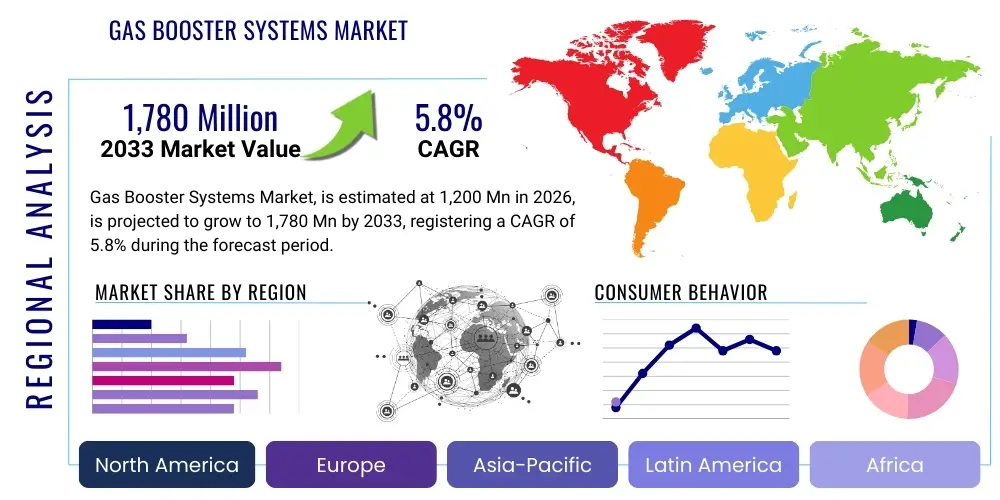

Gas Booster Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441034 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Gas Booster Systems Market Size

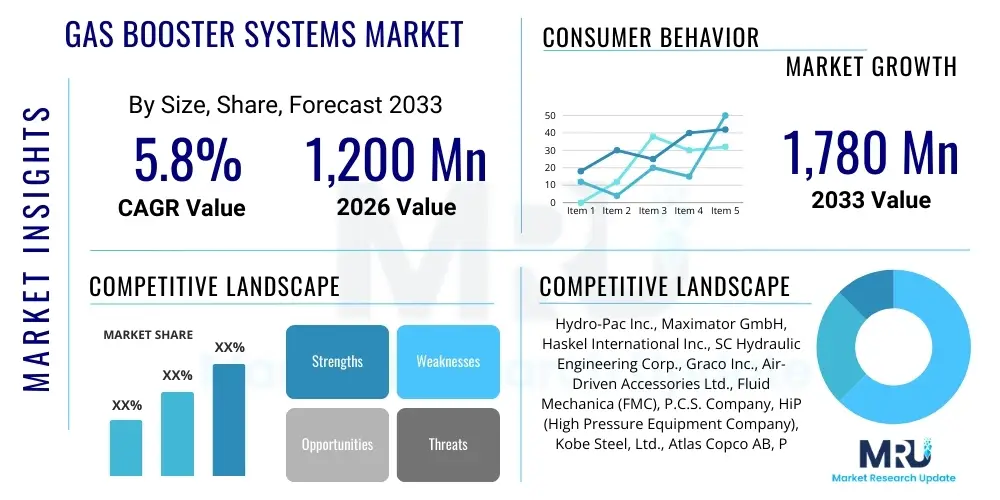

The Gas Booster Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1,200 Million in 2026 and is projected to reach USD 1,780 Million by the end of the forecast period in 2033.

Gas Booster Systems Market introduction

Gas booster systems are specialized mechanical devices designed to elevate the pressure of various gases, including air, nitrogen, hydrogen, helium, and argon, often reaching high pressures required for specific industrial processes, testing, and storage applications. These systems are crucial in scenarios where the existing supply pressure is insufficient for the intended use, necessitating an external mechanism to amplify kinetic energy into potential pressure energy. The fundamental product comprises a drive section, typically utilizing pneumatic, hydraulic, or electric power, coupled with a compression section. Unlike standard industrial compressors, gas boosters are engineered for high-pressure output relative to their footprint and are frequently employed in intermittent or low-flow, high-pressure demands, such as pressure testing vessels, charging accumulators, or supporting specialized gas mixing operations. The design emphasis is often on reliability, portability, and the ability to handle potentially hazardous or inert gases without contamination.

Major applications of gas booster systems span across critical industries. In the Oil and Gas sector, they are indispensable for pressure testing pipelines, well control equipment (BOPs), and specialized components, ensuring operational safety and integrity. The emerging Energy sector, particularly hydrogen infrastructure, relies heavily on high-pressure gas boosters (often diaphragm types) for efficiently dispensing hydrogen into fuel cell electric vehicles (FCEVs) and storing it in large-scale energy storage facilities. Furthermore, the defense and aerospace industries utilize these systems for charging components, simulating high-altitude environments, and operating pneumatic equipment. The core benefit derived from deploying gas booster systems is the ability to maximize the utility of existing low-pressure gas supplies, leading to significant cost savings compared to sourcing and managing high-pressure cylinders for all operational needs. They provide flexibility and localized pressure control necessary for precise industrial maneuvers.

The market is currently being driven by several macro-economic and technological factors. The global push toward sustainable energy, particularly the rapid expansion of hydrogen production and distribution networks, necessitates robust and reliable high-pressure boosting solutions. Simultaneously, stringent safety regulations across the industrial landscape—mandating frequent and high-integrity pressure testing in sectors like petrochemicals and manufacturing—are consistently driving demand for certified booster equipment. Technological advancements focusing on efficiency, such as the development of electric-driven boosters that offer superior energy management and quieter operation compared to traditional pneumatic models, are also contributing significantly to market expansion. Moreover, the increasing complexity of industrial automation and the need for higher throughput in manufacturing are spurring demand for multi-stage booster systems capable of achieving ultra-high pressures efficiently.

Gas Booster Systems Market Executive Summary

The Gas Booster Systems Market is undergoing significant evolution, primarily characterized by a shift towards electric and hydraulic drive technologies offering superior efficiency and control over traditional pneumatic boosters, especially in large-scale industrial applications and high-duty cycles. Business trends highlight strategic collaborations focused on developing booster solutions specifically tailored for niche markets, such as compressed natural gas (CNG) vehicle refueling and the nascent liquid natural gas (LNG) bunkering infrastructure, driving innovation in materials science for improved seal integrity and reduced maintenance. Furthermore, the integration of condition monitoring sensors and digital control platforms (SCADA integration) is enhancing operational predictability, moving the industry toward a predictive maintenance model, which is highly valued by large enterprise end-users seeking minimized downtime. Key market players are investing heavily in modular designs that allow for easy scalability and customization based on varying pressure and flow requirements.

Regionally, the market dynamics are highly disparate. Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive infrastructure development in China and India, coupled with aggressive investment in renewable energy projects that necessitate gas management solutions. North America remains a mature but resilient market, driven predominantly by the persistent needs of the Oil and Gas sector, particularly in hydraulic fracturing activities requiring consistent high-pressure nitrogen or natural gas injection capabilities. European market growth is concentrated around hydrogen mobility initiatives and strict environmental regulations pushing industries to adopt more energy-efficient compression methods. These regional trends underscore the diverse application needs, with APAC focusing on capacity expansion and infrastructure build-out, while North America and Europe emphasize technological refinement and regulatory compliance.

Segmentation trends indicate strong growth in the multi-stage booster segment, driven by applications requiring ultra-high pressures (above 20,000 psi), common in specialized defense and deep-sea exploration testing. By application, the Energy segment, encompassing hydrogen and fuel cell technologies, is projected to exhibit the highest CAGR due to global policy mandates supporting decarbonization. Conversely, the traditional Oil and Gas segment remains the largest volume consumer, demanding reliable pneumatic and hydraulic boosters for routine pressure testing and well services. The market structure remains moderately consolidated, with a few global leaders dominating the specialized high-pressure segment, while numerous smaller, regional players compete fiercely in standard industrial air boosting applications, often differentiating themselves through competitive pricing and rapid local service response times.

AI Impact Analysis on Gas Booster Systems Market

User inquiries regarding the application of Artificial Intelligence (AI) in the Gas Booster Systems Market predominantly center on optimizing operational expenditure (OpEx), enhancing system longevity, and improving overall safety margins. Key themes explored include the feasibility and ROI of integrating machine learning algorithms for predictive failure analysis, especially concerning critical components like seals, pistons, and valves which are subject to extreme wear under high pressure and temperature cycles. Users are keenly interested in how AI can move maintenance from scheduled outages to real-time, condition-based interventions, thus minimizing unexpected downtime which is costly in continuous process industries. Furthermore, concerns are raised regarding the data security implications of connecting operational technology (OT) systems—like booster controls—to cloud-based AI platforms, requiring robust cybersecurity solutions tailored for industrial environments. The expectation is that AI will eventually lead to fully autonomous operation, dynamically adjusting boost ratios based on instantaneous demand and optimizing energy consumption in real-time, creating a highly efficient, self-managing pressure generation infrastructure.

- AI enables highly accurate predictive maintenance scheduling by analyzing vibration, temperature, and pressure data streams, drastically reducing component failure rates.

- Optimization of energy consumption through real-time load balancing and dynamic operational parameter adjustment, crucial for large electric-driven systems.

- Enhanced operational safety by using machine learning models to identify and flag anomalous operational profiles indicative of potential catastrophic failures or leaks.

- Facilitation of remote monitoring and diagnostics, allowing manufacturers and service providers to troubleshoot complex issues without physical presence, improving service efficiency.

- Improved design cycles by simulating high-stress operational conditions and feeding performance data back into CAD/CAE models, accelerating product refinement.

DRO & Impact Forces Of Gas Booster Systems Market

The market for Gas Booster Systems is shaped by a complex interplay of drivers (D), restraints (R), opportunities (O), and resulting impact forces. A primary driver is the accelerating investment in hydrogen energy infrastructure globally, which mandates extremely high-pressure handling capabilities for refueling stations and storage solutions. Concurrently, stringent industrial safety regulations across developed economies are driving consistent demand for pressure testing equipment compliant with standards such as ASME and PED. However, the market faces significant restraints, chiefly the high initial capital expenditure associated with sophisticated, high-pressure, non-contaminating booster systems, alongside the technical challenge of maintaining seal integrity and minimizing wear in corrosive or high-temperature environments. Opportunities lie in the customization of modular, compact booster systems suitable for mobile applications and the integration of IoT for remote diagnostics, catering to field operations in remote regions.

The convergence of these factors exerts specific impact forces. The growing need for non-contaminating compression methods (e.g., diaphragm boosters for pure gases) is forcing technological innovation in materials science and manufacturing precision. Increased complexity and high operational pressures necessitate highly trained technical staff, creating a demand-side pressure for suppliers to offer comprehensive training and long-term service agreements. The regulatory landscape acts as a dual force: while it drives demand for compliant testing equipment, it also increases the barrier to entry for new market players due to required certifications and adherence to diverse national standards. Ultimately, the market trajectory is strongly influenced by global energy policy shifts, particularly the move away from traditional fossil fuels toward cleaner energy vectors like hydrogen, solidifying the booster system as a vital component in the energy transition.

Segmentation Analysis

The Gas Booster Systems Market is strategically segmented based on factors relating to the mechanism of operation, the maximum pressure output required, the type of gas being handled, and the ultimate end-use application. Understanding these segmentations is crucial for market participants to tailor product offerings and marketing strategies effectively. The core differentiation often relies on the drive mechanism (pneumatic, electric, hydraulic), which determines the system’s portability, efficiency, and duty cycle capabilities. Further segmentation by stage configuration (single versus multi-stage) reflects the achievable pressure ratio and efficiency requirements, with multi-stage boosters dominating the ultra-high-pressure (>30,000 psi) market niche. The application segmentation provides insight into where the highest volume and highest value transactions occur, linking directly to capital spending trends in key industrial sectors.

- By Drive Type:

- Pneumatic Driven

- Electric Driven

- Hydraulic Driven

- By Stage Type:

- Single Stage

- Multi-Stage

- By Gas Type:

- Air

- Nitrogen

- Hydrogen

- Argon/Helium

- Other Industrial Gases

- By Application:

- Oil and Gas (Well Testing, BOP Control, Pressure Testing)

- Energy (Hydrogen Refueling Stations, Fuel Cell Testing, Natural Gas)

- Automotive and Aerospace (Component Testing, Simulation)

- Defense and Military

- Industrial Manufacturing (Pressurization, Material Handling)

- By Pressure Range:

- Low Pressure (Up to 5,000 psi)

- Medium Pressure (5,000 psi to 20,000 psi)

- High Pressure (Above 20,000 psi)

Value Chain Analysis For Gas Booster Systems Market

The value chain for the Gas Booster Systems Market begins with the sourcing of specialized raw materials and components, which include high-grade stainless steel for cylinder bodies, precision-machined piston and plunger sets, and critical sealing materials (e.g., PTFE, proprietary elastomer compounds) engineered to withstand extreme pressures and chemical compatibility requirements. Upstream analysis reveals reliance on suppliers of high-quality drives (pneumatic motors, electric motors, hydraulic pumps) and advanced control systems (PLCs, sensors). The manufacturing stage involves precision engineering, assembly, and rigorous testing—often including hydrostatic and gas pressure tests—to ensure compliance with international safety and performance standards (CE, ASME, ATEX). Due to the demanding nature of the final application, quality control and material traceability are paramount throughout the production process.

Downstream analysis focuses on distribution channels and end-user engagement. The distribution channel is segmented into direct sales, often utilized for highly specialized, custom-engineered high-pressure systems sold to major Oil and Gas operators or national defense entities, and indirect sales, where standard booster systems are supplied through a network of certified distributors, system integrators, and specialized industrial equipment resellers. These indirect channels provide localized support, spare parts inventory, and necessary integration services for smaller and medium-sized enterprises (SMEs). The aftermarket services, including maintenance contracts, spare parts sales, and system upgrades, constitute a significant and high-margin segment of the downstream value chain, often handled directly by the original equipment manufacturer (OEM) or a certified service network.

The efficiency of the value chain is highly dependent on managing inventory for specialized components and ensuring a smooth transition between manufacturing and highly technical field installation. Due to the high cost and complexity of the product, procurement decisions are often centralized and long-term, driven by criteria such as mean time between failures (MTBF), total cost of ownership (TCO), and the manufacturer's global service footprint. The transition toward electric-driven and IoT-enabled boosters is subtly shifting value from purely hardware production toward software integration and data analytics services within the downstream segment, requiring continuous training for sales and service teams to maintain technical expertise.

Gas Booster Systems Market Potential Customers

The primary end-users and buyers of Gas Booster Systems are entities that require precise, scalable, or intermittent high-pressure gas capabilities to support their core operations, testing regimes, or infrastructure development. In the traditional sense, major consumers include global oilfield service companies and exploration & production (E&P) firms that necessitate high-pressure testing units for blowout preventers (BOPs), wellhead components, and subsea equipment. Similarly, industrial manufacturing giants, particularly those involved in producing pressure vessels, specialized piping, and advanced material components, constitute a major customer base requiring systems for cyclic pressure testing and quality assurance purposes. These buyers prioritize reliability, safety certifications, and robust construction capable of surviving harsh operational environments.

A rapidly expanding customer base is found within the emerging energy ecosystem. This includes developers and operators of hydrogen production facilities, transmission pipelines, and retail refueling stations, all of whom rely on diaphragm and piston boosters to achieve the standardized 700 bar (10,000 psi) fill pressures required for FCEVs. Utility companies managing natural gas storage or peak shaving facilities also employ high-capacity boosters. Furthermore, government and defense agencies are key customers, using specialized, ruggedized boosters for missile component testing, aircraft tire inflation, and charging highly specialized inert gas systems vital for operational readiness. The diversity of the end-user landscape necessitates manufacturers to offer a broad portfolio, ranging from small, portable pneumatic bench-top units to large, skid-mounted, continuous-duty electric booster stations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,200 Million |

| Market Forecast in 2033 | USD 1,780 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hydro-Pac Inc., Maximator GmbH, Haskel International Inc., SC Hydraulic Engineering Corp., Graco Inc., Air-Driven Accessories Ltd., Fluid Mechanica (FMC), P.C.S. Company, HiP (High Pressure Equipment Company), Kobe Steel, Ltd., Atlas Copco AB, Parker Hannifin Corporation, Ingersoll Rand, Rix Industries, Pressure Technologies plc, GILL Sensors & Controls Ltd., Teledyne Technologies Incorporated, Fluitron, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Booster Systems Market Key Technology Landscape

The Gas Booster Systems market is characterized by several competing and specialized technological approaches designed to meet varying application requirements, particularly concerning purity, pressure, and flow rates. Piston-type boosters, which utilize reciprocating motion to increase gas pressure, remain the workhorse for high-flow, general industrial applications like air or nitrogen boosting. However, the rapidly growing demand for ultra-pure gases, especially hydrogen, is driving the widespread adoption of Diaphragm Booster Technology. Diaphragm boosters employ a flexing membrane that physically isolates the gas being compressed from the drive mechanism and potential lubricants, ensuring zero contamination. This non-contaminating feature is crucial for sectors like fuel cells and specialized chemical processing. Innovations in diaphragm material science, such as the use of advanced metallic alloys and ceramics, are extending their lifespan and pressure handling capabilities.

Furthermore, the drive mechanism itself is a focus of technological innovation. While pneumatic boosters are valued for their intrinsic safety in hazardous environments (ATEX compliance) and low capital cost, they suffer from lower energy efficiency and require a separate compressed air supply. Consequently, there is a clear trend toward high-efficiency Electric-Driven Boosters, especially for continuous duty cycles and large-scale infrastructure projects. These electric systems integrate variable frequency drives (VFDs) and sophisticated motor controls to optimize energy consumption based on real-time pressure demands, offering significant operational cost savings over the equipment's lifespan. The shift also facilitates easier integration with industrial IoT (IIoT) platforms for remote monitoring and diagnostics.

Another crucial technological element is the development of robust Sealing Technology and advanced component materials. At pressures exceeding 20,000 psi, traditional seals degrade rapidly. Market leaders are investing in proprietary sealing systems, often incorporating high-performance polymers and specialized surface treatments to minimize friction, heat generation, and wear. The integration of advanced sensor technology for monitoring temperature, vibration, and acoustic emissions is becoming standard, forming the foundation for predictive maintenance programs. This technological evolution aims not only to boost performance metrics but also to ensure compliance with increasingly strict safety and operational standards across all high-pressure applications globally.

Regional Highlights

The Gas Booster Systems Market exhibits distinct regional consumption patterns, heavily influenced by industrial infrastructure maturity, energy policies, and regulatory environments.

- North America (NA): Characterized by a mature and highly demanding Oil and Gas sector, particularly in the US and Canada. NA represents a significant market for hydraulic and pneumatic boosters used in fracking, well testing, and subsea component control. Furthermore, early adoption of high-pressure hydrogen infrastructure and stringent regulatory mandates for safety testing ensure consistent demand for sophisticated, certified systems.

- Europe: The European market is highly focused on innovation and sustainability. Demand is rapidly transitioning toward electric-driven boosters for high energy efficiency and is strongly fueled by the European Union’s commitment to the hydrogen economy. Countries like Germany and the Netherlands are key hubs for research, manufacturing, and deployment of specialized diaphragm boosters for hydrogen refueling stations and industrial gas applications compliant with PED and ATEX directives.

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by rapid industrialization, massive investments in infrastructure (pipelines, manufacturing plants), and substantial government funding for renewable energy, especially in China, Japan, and South Korea. The market here is volume-driven, with strong demand across all segments, from standard air boosting in manufacturing to high-pressure nitrogen systems for electronics production.

- Middle East and Africa (MEA): Dominated by large-scale oil and gas operations and chemical processing facilities. The MEA market emphasizes robust, heavy-duty booster systems capable of continuous operation in harsh climatic conditions, primarily driven by upstream pressure testing and enhanced oil recovery (EOR) operations utilizing gas injection.

- Latin America (LATAM): Growth is primarily linked to recovering oil and gas production cycles in countries like Brazil and Mexico. The market often favors cost-effective, reliable pneumatic solutions, although investments in renewable energy and specialized industrial gases are beginning to drive demand for modern, highly efficient technologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Booster Systems Market.- Hydro-Pac Inc.

- Maximator GmbH

- Haskel International Inc.

- SC Hydraulic Engineering Corp.

- Graco Inc.

- Air-Driven Accessories Ltd.

- Fluid Mechanica (FMC)

- P.C.S. Company

- HiP (High Pressure Equipment Company)

- Kobe Steel, Ltd.

- Atlas Copco AB

- Parker Hannifin Corporation

- Ingersoll Rand

- Rix Industries

- Pressure Technologies plc

- GILL Sensors & Controls Ltd.

- Teledyne Technologies Incorporated

- Fluitron, Inc.

- SMC Corporation

- Suncenter Fluid Control Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Gas Booster Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a gas compressor and a gas booster system?

A gas compressor is designed to handle large volumes of gas over continuous operating cycles and typically achieves medium pressures. Conversely, a gas booster is engineered to take a low-pressure gas input and raise it to extremely high pressures, often operating in intermittent or high-ratio pressure applications where flow is secondary to the maximum pressure achieved.

Which drive type is most efficient for continuous, large-scale boosting operations?

Electric-driven gas booster systems are generally the most energy-efficient for continuous, large-scale industrial operations. They offer superior control via Variable Frequency Drives (VFDs) and avoid the energy losses inherent in requiring a separate compressed air supply, unlike pneumatic boosters.

Why are diaphragm boosters essential for the hydrogen energy sector?

Diaphragm boosters are essential for the hydrogen sector because they provide non-contaminating compression. The gas is isolated from the mechanical drive system and lubricants by a metal diaphragm, ensuring the ultra-high purity required for sensitive applications like fuel cells and high-pressure storage remains uncompromised.

What are the main factors driving the high capital cost of gas booster systems?

The high capital cost results from the necessity of using specialized, high-strength materials (e.g., hardened stainless steel) and precision engineering to withstand extreme internal pressures (often exceeding 30,000 psi). Additionally, sophisticated sealing technology and rigorous certification requirements (e.g., ATEX, ASME) contribute significantly to the upfront investment.

How is AI improving the reliability and operational lifespan of gas booster systems?

AI improves reliability by enabling predictive maintenance. Machine learning algorithms analyze real-time operational data—such as vibration and thermal profiles—to detect minute anomalies, predicting component failures (like seal degradation) long before they occur, thereby maximizing uptime and extending the system's operational lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager