Frameless Glass Balcony Railing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443043 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Frameless Glass Balcony Railing Market Size

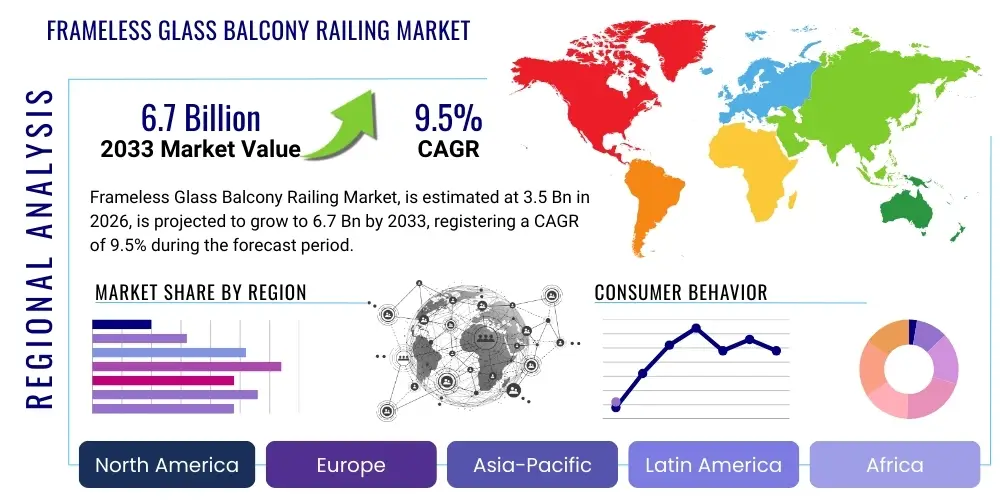

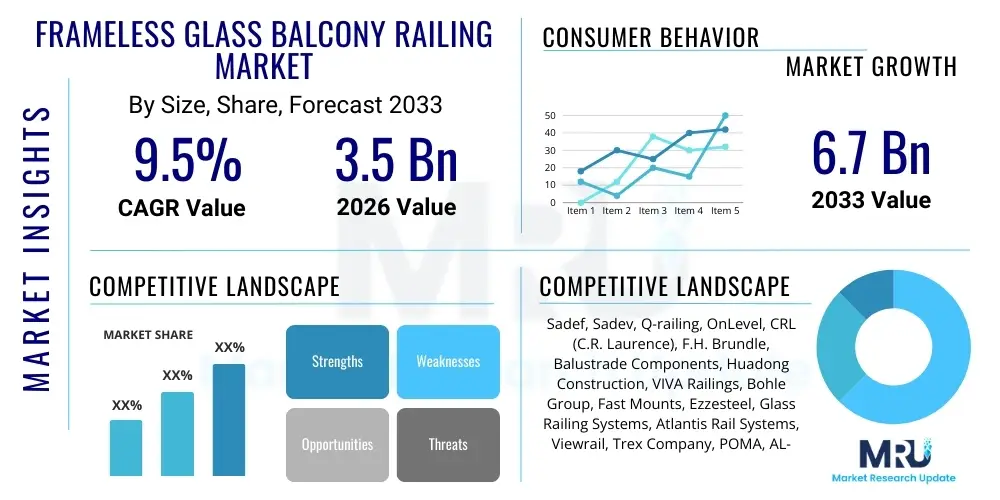

The Frameless Glass Balcony Railing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Frameless Glass Balcony Railing Market introduction

The Frameless Glass Balcony Railing Market encompasses the design, manufacturing, and installation of safety barriers utilizing structural glass panels secured by minimal or concealed fittings, eliminating the need for traditional vertical posts or balusters. This product category is highly valued in modern architectural design for its aesthetic appeal, offering unobstructed views and seamless integration into contemporary building facades. The core product relies on advanced toughened and laminated glass technologies, complemented by robust aluminum base channels, spigots, or standoff systems designed to meet stringent international building codes for load bearing and safety. The market growth is intricately linked to the global boom in high-end residential towers, luxury hotels, and commercial real estate development emphasizing modern, minimalist aesthetics and maximizing natural light utilization in urban environments.

Major applications for frameless glass balcony railings span both new construction and renovation projects, predominantly targeting residential sectors—including apartments, condominiums, and villas—and commercial entities such as office complexes, shopping centers, and hospitality establishments. These systems are favored because they enhance property value, provide superior wind protection without compromising visibility, and offer inherent durability against environmental factors when compared to traditional railing materials like wood or wrought iron. Furthermore, the increasing consumer focus on outdoor living spaces, coupled with innovations in glass treatment for enhanced safety and low-maintenance characteristics, solidifies their position as a premium construction component.

Key benefits driving market adoption include the significant visual enhancement achieved through transparency, which creates an expansive feeling in smaller balcony spaces. Regulatory pressure mandating higher safety standards for balcony barriers, particularly in high-rise buildings, also acts as a primary driving factor, as laminated tempered glass systems provide exceptional strength and splinter resistance upon impact. Technological advancements in hardware, such as self-leveling base shoes and corrosion-resistant alloys, simplify installation processes while ensuring long-term structural integrity, making frameless systems increasingly appealing to architects, developers, and construction firms seeking reliable and aesthetically superior solutions.

Frameless Glass Balcony Railing Market Executive Summary

The Frameless Glass Balcony Railing Market is experiencing robust expansion driven primarily by escalating demand in the global luxury housing sector and large-scale commercial infrastructural development projects across emerging economies. Business trends indicate a strong shift towards customization, where manufacturers are offering bespoke railing solutions tailored to unique architectural requirements, integrating smart features like LED lighting within the railing base or incorporating specialized coatings for anti-glare and self-cleaning properties. The competitive landscape is characterized by intense innovation in hardware systems, focusing on faster, safer installation methodologies that reduce on-site labor costs and minimize project timelines. Key industry participants are also expanding their global supply chain networks to ensure prompt delivery of heavy glass components and specialized aluminum extrusions.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, fuelled by rapid urbanization, significant investments in vertical residential development, particularly in China and India, and the adoption of Western architectural standards that prioritize unobstructed views. North America and Europe maintain leading market shares due to high per capita spending on home renovation, strict adherence to stringent building safety codes, and established consumer preference for high-quality, long-lasting construction materials. The Middle East and Africa (MEA) region is also emerging as a high-potential area, driven by mega-construction projects in the hospitality and real estate sectors in countries like UAE and Saudi Arabia, necessitating aesthetically pleasing and durable balcony solutions suitable for harsh climatic conditions.

Segment trends reveal that the use of Laminated Toughened Glass is dominating the market due to its superior safety profile, which prevents fragments from scattering upon breakage, a critical requirement in high-rise applications. In terms of system type, the Aluminum Base Shoe System maintains the largest market share owing to its robust stability and ability to accommodate slight structural variations, offering comprehensive support along the glass base. The residential application segment remains the primary revenue generator, although the commercial segment, particularly premium hotels and corporate headquarters, is exhibiting the highest growth trajectory, reflecting the global trend toward sophisticated, transparent, and aesthetically advanced external building features that define corporate identity and premium living standards.

AI Impact Analysis on Frameless Glass Balcony Railing Market

Analysis of common user questions regarding AI's impact on the Frameless Glass Balcony Railing Market reveals key themes centered around enhancing design precision, streamlining manufacturing processes, and improving predictive maintenance. Users frequently inquire about the potential for AI-driven software to optimize structural integrity calculations, especially concerning wind load distribution and seismic performance, thereby reducing engineering consultation time and material waste. Another prevalent concern revolves around how Machine Learning (ML) algorithms can be applied to quality control in glass lamination and tempering processes to minimize defects, ensuring that the finished product consistently meets high safety standards. Expectations also include AI facilitating personalized design visualization for end-users and optimizing supply chain logistics for complex, custom-sized glass panels, reducing lead times and ensuring just-in-time delivery to dynamic construction sites.

The application of Artificial Intelligence is beginning to transform the pre-construction phase of frameless glass installations by utilizing advanced computational design tools. AI algorithms can analyze complex architectural drawings and site-specific environmental data—such as prevailing wind patterns and temperature fluctuations—to recommend optimal glass thickness, hardware specifications, and installation methods, surpassing the efficiency of traditional finite element analysis (FEA). This precision in material specification not only enhances the safety margin of the final product but also significantly contributes to cost efficiency by preventing over-engineering and minimizing expensive material adjustments on-site. Furthermore, Generative Design AI is being explored to create innovative base shoe designs that maximize load dispersion while minimizing visible hardware components, catering directly to the market’s aesthetic demand for minimalist profiles.

In the operational and post-installation phase, AI-powered monitoring systems utilizing embedded sensors are projected to play a vital role in predictive maintenance. These systems can continuously analyze stress loads and structural vibrations, providing early warnings for potential hardware failure or glass fatigue, thereby extending the lifespan of the railing system and enhancing long-term safety assurance. Logistics optimization, another crucial area, benefits from AI by forecasting demand variations for specific hardware components (e.g., specialized gaskets, bolts, and mounting channels) based on regional construction activity cycles and project pipelines, ensuring manufacturers maintain optimized inventory levels and responsiveness, which is critical given the typically long lead times associated with custom glass fabrication.

- AI-driven structural analysis optimizes glass thickness and hardware selection based on specific building physics, enhancing safety.

- Machine Learning algorithms improve quality control in tempering and lamination, reducing manufacturing defects and waste.

- Generative Design aids in creating highly optimized, minimalist base shoe and spigot hardware configurations.

- Predictive maintenance systems using sensor data monitor stress and fatigue, providing real-time structural health monitoring.

- AI optimizes supply chain logistics for large, custom glass panels, ensuring efficient inventory management and timely delivery.

- Automated visual inspection of installed railings using computer vision ensures compliance with local safety regulations post-installation.

DRO & Impact Forces Of Frameless Glass Balcony Railing Market

The dynamics of the Frameless Glass Balcony Railing Market are heavily influenced by a confluence of powerful drivers, stringent restraints, and significant opportunities, which collectively define the impact forces shaping its trajectory. The primary driver is the pervasive trend toward architectural modernization and the preference for materials that offer high transparency and visual lightness in construction, especially within high-density urban environments where maximizing light penetration is paramount. Restraints primarily involve the high initial cost associated with specialized tempered or laminated safety glass and the specialized, often custom-engineered, installation hardware, which can make frameless systems prohibitively expensive for budget-constrained projects. Opportunities lie prominently in retrofitting older residential and commercial structures to meet contemporary safety and aesthetic standards, alongside continuous innovation in smart glass technology and composite materials that enhance durability and reduce maintenance needs. These factors create a complex environment where premium product positioning must be balanced against regulatory compliance and construction cost sensitivity.

A major impact force stems from evolving global building safety codes, particularly those relating to fall protection and load-bearing capacity in high-rise constructions. Many jurisdictions are mandating the use of laminated tempered glass specifically for balcony applications, effectively accelerating the adoption of frameless systems which inherently meet these standards through robust engineering and material quality. Conversely, a significant restraint is the specialized skill set required for precise installation; improper fitting of the base shoe or spigots can severely compromise the structural integrity and long-term performance of the entire system, leading to potential liability issues for manufacturers and installers alike. This complexity necessitates rigorous training and quality assurance protocols, adding overhead to operational costs and acting as a barrier to entry for smaller installation firms.

Furthermore, the opportunity presented by material science advancements, such as the integration of polymers into laminates for superior dampening and post-breakage performance, offers manufacturers a competitive edge. The market is also highly sensitive to fluctuations in the global prices of raw materials, particularly aluminum (used for base channels) and specialized chemicals required for glass tempering and lamination. Economic downturns affecting the residential construction sector, especially in key regions like North America and Europe, pose a cyclical restraint. Despite these challenges, the long-term potential for market growth remains strong, driven by the irreversible global trend toward aesthetic minimalism and sustainable building practices, positioning frameless glass railings as a standard element of future-proof architectural design.

Segmentation Analysis

The Frameless Glass Balcony Railing Market is systematically segmented based on Glass Type, System Type, Application, and End-User, providing a comprehensive view of market dynamics and targeted consumer preferences. This detailed segmentation allows manufacturers and stakeholders to focus their strategic efforts on the most lucrative product categories and end-use sectors, particularly identifying high-growth niches such as the adoption of specialized laminated toughened glass for high-wind areas. Understanding these segments is crucial for analyzing material procurement strategies, managing inventory of specific hardware systems (like spigots versus base shoes), and tailoring marketing efforts to distinct end-user needs, ranging from large-scale commercial developers to individual homeowners undertaking renovation projects.

The segmentation by System Type—Aluminum Base Shoe, Spigot, and Standoff—reflects variations in structural support and aesthetic outcomes, with the Base Shoe system dominating due to its concealed fixing method offering maximum transparency and robust structural support, making it the preferred choice for commercial high-rises. In contrast, Spigot and Standoff systems offer distinct architectural aesthetics and are highly popular in lower-rise residential applications and pool surrounds where drainage and floor visibility are key design considerations. The Application segmentation clearly delineates the massive volume consumed by the Residential sector versus the high-value, stringent specification requirements of the Commercial segment, where durability, maintenance schedules, and public safety standards significantly influence product selection and procurement decisions.

Further analysis of the Glass Type segmentation—encompassing Tempered, Laminated, and Toughened Glass—demonstrates the industry's commitment to safety, where Laminated Toughened Glass is rapidly gaining dominance as regulatory bodies worldwide standardize safety measures requiring secondary retention layers. This glass type offers superior post-breakage integrity, retaining glass fragments and preventing immediate structural collapse. The End-User segmentation, separating New Construction from Renovation/Retrofit activities, highlights the significant growth potential in the retrofit market, particularly in mature economies where upgrading existing infrastructure to modern safety and aesthetic standards provides a sustained, long-term revenue stream for market participants specializing in adaptable and modular railing systems.

- By Glass Type:

- Tempered Glass (Single pane safety glass)

- Laminated Glass (Enhanced safety with PVB or SentryGlas interlayer)

- Laminated Toughened Glass (Highest safety rating)

- By System Type:

- Aluminum Base Shoe System (Continuous track support)

- Spigot System (Point-fixed support)

- Standoff System (Side-fixed circular support)

- By Application:

- Residential (Apartments, Condominiums, Private Homes)

- Commercial (Hotels, Offices, Retail Centers)

- Industrial/Public Spaces (Airports, Museums, Walkways)

- By End-User:

- New Construction

- Renovation/Retrofit

Value Chain Analysis For Frameless Glass Balcony Railing Market

The value chain for the Frameless Glass Balcony Railing Market is complex, beginning with upstream raw material suppliers, predominantly focusing on high-quality silica sand for glass production, specialized polymers (PVB/SGP) for lamination, and aluminum/stainless steel for hardware components. The upstream segment is capital-intensive, dominated by large glass manufacturers and metal extrusion firms whose pricing and quality control heavily influence the final product cost and performance. Key activities at this stage include refining raw materials, precise glass cutting, tempering, and lamination processes, which require strict adherence to regulatory standards such as ANSI, ASTM, and specific European Norms (EN). The efficiency of this stage directly impacts the structural reliability and visual clarity of the frameless system.

Midstream activities involve the specialized fabrication and assembly of railing systems, where manufacturers design and produce the proprietary hardware, including base shoes, channels, fasteners, and mounting plates, which are often patented designs crucial for system performance. System integrators and fabricators often purchase pre-cut and treated glass and combine it with custom-engineered hardware to create installation kits specific to project requirements. Downstream activities involve distribution channels, which are bifurcated into direct sales to large construction companies and indirect sales through specialized distributors, retailers, and dedicated architectural glass providers. Direct channels are preferred for massive commercial projects where close collaboration between the manufacturer and the developer is necessary, ensuring highly customized specifications are met efficiently.

The distribution channel landscape emphasizes the necessity of specialized logistics due to the size, weight, and fragility of the large glass panels. Indirect distribution through specialized architectural and construction supply retailers dominates the smaller project and renovation segment, offering localized stock and installation support. Effective value chain management focuses on minimizing material handling risks, ensuring timely component supply, and maintaining high service quality during the crucial installation phase, as the reputation and reliability of the system heavily depend on the final installation quality. The relationship between manufacturers and certified professional installers is paramount for maintaining market standards and minimizing warranty claims.

Frameless Glass Balcony Railing Market Potential Customers

The primary potential customers and end-users of frameless glass balcony railings are distinguished by the scale and nature of their construction projects, spanning both the public and private sectors, with a strong concentration in high-value real estate development. Foremost among these are large-scale residential property developers and construction firms specializing in luxury condominiums, high-rise apartment complexes, and gated communities, as these structures rely heavily on aesthetic appeal and maximum views to justify premium pricing. These customers demand bulk purchasing capabilities, stringent quality certifications, and system scalability, often engaging manufacturers directly for custom design and integration services specific to their multi-tower projects.

Another significant segment comprises commercial developers, particularly those constructing five-star hotels, corporate headquarters, and upscale shopping malls. In the hospitality sector, frameless railings are essential for creating uninterrupted panoramic views from hotel balconies and rooftops, directly enhancing guest experience and property marketability. Corporate clients often use these systems in exterior walkways and atrium overlooks to convey an image of transparency, modernity, and architectural sophistication. These customers prioritize durability, ease of maintenance (e.g., specialized coatings), and compliance with strict commercial liability and public safety standards, often leading them to specify the highest grade of laminated safety glass.

Furthermore, renovation and retrofit specialists, alongside affluent individual homeowners, constitute a resilient market segment. Homeowners undertaking high-end renovations seek frameless systems to modernize existing properties, maximize natural light, and improve curb appeal, particularly in coastal or scenic regions. Architects and interior designers often act as key influencers and direct buyers on behalf of these clients, specifying particular brands based on aesthetic profile, hardware quality, and track record of successful, reliable installations. This segment often values customized hardware finishes and modular, easy-to-install solutions suitable for smaller, non-standard balcony dimensions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sadef, Sadev, Q-railing, OnLevel, CRL (C.R. Laurence), F.H. Brundle, Balustrade Components, Huadong Construction, VIVA Railings, Bohle Group, Fast Mounts, Ezzesteel, Glass Railing Systems, Atlantis Rail Systems, Viewrail, Trex Company, POMA, AL-FARIS, Balcony Systems Solutions, Glass Railing Experts |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Frameless Glass Balcony Railing Market Key Technology Landscape

The technological landscape of the Frameless Glass Balcony Railing Market is continuously evolving, focusing heavily on enhancing safety, simplifying installation, and improving the aesthetic integration of the systems. Core technological advancements revolve around laminated glass technology, specifically the utilization of SentryGlas Plus (SGP) interlayer films, which offer significantly higher stiffness and post-breakage load capacity compared to traditional Polyvinyl Butyral (PVB). This material innovation allows for the engineering of lighter, yet stronger, glass panels, which are critical for high-rise applications subject to extreme wind loads and regulatory requirements for minimal deflection upon impact. Furthermore, the development of highly specialized glass coatings, such as hydrophobic and photocatalytic treatments, is gaining traction, providing self-cleaning properties and reduced maintenance cycles, adding significant value for commercial property owners and affluent residential customers.

Hardware technology constitutes another critical area of innovation, particularly concerning the base support systems. Advancements in aluminum extrusion techniques have led to the creation of modular, adjustable base shoe systems that feature self-leveling capabilities. These systems incorporate precision mechanisms that allow installers to easily align and plumb the glass panels without the need for traditional shims or extensive pre-installation site work, significantly reducing labor time and potential installation errors. Moreover, the integration of advanced alloys, such as marine-grade stainless steel for spigots and standoffs, addresses concerns related to corrosion and material fatigue, especially in coastal environments, ensuring the long-term structural integrity and aesthetic performance of the railing system throughout its operational life.

Digitalization also plays an integral role, with technologies such as Building Information Modeling (BIM) becoming standard practice. BIM software integration allows architects and manufacturers to precisely model the frameless railing system within the broader construction project, ensuring accurate specification of dimensions, loads, and hardware requirements, which minimizes manufacturing errors and accelerates project delivery. Furthermore, manufacturers are increasingly using sophisticated Computer Numerical Control (CNC) machinery for precise drilling, cutting, and shaping of both glass and hardware components, ensuring perfect fit and finish. These combined technological improvements—from material science in the glass to precision engineering in the hardware and digital integration in the design phase—are central to maintaining the premium positioning and safety standards expected in the contemporary frameless glass market.

Regional Highlights

- North America: The North American market, particularly the United States and Canada, represents a mature but highly lucrative segment characterized by stringent safety codes and a strong consumer preference for high-end, contemporary architectural finishes. Market growth here is primarily driven by significant activity in the high-density residential and luxury commercial sectors, particularly in metropolitan areas like New York, Toronto, and Los Angeles, where maximizing views and natural light is a core design requirement. The widespread adoption of laminated tempered glass is mandatory under many local building codes, which further solidifies the demand for high-quality frameless systems. Furthermore, the robust renovation market, particularly the upgrading of older apartment buildings and commercial properties to modern aesthetic and safety standards, contributes substantially to the region's steady growth trajectory. Manufacturers in North America often focus on offering highly certified, fast-install systems that reduce reliance on specialized on-site fabrication.

- Europe: Europe holds a dominant position in the frameless glass railing market, largely due to early adoption of minimalist design philosophies and the presence of globally leading hardware and glass technology innovators, particularly in Germany, Italy, and the Nordic countries. The European market is characterized by exceptionally rigorous quality and safety standards, enforced through harmonized Eurocodes, which favor sophisticated system types like robust aluminum base shoe systems capable of achieving high safety factors without visible support posts. Sustainability is a growing driver; customers increasingly prefer systems made from recyclable materials like aluminum and glass, aligning with the EU's Green Deal objectives. The region's growth is bolstered by historic renovation projects and a sustained demand for premium architectural solutions in the hospitality and affluent private residence sectors across Western and Northern Europe.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally, fueled by unprecedented levels of urbanization and massive investments in both residential and commercial infrastructure, particularly in developing economies like China, India, and Southeast Asia. The rise of a large middle class and the corresponding boom in high-rise construction mean that frameless glass is rapidly becoming the aesthetic standard for modern urban living. While price sensitivity remains a factor in certain segments, the overall volume of new construction projects ensures rapid market expansion. Key challenges in this region include navigating diverse local building codes and addressing logistical complexities related to transporting large, fragile glass components across varied infrastructures. Local manufacturers are rapidly gaining market share by adapting international system designs to local labor practices and material availability.

- Latin America: The Latin American market exhibits moderate growth, driven primarily by construction activity in major economic hubs such as Brazil, Mexico, and Chile. Demand is strongest in the luxury residential and coastal property development segments, where unobstructed views are critical selling points. However, market adoption can be volatile due to fluctuating economic conditions and dependence on imported high-specification glass and proprietary hardware. Opportunities exist in countries with growing tourism infrastructure, requiring high-quality, weather-resistant balcony solutions. Manufacturers must contend with regional logistical challenges and competitive pricing pressures, often relying on simplified spigot and standoff systems which offer flexibility and cost advantages compared to complex base shoe channel systems.

- Middle East and Africa (MEA): The MEA region is characterized by high-value, large-scale construction mega-projects, particularly in the UAE, Saudi Arabia, and Qatar, driven by government diversification strategies away from oil dependence. These projects—including vast residential cities, luxury resorts, and iconic corporate towers—demand aesthetically superior and highly durable frameless railings capable of withstanding extreme heat, sandstorms, and high salinity environments. The use of specialized, corrosion-resistant stainless steel and robust laminated glass is mandatory. While the market size is smaller than APAC or Europe, the average project value is significantly higher, attracting premium international suppliers. The market focuses intensely on products that offer rapid installation timelines while ensuring compliance with stringent safety standards necessitated by the region's extreme architectural heights.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Frameless Glass Balcony Railing Market.- Sadef

- Sadev

- Q-railing

- OnLevel

- CRL (C.R. Laurence)

- F.H. Brundle

- Balustrade Components

- Huadong Construction

- VIVA Railings

- Bohle Group

- Fast Mounts

- Ezzesteel

- Glass Railing Systems

- Atlantis Rail Systems

- Viewrail

- Trex Company

- POMA

- AL-FARIS

- Balcony Systems Solutions

- Glass Railing Experts

Frequently Asked Questions

Analyze common user questions about the Frameless Glass Balcony Railing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary safety considerations and requirements for frameless glass balcony railings?

The primary safety consideration is the structural integrity against horizontal impact and wind loading. Global building codes increasingly mandate the use of Laminated Toughened Glass, often utilizing SentryGlas (SGP) interlayers. This glass type ensures that even if the panel breaks, fragments remain securely adhered to the interlayer, maintaining the barrier function and preventing immediate collapse, which is critical for high-rise residential and commercial applications. Systems must pass rigorous tests for deflection and load-bearing capacity as stipulated by standards like the International Building Code (IBC) or relevant Eurocodes (EN 1991).

How do Aluminum Base Shoe systems differ from Spigot systems, and which is better for commercial projects?

Aluminum Base Shoe systems provide continuous linear support along the entire bottom edge of the glass panel, offering superior load distribution and stability, resulting in a cleaner, post-free aesthetic that is highly preferred for large commercial buildings and high-rise developments due to enhanced structural rigidity and safety compliance. Spigot systems use individual, usually stainless steel, clamp fittings bolted directly into the substrate, offering point fixation. While aesthetically flexible and popular for pool fencing and lower-level residential balconies due to better drainage, they generally offer less structural redundancy than continuous base shoe systems under extreme wind loads, making the Base Shoe system the preferred choice for demanding commercial specifications.

What is the typical lifespan and maintenance requirement for modern frameless glass railings?

The typical lifespan of a high-quality frameless glass railing system can exceed 25 to 30 years, provided the core components (laminated glass and proprietary marine-grade aluminum or stainless steel hardware) are correctly specified and installed. Maintenance is generally low compared to traditional railings; it primarily involves routine cleaning of the glass panels and annual or bi-annual inspection of the hardware components—specifically checking tensioning bolts and drainage channels within the base shoe—to ensure no debris compromises the structural integrity. The use of self-cleaning or low-emissivity glass coatings further reduces the frequency of intensive cleaning.

What impact do raw material price fluctuations (aluminum and glass) have on market growth and profitability?

Fluctuations in the price of key raw materials, specifically primary aluminum (used for base channels and hardware) and essential polymers (PVB/SGP) for lamination, significantly impact the manufacturing cost structure. Because frameless railings are high-value, bespoke products, manufacturers often absorb short-term volatility or implement strategic long-term supply contracts. However, sustained increases in input costs necessitate corresponding price hikes in the final product, potentially constraining market growth in cost-sensitive segments, particularly in the rapidly expanding Asia Pacific region where material efficiency and cost optimization are critical factors for securing large commercial bids against localized, lower-cost competitors.

What emerging technologies are set to revolutionize the frameless glass balcony railing industry?

Several emerging technologies are poised to revolutionize the sector. The integration of Building Information Modeling (BIM) into the design and fabrication workflow ensures perfect dimensional accuracy and speeds up project timelines. Furthermore, the development and commercialization of Smart Glass technology, capable of switching transparency levels electronically (electrochromic glass) for instant privacy or shading control, is generating significant interest in the luxury segment. On the manufacturing front, advanced robotics and AI-driven quality control systems are being implemented to ensure flawless glass tempering and hardware assembly, minimizing human error and enhancing the reliability of the safety systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager