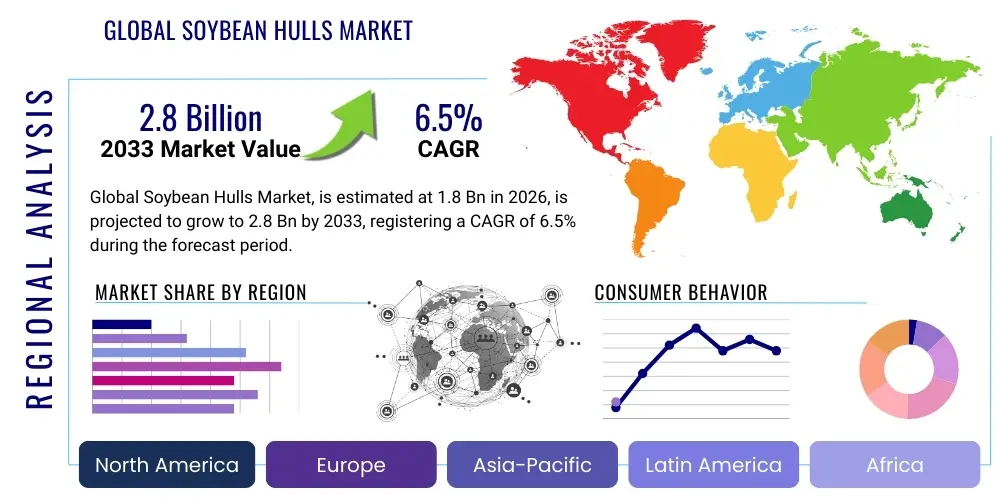

Global Soybean Hulls Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442685 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Global Soybean Hulls Market Size

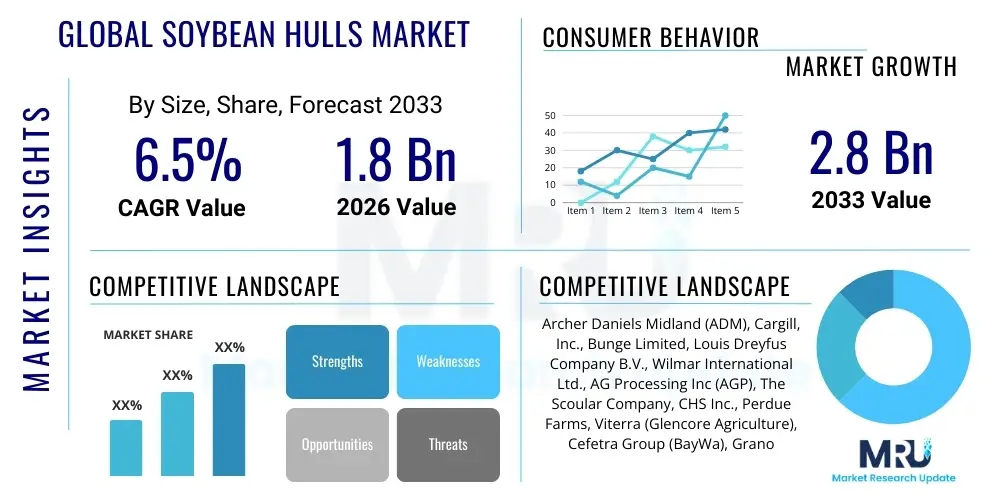

The Global Soybean Hulls Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $1.8 Billion in 2026 and is projected to reach $2.8 Billion by the end of the forecast period in 2033.

Global Soybean Hulls Market introduction

The Global Soybean Hulls Market centers around the utilization of the outer protective covering of the soybean seed, a primary byproduct generated during the soybean processing industry, specifically oil extraction and meal production. Soybean hulls are predominantly recognized for their high dietary fiber content, low starch levels, and moderate protein contribution, making them a valuable, yet often underutilized, ingredient across various sectors. Historically, they have been primarily used as a roughage source in livestock feed, especially for ruminants, due to their ability to support gut health and facilitate slow digestion.

Major applications for soybean hulls extend beyond traditional livestock feeding, diversifying into pet food manufacturing, functional food ingredients (after further processing), and industrial uses such as bedding material or bio-fuel components. Their low caloric density and high water-holding capacity also make them attractive for specialized dietary formulations. The increasing focus on sustainable agriculture and the reduction of agricultural waste globally are significantly bolstering the market's relevance, positioning soybean hulls as an economically viable and environmentally sound ingredient source.

Key benefits driving market adoption include cost-effectiveness compared to competing fiber sources, reliable supply availability due to massive global soybean production, and inherent nutritional advantages, particularly their fermentable fiber profile essential for animal health. Driving factors encompass the rising global demand for meat and dairy products, necessitating increased feed production; advancements in processing technology allowing for enhanced digestibility; and regulatory pressures pushing agricultural operations towards utilizing byproducts efficiently to achieve circular economy objectives.

Global Soybean Hulls Market Executive Summary

The Global Soybean Hulls Market is experiencing robust expansion, fundamentally driven by the escalating requirements of the global animal husbandry sector and a paradigm shift towards valorizing agricultural waste products. Business trends indicate a strong move toward advanced processing techniques, such as micronization and extrusion, which improve the digestibility and nutritional value of hulls, thereby expanding their applicability in monogastric diets (swine and poultry) beyond traditional ruminant feed. Strategic investments in large-scale dedicated hull pelletizing facilities in major soybean producing regions, particularly in North America and South America, are streamlining logistics and reducing transportation costs, significantly impacting global trade flows.

Regionally, the market is spearheaded by the Asia Pacific (APAC) region, which exhibits the fastest growth trajectory, propelled by massive and expanding swine and aquaculture industries, coupled with insufficient domestic fiber alternatives. North America remains a dominant force, capitalizing on mature soybean crushing infrastructure and advanced feed formulation practices. European trends are characterized by stringent quality control and a growing demand for Non-GMO and sustainably sourced feed inputs, leading to premium pricing for certified soybean hull products. Latin America, particularly Brazil and Argentina, serves as the critical global supply base, benefiting from currency advantages and economies of scale in raw material availability.

In terms of segment trends, the Pelletized segment currently holds the largest market share due to ease of storage, handling, and transportation, which is crucial for international commerce. However, the Meal/Powder segment is projected to witness significant growth, driven by specialized applications in pet food and niche equine diets requiring finer particle sizes for integration. Application-wise, the Cattle Feed segment remains the primary consumer, though the fastest growth is observed in the Pet Food and Aquaculture Feed segments, reflecting diversification into higher-value end-uses demanding specialized fiber sources for digestive health.

AI Impact Analysis on Global Soybean Hulls Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Soybean Hulls Market frequently revolve around supply chain resilience, optimization of feed formulation, and predictive quality assessment. Users are keenly interested in how machine learning models can accurately forecast global soybean hull availability amidst volatile geopolitical and environmental conditions, ensuring stable supply for feed mills. Furthermore, significant inquiry focuses on the integration of AI-driven optimization algorithms within specialized feed production facilities to determine the precise inclusion rates of soybean hulls based on real-time nutritional profiles of other ingredients, maximizing cost-efficiency while meeting exacting dietary specifications for different livestock species.

The key themes emerging from this analysis highlight the expectation that AI will transition soybean hull utilization from a basic bulk ingredient to a precisely managed component. Concerns often center on the initial investment required for sophisticated sensor technology and data infrastructure necessary to leverage AI effectively, particularly in emerging markets. Expectations are high regarding the use of predictive maintenance enabled by AI in soybean crushing plants, minimizing downtime and ensuring a consistent flow of high-quality hull byproducts. AI is anticipated to play a crucial role in validating sustainability claims, tracking the origin, and processing conditions of the hulls, thereby meeting the traceability demands of premium markets in Europe and North America.

Ultimately, AI’s influence is expected to stabilize pricing, improve utilization efficiency, and unlock new application potential by enabling better segmentation and refinement of the hull product based on physical and chemical characteristics detected through advanced analytics. This includes optimizing pellet density, predicting shelf life based on environmental data, and developing novel extraction methods for high-value compounds (like polysaccharides) present in the hull structure, moving the market away from simple commodity trading towards value-added product development.

- Enhanced Supply Chain Predictability: AI models optimize logistics, predict yield fluctuations, and ensure stable sourcing of hulls globally.

- Precision Feed Formulation: Machine learning algorithms dynamically adjust hull inclusion levels in feed based on livestock needs and fluctuating raw material nutrient content.

- Automated Quality Control: Utilizing computer vision and NIR spectroscopy, AI rapidly assesses hull quality, moisture, and contamination levels during processing.

- Resource Efficiency Optimization: AI systems minimize waste in the processing phase, optimizing energy consumption during drying and pelletizing.

- Traceability and Sustainability Validation: Blockchain integrated with AI verifies the source and processing pathway of hulls, supporting sustainable sourcing mandates.

DRO & Impact Forces Of Global Soybean Hulls Market

The Global Soybean Hulls Market is dynamically shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the primary Impact Forces determining market trajectory. The overarching driver is the continuous and escalating global requirement for cost-effective, high-fiber feed ingredients necessary to sustain the rapidly expanding livestock and poultry industries, particularly in Asia and Latin America. Simultaneously, environmental mandates promoting circular economy principles provide a structural opportunity, pressuring the agricultural supply chain to convert byproducts like hulls from waste streams into valuable commercial inputs, significantly reducing disposal costs and generating new revenue streams for soybean processors.

Key restraints, however, temper this growth trajectory. These include inherent challenges related to the physical characteristics of soybean hulls, such as low bulk density in their loose form, which drastically increases handling, storage, and transportation costs before pelletization. Furthermore, competition from alternative, regionally available, high-fiber sources, such as rice bran, wheat bran, and various cellulosic biomasses, particularly in markets where soybean processing is limited, presents a significant competitive constraint. Nutritional limitations, specifically the high lignin content in raw hulls and the requirement for specialized enzymatic treatment to maximize digestibility in monogastrics, also necessitate further investment and expertise, posing a technical hurdle for some end-users.

Opportunities for strategic expansion are centered on technological advancements and diversification into non-feed applications. Significant potential exists in refining hulls for human consumption as a source of clean, non-GMO dietary fiber supplements, capitalizing on the growing consumer focus on gut health. Moreover, ongoing research into bio-conversion technologies—specifically using hulls as a substrate for bio-fuel production, bio-plastics, or specialized chemical precursors—presents long-term growth avenues that could fundamentally shift the value proposition of the product beyond the feed sector. The market's stability is further enhanced by its position as a non-cyclical byproduct, ensuring a consistent supply tied to essential food demands.

Segmentation Analysis

The Global Soybean Hulls Market is meticulously segmented based on product form, specific end-use application, and geographical distribution, allowing for granular analysis of demand patterns and strategic supply deployment. Segmentation by form—comprising Pellets, Meal/Powder, and Raw/Loose Hulls—is critical as it dictates logistics costs, storage requirements, and the suitability for various processing stages. The pelletized form dominates due to its efficiency in international trade and bulk handling for large feed mills. Segmentation by application highlights the dependence of the market on the animal feed sector, which is further refined into ruminants, monogastrics, and niche sectors like pet food and aquaculture, each requiring distinct processing levels and nutritional specifications.

- By Product Form:

- Pelletized Hulls

- Meal/Powder Hulls

- Raw/Loose Hulls

- By Application:

- Cattle Feed (Ruminants)

- Swine Feed

- Poultry Feed

- Aquaculture Feed

- Pet Food

- Other Applications (e.g., Equine Feed, Bedding Material, Biofuels)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Global Soybean Hulls Market

The value chain for the Global Soybean Hulls Market commences with the upstream agricultural activities of soybean cultivation and harvest, followed immediately by the crucial industrial step of soybean crushing and oil extraction. Soybean processing plants act as the core manufacturing hub, where the hull is mechanically separated from the cotyledon. The efficiency of this upstream process directly impacts the quality and quantity of the hull byproduct. Major integrated agricultural conglomerates often control both the cultivation and processing stages, providing significant leverage in raw material supply consistency. Key upstream factors also involve the sourcing and cost of energy required for the subsequent drying and pelletizing processes.

The midstream phase focuses on transforming the raw hull byproduct into commercially viable forms. This typically involves drying to reduce moisture content, grinding or milling to achieve desired particle size, and most importantly, pelletizing, which is essential for densification and cost-effective logistics. Value addition at this stage often includes the application of specialized enzymes or binding agents to enhance digestibility and physical stability. Distribution channels are categorized into direct and indirect routes. Direct sales often occur between large integrated processors and major animal feed manufacturers (e.g., Cargill, ADM) through long-term contracts, ensuring stable procurement. Indirect channels involve commodity traders, regional distributors, and brokers who manage the supply to smaller feed mills, individual farmers, and international markets.

The downstream analysis focuses on the end-users. The primary end-users are concentrated in the commercial livestock sector, where soybean hulls are blended into complete feed formulations. Logistics, warehousing, and inventory management capabilities of downstream customers are critical, especially for large-volume purchasers. The market also sees specialized distribution networks for high-value segments, such as pet food manufacturers, who demand rigorous quality control and certification standards, often relying on specialized third-party logistics providers capable of handling food-grade ingredients, distinguishing this supply route from the general feed commodity trade.

Global Soybean Hulls Market Potential Customers

The primary and most significant segment of end-users for the Global Soybean Hulls Market comprises commercial animal feed manufacturers, who utilize the product as a cost-effective, fermentable fiber source within composite feed mixtures. Large integrated agricultural companies that operate extensive livestock farms (cattle, swine, and poultry) are also major direct buyers, seeking to minimize feed costs and optimize nutritional profiles specific to their herds. Ruminant farmers, particularly beef and dairy cattle operations, constitute the most stable consumer base, as soybean hulls function excellently as a partial replacement for high-cost hay or silage, ensuring essential roughage requirements are met while maintaining milk production efficiency or weight gain.

A rapidly expanding segment of potential customers includes specialized pet food and premium aquaculture feed producers. These buyers focus less on volume and more on the quality and consistent characteristics of the hulls, often demanding finely ground or specially treated hull meal. In pet food, the high fiber content aids digestive regularity and weight management formulas, addressing the growing prevalence of pet obesity. Similarly, in aquaculture, particularly shrimp and herbivorous fish farming, processed hulls are increasingly utilized as sustainable, plant-based bulk ingredients to replace traditional, more expensive protein sources, supporting the industry’s push for sustainable sourcing and cost containment.

Furthermore, emerging buyers include bio-energy production facilities and chemical manufacturers exploring the use of cellulosic biomass. These industrial customers view soybean hulls as a promising feedstock for advanced biofuels (e.g., cellulosic ethanol) or as a source material for producing bioplastics and specific chemical compounds derived from lignocellulose. While currently a minor segment, the structural potential in these industrial applications represents a significant long-term growth opportunity, attracting buyers focused on renewable resource utilization and sustainable manufacturing processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.8 Billion |

| Market Forecast in 2033 | $2.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Archer Daniels Midland (ADM), Cargill, Inc., Bunge Limited, Louis Dreyfus Company B.V., Wilmar International Ltd., AG Processing Inc (AGP), The Scoular Company, CHS Inc., Perdue Farms, Viterra (Glencore Agriculture), Cefetra Group (BayWa), Granol Indústria Comércio e Exportação S.A., Caramuru Alimentos S.A., Amaggi, Jiusan Group, Gremio Agricola, SunOpta Inc., LDC Argentina S.A., TDM Berhad, Associated British Foods plc (ABF) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Soybean Hulls Market Key Technology Landscape

The technological landscape of the Global Soybean Hulls Market is characterized by innovations focused primarily on enhancing digestibility, optimizing physical handling characteristics, and expanding application potential through advanced processing. A critical technology is the high-pressure pelletizing and densification process, which uses sophisticated machinery to compress low-density hulls into stable, durable pellets. This significantly reduces volume, lowering freight costs, and minimizes dust, improving operational safety in feed mills. Advancements here involve optimizing binder use and cooling systems to maximize pellet durability and resistance to breakage during transit, ensuring product integrity for global distribution.

Enzymatic hydrolysis and specialized extrusion are increasingly pivotal technologies, particularly for refining hulls targeted at monogastric animals and pet food. Raw soybean hulls contain anti-nutritional factors and high levels of lignified fiber that limit energy utilization in non-ruminants. Enzymatic pretreatment using cellulases and hemicellulases breaks down complex carbohydrates, significantly improving nutrient bioavailability and digestibility. Extrusion technology utilizes heat, moisture, and pressure to gelatinize the fiber matrix, making it more accessible to digestive enzymes, thereby enabling higher inclusion rates in high-performance animal diets and functional food formulations. These advanced processing methods shift the value proposition of the hull byproduct from a simple filler to a functional dietary component.

Furthermore, the integration of advanced analytical and sorting technologies, often leveraging Artificial Intelligence, is crucial for maintaining quality assurance and consistency. Near-Infrared (NIR) spectroscopy is widely adopted by major processors to rapidly analyze the moisture, protein, and crude fiber content of the hulls in real-time, ensuring strict compliance with quality specifications before shipment. Similarly, sophisticated grinding and micronization equipment is employed to produce ultra-fine hull powders necessary for specialized applications like human dietary fiber supplements or pharmaceutical excipients, representing the cutting edge of product diversification within the market.

Regional Highlights

- North America: North America remains a cornerstone of the global soybean hulls market, driven by the United States, which is one of the world’s largest producers of soybeans and a primary exporter of processed soybean products. The region benefits from highly integrated and technologically advanced soybean crushing facilities, ensuring a steady, high-volume supply of hulls. Demand is primarily robust in the large-scale beef and dairy industries, which require massive quantities of consistent roughage. Technological adoption of pelletizing and quality control is high, facilitating significant intra-regional and international trade. Regulatory frameworks, while strict, are clear, allowing for stable market operations. The regional focus is increasingly on sustainable sourcing and Non-GMO verification for export markets, especially Europe. The US acts as a major price setter and supply anchor for the global market.

- Europe: The European market is characterized by high demand for high-quality, traceable, and often certified Non-GMO feed ingredients, positioning soybean hulls as a valuable imported product, as domestic soybean production is insufficient. European consumption is driven by intensive swine and dairy farming, operating under some of the world's most stringent feed safety regulations. This necessitates rigorous quality control and documentation from suppliers. While overall volume consumption may be lower than in North America or APAC, the European market often commands premium pricing due to its stringent requirements regarding origin, processing standards, and absence of chemical residues. The primary challenge is reliance on imports, making the market highly sensitive to logistical disruptions and global commodity price volatility.

- Asia Pacific (APAC): APAC is the fastest-growing region and the largest consumer of soybean hulls, primarily driven by massive, expanding populations of swine, poultry, and aquaculture (especially in China, India, and Southeast Asia). The rapid modernization and industrialization of the feed industry across the region require stable and large volumes of raw materials. Although some countries, notably China, are large soybean crushers, the overall regional demand far outstrips domestic supply, necessitating substantial imports from the Americas. Soybean hulls are essential for adding fiber to feed formulations that rely heavily on energy-dense grains. The growth is fueled by rising disposable incomes leading to increased consumption of meat and dairy, coupled with strong government support for agricultural modernization and waste valorization initiatives.

- Latin America: Latin America, led by Brazil and Argentina, serves as the critical global supply hub for soybean hulls, benefiting from immense soybean production volumes and highly competitive processing costs. These nations are leading exporters of pelletized hulls, leveraging efficient logistics (albeit often challenged by port capacity and inland transportation infrastructure) and favorable exchange rates. The regional market structure is dominated by large, international commodity trading houses. Domestically, there is growing consumption, particularly in Brazil's burgeoning livestock sector. The strategic advantage of this region lies in its raw material abundance and capacity for low-cost, high-volume production, making it indispensable for meeting APAC and European import demand.

- Middle East & Africa (MEA): The MEA market represents a growing, albeit smaller, consumer base, with demand concentrated in countries with significant import capabilities and established commercial livestock operations, such as Saudi Arabia, UAE, and South Africa. These regions rely heavily on imports of both soybeans and processed byproducts like hulls due to arid conditions limiting local fiber production. Demand is driven by the necessity to maintain large dairy and poultry flocks under challenging climatic conditions. Logistics and import tariffs pose significant hurdles. However, regional sustainability initiatives and investments in advanced feed mills are expected to stimulate moderate, consistent growth in demand for standardized, pelletized soybean hulls.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Soybean Hulls Market.- Archer Daniels Midland (ADM)

- Cargill, Inc.

- Bunge Limited

- Louis Dreyfus Company B.V.

- Wilmar International Ltd.

- AG Processing Inc (AGP)

- The Scoular Company

- CHS Inc.

- Perdue Farms

- Viterra (Glencore Agriculture)

- Cefetra Group (BayWa)

- Granol Indústria Comércio e Exportação S.A.

- Caramuru Alimentos S.A.

- Amaggi

- Jiusan Group

- Gremio Agricola

- SunOpta Inc.

- LDC Argentina S.A.

- TDM Berhad

- Associated British Foods plc (ABF)

Frequently Asked Questions

Analyze common user questions about the Global Soybean Hulls market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth for the Global Soybean Hulls Market?

The primary drivers are the massive and consistent growth in global livestock production, particularly in the swine, poultry, and dairy sectors, which necessitate high volumes of affordable, high-fiber roughage. Additionally, increasing global focus on maximizing agricultural byproduct utilization and minimizing waste aligns perfectly with the economic and environmental benefits of using soybean hulls as a commercial input.

How is the digestibility of soybean hulls improved for specialized animal feeds, such as for poultry or aquaculture?

Digestibility for monogastric and aquaculture diets is significantly enhanced through specialized processing technologies. This includes enzymatic pretreatment using cellulases and hemicellulases to break down the complex fiber structure, and high-heat extrusion or micronization techniques that alter the physical structure of the hull, making the nutrients more accessible and improving inclusion rates without negatively affecting animal performance.

Which geographical region holds the highest growth potential for soybean hull consumption?

The Asia Pacific (APAC) region, led by countries such as China, India, and Vietnam, holds the highest growth potential. This growth is fueled by rapid industrialization of animal farming, increasing per capita meat consumption, and reliance on imported feed ingredients, positioning APAC as the largest and most dynamic end-use market globally.

What is the market impact of using pelletized hulls compared to raw or loose hulls?

Pelletization is crucial for market efficiency, drastically improving bulk density and reducing volumetric costs associated with transportation and storage—key advantages for international trade. Pelletized hulls offer consistent quality and ease of handling, leading to higher adoption rates among large feed mill operators, whereas raw hulls are typically confined to local consumption due to prohibitive logistics expenses.

Are soybean hulls finding applications outside of traditional animal feed, and how significant are these emerging uses?

Yes, significant opportunities exist in diversification. Soybean hulls are increasingly being researched and utilized as a raw material for cellulosic ethanol and other advanced biofuels, as a component in biodegradable plastics, and, when refined, as a source of dietary fiber supplements for human food products. While the feed sector currently dominates volume, these emerging bio-industrial and human nutrition applications represent high-value growth segments essential for long-term market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager