food vacuum cooler Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440768 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

food vacuum cooler Market Size

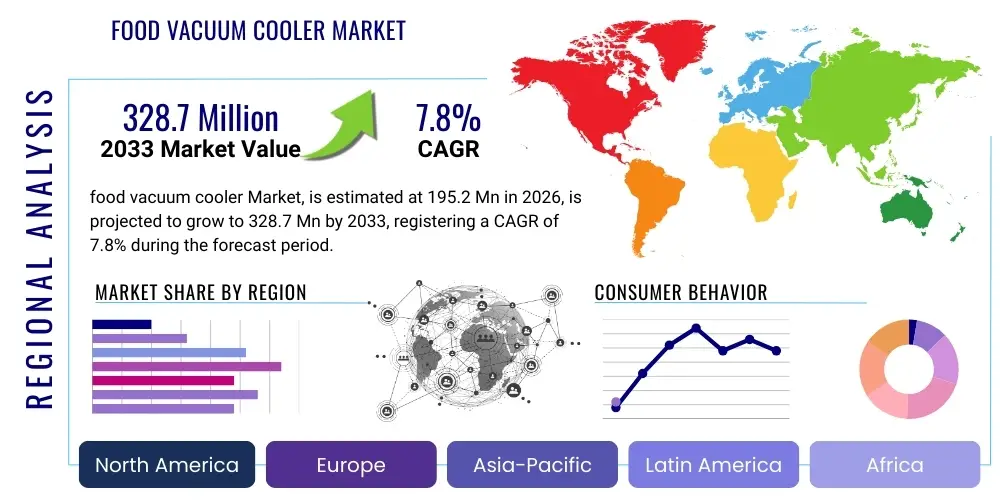

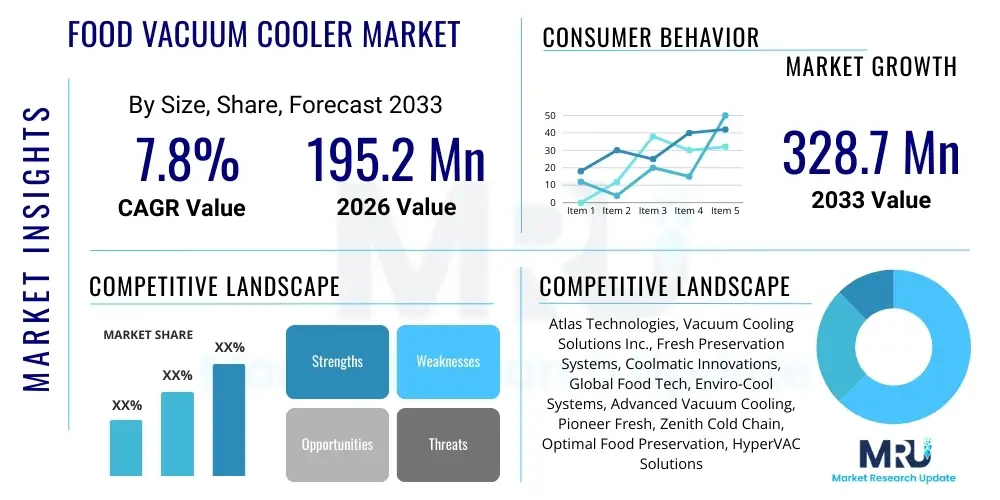

The food vacuum cooler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 195.2 Million in 2026 and is projected to reach USD 328.7 Million by the end of the forecast period in 2033.

food vacuum cooler Market introduction

The food vacuum cooler market encompasses advanced refrigeration systems designed to rapidly cool freshly harvested produce, baked goods, prepared meals, and other food products by leveraging the principle of evaporative cooling under a vacuum. This technology significantly extends the shelf life of perishable items, preserves their nutritional value, and maintains their sensory qualities, making it an indispensable tool across the food supply chain. The core function involves placing food items in a vacuum chamber, where the reduced atmospheric pressure causes water within the food to evaporate rapidly, absorbing latent heat and thereby cooling the product uniformly and quickly.

Major applications of food vacuum coolers span a wide array of sectors within the food industry, including fresh produce farming, bakeries, meat and seafood processing, and the prepared foods segment. For instance, in agriculture, vacuum cooling is widely used for leafy greens, mushrooms, and various fruits and vegetables immediately after harvest, allowing them to reach consumers fresher and with reduced post-harvest losses. In bakeries, it rapidly cools bread and pastries, preventing staleness and improving crust quality, while in the ready-to-eat meals sector, it ensures rapid cooling for hygiene and extended shelf stability.

The primary benefits driving the adoption of food vacuum coolers include unparalleled speed in cooling, which is often several times faster than conventional hydro-cooling or forced-air cooling, leading to substantial energy savings and reduced operational costs. Furthermore, this method minimizes moisture loss, retains food texture and appearance, and crucially, inhibits microbial growth effectively. These advantages are propelling market growth, alongside increasing consumer demand for fresh, high-quality food products, stringent food safety regulations, and a growing global focus on reducing food waste throughout the supply chain. The efficiency and versatility of vacuum cooling systems position them as critical enablers for modern food preservation and distribution strategies.

food vacuum cooler Market Executive Summary

The food vacuum cooler market is currently experiencing robust growth, primarily driven by evolving business trends centered on automation, sustainability, and efficiency across the food processing and logistics sectors. Businesses are increasingly investing in technologies that not only enhance product freshness and extend shelf life but also optimize energy consumption and minimize environmental impact. The integration of IoT and advanced control systems into modern vacuum coolers represents a significant trend, allowing for precise temperature management, remote monitoring, and predictive maintenance, thereby improving operational reliability and reducing downtime for food manufacturers and distributors. There is also a notable shift towards modular and customizable vacuum cooling solutions to cater to diverse operational scales and specific product requirements, from small-batch artisanal producers to large-scale industrial processors, reflecting a versatile and adaptable market landscape.

Regionally, the market exhibits diverse growth patterns influenced by varying levels of industrial development, consumer preferences, and regulatory frameworks. North America and Europe continue to be leading markets, characterized by high adoption rates driven by stringent food safety standards, sophisticated cold chain infrastructure, and a strong emphasis on reducing food waste. The Asia Pacific region is emerging as a critical growth engine, propelled by rapid urbanization, expanding food processing industries, increasing disposable incomes, and a growing demand for fresh and packaged foods in countries like China, India, and Southeast Asian nations. Latin America and the Middle East & Africa are also demonstrating nascent but significant potential, driven by infrastructure development in agriculture and food processing, and a rising awareness of advanced food preservation techniques.

Segment-wise, the market is witnessing notable trends across different applications and capacities. The fresh produce segment remains a dominant force, with continued innovation in vacuum cooling for delicate items like leafy greens, mushrooms, and berries. However, there is an accelerating trend of adoption in non-traditional segments such as baked goods, where vacuum cooling drastically reduces cooling times and improves product quality, and in the prepared meals sector, where rapid chilling is crucial for food safety and convenience. Furthermore, the demand for medium to large-capacity continuous vacuum coolers is on the rise as industrial food processing facilities scale up operations, seeking greater throughput and efficiency. Simultaneously, the emergence of more compact and energy-efficient batch vacuum coolers is catering to smaller enterprises and specialized applications, indicating a diversified market responding to a wide spectrum of end-user needs and operational scales.

AI Impact Analysis on food vacuum cooler Market

Users are increasingly seeking to understand how Artificial Intelligence (AI) can revolutionize the efficiency, precision, and sustainability of food vacuum cooling operations. Key user questions often revolve around AI's ability to optimize cooling cycles, predict equipment failures, enhance food quality control, and streamline integration within larger smart factory ecosystems. Users are concerned about leveraging AI for predictive analytics to minimize energy consumption, reduce operational costs, and improve overall product consistency. Expectations are high for AI to provide real-time insights into cooling performance, facilitate automated adjustments based on environmental conditions and product characteristics, and contribute significantly to advanced traceability and compliance with food safety standards. The overarching theme is the desire for more intelligent, autonomous, and data-driven cooling solutions that transcend traditional manual or semi-automated systems, offering a pathway to unparalleled operational excellence and competitive advantage in the food preservation sector.

- AI-driven optimization of vacuum cooling cycles based on real-time product data and ambient conditions, leading to enhanced energy efficiency and faster cooling times.

- Predictive maintenance for vacuum cooler components, leveraging machine learning algorithms to anticipate equipment failures, minimize downtime, and extend asset lifespan.

- Enhanced quality control through AI-powered sensors and vision systems, monitoring food appearance, temperature uniformity, and detecting anomalies during the cooling process.

- Integration with broader smart factory systems, enabling seamless data exchange for end-to-end supply chain optimization, from farm to consumer.

- Automated anomaly detection and corrective action, reducing human error and ensuring consistent adherence to food safety and quality protocols.

- Forecasting demand and optimizing inventory management by combining cooling data with sales trends and seasonal variations.

- Personalized cooling recipes for diverse food products, allowing for adaptive process parameters to achieve optimal preservation outcomes.

DRO & Impact Forces Of food vacuum cooler Market

The food vacuum cooler market is propelled by a robust set of drivers that underscore its value proposition in modern food preservation. A primary driver is the escalating global consumer demand for fresh, minimally processed, and high-quality food products that retain their nutritional integrity and sensory attributes. This trend directly benefits vacuum cooling, which excels at rapid chilling without significantly altering food structure or taste. Furthermore, increasingly stringent food safety regulations worldwide compel food processors to adopt advanced cooling technologies that effectively inhibit microbial growth and extend product shelf life, making vacuum coolers an attractive compliance solution. The undeniable efficiency benefits, including significantly reduced cooling times and lower energy consumption compared to traditional methods for many applications, also act as powerful incentives for investment, alongside a growing industry-wide focus on minimizing food waste across the supply chain, where vacuum cooling plays a crucial role in preventing spoilage from farm to fork.

However, the market also faces considerable restraints that temper its growth trajectory. The most significant barrier to widespread adoption is the high initial capital investment required for purchasing and installing vacuum cooling systems, which can be prohibitive for small and medium-sized enterprises (SMEs) with limited budgets. Moreover, the technical complexity associated with operating and maintaining these specialized systems often necessitates skilled personnel and specialized training, adding to operational costs and posing a challenge for regions with limited technical expertise. A lack of comprehensive awareness about the specific advantages and versatile applications of vacuum cooling technology, particularly in developing economies, further limits market penetration. These factors collectively create hurdles that must be addressed for the market to realize its full potential.

Despite the restraints, significant opportunities exist for market expansion and innovation. Emerging economies, particularly in Asia Pacific and Latin America, present vast untapped markets with burgeoning food processing industries and a rapidly growing middle class demanding higher quality food products. Technological advancements aimed at developing more compact, energy-efficient, and cost-effective vacuum cooling units, along with modular designs that can be integrated into existing infrastructure, are creating new avenues for market entry. The growing trend towards automation and integration with IoT and Industry 4.0 technologies offers opportunities for smart vacuum cooling solutions that provide real-time monitoring and predictive capabilities. Additionally, the potential for customization to suit niche food products or specialized processing needs, such as in the pharmaceutical or floral industries, represents a promising area for diversification and market growth. The evolving landscape of food production and distribution continues to open new doors for innovative vacuum cooling applications, presenting compelling long-term growth prospects for industry players willing to invest in research and development.

Segmentation Analysis

The food vacuum cooler market is meticulously segmented across various parameters to provide a granular understanding of its diverse applications, operational scales, and end-user demands. This segmentation allows for a comprehensive analysis of market dynamics, identifying specific growth pockets and competitive landscapes within the broader industry. The primary segmentation criteria include the type of cooling system, the capacity of the units, the specific application areas where the technology is deployed, and the end-user industries that benefit from these advanced cooling solutions. Each segment is influenced by unique drivers and faces distinct challenges, contributing to the overall complexity and dynamism of the market. Understanding these segments is crucial for strategic planning, product development, and market entry strategies for new and existing players, ensuring that solutions are tailored to meet precise industry needs and maximize market penetration.

- By Type

- Batch Vacuum Coolers

- Continuous Vacuum Coolers

- By Capacity

- Small Capacity (Up to 500 kg/hr)

- Medium Capacity (501 – 2000 kg/hr)

- Large Capacity (Above 2000 kg/hr)

- By Application

- Fresh Produce (Fruits, Vegetables, Herbs, Flowers)

- Baked Goods (Bread, Pastries)

- Meat and Poultry

- Seafood

- Prepared Meals and Ready-to-Eat Foods

- Dairy Products

- By End-User

- Food Processing Companies

- Catering Services

- Restaurants and Hospitality

- Supermarkets and Retailers

- Logistics and Cold Chain Providers

Value Chain Analysis For food vacuum cooler Market

The value chain for the food vacuum cooler market begins with upstream activities involving the sourcing of raw materials and specialized components critical for the manufacturing process. This includes suppliers of high-grade stainless steel for vacuum chambers, advanced vacuum pumps, refrigeration units, control systems (PLCs, sensors), and sealing technologies. The quality and reliability of these upstream components directly impact the performance, durability, and cost-effectiveness of the final vacuum cooler system. Strong relationships with reputable component suppliers are essential for manufacturers to ensure consistent quality, manage costs, and innovate. Research and development efforts at this stage focus on optimizing materials for better vacuum integrity, enhancing pump efficiency, and integrating more sophisticated control software to improve overall system performance and energy efficiency.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing of the vacuum cooling systems, followed by their distribution to end-users. Manufacturers specialize in designing and fabricating vacuum chambers, integrating cooling and vacuum systems, and developing user-friendly interfaces. The distribution channel plays a pivotal role in delivering these complex systems to a global customer base. This typically involves a mix of direct and indirect channels. Direct sales often target large industrial food processors, catering to their specific customization needs and providing direct installation, training, and after-sales support. This direct engagement fosters stronger customer relationships and allows for tailored solutions. Indirect channels, on the other hand, involve a network of authorized distributors, resellers, and system integrators who have established regional presence and expertise in specific end-user segments. These partners are crucial for reaching a broader market, particularly smaller and medium-sized enterprises (SMEs) and specialized niche markets, by offering localized sales, service, and maintenance support. Effective logistics and supply chain management are paramount to ensure timely delivery and efficient deployment of these large and sensitive equipment systems.

Ultimately, the value chain culminates with the end-users—food processing companies, bakeries, catering services, supermarkets, and cold chain logistics providers—who utilize the vacuum coolers for their core operations. Post-sales services, including installation, commissioning, maintenance contracts, spare parts supply, and technical support, constitute a critical part of the downstream value chain. The effectiveness of these services significantly influences customer satisfaction, repeat business, and brand reputation. Manufacturers often invest in training programs for client staff to ensure optimal operation and longevity of the equipment. Furthermore, the feedback loop from end-users to manufacturers is vital for continuous product improvement and innovation, addressing evolving market needs and technological advancements. This integrated approach across the entire value chain ensures that the market for food vacuum coolers remains robust, responsive, and oriented towards long-term customer value, facilitating the efficient preservation of food products across diverse global markets.

food vacuum cooler Market Potential Customers

The food vacuum cooler market targets a diverse and expanding base of potential customers across the entire food supply chain, all seeking to enhance the freshness, safety, and shelf life of their perishable products while optimizing operational efficiency. At the forefront are large-scale food processing companies, particularly those dealing with fresh produce, baked goods, and prepared meals. These enterprises require robust and high-capacity cooling solutions to handle significant volumes of product quickly and uniformly, ensuring quality and meeting stringent regulatory standards. For them, vacuum coolers offer a critical advantage in maintaining consistency, reducing spoilage, and accelerating throughput, thereby directly impacting profitability and market competitiveness. The increasing demand for ready-to-eat and convenience foods further solidifies this segment as a primary customer base, as rapid cooling is essential for both food safety and extending the saleable period of such items.

Beyond large processors, a significant and growing segment of potential customers includes medium-sized bakeries, catering services, and institutional food service providers. These entities often operate with diverse product portfolios and varying cooling needs, for which the flexibility and efficiency of vacuum cooling systems are highly beneficial. Bakeries, for instance, utilize vacuum coolers to rapidly cool bread and pastries, improving crust quality and extending freshness without moisture loss. Catering companies and hospitality businesses, which frequently prepare large quantities of food in advance, leverage vacuum cooling to quickly bring cooked dishes down to safe temperatures, preventing bacterial growth and maintaining food quality for subsequent service or packaging. This segment is characterized by a need for reliable, easy-to-operate systems that can integrate seamlessly into existing kitchen or production workflows, offering a balance between initial investment and long-term operational savings.

Furthermore, the market extends to supermarkets, retail chains, and logistics companies specializing in cold chain management. For retailers, vacuum cooling can be deployed at distribution centers or even in-store to rapidly chill incoming produce or prepared foods, directly impacting shelf life and reducing shrink. Logistics and cold chain providers benefit by ensuring that products maintain optimal freshness during transportation, especially for exports or long-distance distribution. The ability of vacuum cooling to remove field heat quickly, even from packaged goods, makes it an invaluable asset in preserving quality during transit, reducing spoilage rates, and enhancing customer satisfaction upon delivery. This wide array of end-users underscores the broad applicability and intrinsic value of food vacuum cooler technology across multiple critical junctures of the modern food system, addressing diverse challenges from farm gate to consumer plate.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 195.2 Million |

| Market Forecast in 2033 | USD 328.7 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Technologies, Vacuum Cooling Solutions Inc., Fresh Preservation Systems, Coolmatic Innovations, Global Food Tech, Enviro-Cool Systems, Advanced Vacuum Cooling, Pioneer Fresh, Zenith Cold Chain, Optimal Food Preservation, HyperVAC Solutions, Integrated Cooling Systems, PrimeChill Group, NextGen Food Tech, GreenHarvest Cooling, Agro-Vac Technologies, UltraFresh Solutions, OmniCool Systems, TechFresh Engineering, Future Harvest Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

food vacuum cooler Market Key Technology Landscape

The key technology landscape of the food vacuum cooler market is characterized by a sophisticated integration of mechanical engineering, thermodynamics, and advanced control systems, all working in concert to achieve rapid and uniform cooling. At its core are high-efficiency vacuum pump systems, which are crucial for rapidly reducing the atmospheric pressure within the cooling chamber to the desired vacuum level. These pumps, often rotary vane or liquid ring types, must be robust, reliable, and energy-efficient, capable of maintaining consistent vacuum levels under demanding operational conditions. The design of the vacuum chamber itself is also critical, requiring strong construction materials, precise sealing mechanisms, and optimal internal geometry to facilitate efficient vapor removal and uniform heat transfer from the food products. Innovations in pump technology, such as variable speed drives and improved sealing materials, are continuously enhancing system performance and reducing maintenance requirements, contributing to the overall appeal of vacuum cooling solutions for various food applications. Furthermore, the refrigeration units connected to the vacuum system play a vital role in condensing the water vapor removed from the food, effectively completing the cooling cycle and ensuring continuous operation.

Beyond the fundamental vacuum and refrigeration components, the technological landscape is increasingly defined by automation, digital control, and connectivity. Modern food vacuum coolers incorporate advanced Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that allow for precise temperature and pressure control, customized cooling recipes for different products, and automated process management. These control systems enable operators to monitor and adjust cooling parameters in real-time, ensuring optimal cooling cycles, reducing human error, and enhancing food safety. The integration of Internet of Things (IoT) sensors and connectivity is a rapidly growing trend, allowing for remote monitoring, data logging, and predictive maintenance. This connectivity facilitates comprehensive data analysis on cooling performance, energy consumption, and equipment health, enabling food processors to optimize operations, schedule maintenance proactively, and comply with traceability requirements. These digital enhancements transform vacuum coolers from mere pieces of equipment into intelligent, interconnected components of a larger smart factory ecosystem, driving efficiency and responsiveness in food production environments.

Further technological advancements contributing to the market include innovations in energy recovery systems, which capture and reuse waste heat generated during the cooling process, significantly improving the overall energy footprint of the units. The development of modular designs and scalable solutions allows manufacturers to offer vacuum coolers that can be tailored to various operational capacities, from small-batch artisanal production to large-scale industrial lines, enhancing their versatility and market reach. Material science also plays a role in developing more durable, corrosion-resistant, and hygienic chamber materials, ensuring compliance with strict food safety regulations and extending the operational life of the equipment. Moreover, ongoing research into hybrid cooling systems that combine vacuum cooling with other methods, such as forced-air or hydro-cooling, aims to address specific product requirements and further optimize cooling efficiency. This holistic approach to technological development, encompassing core mechanics, intelligent controls, and sustainable practices, continuously pushes the boundaries of food preservation, making vacuum coolers more efficient, reliable, and adaptable to the evolving demands of the global food industry.

Regional Highlights

- North America: This region stands as a mature yet highly innovative market, driven by stringent food safety regulations, a strong consumer preference for fresh and organic produce, and significant investment in advanced food processing technologies. The presence of major food processing giants and a well-established cold chain infrastructure further propels the adoption of vacuum coolers. Continued focus on reducing food waste and enhancing supply chain efficiency also contributes to its market dominance, with a particular emphasis on automation and integrated solutions in manufacturing.

- Europe: Europe represents another key market, characterized by an early adoption of advanced food preservation techniques and a strong regulatory environment focused on sustainability and food quality. Countries like Germany, the Netherlands, and France are at the forefront, driven by their robust agricultural sectors and sophisticated food processing industries. The region’s emphasis on reducing carbon footprints and adherence to high environmental standards encourages the adoption of energy-efficient vacuum cooling systems, while strong domestic and export markets for fresh produce and baked goods sustain demand.

- Asia Pacific (APAC): The APAC region is poised for the most rapid growth in the food vacuum cooler market, fueled by explosive population growth, increasing urbanization, rising disposable incomes, and a dramatic shift in consumer diets towards processed and fresh packaged foods. Countries such as China, India, Japan, and Australia are investing heavily in modernizing their food processing and cold chain infrastructure. The vast agricultural output, coupled with significant post-harvest losses, creates a compelling need for efficient preservation technologies like vacuum cooling to extend shelf life and reduce waste, driving substantial market expansion and technological adoption across the diverse economies of the region.

- Latin America: This region offers considerable growth potential, particularly in countries with strong agricultural bases like Brazil, Mexico, and Argentina. The increasing globalization of food trade, coupled with a growing awareness of food safety and quality standards, is driving investment in advanced cooling technologies. While infrastructure development can be a challenge, the rising demand for efficient post-harvest handling of fresh produce and the expansion of the food processing sector are key factors contributing to the gradual but steady adoption of food vacuum coolers.

- Middle East and Africa (MEA): The MEA market for food vacuum coolers is emerging, driven by efforts to enhance food security, diversify economies beyond oil, and develop modern food processing capabilities. Investments in agriculture, particularly in arid regions requiring specialized preservation techniques, and the expansion of hospitality and catering sectors are creating new opportunities. Despite facing challenges related to climate and infrastructure, the growing awareness of food waste reduction and the push for higher quality food products are slowly but surely paving the way for the adoption of vacuum cooling solutions in key countries across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the food vacuum cooler Market.- Atlas Technologies

- Vacuum Cooling Solutions Inc.

- Fresh Preservation Systems

- Coolmatic Innovations

- Global Food Tech

- Enviro-Cool Systems

- Advanced Vacuum Cooling

- Pioneer Fresh

- Zenith Cold Chain

- Optimal Food Preservation

- HyperVAC Solutions

- Integrated Cooling Systems

- PrimeChill Group

- NextGen Food Tech

- GreenHarvest Cooling

- Agro-Vac Technologies

- UltraFresh Solutions

- OmniCool Systems

- TechFresh Engineering

- Future Harvest Systems

Frequently Asked Questions

Analyze common user questions about the food vacuum cooler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a food vacuum cooler and how does it work?

A food vacuum cooler rapidly chills food products by placing them in a sealed chamber, reducing atmospheric pressure to cause water within the food to evaporate. This evaporation absorbs latent heat, quickly and uniformly cooling the product, significantly extending its shelf life while preserving quality.

What are the primary benefits of using a vacuum cooler for food preservation?

The main benefits include exceptionally fast and uniform cooling, extended product shelf life, superior preservation of freshness, texture, and nutritional value, reduced energy consumption compared to traditional methods for many items, and effective inhibition of microbial growth.

Which types of food products are most suitable for vacuum cooling?

Vacuum cooling is highly effective for products with high moisture content and a large surface area, such as fresh leafy greens, fruits, vegetables, mushrooms, herbs, and cut flowers. It is also increasingly used for baked goods, prepared meals, and even some meats and seafood due to its rapid and non-damaging cooling process.

What are the key factors driving the growth of the food vacuum cooler market?

Market growth is primarily driven by increasing global demand for fresh and minimally processed foods, stringent food safety regulations, the imperative to reduce food waste across the supply chain, the proven energy efficiency benefits of the technology, and continuous advancements in automation and IoT integration within cooling systems.

What is the typical initial investment for a food vacuum cooler, and what are the operational costs?

The initial investment for a food vacuum cooler can be substantial, varying widely based on capacity and features, often ranging from tens of thousands to several hundred thousand USD. Operational costs include electricity for vacuum pumps and refrigeration, maintenance, and skilled labor. However, these are often offset by significant savings from extended shelf life, reduced spoilage, and potentially lower energy consumption compared to traditional cooling methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager