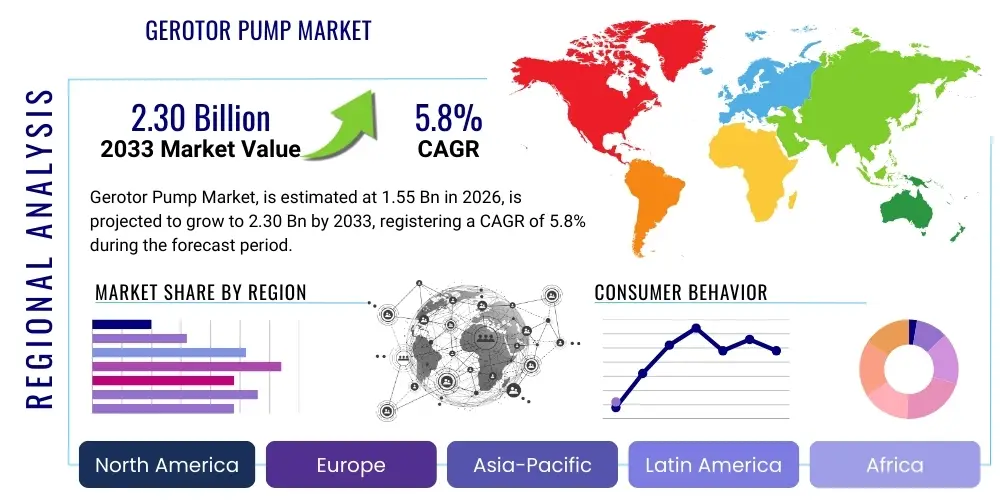

Gerotor Pump Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442985 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Gerotor Pump Market Size

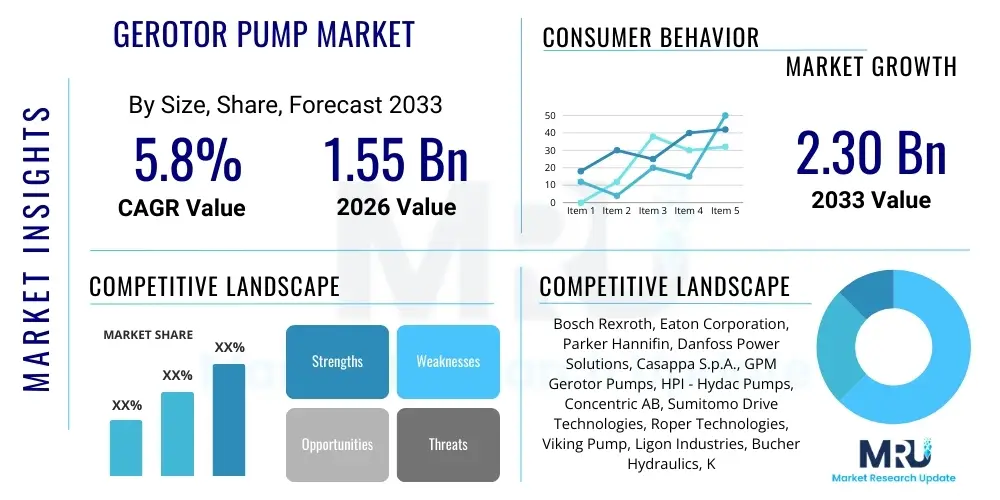

The Gerotor Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.55 Billion in 2026 and is projected to reach $2.30 Billion by the end of the forecast period in 2033.

Gerotor Pump Market introduction

The Gerotor Pump Market encompasses a specialized segment within positive displacement pumps, characterized by its unique design involving an inner rotor with N teeth and an outer rotor with N+1 teeth. This configuration allows for high-efficiency fluid transfer, exceptional volumetric performance, and compact packaging. Gerotor pumps are predominantly utilized in applications requiring reliable, continuous, and often high-pressure fluid delivery, such as lubrication systems, fuel delivery, and hydraulic power units. Their inherent design provides smooth, pulsation-free flow, making them ideal for sensitive mechanical systems and high-speed rotary equipment.

Product descriptions typically highlight the pump's robustness, low noise operation, and ability to handle fluids with varying viscosities. Key major applications span across the automotive industry, particularly in engine oil and transmission fluid circulation; aerospace and defense, where lightweight and reliable hydraulic actuation is critical; and industrial machinery, serving cooling and filtration circuits. The operational mechanism ensures low shear stress on the transferred fluid, preserving fluid integrity over extended periods, which is a significant advantage in demanding industrial settings. This versatility and efficiency solidify their position as essential components in modern mechanical systems.

The primary driving factors for market growth include the escalating demand for highly efficient, compact fluid power solutions in electric and hybrid vehicles, stringent environmental regulations necessitating precise lubrication and fuel metering, and the ongoing expansion of industrial automation globally. Furthermore, the inherent benefits of gerotor pumps—including their simple construction, minimal maintenance requirements, and long operational lifespan—make them an increasingly preferred choice over traditional gear or vane pumps in many high-performance and space-constrained applications. Technological advancements focusing on optimizing material composition for enhanced wear resistance and improved volumetric efficiency are further stimulating market adoption across emerging industrial sectors.

Gerotor Pump Market Executive Summary

The Gerotor Pump Market is demonstrating strong momentum, driven primarily by robust business trends in the automotive and aerospace sectors, coupled with increasing industrial automation adoption worldwide. Key business trends indicate a shift towards customization and the integration of smart pumping solutions featuring embedded sensors for predictive maintenance and real-time performance monitoring. Manufacturers are focusing on reducing the pump footprint while maximizing pressure capability and efficiency, catering to the growing need for compact machinery. Strategic collaborations and mergers among component suppliers and system integrators are reshaping the competitive landscape, aiming to offer integrated fluid management systems rather than standalone pump units.

Regionally, Asia Pacific is forecasted to exhibit the highest growth rates, fueled by massive investments in automotive manufacturing, particularly in China and India, and rapid industrialization across Southeast Asian nations. North America and Europe maintain a mature market presence, characterized by high demand for precision and high-specification pumps for aerospace and advanced manufacturing applications, emphasizing regulatory compliance and technological innovation. Trends across regions are segment-specific; for instance, the demand for powder metallurgy-based gerotors is surging in high-volume production areas due to cost-effectiveness, while specialized materials like PEEK composites are gaining traction in chemical and medical sectors for compatibility and inertness.

Segmentation trends highlight the dominance of the oil pump segment by application, owing to the massive installed base in internal combustion engines (ICEs) and increasing adoption in electric vehicle (EV) thermal management systems. By design, external gerotor pumps are witnessing renewed interest in high-pressure hydraulic circuits, while internal gerotors remain the staple for lubrication. The market is also seeing polarization based on material, with steel and cast iron dominating heavy machinery, and aluminum/advanced composites capturing lightweight and electric vehicle niches. Overall, the market trajectory is highly positive, underpinned by innovation aimed at efficiency, durability, and integration into complex mechatronic systems.

AI Impact Analysis on Gerotor Pump Market

Common user inquiries regarding AI's influence on the Gerotor Pump Market typically revolve around three major themes: predictive maintenance, design optimization, and operational efficiency improvements. Users are keenly interested in how machine learning algorithms can analyze vast datasets from pump sensors—including pressure, temperature, vibration, and flow rate—to predict potential failures before they occur, thereby minimizing downtime and maximizing asset lifespan. Another frequent query concerns the role of generative design and topology optimization, enabled by AI, in creating lighter, more efficient, and structurally superior gerotor profiles, moving beyond traditional fluid dynamics modeling. Finally, users seek clarification on how AI-driven process control systems can optimize pump performance in real-time, adapting to changing fluid characteristics or load demands, especially in complex industrial networked environments.

The core concerns center on the necessary infrastructure investment (sensors, cloud computing, data pipelines), the cybersecurity risks associated with integrating smart components, and the standardization required for interoperability across different manufacturers’ systems. Expectations are high, anticipating a paradigm shift from routine, time-based maintenance schedules to highly accurate condition-based monitoring. This transition is expected to drastically reduce total cost of ownership (TCO) for end-users and introduce new value propositions for pump manufacturers based on service contracts and performance guarantees rather than merely component sales. AI’s ability to handle the non-linear relationship between pump wear, fluid contamination, and performance degradation is particularly valued in high-stakes applications like aerospace and high-speed manufacturing.

Ultimately, AI is not viewed as replacing the mechanical function of the gerotor pump but as augmenting its intelligence and reliability. The integration of AI/ML models is transitioning the gerotor pump from a passive mechanical component to an active, connected device within the Industrial Internet of Things (IIoT). This transformative impact extends from the factory floor, where production quality can be monitored and adjusted instantly using vision systems and predictive analytics, to the design phase, where iterative optimizations driven by neural networks lead to patented, proprietary rotor geometries offering superior efficiency curves. Manufacturers investing early in these capabilities are positioning themselves as leaders in the next generation of fluid power technology.

- AI-driven Predictive Maintenance: Utilizing ML algorithms on vibration and temperature data to forecast component failure, reducing unplanned downtime by up to 30%.

- Generative Design Optimization: Employing AI to iterate and refine rotor profiles for maximized volumetric and overall efficiency, optimizing flow path geometry.

- Real-Time Performance Tuning: Implementing closed-loop control systems using reinforcement learning to adjust pump speed and displacement based on instantaneous system requirements.

- Manufacturing Quality Control: Using AI-powered vision systems for high-speed inspection of gerotor tolerances during production, ensuring zero-defect output.

- Supply Chain Resilience: Applying predictive analytics to manage inventory levels of critical raw materials and components, optimizing production schedules.

DRO & Impact Forces Of Gerotor Pump Market

The dynamics of the Gerotor Pump Market are shaped by a confluence of accelerating drivers, structural restraints, compelling opportunities, and powerful impact forces that influence market adoption and trajectory. Key drivers include the global expansion of the automotive sector, specifically the transition to electric vehicles (EVs) which require sophisticated thermal management and lubrication systems relying heavily on compact gerotor designs. Additionally, the industrial sector's continuous pursuit of energy efficiency mandates the replacement of older, less efficient pumping technologies with modern, high-precision gerotor alternatives. These technological drivers provide consistent upward pressure on market demand, particularly in applications requiring silent operation and long service life.

However, the market faces significant restraints, primarily stemming from the complexity and high precision required in the manufacturing process of gerotor components. Achieving the tight tolerances necessary for optimal performance often results in higher initial manufacturing costs compared to simpler pump types. Furthermore, the performance of gerotor pumps can be highly sensitive to fluid contamination and viscosity variations, requiring meticulous filtration and careful fluid selection, which can be an operational barrier in rugged industrial environments. The cyclical nature of the automotive industry, which represents a large share of demand, also poses a constraint, subjecting market growth to macroeconomic volatility and shifts in consumer spending on durable goods.

Opportunities abound in emerging applications, such as the deployment of hydrogen fuel cells, which necessitate specialized cooling and fluid circulation pumps compatible with highly volatile substances, offering a lucrative niche for custom-designed gerotors. The ongoing maturation of additive manufacturing (3D printing) presents an opportunity to produce complex, customized gerotor profiles quickly and cost-effectively, reducing tooling expenses and lead times for low-volume, high-specification applications. Impact forces, driven by global sustainability goals, are compelling manufacturers to develop pumps compatible with bio-based hydraulic fluids and refrigerants, creating a potent force that favors innovation in material science and sealing technologies within the gerotor pump ecosystem.

Segmentation Analysis

The Gerotor Pump Market is comprehensively segmented based on its structural characteristics, application domain, material composition, and regional presence, allowing for granular analysis of market penetration and growth potential. The segmentation highlights the diverse end-use spectrum, ranging from high-precision fluid metering in medical devices to heavy-duty lubrication in large-scale industrial gearboxes. Understanding these segments is crucial as design requirements, regulatory compliance, and pricing strategies differ vastly across applications. For instance, pumps utilized in aerospace must adhere to strict weight and safety standards, driving demand for specialized materials like titanium and aluminum alloys, whereas high-volume automotive pumps prioritize cost-efficiency and durability in steel or powdered metal formulations.

The primary axes of segmentation reveal distinct growth vectors. Segmentation by product type (internal vs. external) reflects usage patterns: internal gerotors dominate lubrication circuits due to their efficiency and compactness, while external gerotors are often preferred for higher-pressure hydraulic applications. By application, the market is broadly divided into fluid power, fuel transfer, lubrication, and cooling systems, with the lubrication segment holding the largest revenue share due to the ubiquitous nature of rotating machinery. The rapid expansion of electric vehicle manufacturing is fundamentally reshaping the cooling system application segment, demanding high-performance, variable-speed electric gerotor pumps for battery and motor thermal management, offering a significant future growth pathway.

Analyzing the segmentation by end-user industry—Automotive, Aerospace & Defense, Industrial, Oil & Gas, and Others—provides insight into specific investment trends. The automotive sector's pivot towards electrification necessitates massive investment in new pump technologies optimized for EVs. Simultaneously, the Industrial Machinery segment, encompassing machine tools, robotics, and agricultural equipment, continues to drive steady demand for robust, reliable pumps for hydraulic and gear lubrication systems. This detailed segmentation analysis is instrumental for stakeholders seeking to target specific high-growth niches and allocate research and development resources effectively based on industry-specific requirements and technological readiness.

- By Product Type:

- Internal Gerotor Pumps

- External Gerotor Pumps

- By Application:

- Lubrication Systems (Engine Oil Pumps, Transmission Systems)

- Fuel Transfer and Injection Systems

- Hydraulic Power Systems

- Cooling and Thermal Management Systems

- Metering and Dosing Systems

- By Material:

- Cast Iron and Steel

- Aluminum Alloys

- Powder Metallurgy Components

- Advanced Composites and Plastics

- By End-Use Industry:

- Automotive (ICE and EV)

- Aerospace & Defense

- Industrial Machinery (Machine Tools, Robotics)

- Oil & Gas and Power Generation

- Medical and Pharmaceutical

Value Chain Analysis For Gerotor Pump Market

The value chain for the Gerotor Pump Market begins with upstream activities focused on raw material procurement, including high-grade steels, cast iron, and increasingly, specialized aluminum alloys and advanced polymers required for lightweight designs. This stage is highly sensitive to global commodity prices and metallurgical expertise, as the quality of the raw material directly dictates the precision and longevity of the final gerotor components. Following material selection, the critical manufacturing phase involves precision machining, powder metallurgy processes (sintering and pressing), and heat treatment. Manufacturers invest heavily in CNC machinery and quality control systems to ensure the extremely tight tolerances (often measured in microns) required for optimal pump efficiency and sealing performance. Specialized tooling and proprietary manufacturing techniques, particularly for rotor profile grinding and polishing, represent a significant competitive barrier in the upstream segment.

Midstream activities primarily focus on assembly, testing, and integration. Pump assemblers procure finished rotors, casings, seals, and drive components, integrating them into the final pump unit. Rigorous testing protocols, including pressure testing, flow rate calibration, and noise/vibration analysis, are mandatory before shipment. Furthermore, customization is a significant element in the midstream, where pumps are adapted with specific mounting flanges, port configurations, and electronic controls (e.g., variable speed drives) to meet OEM specifications for various engine types or hydraulic circuits. This stage often involves collaboration between the pump manufacturer and the end-use system designer to ensure seamless integration and optimized system performance.

Downstream analysis encompasses distribution channels and end-user engagement. Distribution is generally bifurcated: direct sales channels dominate in large volume contracts with major Original Equipment Manufacturers (OEMs) in the automotive and aerospace sectors, ensuring supply chain security and technical support. Indirect distribution, involving specialized industrial distributors, component wholesalers, and aftermarket service providers, handles replacement parts, maintenance, and smaller-volume industrial orders. The aftermarket channel is crucial for revenue generation through the provision of repair kits and replacement pumps. Success in the downstream market is increasingly tied to providing rapid, localized technical support and maintaining extensive spare parts inventories globally, driven by the end-users' prioritization of minimal operational downtime.

Gerotor Pump Market Potential Customers

The potential customers for the Gerotor Pump Market are highly diversified, primarily comprising major industrial manufacturers and OEMs that require reliable, high-efficiency positive displacement fluid transfer. The largest consuming sector remains the automotive industry, which utilizes gerotor pumps extensively for engine oil circulation, automatic transmission fluid (ATF) delivery, and vacuum assistance in braking systems. With the rise of electric vehicles, these customers are evolving, focusing now on electric gerotor pumps for battery cooling loops, power electronics cooling, and specialized heat pump circuits, necessitating partnerships with manufacturers capable of producing high-voltage, quiet, and thermally optimized units.

Another significant customer base resides in the industrial machinery sector, including manufacturers of machine tools, heavy construction equipment, agricultural machinery, and textile equipment. These end-users purchase gerotor pumps predominantly for hydraulic actuation systems and high-pressure gear lubrication, valuing the pump’s durability, consistent flow, and resistance to harsh operating conditions. Original Equipment Manufacturers (OEMs) in the power generation and oil & gas industries also constitute vital customers, utilizing specialized, often stainless steel or corrosion-resistant, gerotor pumps for fuel injection, burner management, and precise fluid metering in critical energy infrastructure applications.

Finally, niche, high-value potential customers are found in the aerospace and defense sectors, where reliability, low weight, and performance across extreme temperature ranges are paramount. These customers demand pumps for hydraulic flight control systems, landing gear actuation, and auxiliary power units (APUs). Medical device manufacturers also represent an expanding customer segment, requiring micro-gerotor pumps for precise fluid handling in drug delivery systems, hemodialysis machines, and laboratory automation equipment, emphasizing sterility and non-pulsating flow characteristics. Targeted marketing towards these diverse, yet specific, engineering requirements is key to market penetration.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.55 Billion |

| Market Forecast in 2033 | $2.30 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth, Eaton Corporation, Parker Hannifin, Danfoss Power Solutions, Casappa S.p.A., GPM Gerotor Pumps, HPI - Hydac Pumps, Concentric AB, Sumitomo Drive Technologies, Roper Technologies, Viking Pump, Ligon Industries, Bucher Hydraulics, KNF Neuberger, Nidec Corporation, SHW Automotive, Pierburg GmbH, Melling Engine Parts, Oilgear, Idex Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gerotor Pump Market Key Technology Landscape

The technology landscape of the Gerotor Pump Market is characterized by continuous advancements aimed at improving efficiency, reducing size, and integrating smart functionalities. A major technological focus involves optimizing the tooth profile geometry using computational fluid dynamics (CFD) and specialized design software. Modern gerotor designs leverage cycloidal and epitrochoidal curves to minimize leakage paths, reduce cavitation noise, and maximize flow per revolution. This precision engineering allows for higher operating speeds and pressures without compromising durability or volumetric efficiency. Furthermore, the development of specialized coatings, such as plasma nitriding or diamond-like carbon (DLC), applied to rotor surfaces, significantly enhances wear resistance, making pumps viable for aggressive fluids or high-temperature environments where traditional materials would rapidly degrade.

Another crucial technological trend is the adoption of advanced material processing, specifically in powder metallurgy (PM). PM allows for the precise, cost-effective creation of complex, near-net-shape gerotor profiles from sintered steel, which is essential for high-volume manufacturing in the automotive industry. Recent innovations in PM involve higher density sintering and the use of specialized alloy powders to achieve mechanical properties previously only attainable through extensive machining, driving down unit costs while maintaining performance specifications. For lightweight applications, particularly in aerospace and electric vehicles, the focus is shifting towards high-strength aluminum alloys and engineering plastics like PEEK, which offer excellent weight reduction and chemical compatibility, provided they meet stringent performance criteria regarding thermal expansion and dimensional stability under load.

Furthermore, the integration of electronics and variable flow control mechanisms represents the future of gerotor technology. Electronically controlled variable displacement gerotor pumps are replacing fixed-displacement units, particularly in automotive engine lubrication and cooling. These smart pumps use sensors and actuators to dynamically adjust flow rate based on real-time engine or system load, dramatically improving fuel economy and reducing parasitic losses. The incorporation of brushless DC (BLDC) motors into these units ensures quiet operation, high reliability, and simplifies integration into existing vehicle electrical architectures, supporting the broader industry shift towards intelligent, energy-efficient mechatronic systems. These technological pillars—advanced geometry, material innovation, and electronic integration—are defining the competitive edge in the contemporary Gerotor Pump Market.

Regional Highlights

The Gerotor Pump Market exhibits distinct regional growth patterns and technological preferences driven by local industrial concentration and regulatory frameworks. Asia Pacific (APAC) stands out as the fastest-growing region, primarily due to the vast manufacturing bases in China, India, Japan, and South Korea. The colossal automotive production volumes, coupled with significant investments in industrial automation and infrastructure development, particularly in fluid power systems, propel demand for cost-effective, high-volume gerotor pumps. China, in particular, is a major consumption hub, reflecting its dominance in global electric vehicle and machinery production, prioritizing suppliers who can ensure rapid, scalable supply chains.

North America and Europe represent mature markets characterized by high technological sophistication and stringent quality demands, especially in the aerospace and high-end industrial machinery sectors. In North America, demand is heavily influenced by the robust defense industry and ongoing advancements in shale gas extraction, requiring durable pumps for specialized fluid handling. European markets, led by Germany and Italy, focus on precision engineering, driving demand for technologically advanced, variable-speed electric gerotor pumps that comply with strict EU energy efficiency directives (e.g., Ecodesign requirements). These regions emphasize product differentiation through durability, efficiency certifications, and advanced monitoring features.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions offering promising growth potential, albeit starting from a lower base. LATAM’s demand is tied mainly to automotive manufacturing (Brazil and Mexico) and agricultural machinery. MEA market growth is primarily fueled by capital expenditure in the oil and gas sector, particularly for fluid transfer and lubrication systems used in extraction and refining processes. In both regions, market penetration is often driven by international OEMs establishing local production facilities, stimulating localized demand for reliable pump components and associated aftermarket services.

- Asia Pacific (APAC): Dominates growth due to high-volume automotive production (ICE and EV), rapid industrialization, and favorable manufacturing cost structures. Key markets include China, India, and Japan, focusing on lubrication and thermal management systems.

- North America: Strong demand originating from high-specification sectors like aerospace, defense, and oil & gas. Emphasis on high reliability, integrated sensors, and compliance with high-pressure fluid power standards.

- Europe: Characterized by technological leadership and strict environmental mandates. High adoption rates of electric and variable displacement pumps in automotive and advanced industrial manufacturing (Germany, Italy, France).

- Latin America (LATAM): Growth linked to recovering automotive output and investments in mining and construction machinery, favoring durable, cost-competitive solutions.

- Middle East and Africa (MEA): Demand heavily concentrated in the Oil & Gas industry for robust pumping solutions and increasing application in power generation plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gerotor Pump Market.- Bosch Rexroth (A segment of Robert Bosch GmbH)

- Eaton Corporation

- Parker Hannifin Corporation

- Danfoss Power Solutions (part of Danfoss A/S)

- Casappa S.p.A.

- Concentric AB

- SHW Automotive GmbH

- Sumitomo Drive Technologies (part of Sumitomo Heavy Industries)

- Roper Technologies, Inc. (Viking Pump)

- HPI - Hydac Pumps

- Ligon Industries, LLC (Haldex Hydraulics)

- Bucher Hydraulics (part of Bucher Industries AG)

- Pierburg GmbH (part of Rheinmetall Automotive)

- Melling Engine Parts

- Oilgear Company

- Idex Corporation

- GPM Gerotor Pumps S.r.l.

- Nidec Corporation (Through various subsidiaries)

- KNF Neuberger GmbH

- Eckerle Industrie-Elektronik GmbH

Frequently Asked Questions

Analyze common user questions about the Gerotor Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of a gerotor pump over other positive displacement pumps?

Gerotor pumps offer superior advantages including highly compact design, exceptional volumetric efficiency, smooth and nearly pulsation-free flow, and extremely low noise levels compared to traditional gear or vane pumps. Their simple construction also contributes to enhanced reliability and a longer operational lifespan, making them ideal for integration into space-constrained and sensitive mechanical systems.

How is the adoption of electric vehicles (EVs) impacting the demand for gerotor pumps?

The transition to EVs is significantly increasing demand for specialized, high-performance electric gerotor pumps. These pumps are critical for managing complex thermal systems, including battery cooling, motor temperature regulation, and HVAC systems, requiring quiet, variable-speed operation and integration with high-voltage architectures, representing a major growth area.

Which materials are most commonly used in the manufacturing of gerotor components, and why?

Common materials include high-grade cast iron and hardened steel for demanding industrial and engine applications requiring durability and high pressure capability. Increasingly, powder metallurgy (PM) components are used for cost-effective, high-volume automotive production, while aluminum alloys and engineering plastics (like PEEK) are employed in aerospace and medical sectors to achieve weight reduction and chemical compatibility.

What is the role of sensor technology and IoT in modern gerotor pump design?

Sensor technology (pressure, temperature, vibration) and IoT connectivity enable modern gerotor pumps to become 'smart' devices. This integration supports advanced predictive maintenance programs, allowing operators to monitor performance in real-time and predict failures, significantly reducing unplanned downtime and optimizing overall fluid system efficiency through data analytics.

In which applications are external gerotor pumps typically preferred over internal gerotor pumps?

Internal gerotor pumps are generally preferred for low-pressure, high-volume lubrication and oil transfer due to their compactness. External gerotor pumps, featuring both rotors geared externally to the axis of rotation, are typically preferred for higher-pressure hydraulic power applications, where their robust structure provides greater mechanical strength and tolerance for fluctuating load conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager