Galvo Scanner Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442060 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Galvo Scanner Market Size

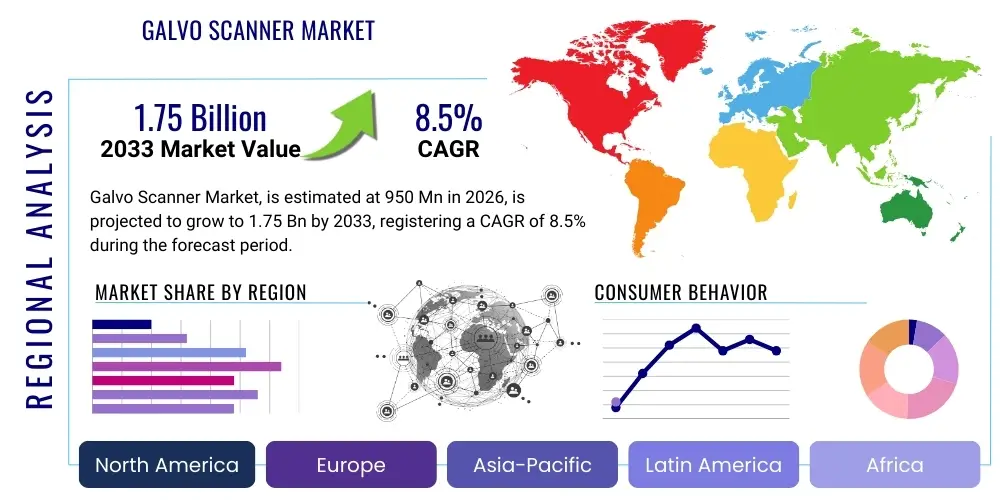

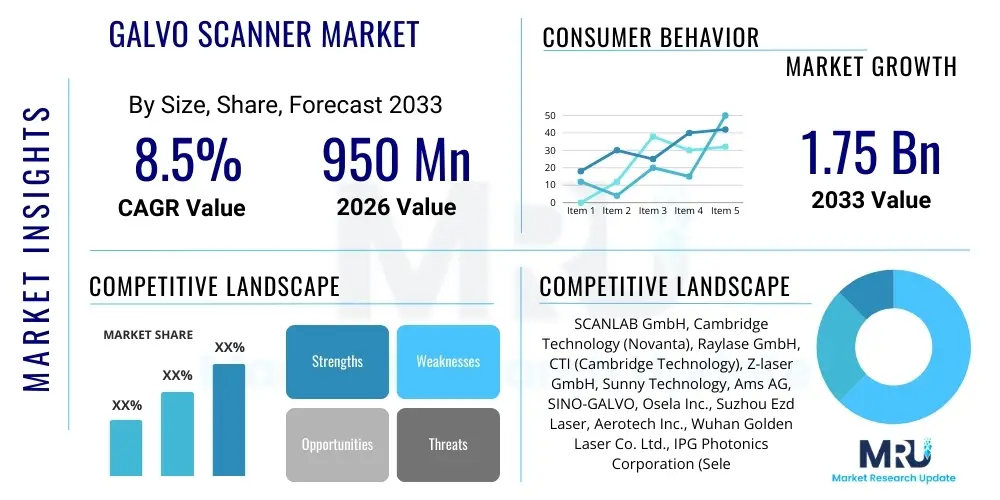

The Galvo Scanner Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 950 million in 2026 and is projected to reach USD 1.75 billion by the end of the forecast period in 2033. This robust growth trajectory is primarily attributed to the escalating demand for high-precision, high-speed material processing across diverse industrial sectors, particularly in microelectronics manufacturing and advanced medical device production. The sustained innovation in laser technology, coupled with the need for larger scan fields and superior dynamic performance, continues to define the market's expansion.

Galvo Scanner Market introduction

The Galvo Scanner Market encompasses devices utilizing galvanometers, which are precise motor mechanisms equipped with mirrors, designed to rapidly deflect laser beams across a working surface with exceptional accuracy. These systems are fundamental components in sophisticated laser-based applications where speed, precision, and repeatability are paramount. Galvo scanners facilitate highly complex geometries and rapid throughput, distinguishing them from traditional mechanical laser positioning systems. The core product description involves high-performance rotating mirrors driven by advanced electromagnetic coils and controlled via digital servo drivers, ensuring minimal drift and maximum responsiveness even at demanding frequencies. Key specifications include mirror aperture size, positioning speed (measured in markings per second or scan angle/time), and thermal stability.

Major applications of Galvo scanners span across industrial laser marking, cutting, and welding, especially for complex or delicate materials in sectors like automotive, aerospace, and general manufacturing. In the medical field, they are essential for surgical procedures, dermatology treatments, and advanced imaging modalities such as Optical Coherence Tomography (OCT). Furthermore, the electronics sector heavily relies on these scanners for intricate tasks like circuit board production, semiconductor wafer processing, and precision soldering. The inherent benefits of Galvo scanner technology include ultra-fast beam positioning, significantly reducing production cycle times, non-contact processing which minimizes material deformation, and superior spatial resolution necessary for micromachining operations.

The primary driving factors fueling market expansion are the continuous miniaturization of electronic components, necessitating finer and faster laser processing techniques, and the global adoption of Industry 4.0 standards, which demand automated, high-throughput manufacturing solutions. Increased investments in research and development focused on optimizing mirror coatings, enhancing servo control algorithms, and integrating larger aperture scanners for expanded field of view applications are also critical drivers. Additionally, the rising prevalence of laser additive manufacturing (3D printing) and the evolution of fiber laser technologies, which pair excellently with Galvo systems, contribute substantially to market vitality.

Galvo Scanner Market Executive Summary

The Galvo Scanner Market is characterized by intense technological evolution, driven by the persistent industrial need for higher precision and greater speed in laser material processing. Current business trends indicate a strong shift toward 3D scanning solutions capable of processing complex, contoured surfaces without requiring mechanical movement of the workpiece. This transition is heavily influencing R&D efforts among leading manufacturers, focusing on dynamic focus technologies and advanced software algorithms for geometric correction and trajectory planning. Furthermore, there is a growing trend toward integrated scanning heads—combining Galvo mirrors, focusing optics, and control electronics into compact, standardized modules—to simplify integration into manufacturing lines, particularly in high-volume production environments like consumer electronics assembly.

Regionally, Asia Pacific (APAC) stands as the dominant market, propelled by massive manufacturing bases in China, Japan, and South Korea, which are rapidly deploying automation and advanced laser systems in electronics, automotive, and solar panel production. North America and Europe maintain significant market shares, largely due to strong demand from high-value, specialized sectors such as medical device manufacturing, defense applications, and high-end aerospace component fabrication, where performance and reliability take precedence over cost. Emerging regional trends involve accelerated adoption in Southeast Asia, driven by the relocation of manufacturing capacity seeking lower operational costs, thus boosting the demand for entry-level and mid-range Galvo systems for basic marking and cutting applications.

Segment-wise, the 3D Galvo Scanners segment is exhibiting the fastest growth due to its versatility in handling complex geometries and integration into additive manufacturing processes. The Application segment is dominated by Laser Processing (marking and micromachining), reflecting its core utility across all industrial manufacturing. Within the end-user industries, Electronics & Semiconductors is the largest consumer, necessitated by the stringent requirements for micro-level precision in circuit fabrication and chip encapsulation. Key market players are strategically investing in vertical integration, acquiring specialized software firms, and forming partnerships with laser source manufacturers to offer complete, optimized processing solutions, thereby solidifying their market positioning and expanding their global footprint.

AI Impact Analysis on Galvo Scanner Market

Analysis of common user questions reveals significant interest in how Artificial Intelligence (AI) and machine learning (ML) will enhance the precision, speed, and autonomous operation of Galvo scanner systems. Key themes include the implementation of AI for predictive maintenance of scanner optics and motors, optimizing complex laser paths in real-time to minimize thermal stress and maximize throughput, and using ML algorithms for automated quality control (QC) by analyzing in-process imagery captured by integrated cameras. Users are highly concerned about the latency challenges associated with integrating high-speed AI processing into microsecond-level laser control loops, and they are seeking confirmation that AI can genuinely improve process yield and consistency in highly critical applications like medical device inscription or semiconductor processing.

The integration of AI fundamentally transforms Galvo scanner utilization by transitioning systems from reactive control mechanisms to predictive and adaptive platforms. AI algorithms are being deployed to dynamically adjust scanner parameters—such as mirror velocity, acceleration profiles, and laser power modulation—to compensate for variations in material properties, ambient temperature fluctuations, and subtle wear within the scanning mechanism itself. This level of real-time optimization far surpasses traditional fixed-parameter controls, ensuring higher quality output and greater operational consistency, especially in continuous, high-volume manufacturing environments. Furthermore, ML models trained on vast datasets of material interactions are increasingly enabling "first-time-right" parameter selection for novel materials, drastically reducing setup time and material wastage.

AI's influence extends significantly into maintenance and system reliability. By continuously monitoring vibrational data, current draw, temperature profiles, and reflected light patterns, ML models can predict imminent component failure, such as mirror bearing degradation or control board malfunction, long before operational failure occurs. This capability shifts maintenance from scheduled downtime to condition-based intervention, maximizing operational uptime. Moreover, in advanced 3D scanning applications, AI facilitates intricate path planning by calculating the optimal sequence and angle of laser incidence to maintain focus uniformity across complex, non-planar surfaces, which is critical for precision tasks in aerospace component repair and orthopedic implant manufacturing.

- AI-driven real-time optimization of laser scanning parameters (speed, power, focus) based on material feedback.

- Predictive maintenance implemented via Machine Learning analysis of operational data (vibration, temperature, current).

- Enhanced automated quality control (AQC) through visual inspection algorithms (e.g., defect detection in laser marking).

- Optimization of complex 3D scanning trajectories and dynamic focus adjustment on contoured surfaces.

- Acceleration of process development by utilizing deep learning models for optimal material processing recipes.

- Improved system efficiency and throughput by minimizing thermal distortion and maximizing beam utilization time.

DRO & Impact Forces Of Galvo Scanner Market

The dynamics of the Galvo Scanner Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO). The primary drivers include the pervasive global trend toward high-precision micromachining and the expansion of the electronics manufacturing sector, particularly for flexible displays and advanced packaging. Furthermore, the increasing adoption of laser-based additive manufacturing requires highly reliable and fast beam steering, creating substantial demand for advanced 3D Galvo systems. These factors, combined with continuous advancements in fiber and ultrashort pulse (USP) laser sources that necessitate equally responsive beam delivery, form the bedrock of market growth, pushing performance specifications to new limits in terms of speed and accuracy.

However, the market faces significant restraints. The initial high cost associated with high-performance, large-aperture Galvo systems and their corresponding complex control electronics represents a barrier to entry for small and medium-sized enterprises (SMEs). Moreover, the requirement for highly specialized technical expertise for system integration, calibration, and maintenance limits broader adoption in developing regions. A critical technical restraint involves thermal management challenges, especially at high deflection speeds and high laser power, which can lead to mirror distortion and degradation of beam quality, necessitating complex cooling systems and advanced control algorithms to mitigate these effects.

The market is rich with opportunities, notably in the burgeoning fields of electric vehicle (EV) battery manufacturing, where precise laser welding and cutting of delicate materials are essential, and in the rapidly evolving augmented and virtual reality (AR/VR) sector, which requires miniature, high-speed Galvo mirrors for display projection systems. The development of micro-electromechanical systems (MEMS) based scanners offers a future opportunity for ultra-compact, cost-effective beam steering in portable and consumer applications, potentially disrupting the lower end of the conventional Galvo market. The overarching impact forces driving the market expansion include technological push from laser manufacturers and market pull from industries demanding automated, high-throughput manufacturing processes.

Segmentation Analysis

The Galvo Scanner Market is segmented based on critical technical and application parameters, providing a detailed understanding of market dynamics across various product categories and end-user industries. Segmentation by Type distinguishes between standard 2D systems, which operate on a single plane, and advanced 3D systems that incorporate dynamic focus modules to process complex surfaces, reflecting the shift toward intricate manufacturing requirements. Segmentation by Application highlights the dominance of industrial material processing, contrasting it with niche, high-value uses in medical imaging and defense. The analysis by Industry provides insight into consumer uptake, demonstrating the high dependence of the electronics and automotive sectors on these precise instruments.

- By Type:

- 2D Galvo Scanners (For planar processing)

- 3D Galvo Scanners (For volumetric and contoured processing, includes dynamic focus modules)

- High-Speed Galvo Scanners (Optimized for maximum speed and throughput)

- By Application:

- Laser Processing (Marking, Cutting, Welding, Drilling, Ablation)

- Medical/Biomedical (Ophthalmology, OCT, Surgical procedures)

- Display and Projection Systems (Micro-displays, Lidar, AR/VR)

- Scientific & Research

- By Industry Vertical:

- Electronics & Semiconductors

- Industrial Manufacturing (General, Aerospace, Automotive)

- Healthcare and Medical Devices

- Textiles and Packaging

- Defense and Military

- By Mirror Aperture:

- Small Aperture (<= 10 mm)

- Medium Aperture (10 mm to 30 mm)

- Large Aperture (> 30 mm)

Value Chain Analysis For Galvo Scanner Market

The value chain for the Galvo Scanner Market begins with upstream activities centered around the procurement and manufacturing of highly specialized components. This includes ultra-high-precision mirror blanks, often coated with specialized dielectric layers designed to withstand high-power laser irradiation, high-performance magnet components, and sophisticated servo control electronics (ASICs and digital signal processors). These suppliers are highly specialized, forming a critical bottleneck in terms of quality and supply stability. The midstream involves the core Galvo system manufacturers who integrate these components, focusing heavily on proprietary motor design, advanced thermal management solutions, and calibration software to achieve market-leading performance specifications. Differentiation at this stage relies heavily on patented control algorithms and overall system reliability under demanding operating conditions.

Downstream activities involve system integrators and distributors who combine the Galvo scanning head with the appropriate laser source (e.g., fiber, CO2, picosecond, femtosecond), focusing optics, safety enclosures, and industrial software packages to create complete, turnkey laser processing workstations. These integrators are crucial for customizing systems to meet specific end-user requirements, particularly in highly regulated fields like medical device manufacturing or aerospace. The distribution channel is characterized by a mix of direct sales channels, especially for high-volume or bespoke industrial solutions sold directly to large OEMs, and indirect distribution through specialized regional partners and resellers who provide local support, maintenance, and application expertise to smaller end-users.

The increasing complexity of laser processing necessitates a close relationship between Galvo manufacturers and system integrators to ensure optimal performance matching between the scanner, the laser source, and the specific application needs. Direct engagement allows manufacturers to gather crucial feedback regarding field performance and emerging technological requirements, accelerating product iteration. Indirect channels, while adding layers to the cost structure, are vital for market penetration into geographically diverse and highly fragmented SME markets, providing necessary localized engineering support which is a prerequisite for successful laser system implementation. Successful market penetration is increasingly reliant on comprehensive after-sales support and ongoing software updates.

Galvo Scanner Market Potential Customers

Potential customers for Galvo scanners are predominantly found across sectors that require rapid, repeatable, and non-contact material modification or beam manipulation at microscopic scales. The primary end-users/buyers include Original Equipment Manufacturers (OEMs) of laser processing machines, who integrate these scanners into their final product offerings sold to factories worldwide. These industrial customers range from multinational automotive tier-one suppliers needing high-speed marking for traceability and VIN etching, to aerospace manufacturers requiring highly accurate laser drilling and welding of turbine components. The demand is particularly acute among OEMs focused on next-generation manufacturing technologies.

The second major group comprises specialized R&D laboratories and academic institutions utilizing these systems for cutting-edge research in optics, material science, and quantum computing applications, where experimental setups demand extreme beam positioning stability and agility. Furthermore, the healthcare sector represents a high-value customer base, including medical device manufacturers requiring precision cutting of stents and catheters, and hospitals/clinics purchasing sophisticated ophthalmological or dermatological laser systems incorporating these high-speed deflection mechanisms. The critical nature of these applications mandates systems with superior reliability and strict adherence to certification standards, often leading to premium pricing.

Finally, the growing segment of electronics and semiconductor manufacturers constitutes a continuously expanding customer base. These firms utilize Galvo scanners for highly demanding processes such as laser trimming of resistors, stealth dicing of silicon wafers, and repair of photomasks. Given the fast-paced nature and stringent yield requirements of semiconductor fabrication, these customers prioritize maximum throughput and nanometer-level precision, often demanding custom-engineered, ultra-high-speed scanners. The migration of industrial clients toward automation and smart factory concepts ensures sustained demand across all these identified customer profiles, moving away from older, slower mechanical solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 950 million |

| Market Forecast in 2033 | USD 1.75 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCANLAB GmbH, Cambridge Technology (Novanta), Raylase GmbH, CTI (Cambridge Technology), Z-laser GmbH, Sunny Technology, Ams AG, SINO-GALVO, Osela Inc., Suzhou Ezd Laser, Aerotech Inc., Wuhan Golden Laser Co. Ltd., IPG Photonics Corporation (Select components), Nutfield Technology, Inc., Scaps GmbH, Laser Mechanisms, Inc., Shenzhen Chuangxin Laser Technology, Inc., Thorlabs, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Galvo Scanner Market Key Technology Landscape

The technology landscape of the Galvo Scanner market is dominated by advancements in electromagnetic motors, proprietary servo control loops, and specialized mirror fabrication. Core technology relies on high-torque, low-inertia motors—typically moving coil or moving magnet designs—to achieve extremely fast acceleration and settling times, measured in microseconds. A critical ongoing development is the refinement of digital servo control systems. These systems utilize advanced Proportional-Integral-Derivative (PID) controllers coupled with proprietary look-ahead algorithms and nonlinear control techniques to minimize tracking error and drift, ensuring beam positioning accuracy over millions of cycles. The use of high-resolution position sensors, often capacitive or optical encoders, provides nanoradian feedback, which is essential for maintaining precision in micromachining applications.

The move toward 3D processing is facilitated by the integration of dynamic focus units, often referred to as F-Theta lenses with moving elements or vari-focal optics (sometimes including additional mirror axes), which adjust the focal plane dynamically along the Z-axis in synchronization with the X-Y scanning motion. This technological capability allows for complex processing on curved or non-planar surfaces, drastically expanding the applicability of laser systems in additive manufacturing and intricate surface patterning. Material science plays a significant role in mirror technology, where substrates like beryllium or silicon carbide (SiC) are used for their high stiffness-to-weight ratio and excellent thermal conductivity. Specialized highly reflective dielectric coatings are applied to ensure minimal laser energy absorption, which is vital for preventing thermally induced mirror distortion, a primary inhibitor of precision in high-power applications.

Future technological advancements are heavily focused on leveraging miniaturization and integration. Micro-Electro-Mechanical Systems (MEMS) technology is emerging as a potential long-term disruptor, offering extremely small, high-frequency beam steering in compact packages suitable for portable devices and consumer electronics (e.g., Pico projection and Lidar). However, conventional Galvo systems remain superior in terms of aperture size and power handling capacity for industrial use. Furthermore, optimization of software for geometrical distortion correction and field-of-view calibration, alongside increased integration with AI for process monitoring and error compensation, defines the current competitive technology battlefield. Manufacturers are also developing modular designs that allow easy swapping of mirrors and compatibility with a wider range of laser wavelengths, enhancing system versatility and lowering total cost of ownership.

Regional Highlights

Regional dynamics play a crucial role in shaping the Galvo Scanner Market, with varying demand drivers and technological adoption rates across continents. Asia Pacific (APAC) dominates the global market, primarily driven by massive government investments in smart manufacturing infrastructure and the presence of world-leading electronics and automotive manufacturing hubs, particularly in China, South Korea, and Taiwan. The sheer volume of consumer electronics production necessitates high-speed laser marking, cutting, and welding, creating an unparalleled demand for standardized and customized Galvo systems.

North America is characterized by high adoption rates in specialized, high-value industries such as aerospace, defense, and advanced medical device manufacturing. The focus here is less on volume and more on precision, reliability, and compliance with stringent quality standards. This region drives demand for the most sophisticated, high-end 3D Galvo scanners and ultrashort pulse (USP) compatible systems, prioritizing performance over upfront cost. The presence of major R&D centers and leading technology innovators further solidifies North America’s position as a key innovation incubator for future Galvo technologies.

Europe represents a mature market with significant consumption in industrial manufacturing, particularly in Germany (precision engineering and automotive) and Switzerland (medical devices and watchmaking). European demand is strongly influenced by stringent quality control requirements and the pursuit of manufacturing efficiency through automation (Industry 4.0 initiatives). Western European companies are often pioneers in integrating advanced optics and complex software control, focusing heavily on reducing energy consumption and optimizing material yields through integrated laser systems.

Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but are exhibiting promising growth. This growth is linked to increasing industrialization and diversification of their economic bases. In MEA, investments in infrastructure projects and defense procurement drive demand. In Latin America, particularly Brazil and Mexico, the expansion of the automotive and packaging industries contributes to the gradual increase in the uptake of entry-level and mid-range Galvo marking systems.

- Asia Pacific (APAC): Dominant market share fueled by mass production in Electronics and Automotive; fastest growth trajectory due to expanding manufacturing capacity in China, Taiwan, and Vietnam.

- North America: Strong demand for high-end, 3D and USP-compatible scanners; driven by Aerospace, Defense, and Medical device manufacturing excellence.

- Europe: Mature market focusing on advanced automation (Industry 4.0); high adoption in precision engineering (Germany) and medical industries; emphasizes efficiency and quality compliance.

- Latin America: Emerging market driven by growth in regional automotive assembly and general industrial marking needs; gradual shift from mechanical to laser-based solutions.

- Middle East and Africa (MEA): Growth attributed to infrastructure investments and defense modernization programs requiring robust laser systems for material processing and identification.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Galvo Scanner Market.- SCANLAB GmbH

- Cambridge Technology (Novanta)

- Raylase GmbH

- CTI (Cambridge Technology)

- Z-laser GmbH

- Sunny Technology

- Ams AG

- SINO-GALVO

- Osela Inc.

- Suzhou Ezd Laser

- Aerotech Inc.

- Wuhan Golden Laser Co. Ltd.

- IPG Photonics Corporation (Select components)

- Nutfield Technology, Inc.

- Scaps GmbH

- Laser Mechanisms, Inc.

- Shenzhen Chuangxin Laser Technology, Inc.

- Thorlabs, Inc.

- Polaris Motion

- GSI Group (Acquired by Novanta)

Frequently Asked Questions

Analyze common user questions about the Galvo Scanner market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a Galvo scanner over traditional mechanical positioning systems?

The primary advantage is superior speed and dynamic response. Galvo scanners use low-inertia mirrors and high-performance servo motors to achieve beam positioning speeds thousands of times faster than mechanical stages, enabling high-throughput laser processing necessary for modern manufacturing.

How are 3D Galvo scanners different from standard 2D systems, and what are their main applications?

3D Galvo scanners incorporate dynamic focus mechanisms (often a third axis or moving lens element) that adjust the focal point along the Z-axis in real-time. This allows precise laser processing on curved, non-planar, or complex contoured surfaces, essential for applications like laser additive manufacturing and high-precision surface texturing.

Which industry vertical drives the highest demand for Galvo scanner technology?

The Electronics and Semiconductors industry drives the highest demand. This sector requires ultra-high precision for processes such as micro-drilling, laser trimming, marking of components, and specialized fabrication tasks where nanometer-level accuracy and repeatability are crucial for high yield.

What are the main challenges limiting the adoption of high-speed Galvo systems?

Key challenges include the high initial procurement cost of advanced, large-aperture systems, complexity in thermal management to prevent mirror distortion at high power levels, and the requirement for highly skilled technicians to perform precise system calibration and integration into complex manufacturing lines.

How is Artificial Intelligence (AI) influencing the next generation of Galvo scanners?

AI is transforming Galvo scanners by enabling real-time process optimization and predictive maintenance. AI algorithms analyze process feedback to dynamically adjust scanning parameters, maximizing efficiency and minimizing defects, while ML models predict component wear to improve operational uptime and reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager