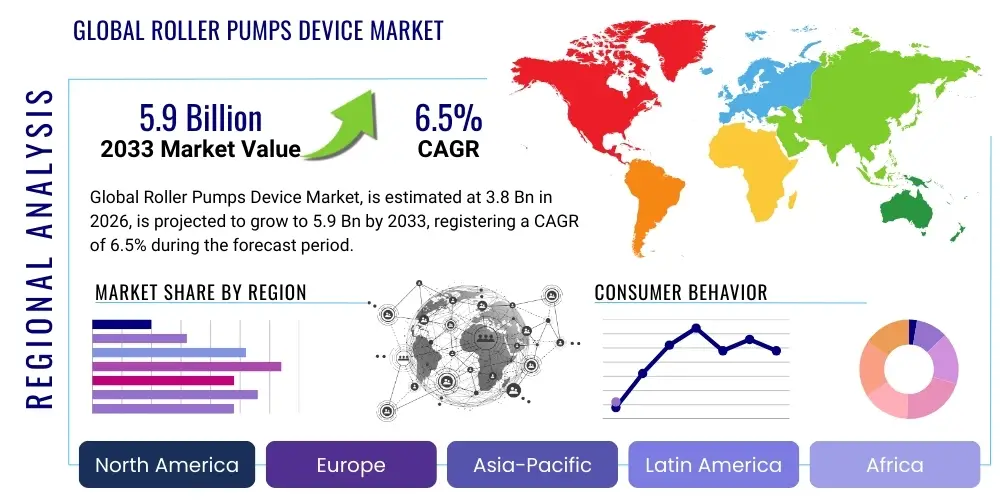

Global Roller Pumps Device Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441075 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Global Roller Pumps Device Market Size

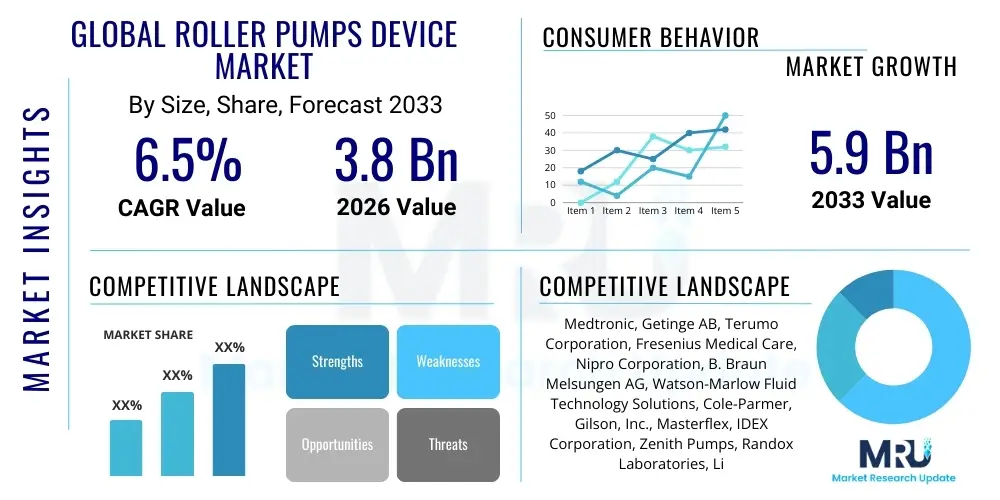

The Global Roller Pumps Device Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.8 Billion in 2026 and is projected to reach USD 5.9 Billion by the end of the forecast period in 2033.

Global Roller Pumps Device Market introduction

The Global Roller Pumps Device Market encompasses a specialized segment within the broader fluid management and medical device industries. Roller pumps, often referred to as peristaltic pumps, function by trapping a volume of fluid between two rollers (or shoes) pressing against a flexible tube, moving the fluid along the tubing path. These devices are crucial for applications requiring high precision, sterile fluid transfer, and controlled flow rates, particularly in medical settings like cardiopulmonary bypass (CPB), renal dialysis, and infusion therapy, as well as critical laboratory and bioprocessing environments.

The core utility of roller pumps lies in their ability to maintain sterility, as the fluid never contacts the mechanical components of the pump head, only the disposable tubing. This non-contaminating feature makes them indispensable in sensitive biological and pharmaceutical manufacturing processes. Furthermore, the capacity to deliver highly accurate, pulsating or non-pulsating flow contributes significantly to their demand. Major applications span extracorporeal circulation systems during open-heart surgery, precise drug delivery in chemotherapy, and use in food processing for viscous fluids or shear-sensitive materials.

Market growth is predominantly fueled by the increasing incidence of cardiovascular diseases globally, necessitating complex surgical interventions involving CPB machines, where roller pumps are a central component. Technological advancements focusing on enhanced flow control accuracy, reduced hemolysis rates, and miniaturization for portable medical devices are further driving adoption. The expansion of the biotechnology and pharmaceutical sectors, demanding specialized fluid handling for fermentation and filtration, also serves as a significant market driver, positioning roller pumps as essential tools across multiple high-growth industries.

Global Roller Pumps Device Market Executive Summary

The Global Roller Pumps Device Market is characterized by robust growth driven by escalating demand in healthcare, particularly for cardiac surgery and dialysis, and significant penetration into industrial fluid transfer and bioprocessing. Business trends indicate a strong focus on developing smart pump technologies integrated with monitoring systems to improve patient safety and operational efficiency. Strategic alliances and mergers among medical device manufacturers and specialized pump providers are common, aiming to consolidate market share and leverage technological expertise in sophisticated clinical applications. The shift towards disposable and single-use tubing sets is also a pivotal business trend, minimizing cross-contamination risks and streamlining sterilization processes in hospital and lab settings.

Regionally, North America and Europe currently dominate the market due to established healthcare infrastructure, high adoption rates of advanced medical technologies, and the strong presence of key market players and research institutions. However, the Asia Pacific (APAC) region is poised for the highest growth trajectory, fueled by rapidly expanding healthcare expenditure, increasing surgical volumes, and growing investments in pharmaceutical manufacturing, notably in countries like China, India, and Japan. Latin America and the Middle East and Africa (MEA) are also exhibiting moderate growth, primarily driven by improvements in dialysis infrastructure and increasing access to specialized medical equipment.

Segmentation analysis highlights the dominance of the medical application segment, specifically in cardiopulmonary bypass and dialysis apparatus, owing to the life-critical nature of these devices and stringent regulatory approvals. By product type, open-channel (or cassette) roller pumps are seeing increasing adoption due to their versatility and ease of use in clinical settings, though traditional peristaltic pumps remain crucial for high-flow industrial and perfusion applications. End-user trends show hospitals and specialty clinics remaining the largest consumers, but the fastest growth is anticipated from research laboratories and Contract Development and Manufacturing Organizations (CDMOs) due to the boom in biological drug development and personalized medicine.

AI Impact Analysis on Global Roller Pumps Device Market

User queries regarding the impact of Artificial Intelligence (AI) on the Global Roller Pumps Device Market often revolve around predictive maintenance, enhancing infusion accuracy, and integrating pumps into complex closed-loop medical systems. Key themes highlight expectations for AI algorithms to detect subtle operational anomalies, preventing pump failures during critical procedures like CPB, and optimizing flow rates based on real-time physiological data inputs from patients. Users are also concerned about the regulatory framework surrounding AI-driven autonomous pump adjustments and the security implications of connecting these life-support devices to hospital networks for data analytics and remote diagnostics.

The implementation of AI promises to revolutionize the reliability and precision of roller pump devices, transforming them from simple mechanical fluid movers into intelligent, self-monitoring systems. Machine learning models can analyze historical performance data, environmental factors, and patient parameters to predict tubing degradation or component wear, scheduling preventative maintenance before failure occurs. This predictive capability is vital in maximizing device uptime in critical care and high-throughput bioprocessing environments, significantly reducing operational risks and associated costs.

Furthermore, AI facilitates the development of next-generation smart infusion pumps. By integrating with electronic health records (EHRs) and patient monitoring devices, AI can calculate optimal drug dosages and adjust flow rates dynamically, minimizing human error and mitigating risks associated with medication misdosing. This integration moves the market toward safer, more personalized therapy delivery, particularly in complex scenarios such as critical care infusions or precise media management in bioreactors, which ultimately boosts the trustworthiness and adoption rate of advanced roller pump devices.

- AI enables predictive maintenance, drastically reducing unexpected device downtime in critical surgical settings.

- Machine learning algorithms enhance flow control accuracy by adjusting rates based on real-time patient physiological feedback.

- Integration of AI supports closed-loop systems, automating fluid delivery (e.g., insulin delivery, bypass flow) to maintain patient homeostasis.

- AI analyzes vast datasets to optimize pump performance parameters, extending the lifespan of tubing and mechanical components.

- Smart connectivity allows for remote diagnostics and software updates, improving compliance and device management efficiency.

DRO & Impact Forces Of Global Roller Pumps Device Market

The dynamics of the Global Roller Pumps Device Market are shaped by a complex interplay of Drivers (D), Restraints (R), and Opportunities (O). Primary drivers include the rising global burden of chronic diseases such as cardiovascular disorders and kidney failure, directly necessitating the use of roller pumps in bypass and dialysis procedures. Opportunities arise from technological miniaturization, allowing for portable and home-care applications, alongside the exponential growth in biopharmaceutical manufacturing, which relies heavily on sterile, precise fluid transfer. These positive forces are partially tempered by restraints such as the high initial cost of advanced perfusion systems, stringent regulatory pathways, and challenges related to tubing compatibility and potential fluid shear stress affecting sensitive biological materials, creating specific market headwinds that manufacturers must navigate carefully.

Drivers: The increasing volume of complex surgical procedures, particularly cardiac and orthopedic surgeries, requires reliable extracorporeal circulation equipment. Rapid adoption of single-use technologies across the pharmaceutical and biotech industries drives demand for dedicated, easily validated roller pump systems. Government initiatives focused on improving healthcare access and expanding dialysis services in emerging economies further stimulate market growth. Furthermore, the inherent advantage of non-contamination provided by peristaltic mechanisms makes them essential in aseptic processing environments, bolstering their indispensable role across various sectors.

Restraints: The market faces significant restraints, including the requirement for frequent calibration and maintenance of precision pumps, which adds to operational costs. Potential issues related to spallation (shedding of small particles from the tubing) and wear and tear in the tubing leading to inconsistent flow can pose quality control challenges, especially in highly sensitive applications. Competition from alternative positive displacement pump technologies, which may offer different flow characteristics or pressure capabilities, also limits market expansion in certain industrial fluid management segments.

Opportunities: Significant market opportunities exist in the development of highly specialized pumps for niche applications, such as microfluidics and targeted drug delivery systems. The convergence of roller pump technology with IoT and sophisticated sensor integration creates pathways for "smart pumps" offering unprecedented precision and data capture capabilities. Expanding manufacturing capacities in Asia Pacific to serve local healthcare needs and utilizing materials science breakthroughs to develop tubing materials that minimize spallation and maximize biocompatibility are also key areas of opportunity for market participants.

- Drivers: Rising incidence of chronic diseases; technological advancements in perfusion systems; growth in biopharmaceutical manufacturing; preference for sterile, non-contaminating fluid transfer.

- Restraints: High initial investment cost; regulatory hurdles for medical devices; potential for tubing failure (spallation) and flow inaccuracy over extended use; competition from alternative pump technologies.

- Opportunities: Integration of AI and IoT for smart flow management; development of portable and home-use dialysis/infusion pumps; expansion into emerging markets; focus on new biocompatible tubing materials.

- Impact Forces: Growing geriatric population driving surgical volumes (Positive); Stringent quality standards necessitating high-precision manufacturing (Positive/Regulatory Pressure); Supply chain vulnerabilities for specialized tubing materials (Negative).

Segmentation Analysis

The Global Roller Pumps Device Market is broadly segmented based on product type, application, end-user, and flow rate capacity. Understanding these segments is vital for stakeholders to tailor product development and marketing strategies effectively. The structure of the market is heavily influenced by the end-use environment, dictating requirements for precision, sterilization method, and flow capacity. For instance, medical applications demand disposable tubing sets and exceptionally high reliability, whereas industrial applications may prioritize durability and high-volume handling.

Segmentation by application clearly delineates the market’s reliance on the medical sector, where cardiopulmonary bypass (CPB) accounts for a substantial revenue share, reflecting the critical function roller pumps serve in heart surgery. However, the fastest growth is observed in the bioprocessing and pharmaceutical development segments, driven by the increased need for automated and validated systems for media preparation, fermentation, and chromatographic separation. This diversification away from purely clinical applications is a key trend shaping future market investments.

The distinction between large-flow rate pumps and micro-flow rate pumps is also critical, aligning with the end-user requirements; micro-flow devices are crucial for laboratory diagnostics and precise clinical dosing, while large-flow models dominate industrial processing and specialized high-volume medical procedures. Furthermore, the segmentation by end-user—hospitals, research institutes, and biopharma companies—helps in defining sales channels and understanding the distinct procurement cycles and compliance needs of each buying group.

- Product Type:

- Standard Peristaltic Pumps (Tube Pumps)

- Roller Pumps for Extracorporeal Circulation (e.g., Heart-Lung Machines)

- Cassette/Open Channel Pumps (Often used for general infusion/laboratory work)

- Application:

- Cardiopulmonary Bypass (CPB)

- Dialysis/Hemodialysis

- Infusion Therapy (Including Chemotherapy)

- Bioprocessing & Fermentation

- Pharmaceutical Manufacturing

- Laboratory & Research Diagnostics

- Flow Rate Capacity:

- Low Flow (Micro-peristaltic)

- Medium Flow

- High Flow (Industrial/Surgical)

- End-User:

- Hospitals & Clinics

- Ambulatory Surgical Centers (ASCs)

- Pharmaceutical & Biotechnology Companies

- Academic & Research Institutes

Value Chain Analysis For Global Roller Pumps Device Market

The value chain for the Global Roller Pumps Device Market begins with the sourcing and manufacturing of high-quality raw materials, primarily specialized elastomer tubing (silicone, Tygon, PVC) and precision mechanical components (motors, casings, rollers). Upstream analysis reveals reliance on a select group of specialized material suppliers capable of meeting stringent medical-grade specifications, especially for biocompatibility and low spallation characteristics required by regulatory bodies like the FDA and EMA. Component manufacturing often involves complex machining and integration of stepper motors and control electronics, defining the core cost structure of the final product.

Midstream activities involve the assembly, sophisticated calibration, quality assurance testing, and final packaging of the roller pump systems. This stage is crucial, particularly for medical pumps, where reliability and flow accuracy must be certified to regulatory standards. Manufacturers often invest heavily in R&D to integrate microprocessors and software for precise control and monitoring functionalities. The value-add here is high, driven by intellectual property related to unique roller geometries, pulsation compensation, and user interface design.

Downstream analysis focuses on distribution channels. Direct sales channels are frequently employed for high-value capital equipment, such as complete heart-lung machines sold directly to specialized hospital departments and major pharmaceutical facilities, allowing manufacturers to provide specialized training and maintenance contracts. Indirect channels involve regional distributors and medical supply resellers, which are critical for reaching smaller clinics, research laboratories, and remote geographical areas. Post-sale support, including maintenance, repair, and the continuous supply of proprietary tubing sets, forms a critical, recurring revenue stream within the downstream segment, heavily influencing customer loyalty and total cost of ownership.

Global Roller Pumps Device Market Potential Customers

Potential customers for the Global Roller Pumps Device Market are diverse but concentrate heavily in sectors requiring sterile, precise, and controlled fluid handling. The largest customer base remains within the healthcare sector, particularly specialized surgical units. Hospitals are perpetual buyers, necessitating pumps for critical applications such as open-heart surgery (Cardiopulmonary Bypass), where reliable flow generation is literally life-sustaining, and intensive care units for controlled, long-term infusion therapies. Dialysis centers, driven by the global increase in end-stage renal disease, represent another massive and growing customer segment requiring dedicated high-volume roller pumps and disposables.

Beyond traditional healthcare, the booming biotechnology and pharmaceutical manufacturing industries are rapidly increasing their consumption of roller pumps. Biopharma companies and their CDMO partners use these devices extensively for critical bioprocessing steps, including sterile transfer of culture media, tangential flow filtration (TFF), and chromatography. These customers value compliance, scalability, and the non-contaminating nature of the pump mechanism. Furthermore, academic research institutions and specialized pathology laboratories purchase lower-flow, high-precision peristaltic pumps for complex analytical tasks, liquid chromatography, and automating diagnostic processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.8 Billion |

| Market Forecast in 2033 | USD 5.9 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Medtronic, Getinge AB, Terumo Corporation, Fresenius Medical Care, Nipro Corporation, B. Braun Melsungen AG, Watson-Marlow Fluid Technology Solutions, Cole-Parmer, Gilson, Inc., Masterflex, IDEX Corporation, Zenith Pumps, Randox Laboratories, LivaNova PLC, Waston-Marlow Fluid Technology Solutions, KNF Neuberger, Flowrox, Ebara Corporation, Bio-Rad Laboratories, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Roller Pumps Device Market Key Technology Landscape

The technological landscape of the Global Roller Pumps Device Market is rapidly evolving, driven primarily by the need for increased accuracy, better patient safety, and higher throughput in industrial applications. A key innovation involves the development of advanced electronic control systems, incorporating microprocessors and sophisticated software to monitor and stabilize flow rates dynamically. This technology addresses the inherent flow variation (pulsation) associated with traditional peristaltic pumps, which is crucial for sensitive applications like blood perfusion where minimizing mechanical stress (shear forces) on biological fluids is paramount. Manufacturers are focusing on developing proprietary control algorithms that minimize hemolysis during CPB procedures, enhancing the clinical outcome for patients.

Another significant technological advancement focuses on the materials used in the tubing. Research is concentrating on developing novel, long-lasting elastomer and thermoplastic materials that exhibit superior chemical resistance, higher pressure ratings, and, most importantly, significantly reduced spallation. Tubing materials that can withstand rigorous sterilization cycles while maintaining dimensional stability are highly sought after by bioprocessing customers who prioritize validation and uptime. Furthermore, the integration of single-use, pre-calibrated tubing sets designed for specific pump models minimizes the risk of human error during setup and simplifies complex validation processes in pharmaceutical manufacturing.

The market is also witnessing the rise of smart pump technology, integrating IoT connectivity and advanced sensor technology. These smart pumps are equipped with pressure sensors, bubble detectors, and flow meters that provide real-time feedback to the central control unit. This connectivity allows for continuous data logging, remote monitoring, and integration into hospital or laboratory information management systems (LIMS). The objective is to create closed-loop systems, particularly in infusion and dialysis, where the pump can autonomously adjust performance based on sensor inputs, moving the industry toward automated, safer, and highly precise fluid management protocols that meet the demands of modern personalized medicine and automated industrial processes.

Regional Highlights

- North America: This region holds the largest market share, characterized by high adoption of advanced medical technologies, substantial healthcare spending, and a robust regulatory environment. The presence of major market leaders and the high volume of cardiovascular and organ transplant surgeries significantly drive demand for high-end perfusion systems and related roller pump devices. Furthermore, the booming biotechnology sector in the US and Canada necessitates continuous investment in specialized bioprocessing pumps.

- Europe: The European market is mature, driven by comprehensive healthcare systems, particularly in countries like Germany, the UK, and France. Emphasis is placed on technological innovation and adherence to strict EU medical device regulations (MDR). Growth is steady, focusing on replacement cycles of legacy equipment and the increasing use of roller pumps in home-care dialysis and specialized critical care units.

- Asia Pacific (APAC): Expected to exhibit the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is primarily attributable to improving healthcare infrastructure, increasing disposable incomes, and the expansion of domestic and international pharmaceutical and biomanufacturing capacities in China, India, and South Korea. Government initiatives to tackle chronic diseases and expand access to modern medical treatments are key accelerators in this region.

- Latin America (LATAM): Growth in LATAM is moderate but steady, centered around expanding access to dialysis treatment and modernization efforts in major private hospital systems in Brazil and Mexico. Economic stability and governmental focus on non-communicable diseases are crucial determinants of market performance, often relying on imported devices from North America and Europe.

- Middle East and Africa (MEA): This region offers emerging opportunities, particularly in the Gulf Cooperation Council (GCC) countries which invest heavily in world-class healthcare facilities. Demand is specialized, focusing on high-tech medical centers and the development of local pharmaceutical production hubs, requiring precise fluid management devices.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Roller Pumps Device Market.- Medtronic

- Getinge AB

- Terumo Corporation

- Fresenius Medical Care

- Nipro Corporation

- B. Braun Melsungen AG

- Watson-Marlow Fluid Technology Solutions

- Cole-Parmer

- Gilson, Inc.

- Masterflex (Antylia Scientific)

- IDEX Corporation

- Zenith Pumps

- Randox Laboratories

- LivaNova PLC

- KNF Neuberger

- Flowrox

- Ebara Corporation

- Bio-Rad Laboratories, Inc.

- CircuLite, Inc. (Part of major medical companies)

- Xylem Inc.

Frequently Asked Questions

Analyze common user questions about the Global Roller Pumps Device market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary application driving the demand for roller pumps?

The primary application driving demand is Cardiopulmonary Bypass (CPB) during open-heart surgery, followed closely by Hemodialysis (dialysis machines) for kidney failure treatment, due to the need for precise, non-contaminating, and continuous flow of bodily fluids.

How do technological advancements address flow accuracy in roller pumps?

Technological advancements, including sophisticated stepper motors, closed-loop feedback systems, and AI integration, are used to compensate for tubing wear and mechanical pulsation, ensuring highly consistent and accurate flow rates crucial for clinical safety and bioprocessing validation.

Which segment of the market is expected to show the fastest growth?

The Bioprocessing and Pharmaceutical Manufacturing application segment is projected to show the fastest growth, driven by the increasing need for sterile and validated fluid transfer systems required for scaling up biologic drug production, fermentation, and filtration processes.

What is the main constraint hindering the wider adoption of roller pumps?

A significant constraint is the maintenance and operational expense associated with the proprietary tubing sets, which need frequent replacement to ensure sterility and prevent mechanical failures like spallation, adding to the total cost of ownership for end-users.

Where does the Asia Pacific region stand in the global market hierarchy?

While currently smaller than North America and Europe, the Asia Pacific region is rapidly gaining market share and is forecasted to be the fastest-growing geographical market due to massive investments in healthcare infrastructure and expanding domestic pharmaceutical manufacturing capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager