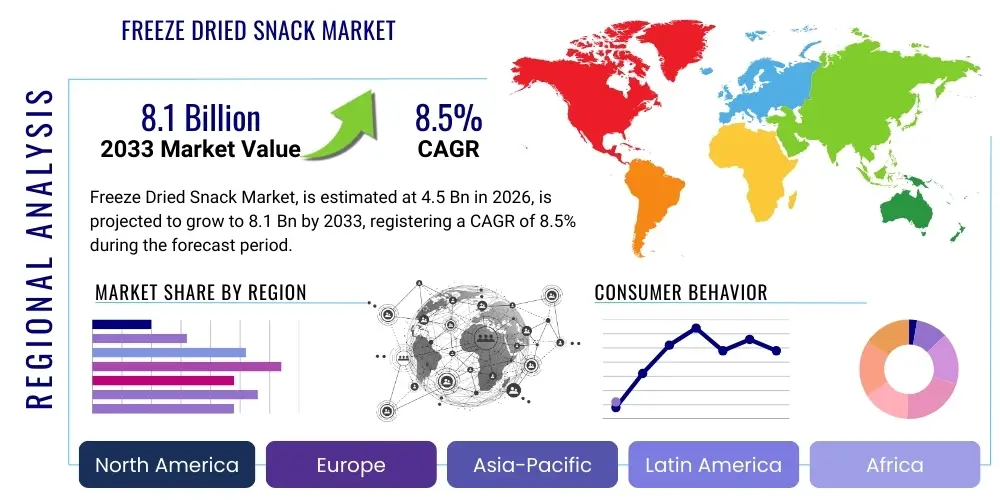

Freeze Dried Snack Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442114 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Freeze Dried Snack Market Size

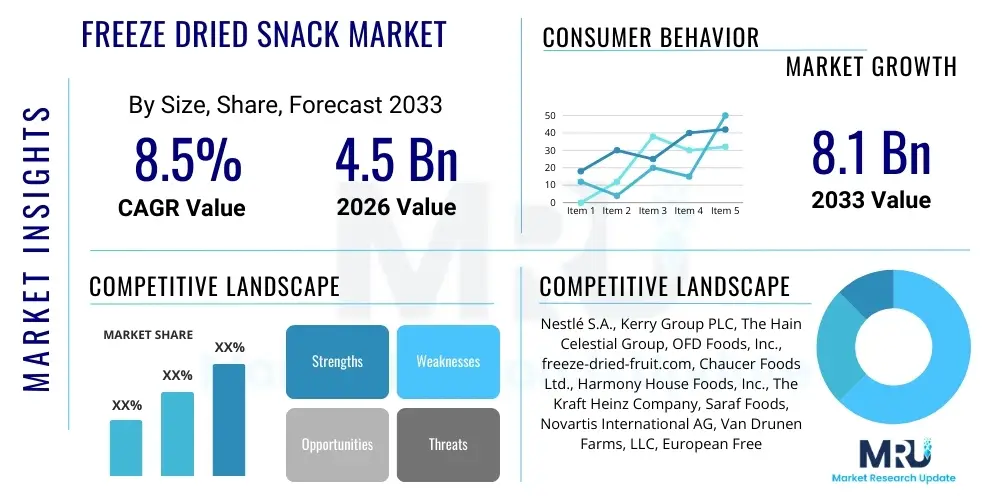

The Freeze Dried Snack Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 8.1 Billion by the end of the forecast period in 2033.

The substantial growth trajectory is underpinned by increasing consumer preference for highly nutritious and minimally processed food options that offer extended shelf life without the need for refrigeration. Freeze drying is recognized as a superior preservation method, retaining up to 90% of the original nutritional content, including vitamins, minerals, and color, which appeals directly to the expanding health-conscious demographic globally. Furthermore, the convenience factor associated with lightweight, easy-to-carry snacks is driving adoption among working professionals, students, and outdoor enthusiasts, solidifying the market's expansion.

Market expansion is also heavily influenced by continuous innovation in product offerings, moving beyond traditional fruits and vegetables to include freeze-dried meals, yogurts, ice creams, and specialized protein sources. Manufacturers are leveraging advanced packaging technologies that ensure moisture barrier protection and aesthetic appeal, further enhancing product differentiation and consumer acceptance. Geographical penetration into emerging economies, coupled with sophisticated e-commerce distribution channels, is expected to maintain the robust CAGR throughout the forecast period, making freeze-dried snacks a rapidly evolving segment within the broader functional food industry.

Freeze Dried Snack Market introduction

The Freeze Dried Snack Market encompasses a variety of food products preserved using the lyophilization process, where water is removed after freezing, transforming solid ice directly into vapor (sublimation) under low pressure. This methodology yields snacks characterized by extremely low moisture content, lightweight structure, high porosity, and exceptional retention of original flavor, texture, and nutritional value. Key products include freeze-dried fruits (such as strawberries, bananas, and apples), vegetables (like corn and peas), and prepared foods. Major applications span daily consumption, emergency food reserves, military and aerospace provisions, and specialized dietary needs for infants and sports enthusiasts. The primary benefits include extended shelf stability, preservation of natural ingredients without artificial additives, and portability. Driving factors involve rising consumer demand for natural, clean-label ingredients, increasing interest in functional foods, the expansion of outdoor and survival activities, and growing awareness regarding the benefits of nutrient-dense, shelf-stable options.

Freeze Dried Snack Market Executive Summary

The Freeze Dried Snack Market is currently experiencing a dynamic phase driven by significant shifts in consumer behavior towards convenient, healthy alternatives. Business trends indicate a strong focus on supply chain resilience, flavor customization, and sustainable sourcing of raw materials, particularly organic and non-GMO produce. Major industry players are heavily investing in automation of the freeze-drying process to enhance production efficiency and reduce costs, aiming to make these premium snacks more accessible to mass markets. Regional trends highlight North America as the dominant market due to high consumer spending power and advanced distribution networks, while the Asia Pacific region, led by China and India, is projected to register the fastest growth, propelled by rapidly urbanizing populations seeking nutritious, easy-to-prepare food options. Segment trends show that freeze-dried fruits maintain the largest market share owing to their natural sweetness and versatility, although the animal products segment (pet food and meat snacks) is exhibiting accelerated growth, driven by premiumization in pet nutrition and demand for high-protein, low-carb options for human consumption.

The market landscape is also being shaped by intense competitive activity centered on ingredient transparency and innovative packaging solutions that cater to on-the-go consumption. Small and medium-sized enterprises (SMEs) are leveraging e-commerce platforms and niche product differentiation (e.g., exotic fruits or functional ingredient inclusions) to challenge established market leaders. Furthermore, regulatory scrutiny regarding food safety and labeling standards continues to influence manufacturing practices, pushing companies toward stricter quality control measures. The integration of advanced analytics in sales forecasting and inventory management is becoming a critical business trend to mitigate risks associated with fluctuating raw material prices and seasonal availability.

Overall, the market is pivoting towards functional health benefits, with products often fortified with probiotics or tailored for specific health conditions, such as diabetes management or gut health. This functional shift is vital for sustained growth, moving freeze-dried snacks from a niche product category to a mainstream functional food staple. The confluence of technological advancements, evolving consumer expectations, and strategic market expansion into previously untapped demographic groups positions the Freeze Dried Snack Market for significant value realization over the next decade.

AI Impact Analysis on Freeze Dried Snack Market

User queries regarding the impact of Artificial Intelligence (AI) on the Freeze Dried Snack Market frequently revolve around optimizing the energy-intensive lyophilization process, enhancing product quality control, and improving supply chain efficiency for perishable raw materials. Users often seek confirmation on whether AI can reduce the high operational costs associated with vacuum freezing and sublimation, making the end product more affordable. Key themes include predictive maintenance of complex freeze-drying machinery, algorithmic approaches to flavor consistency across batches, and leveraging machine learning for demand forecasting to minimize inventory spoilage. Concerns often touch upon the initial investment required for AI integration and the necessity of skilled personnel to manage these advanced systems. Overall, the expectation is that AI will revolutionize the preservation cycle, enabling faster processing, higher yield, and superior quality assurance, thereby democratizing access to freeze-dried products.

AI’s influence extends profoundly into the innovation lifecycle of freeze-dried snacks. Machine learning algorithms are now utilized to analyze vast datasets pertaining to ingredient composition, dehydration curves, and sensory panel feedback. This capability allows manufacturers to precisely model the optimal freezing and drying parameters for novel ingredients, predicting the final texture, crunch, and nutritional retention before physical trials are conducted. For instance, AI can simulate the impact of subtle changes in vacuum pressure or shelf temperature on the final product quality, significantly reducing time-to-market for new formulations and customizing products to regional taste preferences based on real-time market data analysis.

Furthermore, the operational expenditure associated with freeze drying is notoriously high, primarily due to energy consumption. AI-driven predictive control systems are being deployed to monitor energy usage in real-time and dynamically adjust cycles based on the specific load and external environmental factors, resulting in substantial energy savings. In quality control, computer vision systems, powered by deep learning, are replacing manual inspection, enabling rapid and highly accurate detection of defects, color deviations, or foreign materials, ensuring unparalleled consistency and adherence to stringent food safety standards, which is paramount for premium snack positioning.

- AI optimizes the energy consumption of freeze dryers through dynamic cycle adjustments based on load size and moisture content.

- Machine Learning (ML) enhances quality control by utilizing computer vision for automated defect detection and color consistency analysis.

- Predictive Maintenance (PdM) minimizes costly downtime of high-value lyophilization equipment by forecasting component failure.

- AI models improve raw material sourcing and inventory management by accurately predicting consumer demand and optimizing logistics for perishable ingredients.

- Algorithmic flavor profiling assists in new product development, ensuring superior texture and consistent taste across large production batches.

- Robotics guided by AI are increasingly used in aseptic packaging and handling processes, minimizing contamination risks.

DRO & Impact Forces Of Freeze Dried Snack Market

The Freeze Dried Snack Market is primarily driven by consumer desires for healthy, minimally processed food and the unparalleled shelf stability offered by lyophilization technology. Restraints include the high capital investment required for freeze-drying infrastructure and the significant operational costs associated with energy consumption, which often translates into premium pricing that limits mass adoption in price-sensitive markets. Opportunities lie in expanding applications beyond traditional fruits and vegetables, penetrating the rapidly growing pet food and functional ingredient sectors, and leveraging advancements in continuous freeze-drying technology to reduce per-unit costs. Impact forces, such as fluctuating raw material costs due to climate change and increasing regulatory scrutiny on clean labeling, exert significant pressure on profit margins and operational standardization.

Drivers: The fundamental driver is the strong alignment of freeze-dried snacks with prevailing consumer health trends. Consumers are actively seeking foods that retain natural nutritional profiles without relying on chemical preservatives, artificial colors, or excessive sugar, characteristics inherent to freeze-dried products. The inherent light weight and portability make these snacks highly desirable for modern, fast-paced lifestyles, particularly appealing to millennials and Generation Z who prioritize convenient, single-serving options. Furthermore, the rising popularity of camping, hiking, and disaster preparedness initiatives globally creates a consistent, growing demand for long-shelf-life, calorie-dense foods that maintain organoleptic properties better than traditional dehydrated alternatives.

Another significant driver is the increasing adoption of these products in infant nutrition and specialized dietary sectors. Freeze-dried fruits and vegetables are easy to reconstitute and possess superior nutrient retention, making them ideal ingredients for infant cereals and purees, appealing to parents focused on high-quality early nutrition. Simultaneously, the sports nutrition segment utilizes freeze-dried ingredients, such as protein powders and functional blends, due to their ease of incorporation and bioavailability. The continual expansion of e-commerce platforms acts as a powerful channel driver, allowing niche manufacturers to bypass traditional retail bottlenecks and reach specialized consumer bases efficiently, facilitating market access and visibility.

Restraints: The primary constraint impacting market growth is the prohibitive cost structure associated with the batch freeze-drying process. The specialized vacuum equipment, energy demands (for both freezing and sublimation), and extended processing times make freeze-drying significantly more expensive than conventional preservation methods like air drying or canning. This high production cost translates directly into higher retail prices, positioning freeze-dried snacks as premium goods, which restricts their penetration into lower and middle-income demographics. Additionally, dependence on stable raw material supply chains is a challenge; seasonal variations and increasing climate volatility can lead to unpredictable pricing and quality of fresh produce, directly impacting the final product cost and supply consistency.

Opportunities: Significant market opportunities are emerging from technological innovation aimed at improving efficiency. Developments in continuous freeze-drying systems, microwave-assisted freeze drying, and hybrid drying techniques promise to lower processing times and energy usage, potentially reducing the overall cost barrier. Market expansion into the thriving pet food industry presents a lucrative opportunity, as premium, raw-ingredient-based freeze-dried pet foods and treats gain immense popularity among pet owners seeking optimal nutrition for their animals. Furthermore, utilizing freeze-dried ingredients as flavor enhancers, colorants, or texture components in prepared foods (such as cereals, yogurt, and confectionery) offers substantial B2B revenue streams, broadening the market scope beyond direct snack consumption.

Impact Forces: The market is heavily influenced by the force of technological substitution, primarily from advanced air-drying and vacuum-drying methods that are becoming increasingly efficient and cost-competitive, potentially eroding the cost advantage of freeze-drying in certain commodity segments. Regulatory changes regarding food labeling and mandatory nutritional disclosure act as external pressures, requiring manufacturers to rigorously validate nutritional claims and ensure absolute adherence to quality control. Societal shifts towards sustainability demand that packaging solutions for freeze-dried snacks move towards biodegradable or recyclable materials, imposing design and material costs on producers. Finally, global competition necessitates aggressive investment in marketing and brand differentiation to capture consumer attention in a rapidly saturating premium snack aisle, requiring strategic pricing and distribution planning.

Segmentation Analysis

The Freeze Dried Snack Market is intricately segmented based on product type, application, and distribution channel, reflecting the diverse consumption patterns and end-user needs globally. Product segmentation delineates the market into fruits, vegetables, coffee, meat, prepared foods, and others, with fruits holding a dominant share due to widespread use in breakfast foods and direct snacking. Application analysis reveals key consumer segments such as daily snacking, breakfast foods, pet food, and emergency/camping provisions, each driving demand based on unique attributes like portability and nutritional density. The distribution channel segment, encompassing supermarkets, hypermarkets, convenience stores, and the burgeoning e-commerce sector, dictates market accessibility and pricing strategies, with online channels showing the highest growth momentum owing to convenience and direct-to-consumer relationships.

Detailed analysis of the product segment shows rapid diversification. While freeze-dried fruits remain staples, the savory segment, particularly freeze-dried meat and seafood snacks, is accelerating, propelled by ketogenic and high-protein diet trends. Furthermore, the integration of freeze-dried technology into the coffee industry (instant specialty coffee) is creating premium segments. Understanding these granular consumption patterns allows stakeholders to tailor product development, focusing on high-margin categories like organic produce or functional food components enriched with vitamins or probiotics, thereby maximizing market penetration and profitability across different economic strata.

- By Product Type:

- Freeze-Dried Fruits (Strawberries, Bananas, Apples, Berries)

- Freeze-Dried Vegetables (Corn, Peas, Carrots, Broccoli)

- Freeze-Dried Coffee & Tea

- Freeze-Dried Meat & Seafood (Chicken, Beef, Shrimp)

- Freeze-Dried Dairy & Prepared Foods (Yogurt Bites, Ice Cream, Ready Meals)

- Other Products (Herbs, Spices, Ingredients)

- By Application:

- Daily Snacking & Breakfast Foods

- Emergency & Military Rations

- Camping & Outdoor Activities

- Infant Food

- Pet Food & Treats

- Functional Food & Nutritional Supplements

- By Distribution Channel:

- Supermarkets & Hypermarkets (Mass Retail)

- Convenience Stores

- Specialty Stores (Health & Organic Stores)

- Online Retail & E-commerce

- Institutional Sales (Hospitals, Military, Airlines)

Value Chain Analysis For Freeze Dried Snack Market

The value chain for the Freeze Dried Snack Market begins with the upstream segment involving raw material sourcing and specialized equipment manufacturing. Sourcing requires high-quality, fresh produce, meat, or dairy, often necessitating contractual farming and strict quality control to ensure ideal input for the lyophilization process. Equipment manufacturers provide the core technology—batch and continuous freeze dryers, vacuum pumps, and specialized freezing tunnels—which represent a high capital expenditure component. Midstream activities involve the highly technical process of preparation (washing, slicing), freezing, sublimation, and post-processing (e.g., crushing or powdering). This segment is characterized by energy intensity and strict adherence to food safety protocols. Downstream operations focus on packaging, logistics, distribution channels (direct-to-consumer, retail, institutional), and intense marketing efforts to differentiate premium products from conventional snacks.

Upstream efficiency is paramount; minimizing transportation time for perishable raw materials and ensuring optimal moisture content and ripeness directly impacts the effectiveness and cost of the subsequent freeze-drying process. Suppliers of organic and sustainably sourced ingredients gain competitive advantage by meeting the ethical demands of modern consumers. The reliance on highly specialized equipment, typically procured from a limited number of global manufacturers, makes the market vulnerable to supply chain disruptions and technological obsolescence, necessitating strong relationships between manufacturers and equipment providers for maintenance and upgrades. Financial modeling and risk mitigation strategies are crucial at this stage due to the large fixed costs involved.

In the distribution phase, both direct and indirect channels play crucial roles. Indirect distribution, leveraging major supermarkets and specialty organic retailers, provides broad visibility and volume sales. However, direct-to-consumer (D2C) via e-commerce offers higher margins and invaluable customer data, allowing companies to respond rapidly to changing preferences and launch customized products. Effective cold chain logistics management is necessary for the initial freezing stage, although the final freeze-dried product requires only dry storage, simplifying downstream warehousing and reducing spoilage risk, which is a major benefit over fresh or refrigerated alternatives.

Freeze Dried Snack Market Potential Customers

Potential customers for the Freeze Dried Snack Market are highly diverse, spanning demographics driven by health consciousness, convenience requirements, and specialized needs. Key end-users include health-conscious millennials and Gen Z consumers seeking low-calorie, naturally preserved snacks for daily consumption, viewing freeze-dried fruits and vegetables as superior alternatives to processed junk foods. Another significant buyer segment comprises parents focused on infant and toddler nutrition, purchasing freeze-dried yogurt drops and fruit pieces for easy, mess-free, and nutrient-dense feeding. These buyers prioritize ingredient transparency and natural sweetness over artificial additives, aligning perfectly with the core value proposition of lyophilized products.

A second major category includes outdoor enthusiasts, military organizations, and preppers (emergency preparedness buyers). These customers value the extreme lightweight nature, durability, and extended shelf life (often exceeding 25 years) of freeze-dried meals and snacks, which are essential for long-term storage or situations where refrigeration and weight constraints are critical. This segment drives demand for large format packaging and comprehensive meal kits. The pet food industry represents a booming segment, where pet owners are increasingly substituting traditional kibble with premium freeze-dried raw meat and organ treats, driven by perceived health benefits and natural diet alignment for their pets.

Institutional buyers, such as hospitals, schools, and airlines, also constitute significant potential customers. Hospitals use powdered or rehydratable freeze-dried ingredients for specialized patient nutrition, while airlines utilize lightweight, shelf-stable snacks for in-flight service efficiency. The common thread among all potential customers is the value placed on the combination of nutritional integrity, convenience, and minimized waste or spoilage, attributes that freeze drying technology delivers uniquely compared to other food preservation methods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 8.1 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nestlé S.A., Kerry Group PLC, The Hain Celestial Group, OFD Foods, Inc., freeze-dried-fruit.com, Chaucer Foods Ltd., Harmony House Foods, Inc., The Kraft Heinz Company, Saraf Foods, Novartis International AG, Van Drunen Farms, LLC, European Freeze Dry, Inc., Crispy Green, Inc., Astronaut Foods, LLC, Thrive Life, Inc., Backpacker's Pantry, Mountain House, Inc., LYO FOOD, LLC, Freeze-Dry Foods GmbH, and Olam International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Freeze Dried Snack Market Key Technology Landscape

The technological landscape of the Freeze Dried Snack Market is dominated by the advancement of lyophilization equipment and process optimization. The core technology involves highly specialized vacuum chambers and refrigeration systems capable of maintaining extremely low temperatures and pressures necessary for sublimation. Recent technological developments are focused on transitioning from traditional, labor-intensive batch freeze-drying to more efficient continuous freeze-drying systems. Continuous systems, which utilize conveyor belts or fluidized beds within the vacuum chamber, significantly reduce processing time, enhance throughput, and lower per-unit production costs, addressing the main restraint of high operational expenditure in the industry. Furthermore, sophisticated monitoring and control systems, often leveraging AI and IoT sensors, are used to precisely manage temperature gradients and vacuum levels throughout the cycle, ensuring optimal moisture removal and superior product quality consistency.

Beyond the core drying process, parallel technologies, such as advanced pre-treatment methods and post-processing techniques, are gaining prominence. Pre-treatment often involves specialized freezing methods, like cryogenic freezing or impingement freezing, to produce smaller, more uniform ice crystals, which facilitates faster and more complete sublimation, thus preserving cell structure and minimizing shrinkage. In post-processing, innovations in hermetic and moisture-barrier packaging films (including multilayer foil and vacuum-sealed retort pouches) are critical, ensuring the zero-moisture state of the product is maintained over multi-year shelf lives, protecting against spoilage and maintaining the desired crisp texture that consumers expect from freeze-dried snacks.

Hybrid drying technologies represent an emerging technological frontier, seeking to combine the benefits of freeze-drying with less energy-intensive methods. Examples include microwave-assisted freeze drying (MAFD) and refractance window drying, which aim to reduce the reliance on vacuum and heating energy. While MAFD can significantly cut drying time, the challenge lies in scaling the technology while ensuring product safety and quality remain comparable to traditional freeze-drying. Investment in these hybrid systems, alongside automation solutions for material handling and primary packaging, is defining the competitive edge for manufacturers aiming for cost leadership and expanded market accessibility.

Regional Highlights

- North America: North America, particularly the United States, holds the largest market share in the Freeze Dried Snack Market, primarily driven by high consumer awareness regarding health and wellness, significant disposable income, and a strong preference for convenient, on-the-go food solutions. The presence of major market players, coupled with a highly developed infrastructure for both retail distribution and specialized outdoor/survival product supply chains, solidifies its dominance. Innovation in flavors, especially savory and high-protein freeze-dried snacks, originates largely from this region, catering to fitness and diet trends like Keto and Paleo. The robust e-commerce ecosystem allows niche brands to flourish and reach consumers directly.

- Europe: The European market demonstrates steady growth, fueled by stringent regulatory standards encouraging clean label and organic certifications, particularly in Western European countries like Germany, the UK, and France. Consumers here prioritize ethically sourced and sustainably produced ingredients. Demand is strong in the infant food segment and specialty health stores, although the higher price point of freeze-dried products means market penetration is concentrated in higher-income brackets. Eastern Europe is emerging as a potential manufacturing hub due to lower operational costs, providing a strategic base for serving Western and international markets.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market globally, propelled by rapid urbanization, changing dietary habits, and increasing disposable income, particularly in emerging economies like China, India, and Southeast Asian nations. The demand here is often directed towards freeze-dried vegetables and prepared meals due to convenience and the preservation of traditional Asian flavors. Local manufacturers are rapidly adopting freeze-drying technology, often subsidized by government initiatives aimed at reducing food waste and enhancing food security. The immense population base presents a vast, untapped consumer market.

- Latin America (LATAM): The LATAM market is currently characterized by moderate growth, primarily focused on exporting high-value freeze-dried commodities (like coffee and tropical fruits) to North America and Europe. Domestic consumption is growing but remains constrained by price sensitivity. Opportunities exist in capitalizing on the rich indigenous fruit variety through localized freeze-dried snack offerings and expanding institutional consumption, such as in schools and military programs. Foreign investment and technology transfer are key factors influencing future market acceleration.

- Middle East and Africa (MEA): MEA represents a nascent but high-potential market. Growth is driven primarily by the need for stable, non-perishable food solutions for remote areas, military applications, and emergency relief efforts. High-income countries within the Middle East (e.g., UAE, Saudi Arabia) are seeing increased consumption of premium imported freeze-dried snacks mirroring Western consumption trends. Local production is minimal, creating opportunities for international players willing to establish advanced manufacturing facilities to serve this strategically important, food-import-reliant region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Freeze Dried Snack Market.- Nestlé S.A.

- Kerry Group PLC

- The Hain Celestial Group

- OFD Foods, Inc.

- Chaucer Foods Ltd.

- Harmony House Foods, Inc.

- The Kraft Heinz Company

- Saraf Foods

- Novartis International AG

- Van Drunen Farms, LLC

- European Freeze Dry, Inc.

- Crispy Green, Inc.

- Astronaut Foods, LLC

- Thrive Life, Inc.

- Backpacker's Pantry

- Mountain House, Inc.

- LYO FOOD, LLC

- Freeze-Dry Foods GmbH

- Olam International

- Ajinomoto Co., Inc.

Frequently Asked Questions

Analyze common user questions about the Freeze Dried Snack market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Freeze Dried Snack Market?

The primary factor driving growth is the surging consumer demand for healthy, convenient, and minimally processed snacks that retain high nutritional integrity and possess an extended shelf life without requiring chemical additives or refrigeration. This aligns with global wellness and clean-label trends.

How does the cost of freeze-dried snacks compare to conventionally dried or fresh snacks?

Freeze-dried snacks typically command a premium price compared to conventionally dried or fresh snacks due to the high capital investment and significant energy consumption required by the lyophilization process. Technological advancements, however, are working to reduce this cost differential.

Which geographical region holds the largest market share for freeze-dried snacks?

North America currently holds the largest market share, driven by strong consumer purchasing power, established health-conscious lifestyles, and highly developed retail and e-commerce distribution networks specializing in premium and functional foods.

Are freeze-dried snacks safe for long-term emergency food storage?

Yes, freeze-dried snacks and meals are exceptionally safe for long-term storage, often boasting shelf lives exceeding 25 years when packaged correctly in airtight, moisture-proof containers, making them highly reliable for emergency preparedness and survival rations.

What is the role of technology, such as AI, in modern freeze-drying manufacturing?

AI and advanced technology are crucial for optimizing manufacturing efficiency, specifically by automating quality control, enabling precise predictive maintenance of high-value equipment, and dynamically adjusting the energy-intensive drying cycles to reduce operational costs and maximize yield.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager