Freeze Drier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441872 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Freeze Drier Market Size

The Freeze Drier Market, also fundamentally known as the lyophilization equipment market, is positioned for substantial expansion, driven primarily by the escalating demand for high-value preservation techniques in the pharmaceutical and food sectors. This growth trajectory is supported by the increasing prevalence of biological drugs, vaccines, and advanced sensitive food products that necessitate gentle, long-term stability preservation methods. The complex engineering requirements for achieving deep vacuum and precise temperature control, crucial for maintaining product efficacy and structure, contribute significantly to the market's valuation.

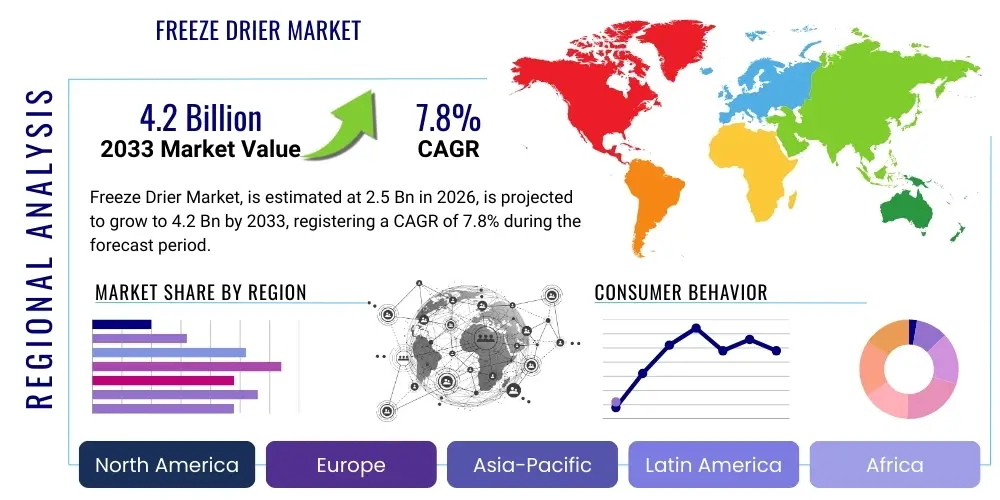

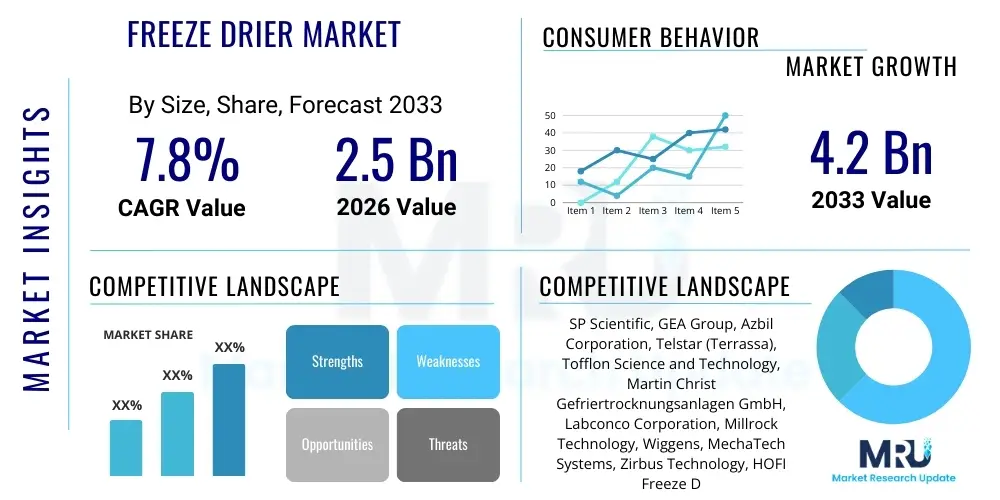

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $2.5 Billion in 2026 and is projected to reach $4.2 Billion by the end of the forecast period in 2033. Market expansion is geographically diverse, with strong investment observed across North America and Europe for specialized pharmaceutical applications, coupled with rapid adoption in the Asia Pacific region, particularly for enhancing food security and scaling up pharmaceutical manufacturing capabilities to meet expanding regional healthcare needs. Regulatory mandates surrounding product quality and stability further solidify the essential role of freeze drying technology.

Freeze Drier Market introduction

The Freeze Drier Market encompasses the manufacturing, distribution, and utilization of equipment designed to remove water or other solvents from heat-sensitive perishable materials, extending their shelf life while preserving their physical, chemical, and biological characteristics. This process, known as lyophilization, involves freezing the product and then reducing the surrounding pressure to allow the frozen solvent to sublime directly from the solid phase to the gas phase. The core product category includes equipment ranging from small-scale laboratory benchtop units used for research and development to massive industrial-scale production systems integral to global pharmaceutical supply chains.

Major applications of freeze drying technology span pharmaceuticals and biotechnology, where it is critical for stabilizing vaccines, antibiotics, proteins, and diagnostic kits, ensuring their potency over extended periods. Beyond healthcare, the technology is vital in the food processing and preservation industry for creating lightweight, nutrient-dense products like instant coffee, dried fruits, and emergency rations. Benefits derived from utilizing freeze driers include superior product quality retention, drastically extended shelf life without refrigeration (reducing logistical costs), and minimizing product weight, which facilitates easier transport and storage, driving its widespread adoption across multiple high-value sectors.

Driving factors for the market include the rapid growth in the biologics sector, the increasing need for advanced preservation of temperature-sensitive drugs, and the consumer trend toward natural, minimally processed food items. Furthermore, advancements in automation and continuous processing techniques within lyophilization equipment are lowering operational costs and increasing throughput, making the technology more accessible and efficient for large-scale industrial deployment globally, thereby significantly contributing to market momentum.

Freeze Drier Market Executive Summary

The Freeze Drier Market is characterized by robust growth, propelled by the inherent need for sophisticated product stabilization in high-growth industries like pharmaceuticals and specialty food manufacturing. Key business trends include the shift towards fully automated, clean-in-place (CIP) and sterilize-in-place (SIP) systems, which enhance operational efficiency and maintain stringent regulatory compliance, particularly within aseptic environments. Furthermore, equipment manufacturers are increasingly integrating advanced control systems and sensors, enabling real-time process monitoring and optimization, addressing the industry's focus on Process Analytical Technology (PAT) to ensure batch consistency and quality.

Regionally, North America and Europe maintain dominance, primarily due to established biotechnology clusters, high healthcare expenditure, and strict regulatory frameworks demanding state-of-the-art preservation methods. However, the Asia Pacific (APAC) region is emerging as the fastest-growing market, driven by expanding pharmaceutical manufacturing capacity, governmental investments in public health infrastructure (including vaccine production), and the burgeoning middle class demanding processed food products with extended shelf lives. Latin America and MEA are focused on implementing smaller to medium-scale lab and pilot units to support localized R&D activities and initial production scaling.

In terms of segment trends, the industrial-scale freeze drier segment, particularly those utilized for large-batch pharmaceutical production, holds the largest market share by value, reflecting the high capital investment required for these systems. Concurrently, the rise of specialized applications in nutraceuticals and personalized medicine is fueling demand for benchtop and pilot-scale units that offer flexibility and precision for smaller, high-value product runs. Technological advancements are focused on developing continuous freeze drying methods over traditional batch processes, promising higher throughput and reduced energy consumption, which will reshape the competitive landscape over the forecast period.

AI Impact Analysis on Freeze Drier Market

User inquiries regarding AI's influence in the freeze drier market commonly revolve around optimizing complex drying cycles, predicting maintenance requirements, and improving process efficiency to reduce energy consumption. Users frequently question how AI can manage the critical process parameters—shelf temperature, condenser temperature, and vacuum pressure—to minimize cycle time without compromising product quality, especially for novel biopharmaceuticals. The core concerns center on validation challenges associated with integrating machine learning algorithms into highly regulated GMP environments and ensuring that AI-driven decisions are auditable and reproducible. Users anticipate that AI could transform traditional, empirical cycle development into predictive, model-based engineering, significantly shortening R&D timelines and enhancing manufacturing reliability.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into freeze drying equipment is moving beyond simple data logging towards predictive modeling and dynamic process control. AI algorithms can analyze vast datasets collected during the primary and secondary drying phases, identifying subtle correlations between initial product characteristics (such as eutectic point) and the optimal drying trajectory. This capability allows manufacturers to automatically adjust operational parameters in real-time, preventing collapse or melt-back, which are common causes of batch failure. Furthermore, ML models are crucial for advanced predictive maintenance, flagging potential equipment failures—like vacuum pump degradation or refrigeration system anomalies—before they impact production, thereby maximizing uptime in highly capital-intensive manufacturing settings.

AI is also poised to revolutionize the initial cycle development phase, dramatically reducing the time and resources required to move a product from research to commercial scale. Instead of relying on lengthy, iterative trial-and-error experiments, AI simulation tools can predict the optimal drying recipe based on the molecular properties of the product and the specifications of the lyophilizer. This shift not only accelerates market entry for new drugs but also ensures consistency across different geographical manufacturing sites using standardized, AI-validated protocols, driving down operational variance and supporting global quality initiatives.

- AI-driven optimization reduces primary and secondary drying cycle times by up to 20%.

- Predictive maintenance schedules minimize unscheduled downtime and capital replacement costs.

- Machine Learning enhances Process Analytical Technology (PAT) through real-time quality monitoring.

- AI facilitates the development of robust, scalable lyophilization recipes for new complex biologics.

- Integration of AI aids in energy consumption reduction by optimizing refrigeration and vacuum cycles.

DRO & Impact Forces Of Freeze Drier Market

The dynamics of the Freeze Drier Market are shaped by a complex interplay of internal market demands (Drivers) and external operational hurdles (Restraints), alongside emerging technological and geographical advantages (Opportunities), collectively defining the Impact Forces. The primary driver remains the indispensable role of lyophilization in preserving high-value, sensitive materials, particularly within the surging biotechnology sector, which necessitates aseptic, stable formulation methods for complex biologics and mRNA-based vaccines. However, this growth is tempered by significant restraints, chiefly the exceptionally high capital expenditure required for purchasing, installing, and validating industrial-scale freeze drying units, coupled with the intensive energy usage associated with maintaining ultra-low temperatures and deep vacuum conditions for extended periods.

Key opportunities in the market lie in the advancements of continuous freeze drying technologies, which offer a viable alternative to traditional batch processing by significantly improving throughput and reducing the physical footprint required in GMP facilities. This technology promises to lower operational expenditure (OPEX) and improve process scalability, attracting major investment from large pharmaceutical companies seeking leaner manufacturing processes. Furthermore, the expanding scope of applications beyond traditional pharmaceuticals, including advanced materials science, cryopreservation of tissues, and the burgeoning global market for personalized nutraceuticals, opens new revenue streams for equipment providers.

The impact forces influencing the market are high, concentrated mainly around regulatory scrutiny and technological innovation. Stringent current Good Manufacturing Practices (cGMP) regulations globally act as a driver for high-quality, reliable equipment, but also as a restraint by increasing validation costs. The immediate impact of the COVID-19 pandemic amplified demand for high-capacity lyophilizers used in vaccine production, creating a lasting impact on market readiness and emphasizing the need for flexible, rapidly deployable systems. Ultimately, the market is pushed toward developing smaller, smarter, and more energy-efficient systems that can meet both the specialized needs of small biotech firms and the massive volume requirements of global pharmaceutical giants.

- Drivers: Increasing demand for biologics and vaccines; extended shelf life requirements for temperature-sensitive drugs; expansion of food processing for long-term storage.

- Restraints: High initial investment costs and operational expenses (energy consumption); long cycle times of traditional batch processes; complexity of cycle development and validation.

- Opportunities: Adoption of continuous freeze drying and automatic loading/unloading systems; emerging applications in tissue engineering and personalized medicine; market penetration in developing economies.

- Impact Forces: Regulatory mandates on product stability and quality; technological advancements in vacuum and refrigeration systems; global health crises driving sudden demand surges.

Segmentation Analysis

The Freeze Drier Market is meticulously segmented based on equipment type, scale of operation, technology utilized, and application area, providing a granular view of specific demand pockets and technological adoption trends. Understanding these segments is crucial for manufacturers to tailor their product offerings, ranging from sophisticated, multi-functional units for pharmaceutical research to robust, high-throughput systems for industrial food processing. The segmentation reflects the diverse end-user needs, where requirements for aseptic processing dominate the biotech segment, while energy efficiency and capacity are paramount in the food sector.

The most lucrative segment by application remains the pharmaceutical and biotechnology sector, driven by the critical need for lyophilization in stabilizing injectables, recombinant proteins, and diagnostic reagents. Within equipment type, industrial-scale units command the highest value share due to their massive capacity and complex installation requirements, representing significant capital investments by global manufacturers. However, the benchtop and pilot-scale segments are exhibiting faster volume growth, fueled by the proliferation of contract research organizations (CROs) and university research laboratories engaged in early-stage formulation development across the globe.

Technological segmentation highlights the ongoing transition from conventional manifold and rotary units, typically used for small-scale or non-aseptic applications, towards sophisticated tray-based systems integrated with advanced monitoring capabilities. This shift underscores the industry's commitment to quality control and efficiency, particularly where product uniformity across large batches is mandatory. Geographic segmentation clearly indicates that growth is shifting eastward, although technological innovation and high-end manufacturing remain concentrated in historically dominant regions.

- By Type: Benchtop, Mobile/Portable, Industrial Scale.

- By Scale of Operation: Lab Scale, Pilot Scale, Industrial Scale.

- By Application: Food Processing & Preservation, Pharmaceuticals & Biotechnology, Medical Devices, Nutraceuticals, Others (Chemicals, Ceramics).

- By Technology: Manifold, Rotary, Tray, Continuous Freeze Drying.

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA).

Value Chain Analysis For Freeze Drier Market

The value chain for the Freeze Drier Market is highly specialized, beginning with the Upstream Analysis involving core component suppliers, particularly manufacturers of high-performance refrigeration systems, vacuum pumps (such as rotary vane and cryopumps), control systems (PLCs, HMI interfaces), and specialized stainless steel fabrication. The integrity and efficiency of the final freeze drier unit are heavily dependent on the quality and reliability of these subcomponents, leading to strong strategic partnerships between equipment manufacturers and component suppliers. Innovation in energy-efficient compressors and high-vacuum technology directly impacts the competitiveness of the final lyophilization system, making R&D collaboration crucial at this foundational stage.

Moving into the midstream, equipment manufacturers assemble these components, focusing on optimizing chamber design, shelf temperature uniformity, and automation capabilities, particularly for aseptic processing environments. Differentiation in this stage is achieved through proprietary software for cycle control, ease of validation (IQ/OQ/PQ documentation), and incorporating advanced monitoring tools like mass spectrometry or tunable diode laser absorption spectroscopy (TDLAS) for monitoring moisture content and sublimation rates. The downstream activities involve distribution channels, which are typically bifurcated into direct sales for large, customized industrial units and indirect distribution via specialized scientific and laboratory equipment dealers for smaller benchtop models.

The distribution network plays a critical role in customer support, installation, and post-sales maintenance, given the technical complexity of lyophilizers. Direct channels are preferred for high-capital projects where customization and complex integration into existing factory automation systems are required, allowing for specialized technical consultation. Indirect channels, including e-commerce platforms and regional distributors, facilitate market penetration for standard models, particularly in emerging economies. The end-user utilization closes the loop, generating feedback that drives future design improvements, particularly concerning user interfaces, energy conservation, and compliance features mandated by global regulatory bodies such as the FDA and EMA.

Freeze Drier Market Potential Customers

The potential customer base for the Freeze Drier Market is diverse yet highly concentrated within regulated industries requiring precise product preservation and long-term stability. The largest and most demanding consumer group consists of global pharmaceutical companies and specialized biotechnology firms. These entities rely on lyophilization for stabilizing critical products such as vaccines, sophisticated protein-based drugs (biologics), complex injectable formulations, and advanced diagnostic reagents. Their procurement decisions are heavily influenced by aseptic design, scalability, validation support, and compliance with stringent cGMP standards.

A secondary, rapidly growing customer segment is the food processing industry, particularly manufacturers of instant beverages (like high-quality freeze-dried coffee), ready-to-eat meals (MREs), and specialized pet foods. These buyers prioritize high throughput, energy efficiency, and systems capable of handling large volumes of non-aseptic materials while maintaining nutritional and sensory quality. Furthermore, nutraceutical companies producing highly sensitive ingredients, probiotics, and dietary supplements represent a significant emerging customer group seeking mid-sized, reliable lyophilization equipment to preserve product potency without heat degradation.

Finally, academic and research institutions, contract research organizations (CROs), and specialized laboratories constitute essential customers, predominantly purchasing benchtop and pilot-scale units. These end-users require flexibility, precision control, and ease of use for small-batch formulation studies, stability testing, and novel materials development. Their purchasing power, while individually smaller than industrial clients, collectively drives innovation and adoption of the latest technological features in smaller equipment footprints, catering to the needs of initial product lifecycle phases.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.5 Billion |

| Market Forecast in 2033 | $4.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SP Scientific, GEA Group, Azbil Corporation, Telstar (Terrassa), Tofflon Science and Technology, Martin Christ Gefriertrocknungsanlagen GmbH, Labconco Corporation, Millrock Technology, Wiggens, MechaTech Systems, Zirbus Technology, HOFI Freeze Dry, HOF Enterprise Group, IMA Group, Freeze Drying Systems, Cynosure, Optima Packaging Group, Cuddon Freeze Dry, BÜCHI Labortechnik AG, Leybold GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Freeze Drier Market Key Technology Landscape

The core technology landscape of the Freeze Drier Market is centered around optimizing the three fundamental phases of lyophilization—freezing, primary drying (sublimation), and secondary drying (desorption)—to achieve maximum product stability and minimal processing time. Contemporary technological focus emphasizes system automation and precision control to manage the delicate balance between maximum heat input and minimizing collapse risk, which is critical for product morphology. Advanced freezing methods, such as controlled nucleation techniques, are gaining traction. Controlled nucleation ensures uniform ice crystal size across a batch, leading to more predictable and efficient sublimation rates, drastically reducing overall cycle time and improving batch uniformity, a critical factor for regulatory compliance.

A significant technological shift is the move towards integrating Process Analytical Technology (PAT) directly into the lyophilizer chamber. Key PAT tools include Manometric Temperature Measurement (MTM), which allows for real-time calculation of the sublimation front temperature, and TDLAS, which precisely measures the vapor concentration and mass flow rate out of the chamber. These technologies move freeze drying from an empirically driven process to a scientifically robust, controlled manufacturing operation. The data generated by these integrated systems is often fed into sophisticated control algorithms, including those utilizing AI, to dynamically adjust shelf temperature and pressure, ensuring optimal performance and consistency for every cycle.

Furthermore, innovations are concentrated on enhancing efficiency and scalability, specifically through the development and commercialization of continuous freeze drying systems. Unlike traditional batch units, continuous systems (often utilizing microwave or radiant heating) process product flowing on a conveyor belt, significantly reducing cycle time from days to hours and offering inherent advantages in quality control and process scale-up. Alongside process improvements, environmental considerations are driving innovations in refrigeration technology, favoring natural refrigerants (hydrocarbons or CO2) over traditional HFCs to comply with global climate change protocols, ensuring that new equipment is both powerful and ecologically responsible.

Regional Highlights

The regional market landscape for freeze driers reflects global concentration in pharmaceutical manufacturing and advanced food processing capabilities, with notable divergence in growth rates and primary application focus across continents. North America, particularly the United States, commands the largest market share, characterized by high spending on R&D, a mature biopharmaceutical industry, and stringent regulatory standards requiring high-end, validated equipment. The region is a primary driver for technological adoption, focusing on continuous processing and advanced automation in large-scale manufacturing facilities, supported by robust governmental funding for health and life sciences.

Europe holds the second-largest market position, driven by the presence of major global pharmaceutical companies (Germany, Switzerland, UK) and a strong focus on laboratory research and vaccine production. The European market is characterized by high demand for energy-efficient systems due to strict regional environmental policies, leading to early adoption of natural refrigerant technologies. Furthermore, strong academic ties and high investment in biotechnology start-ups consistently drive demand for specialized pilot and research-scale lyophilizers.

Asia Pacific (APAC) is projected to exhibit the highest CAGR during the forecast period. This rapid expansion is fueled by increasing government investment in domestic pharmaceutical manufacturing (especially in China and India), the establishment of local vaccine production capabilities, and explosive growth in the processed food market, especially in Southeast Asia. While APAC initially focused on competitive pricing, the trend is shifting towards acquiring high-quality industrial systems to meet global export standards, making it the most critical future growth engine for the industrial segment. Latin America and MEA show slower growth but significant opportunity in localizing drug manufacturing and developing specialized food preservation methods for challenging climatic conditions.

- North America: Dominant market share; highest adoption of advanced automation and continuous processing; strong driver for biopharma R&D lyophilizers.

- Europe: Focus on energy efficiency and cGMP compliance; significant market for pilot and research units; large presence of medical device and vaccine manufacturers.

- Asia Pacific (APAC): Fastest-growing market; rapid capacity expansion in India and China; high demand in both pharma and volume food processing sectors.

- Latin America & MEA: Emerging markets; increasing investment in localized vaccine production and specialized food preservation technologies; potential for smaller, scalable units.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Freeze Drier Market.- SP Scientific

- GEA Group

- Azbil Corporation

- Telstar (Terrassa)

- Tofflon Science and Technology

- Martin Christ Gefriertrocknungsanlagen GmbH

- Labconco Corporation

- Millrock Technology

- Wiggens

- MechaTech Systems

- Zirbus Technology

- HOFI Freeze Dry

- HOF Enterprise Group

- IMA Group

- Freeze Drying Systems

- Cynosure

- Optima Packaging Group

- Cuddon Freeze Dry

- BÜCHI Labortechnik AG

- Leybold GmbH

- Freezedryer GmbH

- LyoBeta Technologies

- Kemet International

- Sartorius AG (indirectly through lab offerings)

- Thermo Fisher Scientific (indirectly through lab equipment)

- Hitachi Industrial Equipment Systems

Frequently Asked Questions

Analyze common user questions about the Freeze Drier market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driver for the growth of the Freeze Drier Market?

The primary driver is the accelerating demand from the pharmaceutical and biotechnology sectors, specifically for the preservation of high-value, temperature-sensitive biologics, vaccines, and advanced therapeutic proteins, ensuring their long-term stability and efficacy without the need for cold chain logistics.

How does continuous freeze drying technology differ from traditional batch lyophilization?

Continuous freeze drying processes materials sequentially, often using specialized conveyer systems and rapid heating methods, significantly reducing cycle times (from days to hours) and increasing throughput compared to traditional batch systems that process an entire chamber load simultaneously.

Which geographical region exhibits the fastest growth rate for freeze drier adoption?

The Asia Pacific (APAC) region is projected to register the fastest growth rate, driven by massive investments in local pharmaceutical manufacturing capabilities, expanding healthcare infrastructure, and rising consumer demand for processed and preserved food products, particularly in China and India.

What role does Process Analytical Technology (PAT) play in modern freeze drying?

PAT, including tools like Manometric Temperature Measurement (MTM) and TDLAS, enables real-time monitoring and control of critical process parameters such as sublimation rate and product temperature, ensuring batch consistency, minimizing risk of product collapse, and facilitating regulatory compliance and validation.

What is the main challenge facing the adoption of industrial freeze driers?

The main challenge is the high capital investment required for purchasing, installing, and validating industrial-scale units, coupled with the significant energy consumption associated with maintaining ultra-low condenser temperatures and deep vacuum levels over extended, multi-day drying cycles.

What types of materials primarily utilize lyophilization for preservation?

Materials include vaccines, live bacterial cultures, highly sensitive protein therapeutics (monoclonal antibodies), diagnostic reagents, blood plasma, various antibiotics, and specialized food ingredients like instant coffee and culinary herbs requiring long-term, ambient stability.

How is AI being applied to optimize freeze drying processes?

AI and Machine Learning are used to analyze vast historical process data to predict optimal drying recipes, dynamically adjust chamber parameters in real-time to prevent batch failures, and implement predictive maintenance schedules for critical system components, thus enhancing efficiency and reliability.

Do stringent regulations impact the market for freeze drying equipment?

Yes, stringent cGMP (current Good Manufacturing Practices) regulations enforced by bodies like the FDA and EMA significantly impact the market, driving demand for automated, highly reliable, and easily validated equipment that provides comprehensive documentation and aseptic capabilities.

Besides pharmaceuticals, what significant emerging application areas exist?

Significant emerging applications include the preparation of advanced materials such as porous ceramics and scaffolding for tissue engineering, high-stability preservation of probiotics and nutraceuticals, and the cryogenic preservation of biological samples and tissues in research.

Which component supplier segment is most critical in the freeze drier value chain?

The suppliers of high-performance vacuum pumps and sophisticated refrigeration systems are the most critical, as the ability to achieve and consistently maintain deep vacuum and ultra-low condenser temperatures directly dictates the efficiency and performance of the entire lyophilization process.

What is the typical operational scale for pilot freeze drying units?

Pilot-scale units bridge the gap between small R&D benchtop models and full production systems. They are typically used to develop and finalize drying recipes (cycles) that can be reliably scaled up to industrial production, handling batches ranging from a few liters up to 50-100 liters.

What is shelf temperature uniformity critical for in lyophilization?

Shelf temperature uniformity is critical because variations across the shelf area can lead to inconsistent sublimation rates. This causes product variation within the same batch, potentially resulting in localized product collapse or melt-back, compromising the final product’s quality and stability.

How do specialized stainless steel requirements affect equipment costs?

Freeze driers used for pharmaceutical applications require specialized, high-grade stainless steel (often 316L) with high surface finishes for the chamber and shelves to prevent contamination, meet aseptic standards, and facilitate rigorous clean-in-place (CIP) and sterilize-in-place (SIP) procedures, contributing significantly to the high capital cost.

What are the benefits of using controlled nucleation techniques?

Controlled nucleation allows for the uniform freezing of the product across all vials, resulting in smaller, more consistent ice crystals. This uniformity leads to shorter, more efficient primary drying cycles and improved product quality by reducing resistance to vapor flow during sublimation.

How does the medical device industry utilize freeze drying technology?

The medical device industry uses lyophilization primarily to sterilize and preserve biological components integrated into devices, such as coatings, antibiotic delivery systems, or biological scaffolds, ensuring the long-term stability and bio-compatibility of these complex components.

What potential environmental constraints affect freeze drier manufacturing?

Environmental constraints include global regulations phasing out high global warming potential (GWP) refrigerants (HFCs). Manufacturers are consequently transitioning to refrigeration systems utilizing natural refrigerants like CO2 or hydrocarbons, necessitating significant R&D in heat exchange and compressor technologies.

What is the significance of the vacuum system in a freeze drier?

The vacuum system is essential as it maintains the chamber pressure below the triple point of water, enabling ice to sublime directly into water vapor, bypassing the liquid phase. The efficiency of the vacuum pump determines the speed and consistency of the drying process, directly impacting cycle duration.

Why are nutraceutical companies increasingly adopting freeze drying?

Nutraceutical companies adopt freeze drying because it is a low-temperature preservation method that minimizes the degradation of heat-sensitive compounds like vitamins, enzymes, and probiotics, thereby maximizing the potency and bioavailability of their health supplements over their shelf life.

How are remote monitoring capabilities changing the market?

Remote monitoring capabilities, enabled by IoT (Internet of Things) integration, allow manufacturers to remotely access real-time lyophilizer data, enabling rapid troubleshooting, preventative maintenance, and secure auditing, which is crucial for decentralized global manufacturing operations.

What is the primary differentiation point between major equipment suppliers?

Key differentiation points include the level of automation integration (e.g., automatic loading/unloading systems), proprietary control software for cycle optimization, robustness of aseptic design, commitment to after-sales service and validation support, and expertise in complex continuous systems.

What impact did the COVID-19 pandemic have on the demand for freeze driers?

The pandemic significantly accelerated demand for high-capacity industrial freeze driers globally, driven by the unprecedented need for stabilizing and rapidly distributing large volumes of mRNA and viral vector vaccines that required lyophilization for long-term storage and distribution.

Why is energy consumption a major restraint in this market?

Freeze driers are highly energy-intensive due to the continuous operation of powerful refrigeration systems required to maintain ultra-low condenser temperatures (often -70°C to -85°C) and the high energy demand of vacuum pumps operating over extended drying cycles, posing a significant operational expense for users.

What defines a 'Benchtop' freeze drier unit?

A benchtop unit is a compact, typically non-aseptic, small-scale lyophilizer used primarily in academic research, feasibility studies, and preliminary formulation development in labs, offering high flexibility for handling minimal sample volumes (typically less than 10 liters).

How does the utilization of nitrogen gas factor into the lyophilization process?

Nitrogen gas is often used to break the vacuum in the chamber safely and quickly at the end of the drying cycle before product unloading. In aseptic pharmaceutical applications, sterile filtered nitrogen ensures that the product is protected from environmental moisture and contamination when returning the chamber to atmospheric pressure.

What are the core benefits of lyophilization over conventional drying methods?

Lyophilization offers superior preservation benefits, including minimal denaturation of heat-sensitive materials, retention of product structure (porosity), significantly extended shelf life (often years) at ambient temperatures, and the ability for the dried product to be readily and completely reconstituted (dissolved) upon use.

What is the typical application for Manifold technology freeze driers?

Manifold freeze driers are generally small, laboratory-scale units where product is dried in individual flasks or ampoules connected to a central manifold. They are often used for small sample volumes and non-aseptic research where individual container sealing is not a critical requirement.

How does equipment validation (IQ/OQ/PQ) influence customer purchasing decisions?

Validation documentation (Installation, Operational, and Performance Qualification) is mandatory for pharmaceutical end-users. Suppliers offering comprehensive, pre-validated systems with robust documentation packages are highly favored, as this streamlines the regulatory approval process for the customer’s facility and product.

What is the current trend regarding automation in industrial freeze driers?

The current trend is towards full integration of robotic loading and unloading systems (ALUS) into aseptic manufacturing lines, which minimizes human intervention, drastically reduces the risk of contamination, and maximizes throughput consistency in sterile processing environments.

Why is the eutectic temperature critical for freeze drying cycle development?

The eutectic temperature represents the lowest temperature at which the frozen product can exist before melting. The shelf temperature must be maintained safely below this point during primary drying to ensure complete sublimation, preventing product collapse and ensuring the integrity of the dried cake structure.

How is the packaging process connected to the freeze drier market?

The packaging process is intrinsically linked, particularly in pharmaceuticals, where freeze driers are often integrated with automatic vial stoppering mechanisms and subsequent secondary packaging lines. This ensures the integrity and sterility of the lyophilized product immediately upon completion of the drying cycle.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager