Global 3D Perfusion Bioreactor System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443485 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Global 3D Perfusion Bioreactor System Market Size

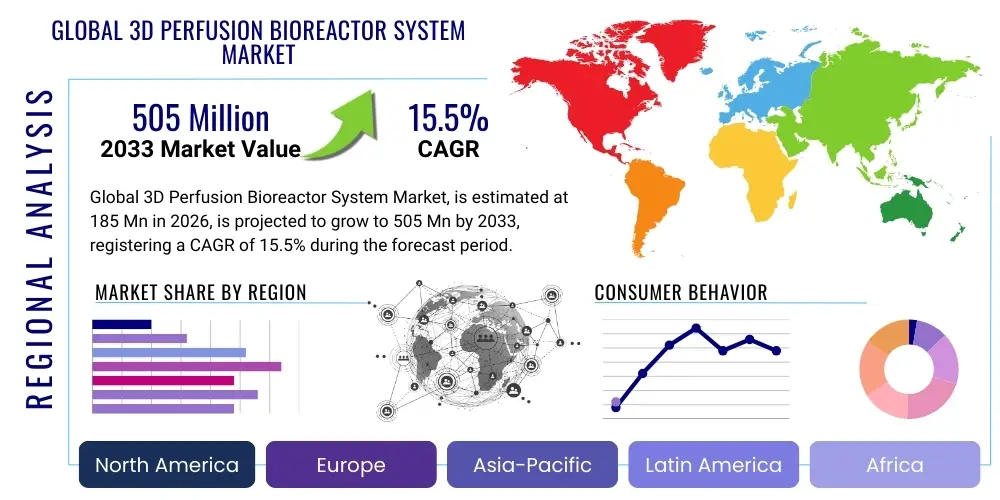

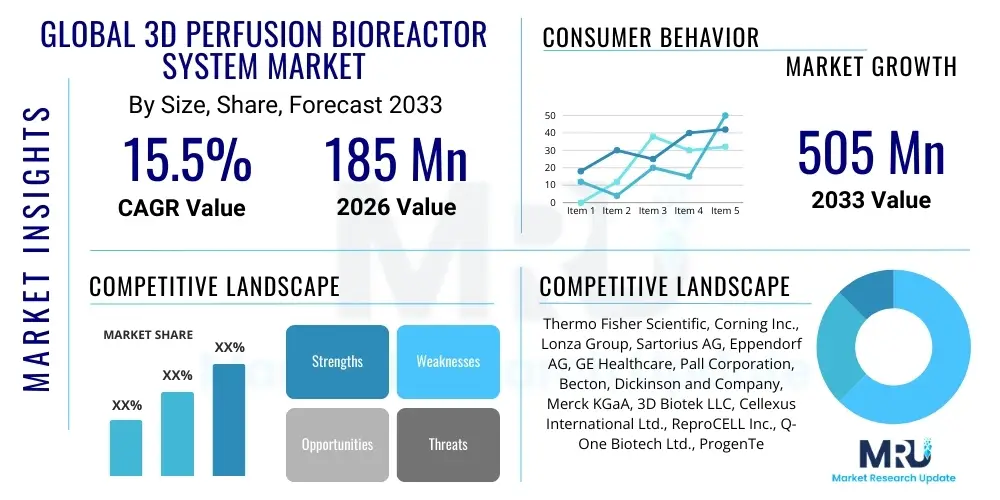

The Global 3D Perfusion Bioreactor System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.5% between 2026 and 2033. The market is estimated at $185 Million in 2026 and is projected to reach $505 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by the increasing demand for advanced in-vitro models that accurately mimic the physiological environment of native tissues and organs. The shift away from traditional two-dimensional (2D) culture methods toward complex three-dimensional (3D) environments, particularly in sophisticated applications like personalized medicine and high-throughput drug screening, significantly contributes to market expansion.

The valuation reflects substantial investment across both academic and pharmaceutical sectors aimed at accelerating drug development pipelines and enhancing toxicology testing efficiency. Perfusion bioreactors offer critical advantages over static culture systems by continuously supplying fresh media and removing metabolic waste, which is essential for maintaining cell viability, proliferation, and function in large, dense 3D tissue constructs. Furthermore, the integration of automation and sensor technology within these systems is optimizing experimental workflow and reproducibility, solidifying their status as indispensable tools in modern biotechnology research and biomanufacturing processes.

Geographically, market expansion is led by regions with mature biotechnology industries and significant governmental and private funding allocated to regenerative medicine and complex disease research. The competitive landscape is characterized by innovation focused on miniaturization, enhanced fluid dynamic control, and improved material compatibility to support long-term culture of complex organoids and vascularized tissues. Stakeholders are heavily investing in product differentiation through features such as automated monitoring, non-invasive sensing, and integration capabilities with high-content imaging platforms, thereby ensuring sustained market growth throughout the forecast period.

Global 3D Perfusion Bioreactor System Market introduction

The Global 3D Perfusion Bioreactor System Market centers on specialized laboratory apparatus designed to culture cells, tissues, or organoids in a three-dimensional environment under continuous media flow (perfusion). These systems are engineered to closely replicate the in-vivo physiological conditions, ensuring efficient mass transfer of nutrients, oxygen, and metabolic byproducts, which is crucial for the long-term viability and functional differentiation of sophisticated 3D constructs. The core product encompasses the bioreactor hardware, pumping mechanisms for media circulation, reservoirs, and sophisticated control units that monitor parameters such as pH, temperature, and dissolved oxygen levels. This technology represents a significant evolution from static 2D cell culture plates and even basic 3D scaffolds, offering unparalleled control over the cellular microenvironment.

Major applications of 3D perfusion bioreactor systems span critical areas including tissue engineering and regenerative medicine, where they are utilized to grow functional replacement tissues (e.g., cartilage, bone, liver), and drug discovery and toxicology screening, providing high-fidelity models for testing compound efficacy and safety. The ability of these systems to support complex, multi-cellular structures, such as organ-on-a-chip models and vascularized spheroids, allows researchers to derive more predictive preclinical data, thereby reducing reliance on traditional animal models. This predictive capability translates directly into accelerated timelines and reduced costs in pharmaceutical research and development.

The primary driving factors propelling this market include the global surge in research and development funding dedicated to chronic diseases, the increasing demand for biologically relevant in-vitro models, and technological advancements leading to automated and scalable bioreactor designs. Benefits derived from using these systems include enhanced cell yield and function, superior experimental reproducibility, and the maintenance of phenotypic stability over prolonged culture periods. Furthermore, regulatory agencies are increasingly recognizing the validity of 3D culture models, providing additional momentum for their widespread adoption across academic, biotechnology, and pharmaceutical industries seeking reliable translational research tools.

Global 3D Perfusion Bioreactor System Market Executive Summary

The Global 3D Perfusion Bioreactor System Market is experiencing robust expansion driven by converging trends in biotechnology innovation and commercial viability. Business trends are dominated by the push toward full automation and scalability, moving these systems from niche research tools into standard manufacturing platforms for cell and gene therapies. Key industry players are focusing on developing integrated systems that offer real-time, non-invasive monitoring capabilities, ensuring process analytical technology (PAT) compliance and simplifying Good Manufacturing Practices (GMP) adoption. There is a noticeable trend towards incorporating disposable components to minimize contamination risks and streamline workflow, which appeals strongly to large pharmaceutical manufacturers and contract manufacturing organizations (CMOs).

Regional trends indicate North America currently holds the dominant market share, primarily due to the presence of leading biotechnology companies, extensive academic research infrastructure, and substantial venture capital investment in regenerative medicine startups. However, the Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR), fueled by supportive government initiatives in countries like China and South Korea focused on domestic pharmaceutical innovation, coupled with a rapidly growing patient pool demanding advanced therapeutic solutions. Europe maintains a strong position, capitalizing on its historical excellence in medical device innovation and robust collaborative networks between research institutes and private industry, particularly in countries such as Germany and the UK.

Segment trends reveal that the Application segment, particularly Drug Discovery and Toxicology Screening, remains a major revenue generator as companies prioritize advanced preclinical testing models to address high attrition rates in clinical trials. Furthermore, within the Product segment, consumables and accessories (such as specialized scaffolds and media circulation components) are growing faster than the core bioreactor systems, reflecting the operational demands and recurring revenue streams associated with long-term, high-volume experimentation. The trend among End-Users leans towards large Biopharmaceutical Companies increasingly adopting these systems to internalize cell line development and process optimization, moving beyond reliance solely on external academic partners.

AI Impact Analysis on Global 3D Perfusion Bioreactor System Market

User inquiries regarding the role of Artificial Intelligence (AI) in 3D perfusion bioreactors frequently revolve around optimizing complex operational parameters, enhancing predictive modeling of cell behavior, and automating sophisticated protocols to ensure batch consistency. Users are keen to understand how AI can overcome the inherent biological variability and technical complexity associated with 3D culture, which requires precise control over numerous interacting variables—such as shear stress, media exchange rate, and nutrient gradients. Key themes summarize to the expectation that AI will transition the technology from specialized laboratory use to scalable industrial production, specifically addressing concerns about maintaining uniform quality and high cell viability across larger scales, a persistent challenge in biomanufacturing. Furthermore, there is strong interest in utilizing Machine Learning (ML) to interpret the massive datasets generated by integrated sensors, translating raw data into actionable insights faster than human analysts can achieve, thereby accelerating process development and quality control.

The integration of AI and Machine Learning models is revolutionizing perfusion bioreactor usage by enabling dynamic, real-time control over the culture environment, a crucial advancement for sensitive 3D constructs like complex organoids. Traditional control systems rely on static setpoints, but ML algorithms can analyze sensor data (e.g., lactate concentration, dissolved oxygen, glucose consumption) and predictively adjust pump speeds or media formulation to preemptively optimize cell health, minimizing waste and maximizing therapeutic yield. This predictive capability moves bioreactor operation from reactive adjustments to proactive management, dramatically improving experimental success rates and process efficiency. By establishing digital twins of the biological process, AI allows for simulation-based optimization before physical implementation, saving valuable time and resources during the scaling phase.

The most profound impact of AI lies in enhancing reproducibility and reducing the steep learning curve traditionally associated with operating complex perfusion systems. AI-driven protocols can self-calibrate based on minor environmental fluctuations or batch-to-batch variations in biological starting materials, ensuring that the final construct quality remains consistent, which is paramount for clinical applications. This automation and quality assurance are vital for achieving regulatory compliance in GxP environments. Moreover, the analytical power of AI helps researchers identify subtle correlations between culture parameters and functional outcomes (e.g., protein expression levels or tissue stiffness), leading to novel insights into tissue development and disease modeling that would be difficult to discern through conventional statistical methods, further cementing the technology's value proposition.

- AI optimizes complex fluid dynamics and shear stress profiles in real-time.

- Machine Learning (ML) enables predictive modeling for nutrient consumption and waste accumulation.

- Automated protocol generation and self-correction enhance experimental reproducibility and reduce human error.

- AI accelerates Process Analytical Technology (PAT) adoption and facilitates GMP compliance through continuous data monitoring.

- Data-driven insights accelerate media optimization and scaffold design for specific cell types.

- Deep Learning algorithms analyze complex sensor data to detect early signs of culture stress or contamination.

DRO & Impact Forces Of Global 3D Perfusion Bioreactor System Market

The market dynamics of 3D perfusion bioreactors are shaped by a powerful confluence of driving forces, significant restraints, and emerging opportunities, collectively defining the trajectory of growth. Key drivers include substantial global increases in research funding directed towards regenerative medicine, oncology, and personalized therapeutics, all of which rely heavily on accurate 3D cell culture models. The increasing clinical validation of cell-based therapies and the need for scalable, consistent manufacturing platforms further amplify demand. Conversely, major restraints include the high initial capital expenditure required for acquiring and setting up these sophisticated systems, coupled with the technical complexity and specialized expertise required for operation and maintenance, which can be prohibitive for smaller laboratories or startups. These factors create significant barriers to entry and adoption, particularly in developing markets.

Opportunities for market penetration and expansion are centered on the rapid technological evolution toward miniaturization, particularly the growth of organ-on-a-chip technologies integrated with perfusion systems, enabling multi-organ models for enhanced systemic drug testing. The increasing strategic collaborations between academic institutions, biotechnology firms, and bioreactor manufacturers focused on standardization and developing user-friendly, modular systems represent a critical avenue for market growth. Furthermore, the rising awareness and acceptance of in-vitro models as replacements for animal testing, often mandated by ethical considerations and regulatory shifts (such as the FDA Modernization Act 2.0 allowing alternatives to animal testing), create a fertile environment for sustained long-term growth and new market entry.

The major impact forces governing the market are primarily regulatory and technological. Regulatory harmonization of standards for 3D bioprinted tissues and cell therapies manufactured using these systems will significantly unlock commercial scaling. Technologically, the ongoing integration of advanced sensor arrays (e.g., optical sensors, electrochemical probes) with automated software provides unprecedented control and data fidelity. Economic forces also play a crucial role; as systems become more efficient and capable of higher throughput, the cost-per-experiment decreases, bolstering their attractiveness compared to traditional methods. Socially, the ethical push for non-animal testing models acts as a potent force accelerating adoption across the global research ecosystem, ensuring that 3D perfusion bioreactors become an ethical standard in preclinical research.

Segmentation Analysis

The Global 3D Perfusion Bioreactor System Market is meticulously segmented based on Product, Application, and End-User, reflecting the diverse technological offerings and distinct industry needs. Understanding these segmentations is critical for market stakeholders to tailor product development and strategic marketing efforts effectively. The Product segment differentiates between the core Bioreactor Systems and the essential Accessories and Consumables required for continuous operation, such as sterile tubing, specialized pumps, microcarriers, and proprietary scaffold materials. The increasing sophistication of these consumables, especially those tailored for specific tissue types or organoid models, drives significant recurring revenue and innovation within this category.

The Application segmentation highlights the primary uses across various fields of life sciences research and biomanufacturing. Tissue Engineering and Regenerative Medicine are foundational segments, leveraging the bioreactors' capability to cultivate large, functional tissue constructs suitable for transplantation or in-depth study of disease mechanisms. Concurrently, Drug Discovery and Toxicology Screening represents a high-growth segment, driven by the pharmaceutical industry’s demand for high-throughput, physiologically relevant models to accurately predict drug efficacy and toxicity early in the development pipeline. The efficacy of 3D perfusion systems in maintaining complex liver, heart, or brain organoids enhances the predictive power of preclinical trials.

The End-User segment provides insight into the primary market adopters, identifying Biopharmaceutical Companies, Academic & Research Institutes, and Contract Research Organizations (CROs) as the dominant purchasing entities. Biopharmaceutical companies are increasingly investing in these systems for internal process development and large-scale manufacturing of cellular products. Academic and research institutions drive innovation and basic research, requiring flexibility and adaptability in their systems. CROs play a vital role by offering specialized 3D culture services to clients, often requiring high-capacity, multi-parameter control systems to handle diverse research projects efficiently. This structured demand across end-users ensures sustained financial viability and continuous technological enhancement across the market.

- By Product:

- Bioreactor Systems (Small Scale, Benchtop, Large Scale/Industrial)

- Accessories and Consumables (Pumps, Tubing Sets, Scaffolds, Sensors, Media)

- By Application:

- Tissue Engineering and Regenerative Medicine

- Drug Discovery and Toxicology Testing

- Disease Modeling

- Cell Line Development and Biomanufacturing

- By End-User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutes

- Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs)

Value Chain Analysis For Global 3D Perfusion Bioreactor System Market

The value chain for the Global 3D Perfusion Bioreactor System Market is characterized by a sophisticated interplay between specialized material science, complex engineering, and highly technical biological applications. The upstream segment involves the critical supply of highly specialized components, including precision microfluidic chips, sterile polymers for disposable parts, high-grade stainless steel for core reactors, and sophisticated sensor technologies (pH, DO, temperature, biomass). Manufacturers rely heavily on specialized suppliers for these high-tolerance components, and ensuring supply chain integrity and material quality is paramount, particularly for GMP-compliant systems. Innovations in biomaterials, such as advanced hydrogels and porous scaffolds designed for specific cell adhesion and nutrient exchange properties, are foundational elements supplied at this stage, dictating the ultimate performance of the downstream system.

The midstream segment is dominated by the design, manufacturing, and assembly of the integrated 3D perfusion bioreactor systems. Key activities involve system engineering (pumping mechanisms, gas exchange units, control software development) and strict quality control to ensure operational consistency and reliability. Differentiation at this stage is achieved through superior system design, ease of use, scalability, and integration capabilities with existing laboratory automation platforms. Direct distribution is common for high-value, complex systems, where manufacturers often engage directly with end-users to provide customized installation, training, and extensive after-sales support. This direct model is necessary due to the complexity of the technology and the requirement for specialized technical support, particularly in highly regulated environments like pharmaceutical manufacturing.

Downstream activities involve the marketing, sales, and ultimate deployment of the bioreactor systems to end-users such as academic laboratories, biopharmaceutical R&D facilities, and dedicated biomanufacturing centers. Distribution channels are typically a mix of direct sales teams for strategic institutional clients and specialized third-party distributors for broader geographical coverage, particularly in emerging markets. Indirect channels, such as specialized scientific equipment dealers, play a role in supplying the wide range of accessories and consumables. The efficiency of the distribution network, particularly the timely delivery of sterile consumables, directly impacts the continuous operation of the end-user facilities. The ultimate value delivery is realized when the systems are successfully integrated into the customer's research or production workflow, leading to accelerated scientific discovery or successful therapeutic scale-up.

Global 3D Perfusion Bioreactor System Market Potential Customers

The primary customers for 3D perfusion bioreactor systems are entities deeply invested in advanced life sciences research, therapeutic development, and high-quality biomanufacturing. Biopharmaceutical companies constitute a major segment, driven by their relentless need to identify new drug candidates and scale up cell-based therapeutic production, demanding systems that offer high precision, throughput, and regulatory compliance (GMP readiness). These customers prioritize features like automated monitoring, minimal manual intervention, and validated performance for long-term culture protocols, particularly when handling expensive or sensitive cell lines for oncology, neurodegenerative, or rare diseases. The ability to model human diseases accurately and conduct reliable preclinical toxicology screening makes these systems indispensable for minimizing late-stage clinical trial failures and accelerating market entry.

Academic research institutions and government-funded laboratories represent another significant customer base. These institutions focus on fundamental research, disease modeling, and exploring novel tissue engineering applications. Their purchasing decisions are often influenced by system flexibility, ease of adaptation for various cell types (stem cells, primary cells), and cost-effectiveness, though they increasingly require sophisticated systems for high-impact translational research. Collaborations between academia and industry often serve as technology incubators, where novel perfusion system designs are rigorously tested before commercialization, driving innovation in both hardware and biological application protocols. Government grants and endowments significantly impact the procurement cycles within this segment.

Furthermore, Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) are rapidly emerging as critical potential customers. CROs leverage 3D perfusion bioreactors to offer specialized testing services, fulfilling the preclinical research needs of multiple biotech and pharma clients efficiently. CMOs utilize these systems for the scaled-up, controlled production of therapeutic cells and tissues under strict regulatory oversight. For both CROs and CMOs, system reliability, capacity for high throughput, and robust validation documentation are crucial factors, enabling them to meet the diverse and stringent demands of their global client base while ensuring high capacity utilization and process consistency necessary for profitable operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185 Million |

| Market Forecast in 2033 | $505 Million |

| Growth Rate | 15.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Corning Inc., Lonza Group, Sartorius AG, Eppendorf AG, GE Healthcare, Pall Corporation, Becton, Dickinson and Company, Merck KGaA, 3D Biotek LLC, Cellexus International Ltd., ReproCELL Inc., Q-One Biotech Ltd., ProgenTech Inc., Microfluidic Systems Inc., HiMedia Laboratories, Bellco Glass, Inc., Infors HT, Scinus Cell Expansion B.V., Curi Bio. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global 3D Perfusion Bioreactor System Market Key Technology Landscape

The technological landscape of 3D perfusion bioreactor systems is highly dynamic, driven by the need for enhanced biomimicry and manufacturing scalability. A foundational technology involves advanced microfluidics, which allows for precise control over fluid flow rates and nutrient gradients at the cellular level. Microfluidic integration is essential for systems designed for small-scale organoid culture and organ-on-a-chip applications, ensuring that the critical parameters such as shear stress are maintained within physiological limits, vital for mimicking capillary blood flow and tissue vascularization. This technological sophistication contrasts sharply with bulk systems and is critical for generating high-fidelity, complex tissue models used in advanced drug screening, demanding extremely precise pumping and valve actuation mechanisms.

Another crucial technological development is the incorporation of sophisticated sensor integration and automated control systems. Modern perfusion bioreactors employ non-invasive sensors (e.g., optical sensors for biomass or dissolved oxygen probes) to provide continuous, real-time feedback on the culture status without the need for destructive sampling. This data is fed into control systems, increasingly utilizing Proportionate-Integral-Derivative (PID) controllers or AI-driven logic, which automatically adjust parameters like pH, temperature, and media flow. This automation enhances experimental reproducibility, reduces labor costs, and is a prerequisite for achieving the robust process control mandated by current Good Manufacturing Practices (cGMP) for therapeutic cell production, ensuring the scalability required for commercial viability.

Furthermore, innovation in material science, particularly relating to specialized scaffolding and construct holders, profoundly influences the market. Biocompatible and often biodegradable materials like hydrogels (e.g., gelatin, collagen, synthetic polymers) are engineered to provide structural support while allowing optimal cell-cell interaction and mass transfer in the 3D environment. Advanced perfusion systems must be compatible with a wide range of these materials. Moreover, the design of the bioreactor vessel itself, transitioning towards disposable and modular components, utilizes advanced polymers to minimize cleaning validation steps and cross-contamination risks, addressing major operational bottlenecks faced by high-throughput biopharma facilities, thereby accelerating the technological adoption cycle across various research and manufacturing settings.

Regional Highlights

- North America: This region maintains its dominance in the global market, primarily driven by the United States, which hosts a high concentration of leading pharmaceutical and biotechnology companies, well-funded academic research institutions, and substantial government support for life science innovation, particularly in cell and gene therapy. High levels of investment in translational research and the early adoption of cutting-edge technologies like organ-on-a-chip and personalized medicine ensure that North America remains the largest revenue generator. The stringent regulatory framework also drives the adoption of highly controlled, automated perfusion systems for clinical-grade manufacturing.

- Europe: Characterized by a strong focus on high-quality academic research and robust governmental funding through organizations like the European Commission, Europe represents the second-largest market. Countries such as Germany, the UK, Switzerland, and France are leaders in biomedical engineering and regenerative medicine. The region is witnessing accelerated market penetration due to strong collaborative networks between universities and industry and increasing ethical pressures to replace traditional animal testing with advanced 3D in-vitro models, spurring demand for perfusion bioreactors.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing regional market throughout the forecast period. This rapid expansion is attributed to increasing government investment in biotechnology infrastructure, rising demand for advanced healthcare solutions, and the strategic establishment of R&D centers by global biopharmaceutical firms in countries like China, India, Japan, and South Korea. Favorable regulatory landscapes focused on promoting domestic innovation, coupled with a growing academic and industrial base adopting Western technologies, are significant market catalysts, offering considerable untapped potential for manufacturers.

- Latin America (LATAM): The LATAM market exhibits moderate growth, driven primarily by increasing investment in academic research focused on regional health challenges and emerging biotech clusters, particularly in Brazil and Mexico. Market adoption is constrained by budgetary limitations and reliance on imported systems, but ongoing efforts to modernize healthcare infrastructure and expand access to advanced research tools signal future growth opportunities.

- Middle East and Africa (MEA): This region is currently the smallest contributor but shows promising growth potential, particularly in the Middle Eastern countries like Saudi Arabia and the UAE, which are diversifying their economies through significant investment in R&D and specialized healthcare hubs (e.g., medical city projects). Adoption is slow but accelerating due to strategic governmental initiatives aimed at building local biopharma manufacturing capabilities and attracting international research talent.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global 3D Perfusion Bioreactor System Market.- Thermo Fisher Scientific

- Corning Inc.

- Lonza Group

- Sartorius AG

- Eppendorf AG

- GE Healthcare

- Pall Corporation

- Becton, Dickinson and Company (BD)

- Merck KGaA

- 3D Biotek LLC

- Cellexus International Ltd.

- ReproCELL Inc.

- Q-One Biotech Ltd.

- ProgenTech Inc.

- Microfluidic Systems Inc.

- HiMedia Laboratories

- Bellco Glass, Inc.

- Infors HT

- Scinus Cell Expansion B.V.

- Curi Bio

Frequently Asked Questions

Analyze common user questions about the Global 3D Perfusion Bioreactor System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a 3D perfusion bioreactor over static culture systems?

The primary advantage is the ability to continuously supply fresh nutrients and remove metabolic waste products while maintaining low shear stress, enabling long-term culture and high cell viability for complex, large 3D tissue constructs, accurately mimicking in vivo physiology.

Which application segment drives the highest demand for 3D perfusion bioreactor systems?

Drug Discovery and Toxicology Screening drive high demand, as pharmaceutical companies require high-fidelity, physiologically relevant 3D models (like organoids) to improve preclinical prediction accuracy and reduce high attrition rates associated with traditional 2D testing.

How is Artificial Intelligence (AI) being utilized within perfusion bioreactor technology?

AI is utilized for real-time process optimization, analyzing sensor data to predictively adjust flow rates and media parameters, ensuring consistent culture quality, accelerating process development, and facilitating GxP compliance through automated control.

What are the main factors restraining the growth of the 3D perfusion bioreactor market?

The main restraints include the high initial capital investment required for system acquisition and setup, along with the complexity of operation and the necessity for specialized technical expertise, limiting adoption among smaller research groups.

Which regional market is anticipated to exhibit the fastest growth rate?

The Asia Pacific (APAC) region is projected to register the fastest CAGR, propelled by significant government investment in domestic biotechnology R&D, rising healthcare expenditure, and increasing adoption of advanced therapeutic manufacturing platforms in countries such as China and South Korea.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager