high-voltage pulse generators, capacitors, treatment chambers (electrodes), and control systems. This stage is dominated by specialized electrical and electronic engineering firms, where intellectual property and precision engineering are crucial competitive advantages. Upstream analysis highlights the high dependency on semiconductor technology and sophisticated power electronics to ensure reliable and consistent pulse delivery, necessitating robust quality control and supply chain resilience for critical components like specialized ceramic insulators and high-frequency switches.

Mid-stream activities are centered on the core PEF equipment manufacturers who integrate these components, design application-specific treatment chambers, develop proprietary software, and provide installation and validation services. These companies are responsible for system customization based on the client's processing capacity and target food matrix. Distribution channels play a vital role, often utilizing a hybrid model involving direct sales teams for large strategic accounts and indirect distributors or system integrators, particularly in geographically dispersed markets or for smaller-scale installations. Technical support, training, and long-term maintenance contracts form a significant part of the mid-stream revenue, emphasizing the necessity of a strong after-sales service network.

Downstream analysis focuses on the end-users—food processors across various sectors (beverages, snacks, dairy). The adoption rate is significantly influenced by the successful commercial validation of the technology in achieving specific quality attributes (e.g., flavor preservation in juices) or efficiency improvements (e.g., yield increase in potato cutting). Direct channels are preferred for highly customized industrial-scale systems, ensuring deep technical engagement throughout the project lifecycle. Indirect channels, primarily through specialized food technology integrators, are often utilized to provide bundled solutions encompassing PEF alongside conventional processing equipment like fillers or sterilizers, facilitating easier integration into existing factory environments and streamlining procurement for the end-user.

Food Industry Pulsed Electric Field (PEF) System Market Potential Customers

The primary potential customers and end-users of Food Industry Pulsed Electric Field (PEF) systems are large multinational food and beverage corporations seeking to optimize production processes, comply with clean label trends, and differentiate their premium product lines. These global enterprises, particularly those engaged in high-volume production of fruit juices, potato chips, and dairy products, possess the necessary capital for initial investment and the operational scale to rapidly realize the return on investment through increased yield, reduced energy costs, and extended shelf life. Their focus is on continuous flow, industrial-scale systems that seamlessly integrate into highly automated, 24/7 manufacturing environments, demanding reliability and high throughput capacity.

A secondary, yet rapidly growing, customer segment includes specialized medium-sized food processors focused on niche or high-value products, such as craft beer, premium ready-to-drink beverages, specialty extracts, and organic foods. These companies utilize PEF to achieve quality characteristics (e.g., non-thermal pasteurization preserving unique flavors) that cannot be replicated by traditional methods, thereby commanding higher market prices. For this segment, the availability of modular, lower-capacity PEF systems that are relatively easy to operate and maintain is a crucial factor influencing purchasing decisions, often favoring systems offered through indirect distribution channels with localized support.

Furthermore, academic research institutions, government food technology laboratories, and startup companies focusing on novel food formulations (e.g., plant-based meat analogs, insect proteins) represent a constant demand for batch and pilot-scale PEF systems. These customers prioritize system flexibility, precise control over electric field parameters, and robust data logging capabilities necessary for research, process development, and regulatory approval trials. Their requirements often drive the market for software advancements and innovative chamber designs tailored for small-volume, high-variability experimental runs, influencing the trajectory of future commercial system development.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 967.2 Million |

| Growth Rate | CAGR 11.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Elea GmbH, Pulsemaster B.V., Energy Pulse Systems S.L., Diversified Technologies Inc. (DTI), P&P Electronic GmbH, GEA Group AG, Hitachi Zosen Corporation, Alfa Laval AB, High-Tech Engineering Center, SCADA Technology, CoolWave Processing, APG-PEF, The High Voltage Company (HVC), PurePulse Technologies, Star Refrigeration (incorporating PEF), Krones AG, Spindt Technologies, Proton Technologies, Q-Pulse Systems, BioElectrics Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Industry Pulsed Electric Field (PEF) System Market Key Technology Landscape

The core technology driving the Food Industry PEF market centers on highly specialized pulse generators, which are responsible for converting mains power into nanosecond or microsecond high-voltage pulses (typically 10 kV/cm to 80 kV/cm) delivered to the treatment chamber. Current technological advancements focus heavily on optimizing these generators to achieve greater efficiency, minimize energy leakage, and ensure pulse reproducibility across millions of cycles, which is critical for industrial-scale continuous operation. Semiconductor-based switches, such as Insulated Gate Bipolar Transistors (IGBTs) and thyristors, are foundational components, and improvements in their performance and lifetime directly correlate with system reliability and maintenance cost reduction. The shift towards solid-state pulsed power technology is significantly enhancing system compactness and modularity compared to older Marx generator architectures.

The design of the treatment chamber, or co-field electrode arrangement, represents another crucial technological area. Optimal chamber design ensures uniform electric field distribution across the entire volume of the food product, which is essential for consistent microbial inactivation or electroporation, especially when processing viscous or non-homogeneous materials. Ongoing research focuses on developing innovative flow configurations, such as coaxial or parallel plate electrode designs, customized for specific food matrices (e.g., highly viscous purees versus low-conductivity fruit juices). Material science advancements in electrode and insulator construction are vital to prevent corrosion, manage heat dissipation, and avoid arcing, thereby maximizing the system's operational lifespan in corrosive food environments.

Furthermore, sensor technology and sophisticated control software are integral to the contemporary PEF landscape. Advanced in-line sensors measure real-time product parameters like temperature and conductivity, allowing the generator to dynamically adjust pulse characteristics. This level of precise process control is enabled by high-speed digital signal processors (DSPs) and Supervisory Control and Data Acquisition (SCADA) systems, which record and validate the lethality achieved during processing. The integration of predictive modeling tools, often utilizing machine learning, allows operators to precisely calibrate PEF exposure based on the incoming raw material quality, ensuring both safety and preservation of desirable nutritional and sensory attributes, establishing a benchmark for Industry 4.0 standards in food processing.

Regional Highlights

- North America: This region holds a leading position in the PEF system market, primarily driven by early adoption in the potato processing industry and high demand for refrigerated, premium fruit juices. Strict FDA regulations promoting non-thermal methods to ensure food safety coupled with robust R&D investment from large food companies like PepsiCo and McCain Foods fuel market growth. Canada and the United States are centers for manufacturing and technological innovation, focusing on integrating PEF systems into large, automated processing plants.

- Europe: Europe is a dominant force, particularly due to the presence of key PEF system manufacturers (like Elea and Pulsemaster) and stringent European Union directives regarding food quality, safety, and sustainable processing. The market benefits from strong academic research collaborations and high consumer willingness to pay a premium for minimally processed and organic foods. Germany, the Netherlands, and Spain are significant adopters, particularly in dairy, wine, and vegetable processing sectors.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR during the forecast period. This growth is attributable to rapid urbanization, increasing disposable income driving demand for high-quality packaged foods, and massive investment in modernizing aging food production infrastructure in countries like China, India, and Japan. While initial costs remain a barrier, the sheer scale of the food processing industry in APAC presents unparalleled opportunities for industrial-scale continuous PEF systems in beverages and local vegetable processing.

- Latin America: This region, led by Brazil and Mexico, presents strong potential, driven primarily by the vast domestic fruit and beverage markets. PEF technology offers a pathway to increase the export competitiveness of Latin American fruit juices by ensuring extended shelf life without compromising the tropical flavors. Market growth is constrained somewhat by economic volatility and reliance on foreign imports for specialized equipment, though domestic manufacturing is slowly emerging.

- Middle East and Africa (MEA): The MEA market is nascent but shows potential, especially in high-income Gulf Cooperation Council (GCC) countries focused on improving domestic food security and quality standards. Adoption is currently concentrated in pilot projects and small-scale operations for high-value products. Challenges include limited infrastructure and the high cost of implementation, necessitating strong government backing for large-scale technological investment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Industry Pulsed Electric Field (PEF) System Market.- Elea GmbH

- Pulsemaster B.V.

- Energy Pulse Systems S.L.

- Diversified Technologies Inc. (DTI)

- P&P Electronic GmbH

- GEA Group AG

- Hitachi Zosen Corporation

- Alfa Laval AB

- High-Tech Engineering Center

- SCADA Technology

- CoolWave Processing

- APG-PEF

- The High Voltage Company (HVC)

- PurePulse Technologies

- Star Refrigeration (incorporating PEF solutions)

- Krones AG

- Spindt Technologies

- Proton Technologies

- Q-Pulse Systems

- BioElectrics Inc.

Frequently Asked Questions

Analyze common user questions about the Food Industry Pulsed Electric Field (PEF) market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Pulsed Electric Field (PEF) technology and how does it benefit food safety?

PEF is a non-thermal food processing technique that uses short bursts of high-voltage electricity to create microscopic pores (electroporation) in the cell membranes of microorganisms. This process effectively inactivates bacteria and enzymes without relying on high heat, ensuring microbial safety while maximally preserving the food's natural flavor, color, and nutritional value, leading to superior product quality and extended shelf life.

Is PEF technology suitable for all types of food products?

PEF is most effective and commercially viable for pumpable food products such as fruit juices, milk, liquid egg products, and vegetable purees, which possess homogeneous properties and appropriate electrical conductivity. While research is expanding its use to solid foods (e.g., potato pre-treatment, meat), its application is currently limited by the physical uniformity required to ensure even electrical field distribution, making highly viscous or structurally complex solid foods challenging to process consistently.

How does the cost of implementing a PEF system compare to traditional pasteurization methods?

The initial capital expenditure for installing a PEF system is substantially higher than conventional thermal pasteurization equipment due to the complexity of the high-voltage pulse generators and specialized chambers. However, PEF offers lower long-term operational costs stemming from reduced energy consumption, minimal heat input, increased raw material yield (especially in extraction applications), and potential reductions in waste, leading to a favorable return on investment (ROI) over the system's lifespan for high-volume processors.

Does PEF processing degrade the vitamins or nutrients in food products?

A key advantage of PEF is its minimal impact on thermosensitive compounds, including essential vitamins (like Vitamin C and B-complex vitamins), antioxidants, and flavor compounds. Since PEF is non-thermal (or mildly thermal), it avoids the chemical degradation pathways induced by traditional high-heat processing, resulting in products that retain significantly higher levels of heat-labile nutrients and superior sensory quality compared to conventionally pasteurized alternatives.

What role do treatment chamber design and flow rate play in PEF system effectiveness?

Treatment chamber design, particularly the electrode geometry, is critical as it determines the uniformity and strength of the electric field applied to the food product. The flow rate through the chamber dictates the residence time of the product within the electric field. Optimal effectiveness requires matching flow rate with pulse parameters (voltage and frequency) to ensure every particle of food receives the necessary cumulative dose of electrical energy (treatment intensity) needed for target microbial inactivation or permeabilization while maintaining continuous processing efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager