Furniture Leveler Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442703 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Furniture Leveler Market Size

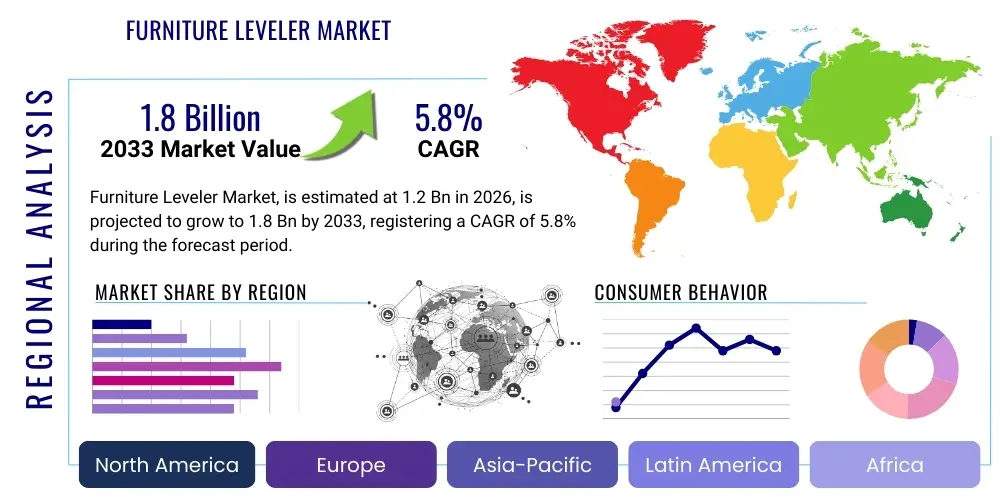

The Furniture Leveler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the continuous expansion of the global residential and commercial construction sectors, alongside increasing consumer focus on furniture longevity, stability, and protection of flooring surfaces. The market's stability is often underestimated, yet its criticality in ensuring ergonomic functionality and aesthetic integrity across diverse furnishing applications drives consistent demand.

The valuation reflects the robust demand from mass-produced furniture manufacturers and custom woodworking artisans alike. While standard plastic and metal levelers form the bulk of the volume, the fastest growth segments involve specialized, heavy-duty, and smart levelers designed for sophisticated commercial environments like high-end restaurants, healthcare facilities, and modern office spaces. These premium products often incorporate advanced materials such as corrosion-resistant alloys and high-density polymers, commanding higher average selling prices and contributing significantly to the market's overall revenue expansion over the forecast period. The Asia Pacific region, specifically China and India, is expected to be a primary catalyst for volume growth due to rapidly urbanizing populations and surging furniture production capabilities.

Furniture Leveler Market introduction

The Furniture Leveler Market encompasses the production, distribution, and sale of small components designed to stabilize, adjust, and protect furniture and equipment. These devices, ranging from simple plastic caps to complex threaded steel inserts and adjustable glides, are essential for correcting uneven surfaces, preventing rocking, and protecting sensitive flooring materials like hardwood and tile from scratches or indentation damage. Major applications span residential settings (tables, chairs, cabinets, beds), commercial environments (office desks, hospitality seating, retail displays), and light industrial equipment (workbenches, shelving units). The primary benefits include enhanced furniture stability, improved structural integrity, noise reduction, and extended floor lifespan. Key driving factors involve the global growth in construction and remodeling activities, increased consumer awareness regarding home aesthetics and protection, and the rising prevalence of customizable and modular furniture designs that require precise leveling mechanisms for optimal performance.

The evolution of the market is characterized by a shift towards more aesthetically pleasing and durable materials. Initially dominated by simple felt pads and basic plastic components, modern furniture levelers now incorporate advanced features such as swivel bases, anti-vibration damping materials, and high load-bearing capabilities. Furthermore, regulatory standards governing furniture safety and stability in regions like North America and Europe mandate the use of reliable leveling mechanisms, further solidifying the market’s necessity. This widespread adoption across multiple industry verticals, from DIY home improvement enthusiasts to large-scale original equipment manufacturers (OEMs), ensures a broad and resilient demand base.

The increasing complexity of modern living spaces, which often feature diverse flooring types and open-plan designs, necessitates specialized leveling solutions. Manufacturers are continually innovating to provide solutions that are easy to install, aesthetically discreet, and capable of handling significant weight discrepancies. The integration of robust mechanisms capable of subtle height adjustments allows furniture to maintain a perfect horizontal plane, crucial for items such as kitchen islands or large storage units where stability is paramount. This perpetual requirement for stability and surface protection defines the enduring nature of the furniture leveler industry.

Furniture Leveler Market Executive Summary

The Furniture Leveler Market is poised for stable and consistent growth, underpinned by significant global business trends, including the robust recovery of the housing sector post-pandemic and the sustained expansion of commercial real estate development, particularly in emerging economies. Key business trends show a pronounced shift toward higher-quality, design-integrated levelers, moving away from purely utilitarian components. Manufacturers are increasingly focusing on specialized solutions for heavy-duty applications, vibration reduction, and severe-environment usage, capturing higher margin opportunities. Furthermore, efficiency in supply chain management and the standardization of thread sizes and mounting methodologies are critical competitive differentiators among leading market players.

Regionally, Asia Pacific is anticipated to exhibit the fastest growth rate, fueled by massive furniture production hubs in China and Vietnam, coupled with expanding domestic consumption in populous countries like India and Indonesia. North America and Europe, while mature markets, maintain high market values due to premium pricing, stringent quality standards, and high demand for specialized, custom-order furniture. The Middle East and Africa are gradually increasing their market share, driven by large-scale infrastructure and hospitality projects requiring durable and aesthetically appropriate commercial levelers. These regional dynamics highlight the decentralized nature of manufacturing and the localized demand for specialized product types.

Segment trends reveal that the metal levelers segment, particularly stainless steel and aluminum, retains the largest revenue share due to superior strength and longevity, essential for commercial and industrial applications. However, the plastic/polymer segment is experiencing faster volumetric growth, driven by cost-effectiveness and versatility in low-load residential furniture. Within applications, the Commercial Furniture sector, encompassing offices and hospitality, shows the highest CAGR, primarily due to faster replacement cycles and higher requirements for weight capacity and floor protection. Distribution channels are favoring online retail platforms and large B2B direct sales, streamlining procurement for large furniture OEMs and professional contractors.

AI Impact Analysis on Furniture Leveler Market

Common user questions regarding AI’s impact on the Furniture Leveler Market typically revolve around automation efficiency, customized manufacturing, inventory optimization, and the potential for "smart" leveling products. Users frequently inquire if AI can streamline the production of customized leg lengths and thread pitches, thereby reducing lead times. Another major theme is how machine learning algorithms might be used for demand forecasting, specifically predicting surges in niche applications like adjustable standing desks or specialized medical furniture, optimizing inventory levels and reducing warehousing costs. The core concern often centers on whether AI integration will lead to entirely autonomous manufacturing floors, lowering labor costs but requiring significant upfront technological investment. These themes underscore a user focus on efficiency gains, predictive capabilities, and novel product development driven by advanced computational intelligence.

While the physical product—the furniture leveler itself—remains a low-tech component, AI and machine learning profoundly affect the value chain and operational efficiencies. In manufacturing, AI-driven quality control systems can monitor production lines in real-time, detecting micro-defects in threading or material consistency far more accurately than human inspection, thereby ensuring higher product quality and reducing waste. Furthermore, predictive maintenance algorithms can optimize machinery uptime by anticipating component failure in stamping, molding, and assembly equipment. This technological integration allows mass producers to handle increased customization requests—such as variable thread lengths or non-standard polymer compositions—without incurring disproportionately high operational overheads, making customized bulk orders economically viable.

Crucially, AI influences the design phase through generative design tools. By inputting criteria such as maximum load capacity, material cost limits, and desired aesthetic profile, AI algorithms can rapidly iterate through thousands of structural designs, optimizing the material distribution within the leveler to maximize strength while minimizing weight and material usage. This results in highly efficient, structurally superior products optimized for cost and performance. Additionally, in the retail and distribution segments, AI tools are enhancing customer support by quickly identifying the correct leveler type, thread specification, and installation method based on customer-provided furniture models or photographs, drastically improving the buyer experience and reducing returns related to incorrect sizing.

- AI-driven Predictive Maintenance: Optimizes stamping and molding machinery uptime, reducing production bottlenecks and minimizing operational costs in high-volume facilities.

- Generative Design Optimization: Utilized to create structurally efficient leveler designs that minimize material use while meeting stringent load-bearing requirements.

- Automated Quality Control: High-speed computer vision systems detect microscopic defects in threading and material composition, enhancing overall product reliability.

- Supply Chain & Demand Forecasting: Machine learning algorithms analyze market signals (construction permits, retail trends) to predict demand fluctuations for specific leveler types, optimizing inventory management.

- E-commerce Recommendation Systems: AI aids online platforms in guiding customers to the exact leveling components required for their specific furniture item, improving conversion rates and reducing purchasing errors.

DRO & Impact Forces Of Furniture Leveler Market

The dynamics of the Furniture Leveler Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. Key drivers include the accelerated pace of global urbanization, which boosts demand for both residential and commercial furnishings, and the sustained consumer preference for modular and adjustable furniture. Restraints primarily involve the high fragmentation of the market, leading to intense price competition, and the susceptibility of raw material costs (especially steel and polymers) to global commodity price volatility, compressing profit margins for manufacturers. Significant opportunities arise from the increasing market for specialized and high-margin products, such as anti-vibration levelers for delicate electronics or levelers integrated with smart sensing capabilities. These forces collectively dictate market expansion rates and define the competitive strategies adopted by industry participants.

The impact forces influencing this market are multifaceted, stemming from technological advancements and macro-economic shifts. The rise of sophisticated Computer Numerical Control (CNC) machining and advanced polymer injection molding techniques acts as a technological force, allowing for the precise and rapid production of intricate leveler designs, thus lowering production costs over time. Economically, fluctuations in global construction spending have an immediate and direct impact on market demand, as the leveler market is intrinsically linked to new furniture production and renovation cycles. Socially, the increasing popularity of Do-It-Yourself (DIY) culture, particularly in North America and Europe, drives the demand for easy-to-install, consumer-friendly leveling solutions available through mass retail channels, further segmenting the product offerings.

Environmental regulatory pressures represent a growing and impactful external force. As sustainability becomes a core consumer and corporate mandate, there is a rising demand for levelers manufactured from recycled or bio-based polymers and components that adhere to stringent material safety standards (e.g., RoHS compliance). Companies that proactively develop sustainable material sourcing and manufacturing processes gain a significant competitive advantage and address the long-term ethical sourcing concerns of large OEM customers. Ultimately, the successful navigation of these drivers and restraints, while capitalizing on technological and sustainability opportunities, will define market leadership in the coming decade.

Segmentation Analysis

The Furniture Leveler Market is meticulously segmented based on material composition, type, primary application, and distribution channel, reflecting the diversity of end-user requirements and operational environments. Material segmentation highlights the trade-off between strength and cost, with metal components dominating high-load applications and plastic/polymer components providing economical solutions for standard furniture. Type segmentation differentiates between fixed installation components and complex adjustable mechanisms, which often incorporate swivel joints or integrated glides. Application segmentation distinguishes between the high-volume residential market and the demanding, specialized commercial and industrial sectors, each requiring unique specifications regarding durability, load capacity, and aesthetic integration.

Understanding these segmentations is vital for manufacturers and distributors to tailor their product offerings and marketing strategies effectively. For instance, the commercial segment often requires bulk purchasing capabilities and specific material certifications, whereas the residential segment relies heavily on user-friendliness and attractive retail packaging. Furthermore, the rising demand for customizable furniture drives the necessity for levelers with standardized yet adjustable features, suitable for modular systems. This detailed breakdown ensures that market forecasts accurately reflect the varied consumption patterns across different industry verticals and end-user demographics, enabling strategic resource allocation.

- By Material:

- Metal (Steel, Stainless Steel, Aluminum, Brass)

- Plastic/Polymer (Nylon, ABS, Polyethylene)

- Rubber and Elastomers

- Hybrid Materials (Metal core with Polymer/Rubber base)

- By Type:

- Threaded Glides (Screw-in Levelers)

- Push-in Inserts and Ferrules

- Adjustable Feet and Legs (Heavy Duty)

- T-Nuts and Inserts

- Casters with Leveling Capability

- By Application:

- Residential Furniture (Tables, Chairs, Cabinets, Beds)

- Commercial Furniture (Office Desks, Hospitality Seating, Retail Fixtures)

- Industrial Equipment (Workbenches, Shelving Units, Machinery Bases)

- Medical and Healthcare Furniture

- By Distribution Channel:

- B2B Direct Sales (OEMs and Contractors)

- Offline Retail (Hardware Stores, Home Improvement Centers)

- E-commerce and Online Platforms

Value Chain Analysis For Furniture Leveler Market

The Value Chain for the Furniture Leveler Market initiates with upstream activities involving the procurement and processing of fundamental raw materials—primarily steel, aluminum, and various engineering-grade polymers. Suppliers in this phase provide bulk materials which are then processed through stamping, casting, forging, or injection molding by specialized component manufacturers. Effective upstream management focuses heavily on negotiating stable contracts for metals and managing the logistics of high-volume commodity inputs, directly impacting final product cost and margin. Material quality control, particularly for corrosion resistance in metal levelers and tensile strength in polymer components, is a crucial function at this stage.

Midstream activities involve the core manufacturing process, assembly, and quality assurance. Leveler manufacturers utilize specialized machinery for precise threading, welding (for complex adjustable units), and surface treatments (plating or coating). This phase also includes packaging, often customized for OEM bulk orders versus retail point-of-sale displays. The downstream segment encompasses the distribution and sales activities. The distribution channel is bifurcated into B2B direct sales, where manufacturers supply large furniture assembly plants and construction contractors, and indirect retail channels, catering to consumers and small-to-medium enterprises (SMEs) through hardware stores, specialty distributors, and increasingly, high-volume e-commerce platforms. The efficiency of the distribution network, particularly the ability to fulfill varied order sizes quickly, dictates competitive success downstream.

Direct sales channels are favored for large-scale furniture production requiring standardized products in massive quantities, where technical support and integrated logistics are paramount. Indirect channels, primarily online and brick-and-mortar retail, rely heavily on effective merchandising, robust inventory systems, and competitive pricing for attracting the DIY consumer and small professional contractor. The increasing complexity of global supply chains necessitates sophisticated logistics management to ensure timely delivery across continents, a challenge exacerbated by fluctuating global shipping costs. Maximizing value throughout this chain requires a continuous focus on material innovation upstream and streamlined digital integration downstream to meet varied customer fulfillment expectations.

Furniture Leveler Market Potential Customers

The potential customer base for the Furniture Leveler Market is exceptionally broad, spanning multiple sectors from large-scale industrial manufacturing to individual residential consumers. Primary end-users include Original Equipment Manufacturers (OEMs) within the furniture industry, responsible for producing residential cabinets, seating, and tables, as well as commercial furnishings for offices, schools, and healthcare facilities. These large buyers prioritize quality certifications, supply consistency, and highly competitive pricing for bulk volumes. Their demand drives technological specifications, requiring levelers designed for high-speed automated assembly and specific load-bearing requirements necessary for institutional use.

Another significant customer segment includes professional contractors, interior designers, and renovation companies. These buyers frequently require specialized or premium levelers for custom installations, such as kitchen remodels, high-end retail fixture setups, or heavy laboratory equipment. They value durability, aesthetic appeal (often requiring discreet or decorative finishes), and reliability in handling complex load distributions. Their procurement often occurs through specialized hardware distributors or trade-focused wholesale suppliers, where availability of diverse product specifications and expert technical advice are key purchasing determinants.

Finally, the consumer retail market, consisting of individual homeowners and DIY enthusiasts, represents a high-volume, though typically lower average order value, customer base. These consumers purchase levelers for repairs, minor stabilization needs, or customization projects, relying heavily on accessibility through major home improvement centers and easily navigable e-commerce platforms. For this segment, ease of installation, clear instructions, and competitive pricing for small pack sizes are paramount. The continued growth of DIY culture ensures sustained demand from this critical retail channel.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Master Manufacturing Co., Dalton Industries Inc., Legrand Furniture Fittings, Danco, Levelizer Corp., B&Q, Hafele, Sugatsune, Richelieu Hardware, Federal Brace, Midwest Fastener, Oatey Co., Waddell Manufacturing, Fast-Cap, Rockler Woodworking and Hardware, Pukalani Industrial, Shepherd Hardware, Knape & Vogt, Futech Industrial, Tente International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Furniture Leveler Market Key Technology Landscape

The technology landscape for the Furniture Leveler Market, while focused on simple mechanical components, is continuously evolving through manufacturing precision and material science application. Core technologies revolve around advanced metal processing techniques such as cold forging and precision stamping, essential for producing high-tolerance threaded components and T-nuts that ensure secure mounting and stable load distribution. For plastic components, multi-shot injection molding allows manufacturers to combine rigid polymer bodies with soft thermoplastic elastomer (TPE) bases in a single, seamless component. This advanced molding capability enhances floor grip and surface protection without compromising the structural integrity of the leveler's main body, addressing a key consumer demand for scratch prevention.

Material innovation is a parallel technological driver. The development and incorporation of high-performance engineering plastics, such as glass-filled nylon, provide metal-like strength and rigidity but with inherent corrosion resistance and lighter weight, making them ideal for outdoor furniture or moisture-prone environments. Furthermore, the integration of quick-adjustment technologies, such as patented self-leveling mechanisms or tool-free adjustment systems, elevates the user experience. These mechanisms often involve complex internal gearing or ratchet systems that allow for millimeter-precise adjustments simply by twisting the foot or pressing a button, offering a distinct advantage in commercial settings where rapid deployment and reconfiguring of furniture are common requirements.

The nascent integration of sensors represents the leading edge of technology. While still niche, smart levelers equipped with internal tilt sensors or pressure sensors are being explored for high-value industrial or medical equipment. These sensors communicate real-time data on floor stability and load distribution back to a central monitoring system, ensuring compliance with safety standards for sensitive machinery or precision medical devices. While mass-market adoption of smart levelers is still distant, these specialized applications demonstrate the market's trajectory towards leveraging IoT and connectivity for enhanced functionality and structural health monitoring.

Regional Highlights

- North America (NA): Represents a high-value, mature market characterized by robust demand for premium, heavy-duty metal levelers and a strong DIY consumer base. The region benefits from significant construction expenditure and high quality control standards in commercial furniture manufacturing, particularly in the office and hospitality sectors. The U.S. remains the dominant market, driving innovation in adjustable and ergonomic furniture systems, requiring superior leveling components.

- Europe: Known for its stringent regulatory environment regarding material safety (REACH compliance) and product durability. Western European countries, particularly Germany and the UK, exhibit strong demand for aesthetically integrated levelers suitable for designer furniture. Eastern Europe serves as a major manufacturing base, contributing significantly to global supply, focusing on cost-efficient, yet high-quality polymer and hybrid components for export and domestic use.

- Asia Pacific (APAC): The powerhouse for market growth, offering the highest volumetric expansion potential. Driven by rapid urbanization in China, India, and Southeast Asia, this region features massive furniture production hubs catering to global demand (OEM export market) and skyrocketing domestic consumption. The market is highly cost-sensitive but is quickly adopting automated manufacturing techniques to ensure consistent quality in high-volume production runs.

- Latin America (LATAM): A growing market influenced by varying economic conditions and construction cycles. Brazil and Mexico are key regional contributors, showing increased industrialization and a rising standard of living, which translates to higher demand for imported and locally manufactured quality furniture. The market frequently demands versatile levelers capable of handling structurally diverse buildings and uneven flooring prevalent in older infrastructure.

- Middle East and Africa (MEA): Growth is propelled by large-scale government-backed infrastructure and hospitality projects in the GCC nations (Saudi Arabia, UAE). These mega-projects require high-end, durable, and often customized commercial-grade levelers for hotels, malls, and public buildings. The African market is nascent but shows potential through increasing urbanization and foreign direct investment in manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Furniture Leveler Market.- Master Manufacturing Co.

- Dalton Industries Inc.

- Legrand Furniture Fittings

- Danco

- Levelizer Corp.

- B&Q

- Hafele

- Sugatsune

- Richelieu Hardware

- Federal Brace

- Midwest Fastener

- Oatey Co.

- Waddell Manufacturing

- Fast-Cap

- Rockler Woodworking and Hardware

- Pukalani Industrial

- Shepherd Hardware Products

- Knape & Vogt Manufacturing Company

- Futech Industrial

- Tente International GmbH

Frequently Asked Questions

Analyze common user questions about the Furniture Leveler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving growth in the Furniture Leveler Market?

The primary factor driving market growth is the consistent global expansion of residential construction and commercial renovation activities, which inherently increases the demand for new furniture and requires stable, durable leveling mechanisms to ensure longevity and proper functionality across varied floor surfaces.

Which material segment holds the largest market share in terms of revenue?

The Metal Levelers segment, particularly those made from steel and aluminum, maintains the largest revenue share. This dominance is due to their superior load-bearing capacity, resistance to structural deformation, and mandatory use in heavy-duty commercial and industrial equipment applications.

How does the commercial application segment differ from the residential segment?

The commercial segment demands levelers with higher durability, rigorous material certifications, and specialized anti-vibration features suitable for high traffic and rapid reconfiguration (e.g., offices and hospitality). The residential segment prioritizes ease of installation, aesthetic integration, and effective floor protection.

What are the major challenges manufacturers face regarding profitability?

Major profitability challenges stem from intense market fragmentation, which results in aggressive price competition, coupled with the volatility of raw material costs, particularly steel and various petroleum-based polymers, which directly compress operating margins.

Are 'smart' furniture levelers a significant trend in the immediate future?

While smart levelers integrating tilt and pressure sensors are emerging, they remain a highly specialized, niche trend primarily focused on high-value industrial machinery and precise medical equipment. Mass-market adoption is not expected in the immediate future due to cost complexity, but their influence on technological development remains significant.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager