Gas Turbine Generators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441168 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Gas Turbine Generators Market Size

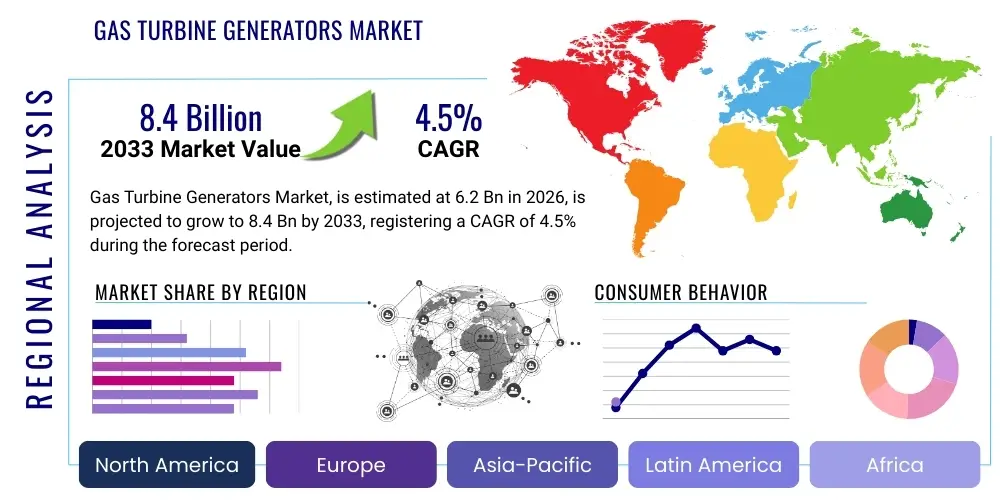

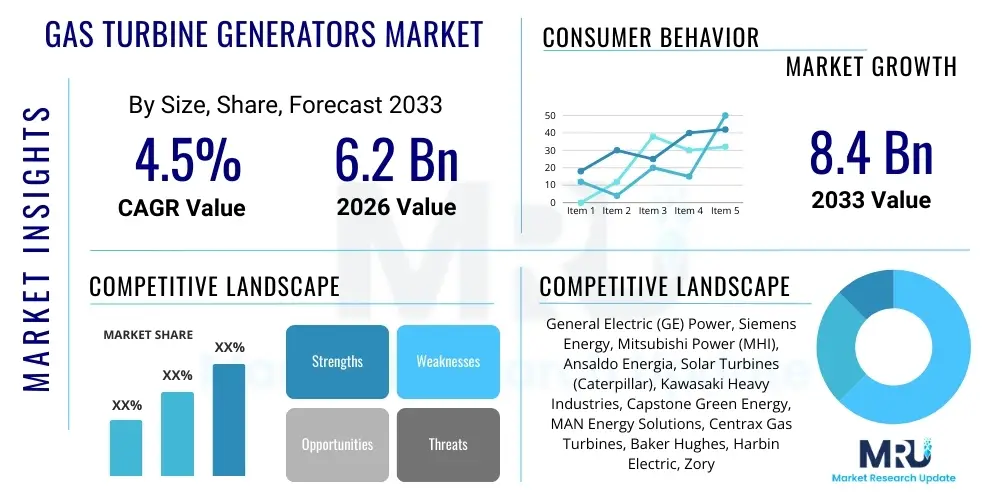

The Gas Turbine Generators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 6.2 Billion in 2026 and is projected to reach USD 8.4 Billion by the end of the forecast period in 2033.

Gas Turbine Generators Market introduction

The Gas Turbine Generators Market encompasses the production, distribution, and utilization of sophisticated power generation systems that convert natural gas or other liquid fuels into mechanical energy to drive an electrical generator. These systems are critical components within the global energy infrastructure, valued for their high power density, operational flexibility, and relatively quick start-up times compared to traditional steam turbines. Gas turbines function on the Brayton cycle, involving compression, combustion, and expansion stages, resulting in efficient, large-scale power output. Their core product definition revolves around the integration of the turbine section, the compressor, the combustor, and the coupling mechanism to the generator, forming a cohesive power block essential for both continuous duty and peaking power applications in various industrial and utility settings worldwide.

Major applications of Gas Turbine Generators span across several high-demand sectors, including centralized utility power generation plants, independent power producers (IPPs), and critical industrial operations such as oil and gas extraction, refining, and petrochemical processing. Furthermore, gas turbines are increasingly deployed in combined cycle power plants (CCPP), where waste heat is recovered to produce additional electricity through a steam turbine, significantly boosting overall thermal efficiency and reducing fuel consumption per unit of electricity generated. The robustness and scalability of these generators make them ideal for regions undergoing rapid industrialization and requiring flexible, reliable base-load or intermediate-load power, especially in areas where natural gas infrastructure is well-developed and accessible for sustained operation.

The primary benefits driving the adoption of modern Gas Turbine Generators include enhanced operational efficiency, lower carbon footprint compared to coal-fired alternatives, rapid responsiveness to grid fluctuations, and reduced capital expenditure per unit of power generation in certain large-scale deployments. Key market driving factors are fundamentally linked to global energy transitions, the increasing penetration of intermittent renewable energy sources (which necessitates flexible backup power), ongoing infrastructure modernization efforts in developed economies, and substantial governmental investments in natural gas pipeline and storage infrastructure across emerging markets. Technological advancements, particularly in metallurgy and thermal barrier coatings, are continually improving the firing temperatures and efficiency ratings of new turbine models, further propelling market growth and replacement cycles.

Gas Turbine Generators Market Executive Summary

The Gas Turbine Generators Market is currently characterized by intense competition driven by technological advancements aimed at improving thermal efficiency, reducing NOx emissions, and increasing operational flexibility, particularly regarding fuel types and cycling capabilities. Business trends highlight a strong focus on long-term service agreements (LTSAs) and digital solutions, utilizing AI and IoT platforms for predictive maintenance and optimized performance management, thereby ensuring minimal downtime and maximizing asset utilization for operators. Key manufacturers are strategically investing in hybrid power solutions, integrating gas turbines with battery storage and solar arrays to offer highly resilient and modular power generation packages that cater to decentralized energy needs and grid stabilization requirements in increasingly complex energy landscapes. Furthermore, the industry is witnessing mergers, acquisitions, and strategic partnerships, primarily aimed at consolidating market share, accessing specialized component technologies, and expanding geographical reach, particularly into rapidly growing Asian power markets.

Regionally, the market exhibits divergent growth trajectories. North America and Europe, characterized by aging infrastructure and stringent environmental regulations, are focusing on replacement cycles, modernization of existing fleets with higher-efficiency models, and adopting gas turbines as crucial enablers of renewable energy integration through flexible peaking power capabilities. Conversely, the Asia Pacific (APAC) region, spearheaded by economies like China, India, and Southeast Asia, represents the fastest-growing segment, driven by surging electricity demand stemming from population growth, rapid urbanization, and massive industrial expansion. These emerging markets are prioritizing the construction of large combined cycle power plants to meet base-load demands reliably, leveraging readily available and relatively inexpensive natural gas resources as a transitional fuel in their path toward decarbonization goals, making APAC the epicenter of new installation activity.

Segmentation trends reveal significant shifts across various product classes and end-user segments. In terms of capacity, the Heavy Duty segment (greater than 100 MW) maintains the largest market share due to its indispensable role in utility-scale centralized power generation, focusing on maximizing efficiency and scale economies. However, the Aeroderivative segment (typically 1 to 50 MW) is gaining momentum due to its superior flexibility, high power-to-weight ratio, and rapid deployment capabilities, making it ideal for distributed generation, emergency power, and offshore applications. End-user dominance remains with the Utility Sector, but the Oil & Gas industry and various manufacturing sectors are robust consumers, requiring reliable cogeneration solutions (Combined Heat and Power, or CHP) to simultaneously meet electricity and thermal energy requirements, thereby boosting overall energy economics and operational stability within their complex facilities.

AI Impact Analysis on Gas Turbine Generators Market

User queries regarding the impact of Artificial Intelligence (AI) on the Gas Turbine Generators Market overwhelmingly center on themes related to predictive maintenance, performance optimization, and autonomous operation. Common questions address how AI can reduce unscheduled downtime, increase the time between major inspections (TMIs), and optimize fuel consumption under various load profiles and environmental conditions. Users are particularly keen on understanding the financial return on investment (ROI) associated with implementing machine learning models for anomaly detection and root cause analysis in complex turbine components, such as blades and combustors. Furthermore, there is significant interest in how AI algorithms can enhance the operational flexibility required to manage the increasingly volatile grid, where turbines must ramp up and down quickly to compensate for fluctuating solar and wind generation, ensuring system stability while minimizing mechanical stress and component degradation.

The adoption of AI-driven platforms, often integrated with the Industrial Internet of Things (IIoT), is fundamentally transforming the operational lifecycle of Gas Turbine Generators, shifting maintenance philosophy from time-based scheduling to condition-based and predictive strategies. These advanced systems utilize vast datasets gathered from hundreds of sensors monitoring temperature, vibration, pressure, and exhaust gases. Machine learning models process this data in real-time to identify subtle deviations from normal operational envelopes, flagging potential failures days or weeks before they manifest critically. This proactive approach significantly extends asset life, maximizes availability, and drastically reduces the high costs associated with emergency repairs and forced outages, which are particularly detrimental in high-capital, high-utilization power generation assets like large gas turbines.

Furthermore, AI is instrumental in optimizing the performance parameters of the combustion process, leading to improvements in heat rate (efficiency) and adherence to strict environmental regulations regarding NOx and CO emissions. Generative AI and advanced computational fluid dynamics (CFD) simulations, informed by operational feedback loops, are being used in the design phase to create more efficient blade geometries and combustor designs optimized for various fuel mixtures, including hydrogen co-firing. This integration of AI across design, operation, and maintenance cycles ensures that new and existing Gas Turbine Generator fleets can operate closer to their theoretical maximum efficiency while simultaneously reducing their environmental footprint, thereby sustaining the relevance of gas power generation in a rapidly evolving, decarbonizing energy sector.

- Implementation of predictive analytics for condition-based monitoring, reducing unexpected failures.

- Optimization of combustion parameters using machine learning to maximize efficiency and minimize emissions.

- AI-driven automated dispatch and load-following capabilities for enhanced grid flexibility and stability.

- Development of digital twins for real-time simulation and lifespan prediction of critical turbine components.

- Automated diagnostics and root cause analysis, shortening troubleshooting and repair times during outages.

- Enhanced cybersecurity measures for interconnected IIoT infrastructure supporting remote turbine operations.

DRO & Impact Forces Of Gas Turbine Generators Market

The dynamics of the Gas Turbine Generators Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the fundamental Impact Forces determining market trajectory. The foremost driver is the unwavering global demand for reliable electricity, especially in emerging economies requiring large-scale, consistent base-load power to support industrial growth and rising living standards. The necessity for grid modernization in developed nations, requiring highly flexible power sources to balance the massive influx of intermittent renewable energy, further accelerates demand for fast-ramping gas turbines. Conversely, the market is restrained primarily by the global imperative for deep decarbonization and climate mitigation, which increasingly pressures utilities to transition away from all fossil fuels, including natural gas, favoring zero-emission sources like wind and solar, creating long-term regulatory uncertainty for gas infrastructure investments. This pressure is compounded by the high initial capital investment required for installing utility-scale gas turbine facilities, presenting a significant barrier to entry in some capital-constrained markets.

Opportunities within this market are strongly tied to technological adaptation and fuel flexibility. The substantial potential of hydrogen co-firing and 100% hydrogen capability in next-generation gas turbines represents a massive commercial opportunity, positioning gas power as a viable, low-carbon bridging solution compatible with future clean energy standards. Furthermore, the expansion of distributed generation (DG) and microgrid infrastructure creates demand for smaller, highly efficient aeroderivative turbines capable of providing localized power and resiliency, particularly valuable in industrial parks and critical infrastructure settings, offering immunity from widespread grid failures. The strategic focus on upgrading and repowering existing coal-fired power plants with advanced, high-efficiency combined cycle gas turbines (CCGT) is another lucrative pathway, providing a quick, cost-effective method to reduce regional carbon intensity while maintaining essential generation capacity.

The synthesized impact forces demonstrate a market under sustained, dual pressure: robust short-to-medium term demand driven by energy security and renewable balancing needs, contrasted with long-term headwinds from climate policy and renewable energy costs rapidly declining. The market's success hinges on manufacturers’ ability to rapidly commercialize technologies that mitigate the climate constraint, such as hydrogen readiness and advanced carbon capture integration. Geopolitical stability affecting natural gas supply chains also acts as a critical external impact force, influencing fuel price volatility and the economic viability of gas-fired generation projects. Ultimately, policy decisions related to carbon pricing mechanisms and infrastructural support for gas transportation will heavily dictate the pace and nature of market expansion over the forecast period, emphasizing flexibility and environmental performance as key competitive differentiators.

Segmentation Analysis

The Gas Turbine Generators Market is meticulously segmented based on Capacity, Technology, Application, and Fuel Type, providing a structured framework for analyzing market dynamics, competitive positioning, and consumer behavior across various operational contexts. Capacity segmentation, typically divided into Heavy Duty, Medium Duty, and Aeroderivative, dictates the primary end-use (utility vs. industrial) and deployment scale, reflecting the economic requirements of centralized versus decentralized power generation. Technology categories differentiate between simple cycle and combined cycle architectures, impacting thermal efficiency and initial setup complexity. The detailed segmentation allows market players to tailor product development and sales strategies to specific regional infrastructure needs and regulatory environments, ensuring optimal resource allocation and maximum market penetration in high-growth segments globally.

The application-based segmentation reveals the critical reliance of key economic sectors, particularly Electric Power Generation and the Oil & Gas industry, on reliable gas turbine technology for both motive power and electricity production. Furthermore, the segmentation by Fuel Type, encompassing natural gas, LNG, and diesel/other liquids, highlights regional dependency on fuel availability and transportation infrastructure, influencing technology choices and operational costs for utilities and industrial consumers alike. This comprehensive segmentation structure is crucial for accurate market forecasting, allowing stakeholders to identify niche opportunities, such as the growing demand for smaller, modular systems in distributed energy networks or the specialized requirements of marine propulsion and industrial heat applications.

- By Capacity:

- Heavy Duty (> 100 MW)

- Medium Duty (50 MW – 100 MW)

- Aeroderivative (1 MW – 50 MW)

- By Technology:

- Simple Cycle

- Combined Cycle

- Combined Heat and Power (CHP/Cogeneration)

- By Application:

- Electric Power Generation (Utility and IPP)

- Oil & Gas (Upstream, Midstream, Downstream)

- Industrial (Manufacturing, Chemicals, Metallurgy)

- Marine

- By Fuel Type:

- Natural Gas

- Liquefied Natural Gas (LNG)

- Liquid Fuels (Diesel, Kerosene)

- Alternative Fuels (Hydrogen, Biogas – emerging)

Value Chain Analysis For Gas Turbine Generators Market

The value chain for the Gas Turbine Generators Market begins with upstream activities focused on the procurement and processing of highly specialized raw materials and complex components, which dictates final product quality and manufacturing costs. This initial phase involves the acquisition of high-strength, temperature-resistant superalloys (nickel, cobalt, titanium) essential for manufacturing hot gas path components like turbine blades and vanes, as these components must withstand extreme thermal and mechanical stresses during operation. Key upstream suppliers include specialized metallurgy companies, precision casting and forging firms, and advanced electronics providers for control systems. The efficiency of the upstream supply chain is critical; disruptions in the supply of critical materials can severely impact lead times and inflate manufacturing expenses, emphasizing the need for robust vendor relationships and resilient material sourcing strategies, often globally distributed to mitigate geopolitical risks and sourcing constraints.

The core manufacturing and assembly phase constitutes the central segment of the value chain, where core components (compressors, combustors, turbines) are engineered, fabricated, and integrated with the generator and auxiliary systems. This stage is dominated by a few global Original Equipment Manufacturers (OEMs) who invest heavily in R&D to optimize thermal efficiency, reduce emissions, and increase operational flexibility, relying heavily on advanced robotics, numerical control machining, and sophisticated quality assurance processes. Following manufacturing, the distribution channel for Gas Turbine Generators is predominantly a direct sales model for large utility-scale units, involving complex contractual negotiations, detailed project management, and specialized logistics for the transportation of multi-ton components. For smaller, standard units, indirect channels through authorized distributors or system integrators may be utilized, especially in niche industrial or commercial applications, requiring specialized engineering support for installation and commissioning.

Downstream activities are primarily focused on the installation, commissioning, operation, and maintenance (O&M) lifecycle of the installed base. The long operating life of gas turbines (often 20+ years) means the O&M phase, supported by long-term service agreements (LTSAs), constitutes a significant revenue stream and profit center for OEMs. This downstream reliance necessitates a strong global service network capable of rapid response, parts replacement, and technical expertise, often leveraging digital platforms for remote monitoring and predictive diagnostics. The end-users (utilities, IPPs, industrial entities) are crucial downstream stakeholders; their operational requirements and fuel choices ultimately validate the product design and determine the necessary maintenance intensity. The shift toward outcome-based contracts and integrated energy solutions is enhancing the coupling between OEMs and downstream operators, making service capability a key competitive differentiator across the entire value chain.

Gas Turbine Generators Market Potential Customers

The primary and most significant segment of end-users for the Gas Turbine Generators Market is the global Electric Power Generation sector, which encompasses governmental utilities, privately-owned integrated power companies, and independent power producers (IPPs). These entities utilize gas turbine generators, particularly those in the Heavy Duty and Combined Cycle configurations, for large-scale, consistent base-load power supply and crucial intermediate-load generation to meet peak consumer demand periods. As these customers face increasing regulatory pressure to integrate renewables while maintaining grid stability, they rely on the flexible and rapid-start capabilities of modern gas turbines as indispensable complements to intermittent energy sources. Investment decisions within this customer base are driven by factors such as long-term fuel price forecasts, regulatory emission standards, system reliability requirements, and the desire for maximum thermal efficiency to optimize operational expenses over decades of use.

A second major category of potential customers includes large industrial entities and commercial facilities requiring both electricity and substantial process heat, making them ideal candidates for Combined Heat and Power (CHP) or cogeneration systems utilizing gas turbines. The Oil & Gas industry, spanning upstream drilling and production, midstream pipeline compression and LNG liquefaction, and downstream refining and petrochemical processing, is a particularly intensive user. In these sectors, gas turbines provide reliable mechanical drive for compressors and pumps, alongside essential on-site electricity generation, often utilizing process gas as fuel, thereby enhancing energy self-sufficiency and operational resilience in remote or critical environments. Other key industrial buyers include large manufacturing plants, chemical complexes, and mining operations that require reliable, high-power density generation to ensure continuous operation and avoid costly production interruptions.

Furthermore, specialized end-users represent high-value, albeit smaller, segments for specialized Gas Turbine Generators, predominantly aeroderivative models. This includes the marine sector, where high power-to-weight ratios are essential for naval vessels and certain high-speed commercial ships, and the military/defense sector, requiring resilient, mobile, and reliable emergency power solutions. Additionally, the growing focus on energy resilience is driving demand from critical infrastructure facilities, such as data centers and large hospitals, which utilize gas turbines for standby and black start capabilities, ensuring continuity of mission-critical operations even during major grid failures. These specialized segments prioritize operational availability, footprint minimization, and the capability to run on diverse liquid or gaseous fuels, often dictating bespoke engineering solutions from turbine manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.2 Billion |

| Market Forecast in 2033 | USD 8.4 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | General Electric (GE) Power, Siemens Energy, Mitsubishi Power (MHI), Ansaldo Energia, Solar Turbines (Caterpillar), Kawasaki Heavy Industries, Capstone Green Energy, MAN Energy Solutions, Centrax Gas Turbines, Baker Hughes, Harbin Electric, Zorya-Mashproekt, Wärtsilä, Vericor Power Systems, OPRA Turbines, Hindustan Aeronautics Limited (HAL), MTU Aero Engines. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Turbine Generators Market Key Technology Landscape

The contemporary technology landscape of the Gas Turbine Generators Market is dominated by relentless innovation focused on increasing firing temperatures and achieving near-zero emissions, leveraging advancements in material science and combustion physics. A primary technological focus is the development and commercialization of advanced class (H-Class and J-Class) turbines, which utilize highly complex cooling schemes and superior thermal barrier coatings to operate at extreme temperatures (over 1500°C). These higher operating temperatures directly translate into significantly higher thermal efficiency—often exceeding 64% in combined cycle configurations—setting new benchmarks for fuel economy and power output. Furthermore, the integration of 3D printing (additive manufacturing) is revolutionizing the production of complex components like fuel nozzles and hot gas path parts, enabling rapid prototyping of innovative designs and facilitating the repair and overhaul of existing fleet assets with superior component quality and reduced lead times.

A second critical technological pillar is the evolution of combustor technology aimed at achieving ultra-low emissions, particularly regarding nitrogen oxides (NOx), even under transient load conditions. Dry Low NOx (DLN) and catalytic combustion systems are standard, but the future lies in developing burners capable of efficiently handling hydrogen blended fuels, often up to 50% or even 100% volume in the gas stream, without requiring substantial hardware modification or compromising operational reliability. This "hydrogen-ready" capacity is a major investment area, driven by the need to future-proof gas-fired power generation assets against aggressive decarbonization mandates. Successful implementation requires precise control over the flame stability and temperature distribution within the combustor, demanding sophisticated computational modeling and advanced control algorithms to ensure safe and compliant operation across varying fuel compositions.

The digitalization of turbine operations through integrated control systems and remote monitoring technologies constitutes the third key element transforming the market. Modern gas turbine systems are equipped with integrated control panels utilizing predictive algorithms and machine learning (as discussed in the AI section) to manage start-up sequences, optimize load following, and coordinate maintenance activities. This technological integration extends to robust fault detection systems and automated performance diagnostics, minimizing human intervention and maximizing the turbine’s operational envelope. The continued refinement of these digital solutions, combined with improvements in rotor dynamics, bearing technology, and air intake filtration systems, ensures the Gas Turbine Generator remains a reliable, high-performance asset capable of operating efficiently in diverse and challenging environmental conditions worldwide, maintaining its competitive edge over other fossil-fuel alternatives.

Regional Highlights

- Asia Pacific (APAC): APAC is the primary engine of global market growth, driven by massive requirements for new power capacity, especially in India, China, and Southeast Asian nations like Vietnam and Indonesia. The region’s rapid industrialization and urbanization fuel strong demand for large-scale combined cycle power plants (CCPP). Abundant natural gas supplies (often imported LNG) and relatively less stringent legacy environmental regulations compared to Western counterparts make gas turbines a favorable choice for reliable, large-scale generation. Investment is robust, often involving joint ventures between local utilities and international OEMs, focusing heavily on Heavy Duty (>100 MW) capacity installations to meet soaring energy needs efficiently.

- North America: This region is defined by infrastructure modernization and the necessity for grid stability in the face of burgeoning renewable energy penetration. The market is mature, leading to strong demand for replacement of older, less efficient units with advanced H-Class and J-Class turbines. North America leads in the deployment of fast-ramping aeroderivative turbines for peaking power and distributed generation, crucial for managing solar and wind intermittency. Policy trends, particularly in the US, favoring natural gas as a transition fuel, sustain significant investment in pipeline capacity and new combined cycle facilities, balancing environmental goals with energy security.

- Europe: Europe represents a highly regulated and efficiency-focused market, characterized by stringent emission standards and a pronounced long-term shift away from all fossil fuels. The demand here is centered on high-efficiency repowering projects, adopting state-of-the-art CCGT technology, and the development of small-scale, decentralized gas turbines for urban CHP applications. European OEMs are pioneering hydrogen-ready turbine technology, driven by aggressive national decarbonization targets, making this region a crucial hub for next-generation, low-carbon gas turbine R&D and pilot projects aimed at 100% green gas utilization.

- Middle East and Africa (MEA): The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is a historical stronghold for Gas Turbine Generators due to vast, indigenous natural gas reserves and rapidly increasing domestic power demand driven by extreme climate control requirements and industrial expansion. The region relies heavily on gas turbines for utility power and essential processes in the oil and gas sector (e.g., desalination plants). Investments focus on integrating renewable energy with flexible gas capacity and ensuring stable power supply for massive, rapidly growing urban centers, often requiring highly robust turbines capable of operating reliably in high heat and dust environments.

- Latin America: This region presents moderate, yet steady, growth driven by infrastructure deficits and the necessity to diversify the energy mix away from often unreliable hydroelectric power, especially during drought cycles. Countries like Brazil, Mexico, and Argentina are investing in new gas-fired capacity to ensure energy security and provide a stable base load. Market activity is project-specific, often dependent on local governmental financial stability and international financing for large-scale energy infrastructure developments, prioritizing reliability and proven operational track records in challenging geographical terrains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Turbine Generators Market.- General Electric (GE) Power

- Siemens Energy

- Mitsubishi Power (MHI)

- Ansaldo Energia

- Solar Turbines (Caterpillar)

- Kawasaki Heavy Industries

- Baker Hughes

- MAN Energy Solutions

- Centrax Gas Turbines

- Capstone Green Energy

- Wärtsilä

- Zorya-Mashproekt

- Harbin Electric

- Rolls-Royce plc

- Vericor Power Systems

- OPRA Turbines

- Bharat Heavy Electricals Limited (BHEL)

- Dresser-Rand (Siemens Energy Company)

- MTU Aero Engines

- Hindustan Aeronautics Limited (HAL)

Frequently Asked Questions

Analyze common user questions about the Gas Turbine Generators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving current investment in Gas Turbine Generators globally?

The primary factor driving current global investment is the critical need for flexible, high-reliability power generation assets to effectively balance the increasing integration of intermittent renewable energy sources, such as wind and solar, onto national power grids. Gas turbines offer rapid start-up and ramping capabilities essential for grid stability.

How are environmental regulations impacting the design and adoption of new gas turbines?

Environmental regulations, particularly those concerning CO2 and NOx emissions, are forcing manufacturers to prioritize high-efficiency Combined Cycle Gas Turbine (CCGT) technologies and invest heavily in hydrogen-ready combustor systems. The adoption curve favors turbines capable of utilizing green or low-carbon fuels to meet future decarbonization targets.

What role does the aeroderivative segment play in the overall Gas Turbine Generators Market?

The aeroderivative segment, typically ranging from 1 MW to 50 MW, plays a crucial role in providing distributed generation, peaking power, and mechanical drive for oil and gas operations. Their light weight, high power-to-weight ratio, and ability to start quickly make them essential for enhancing grid resiliency and for critical industrial applications.

Which geographical region is expected to demonstrate the highest growth rate for new installations?

The Asia Pacific (APAC) region, specifically emerging economies like India and Southeast Asia, is projected to demonstrate the highest growth rate for new Gas Turbine Generator installations. This growth is directly attributable to massive, rising electricity demand driven by urbanization, industrial expansion, and the need for reliable centralized power infrastructure.

How is AI fundamentally changing the operation and maintenance of gas turbine fleets?

AI is transforming O&M by enabling predictive maintenance through real-time data analytics and machine learning. This shifts service from scheduled inspections to condition-based monitoring, optimizing operational cycles, increasing time between overhauls, reducing unscheduled downtime, and maximizing overall asset utilization and efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager