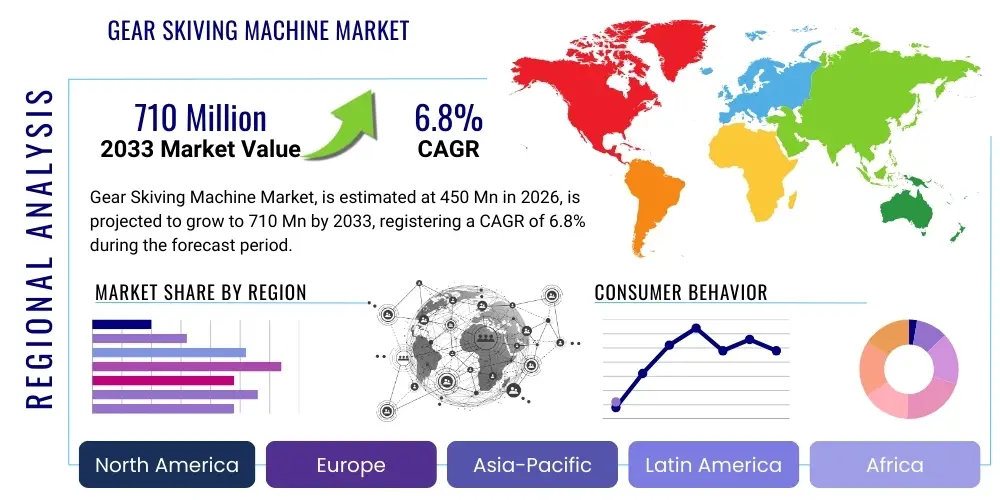

Gear Skiving Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442017 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Gear Skiving Machine Market Size

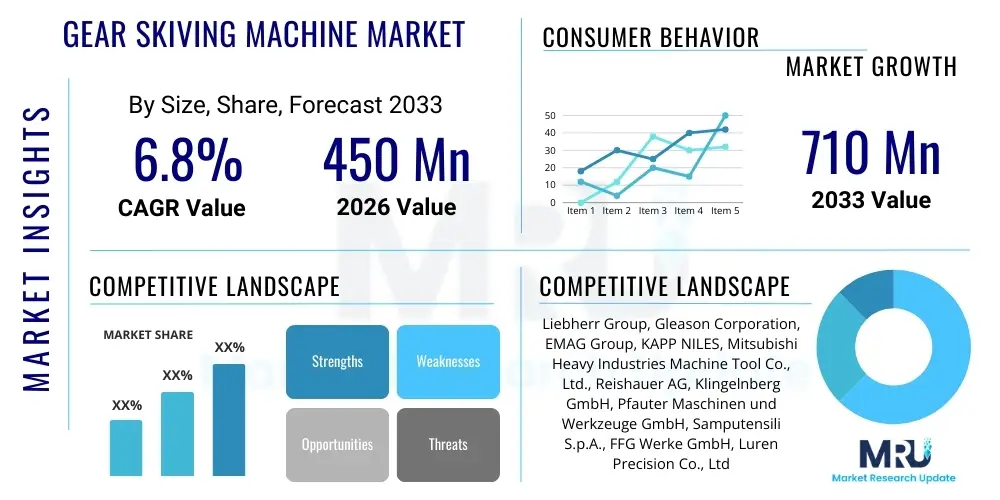

The Gear Skiving Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033. This steady expansion is largely attributable to the increasing demand for high-precision gears, particularly within the rapidly evolving automotive sector, where stringent noise, vibration, and harshness (NVH) requirements necessitate superior finishing processes.

The specialized nature of gear skiving—which combines the principles of gear hobbing and shaping—allows for the efficient manufacturing of internal gears and complex profile components that are difficult or impossible to produce using traditional methods. The capital intensity of these machines, coupled with the precision they offer, places them primarily in high-volume production environments, driving sustained growth in industrialized economies and emerging manufacturing hubs. Furthermore, the longevity and reduced cycle times provided by modern Computer Numerical Control (CNC) gear skiving systems contribute significantly to their rising adoption across various end-use industries.

Gear Skiving Machine Market introduction

The Gear Skiving Machine Market encompasses the sale, installation, and servicing of specialized machine tools designed for generating gear profiles through a synchronized, continuous cutting process. Gear skiving is fundamentally a generating process where two helical gears, the cutter and the workpiece, are meshed together, and the cutter, featuring relief angles, simultaneously rotates and traverses the workpiece, removing material efficiently. This technique is especially critical for manufacturing internal gears, cluster gears, and components requiring complex geometries or large batch production with superior surface finish and accuracy.

Major applications for gear skiving machines span across key industrial verticals, including automotive transmission systems (especially in electric vehicles (EVs) and hybrid vehicles where lightweight and quiet operation are paramount), aerospace components (requiring extremely high precision and reliability), heavy machinery, and industrial robotics. The primary benefit of gear skiving over traditional methods like shaping or hobbing lies in its significantly reduced cycle times, high productivity rates, and the ability to produce highly accurate, distortion-free components efficiently, often eliminating the need for subsequent grinding processes in specific applications. These advantages position gear skiving as a cornerstone technology for modern high-volume gear manufacturing.

Key driving factors accelerating the market's growth include the global transition towards advanced mobility solutions, demanding more complex and quieter gear trains. Furthermore, the integration of automation and Industry 4.0 standards into gear manufacturing facilities is boosting the attractiveness of highly precise, repeatable CNC skiving machines. Continuous innovation in tooling materials and machine rigidities allows for faster cutting speeds and extended tool life, making skiving a more economically viable choice for manufacturers facing intense global competition and strict quality mandates.

Gear Skiving Machine Market Executive Summary

The Gear Skiving Machine Market is experiencing robust growth driven by foundational shifts in the automotive and industrial machinery sectors, characterized by a heightened need for precision and throughput. Business trends indicate a strong move toward highly automated, multi-axis CNC machines capable of handling diverse materials and complex geometries, reflecting manufacturers' focus on integrating flexible production systems. Key players are heavily investing in developing hybrid machines that combine skiving with other processes like milling or grinding, aiming to reduce handling time and improve overall component accuracy in a single setup. Supply chain resilience, following recent global disruptions, is also a critical focus, leading to strategic partnerships between machine manufacturers and specialized tooling suppliers to ensure optimal performance and reduced downtime.

Regional trends reveal Asia Pacific (APAC), particularly China, Japan, and South Korea, as the dominant and fastest-growing region, fueled by massive investments in EV manufacturing and industrial automation infrastructure. North America and Europe maintain stable demand, primarily driven by the aerospace and defense industries, which require ultra-high precision gearing, and by the replacement cycle of older, less efficient machinery. Emerging markets in Latin America and MEA are showing increasing potential as localized automotive assembly and heavy industrial projects gain momentum, creating a latent demand for efficient gear production technologies.

Segment trends highlight the dominance of the CNC Gear Skiving Machine segment due to superior control, repeatability, and ease of integration into automated production lines. In terms of application, the Automotive segment remains the largest consumer, though the Industrial Machinery and Robotics segment is projected to exhibit the highest CAGR as global efforts toward advanced automation accelerate. The market is also seeing segmentation based on automation level, with fully automated loading/unloading systems gaining significant traction to maximize production efficiency and reduce reliance on manual intervention, addressing chronic labor shortages in developed economies.

AI Impact Analysis on Gear Skiving Machine Market

User queries regarding AI's influence in the gear skiving domain primarily revolve around three themes: process optimization, predictive maintenance, and quality assurance. Users frequently ask how AI can refine cutting parameters in real-time to maximize tool life and surface finish, and whether AI-driven sensor data analysis can prevent catastrophic machine failures. Furthermore, there is strong interest in utilizing machine learning algorithms for defect classification and geometric error prediction, moving quality control from post-process inspection to in-process monitoring. The consensus expectation is that AI integration will transform gear skiving from a highly empirical process, reliant on operator experience, into a data-driven, fully optimized manufacturing system, significantly reducing scrap rates and improving overall equipment effectiveness (OEE).

- Enhanced Predictive Maintenance: AI algorithms analyze vibration, temperature, and current data from machine spindles and tool holders to predict tool wear and component failure, minimizing unplanned downtime.

- Real-Time Parameter Optimization: Machine learning models continuously adjust skiving speeds, feeds, and depth of cut based on material properties and measured surface finish to optimize cycle time and extend tooling longevity.

- In-Process Quality Control: AI-powered vision systems and acoustic sensors monitor the cutting process for anomalies, flagging potential defects immediately, thus ensuring zero-defect manufacturing standards.

- Digital Twin Integration: AI enhances digital twins of gear skiving machines, allowing complex process simulations and testing of new gear geometries or tooling strategies virtually before physical implementation.

- Automation and Setup Reduction: AI assists in rapid program generation and automatic calibration of multi-axis machines, drastically reducing setup times for switching between different gear types.

DRO & Impact Forces Of Gear Skiving Machine Market

The market dynamics of gear skiving machines are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO). A primary driver is the accelerating demand from the Electric Vehicle (EV) industry, where precision-machined, quiet, and highly efficient gears are fundamental to mitigating powertrain noise (NVH). Traditional gear manufacturing methods often fall short of the stringent requirements necessary for silent, high-speed EV transmissions, pushing manufacturers toward advanced solutions like gear skiving. Additionally, the global push toward industrial automation and robotics, which rely on highly precise planetary gearboxes and harmonic drives, further fuels the adoption of these specialized machine tools.

Conversely, significant restraints limit the market's trajectory. Gear skiving machines represent a substantial capital investment, often prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the technology requires highly skilled technicians and operators for optimal setup, programming, and maintenance, creating a dependency on specialized labor which is increasingly scarce globally. Tooling costs are also high, and the specialized nature of the skiving cutters means that sourcing and lead times can be complex, adding operational rigidity for manufacturers.

The primary opportunities lie in the continuous development of process software and integrated metrology solutions, which simplify machine operation and enable closed-loop manufacturing. The market can also capitalize on the growing adoption of hybrid machines that combine skiving with other processes, streamlining the production floor. The impact forces—ranging from regulatory mandates for efficiency to competitive pressures for faster time-to-market—collectively push the industry towards more automated, precise, and economically sustainable gear production methods, ensuring gear skiving remains a central technology in high-end manufacturing.

Segmentation Analysis

The Gear Skiving Machine Market is comprehensively segmented based on machine type, technology, application, and level of automation, providing manufacturers and end-users with tailored solutions that address specific production volume and precision requirements. Machine type segmentation, covering internal and external gear skiving, highlights the specialized capability of the technology to efficiently handle complex internal geometries critical for planetary gear sets used in automotive and aerospace transmissions. Technology-based segmentation, differentiating between CNC (Computer Numerical Control) and Conventional machines, clearly demonstrates the industry’s overwhelming shift toward highly precise, multi-axis CNC systems that facilitate rapid setup changes and superior process control, aligning with Industry 4.0 paradigms. The application segment remains dominated by the automotive industry, which requires massive volumes of high-quality gears, but significant growth is anticipated in the robotics and heavy machinery sectors, reflecting global automation trends. Automation level, ranging from manual loading to fully integrated robotic cells, dictates the productivity and labor intensity of the system, with full automation becoming the standard in high-wage economies.

- By Machine Type:

- Internal Gear Skiving Machines

- External Gear Skiving Machines

- By Technology:

- CNC Gear Skiving Machines

- Conventional Gear Skiving Machines

- By Application:

- Automotive (Passenger Cars, Commercial Vehicles, EVs)

- Aerospace and Defense

- Industrial Machinery and Equipment

- Robotics and Automation

- Other Heavy Machinery

- By Automation Level:

- Manual Loading Systems

- Semi-Automatic Systems

- Fully Automated Systems (Robotic Integration)

- By End-Use Industry:

- Transmission Manufacturers

- OEMs

- Tier 1 and Tier 2 Component Suppliers

Value Chain Analysis For Gear Skiving Machine Market

The value chain for the Gear Skiving Machine Market begins with upstream activities focused on raw material suppliers, predominantly providers of high-grade steel, cast iron, and complex electronic components necessary for machine construction. This upstream segment also includes specialized suppliers of ultra-hard tooling materials, such as High-Speed Steel (HSS) and various carbide grades, which are crucial for the skiving cutter's performance and longevity. Machine tool manufacturers constitute the core segment, involving sophisticated R&D for developing high-precision CNC controls, highly rigid machine frames, and specialized skiving kinematic software. Differentiation at this stage relies heavily on engineering expertise, intellectual property regarding cutter design, and the ability to integrate advanced sensor technology for process monitoring.

Midstream activities involve the distribution channel, which is often a blend of direct and indirect sales. Direct sales are typically preferred for large, customized, or highly complex machine orders, ensuring close communication between the manufacturer and the end-user for installation, training, and maintenance contracts. Indirect distribution relies on regional distributors and authorized agents, particularly in geographically dispersed markets or for standard machine models, leveraging local expertise in sales and after-sales service. These intermediaries play a vital role in providing immediate technical support and local inventory, thereby reducing lead times for consumable tooling and parts.

The downstream segment centers on the end-users—the component manufacturers who utilize these machines to produce high-precision gears for applications like automotive transmissions or aerospace actuators. The value chain extends through after-sales support, including software updates, technical consulting for process optimization, preventative maintenance services, and the crucial supply of specialized skiving tooling. The success of the machine manufacturer is intrinsically linked to the ongoing performance and reliability provided to the end-user, making long-term service contracts and accessible, high-quality tooling supply critical components of the total value proposition.

Gear Skiving Machine Market Potential Customers

The primary consumers and end-users of gear skiving machines are large-scale component manufacturers and original equipment manufacturers (OEMs) operating in sectors demanding high volumes of precision-engineered gear components. The automotive industry represents the largest buyer base, encompassing traditional powertrain manufacturers transitioning to advanced automatic transmissions, as well as new electric vehicle (EV) manufacturers focused on reducing gear noise and increasing efficiency through superior gear finishing. These customers prioritize high throughput, minimal cycle times, and the ability to integrate machines seamlessly into highly automated production lines. They require machines capable of producing complex internal gears and cluster gears with strict tolerance adherence, often necessitated by regulatory standards for fuel efficiency and vehicle performance.

Beyond the automotive sector, potential customers include Tier 1 and Tier 2 suppliers specializing in the production of gear assemblies for industrial applications, such as heavy machinery, mining equipment, and construction vehicles. These buyers often prioritize machine rigidity and durability to handle larger, coarser-pitch gears and continuous operation cycles. The aerospace and defense industries represent a niche but highly valuable customer segment, demanding machines with the highest level of precision and metrology capabilities for mission-critical components, where material integrity and geometric accuracy are paramount, often justifying premium pricing for specialized, ultra-high-end skiving solutions. Robotics and general automation manufacturers are also rapidly emerging customers, requiring high-precision components for harmonic drives and servo gearboxes used in articulated robots, further broadening the market's customer base.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Liebherr Group, Gleason Corporation, EMAG Group, KAPP NILES, Mitsubishi Heavy Industries Machine Tool Co., Ltd., Reishauer AG, Klingelnberg GmbH, Pfauter Maschinen und Werkzeuge GmbH, Samputensili S.p.A., FFG Werke GmbH, Luren Precision Co., Ltd., Murata Machinery, Ltd., Pittler T&S GmbH, Schiess GmbH, Taiwan Takisawa Technology Co., Ltd., Sicmat S.p.A., Bourn & Koch Inc., HMT Machine Tools Limited, Qinchuan Machine Tool Group, DVS Technology Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gear Skiving Machine Market Key Technology Landscape

The technological evolution within the Gear Skiving Machine Market is characterized by a strong convergence of mechanical precision and digital control. Modern machines predominantly feature multi-axis CNC technology, often 5-axis or more, which allows for highly synchronized movements between the cutter spindle and the workpiece spindle. This synchronization is critical to the skiving process, requiring advanced control algorithms to maintain the precise helix angle and geometry. Key technological advancements center on developing highly rigid machine structures, often utilizing polymer concrete bases, to dampen vibrations and enable high-speed cutting parameters while maintaining nanometer-level precision, directly impacting the final quality of the gear surface finish and profile accuracy.

Furthermore, significant focus is placed on tooling technology and optimization software. Specialized skiving cutters, made from advanced materials and featuring complex geometries, are essential components, and continuous research is dedicated to applying high-performance coatings (like TiN or AlTiN) to extend tool life and improve thermal stability during dry cutting operations, which are often favored for environmental and cost reasons. The integration of closed-loop manufacturing systems is also a major trend, where in-situ metrology sensors measure the gear profile immediately after machining, feeding correction data back to the CNC control unit to compensate for thermal drift or tool wear in real-time. This sophisticated interplay between hardware, tooling, and software significantly distinguishes leading market players.

The integration of Industry 4.0 principles, including the Internet of Things (IoT) and smart manufacturing, is transforming the technological landscape. Machines are now equipped with extensive sensor packages monitoring parameters such as torque, vibration, temperature, and acoustic emissions. This sensor data facilitates advanced monitoring for predictive maintenance programs and offers valuable insights for process improvement. The ability to network these machines globally and analyze production data centrally allows manufacturers to achieve true optimization across multiple facilities, boosting overall operational efficiency and reducing total cost of ownership (TCO) for these complex capital goods.

Regional Highlights

- Asia Pacific (APAC): This region dominates the global market share and is projected to register the highest growth rate, primarily driven by China, Japan, and South Korea. The rapid expansion of EV manufacturing bases in these countries, coupled with massive government investments in industrial automation and smart factories, creates an unparalleled demand for high-speed, precision gear manufacturing capabilities. Japan and South Korea also maintain strong leadership in high-end machine tool technology and advanced robotics, sustaining local market demand.

- Europe: Europe represents a mature but highly sophisticated market, driven by the strong presence of automotive OEMs (especially premium and luxury vehicles) and a robust aerospace industry (e.g., Germany, Italy, France). The demand here centers on high-precision, low-volume machines and flexible production systems capable of manufacturing complex, prototype, or specialized gear components while adhering to strict environmental and quality standards.

- North America: Market growth in North America is stable, spurred primarily by the defense, aerospace, and heavy industrial machinery sectors. The resurgence of domestic manufacturing and initiatives focusing on supply chain resilience have increased investments in advanced manufacturing technologies, with a strong emphasis on integrating automation and digital solutions like AI-driven process optimization into gear production facilities.

- Latin America (LATAM): This region is characterized by steady, incremental growth, supported by localized automotive assembly operations (e.g., Brazil, Mexico). The market demand is predominantly for reliable, mid-range CNC skiving machines that offer improved productivity compared to older shaping technology, focusing on cost-efficiency and regional market responsiveness.

- Middle East and Africa (MEA): Currently the smallest market segment, MEA exhibits potential for future growth tied to planned investments in large-scale infrastructure projects, oil and gas extraction machinery maintenance, and diversification efforts into localized manufacturing capabilities, particularly in countries like Saudi Arabia and the UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gear Skiving Machine Market.- Liebherr Group

- Gleason Corporation

- EMAG Group

- KAPP NILES

- Mitsubishi Heavy Industries Machine Tool Co., Ltd.

- Reishauer AG

- Klingelnberg GmbH

- Pfauter Maschinen und Werkzeuge GmbH

- Samputensili S.p.A.

- FFG Werke GmbH

- Luren Precision Co., Ltd.

- Murata Machinery, Ltd.

- Pittler T&S GmbH

- Schiess GmbH

- Taiwan Takisawa Technology Co., Ltd.

- Sicmat S.p.A.

- Bourn & Koch Inc.

- HMT Machine Tools Limited

- Qinchuan Machine Tool Group

- DVS Technology Group

Frequently Asked Questions

Analyze common user questions about the Gear Skiving Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of gear skiving over traditional hobbing or shaping?

Gear skiving offers significantly reduced cycle times and superior surface finishes, especially for internal gears and cluster gears, which are challenging for hobbing. Skiving's continuous generating process is faster and produces highly accurate profiles with less distortion, often eliminating the need for post-machining grinding.

How is the electric vehicle (EV) industry influencing the demand for gear skiving machines?

The EV industry requires highly precise, high-quality gears with low noise characteristics (NVH) to compensate for the absence of engine noise. Gear skiving machines meet this critical requirement by producing complex, highly accurate internal and external helical gears essential for quiet and efficient EV transmissions, thus driving significant market demand.

Which geographic region currently dominates the global Gear Skiving Machine Market?

The Asia Pacific (APAC) region, driven primarily by manufacturing powerhouses like China, Japan, and South Korea, holds the largest market share. This dominance is due to extensive automotive production, particularly in EV components, and robust investments in industrial automation and advanced machinery.

What are the main financial barriers to entry in the Gear Skiving Machine Market for smaller manufacturers?

The chief financial barrier is the high initial capital investment required for modern, multi-axis CNC gear skiving machines. Additionally, the recurring costs associated with specialized skiving tooling and the need for highly skilled technical labor increase the operational expenses, limiting accessibility for small and medium-sized enterprises (SMEs).

How do technological developments like Industry 4.0 and AI integrate with gear skiving processes?

Industry 4.0 and AI integration enable smart manufacturing through sensor-driven data collection. This facilitates predictive maintenance to prevent downtime, allows for real-time optimization of cutting parameters (feeds and speeds) to maximize tool life, and provides closed-loop quality control through in-process metrology, thereby enhancing overall machine efficiency and part consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager