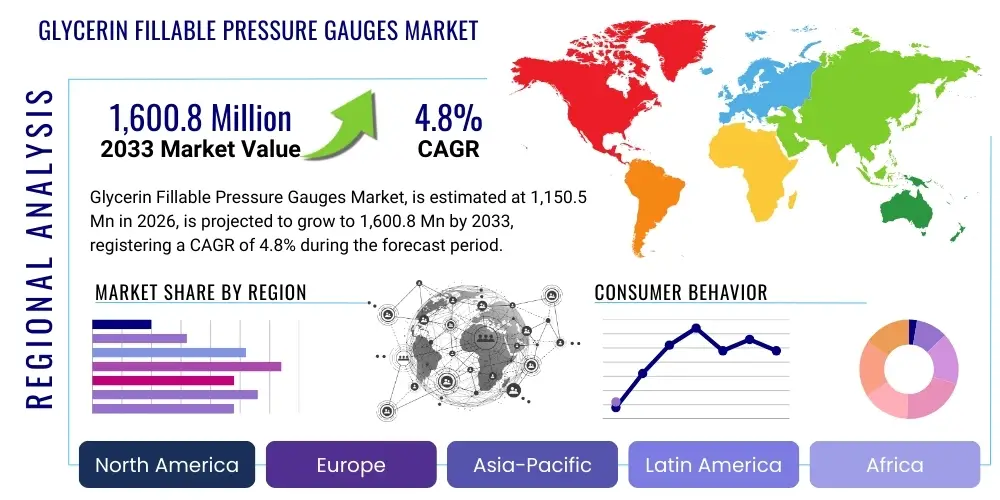

Glycerin Fillable Pressure Gauges Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443304 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Glycerin Fillable Pressure Gauges Market Size

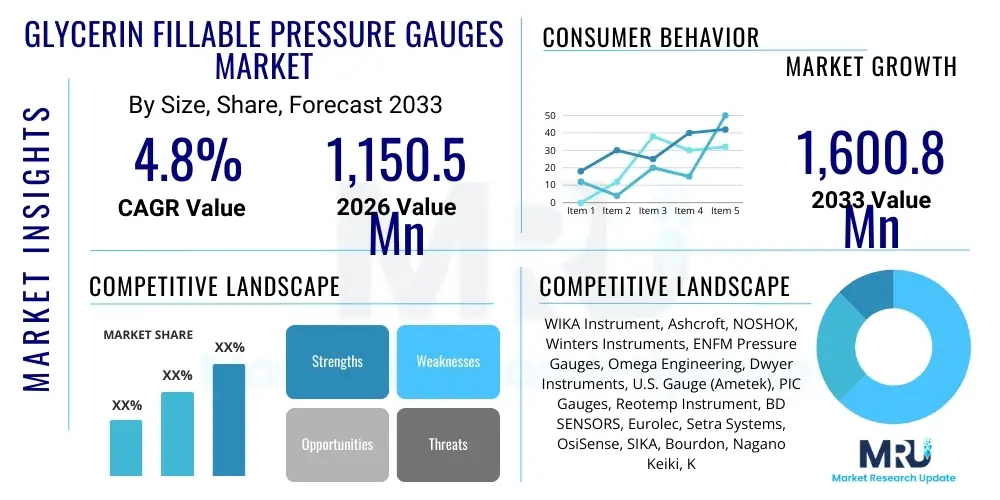

The Glycerin Fillable Pressure Gauges Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1,150.5 Million in 2026 and is projected to reach USD 1,600.8 Million by the end of the forecast period in 2033.

Glycerin Fillable Pressure Gauges Market introduction

Glycerin fillable pressure gauges are precision instruments crucial for monitoring and measuring pressure in various industrial processes. These devices utilize glycerin as a liquid filling medium, which serves the primary function of dampening internal movement caused by vibration, pulsation, and rapid pressure changes inherent in harsh operating environments. This liquid filling significantly extends the lifespan of the gauge mechanism, enhances readability by stabilizing the pointer movement, and lubricates internal components, ensuring sustained accuracy and reliability. The robust nature and anti-vibrational properties of these gauges make them indispensable across sectors characterized by heavy machinery and dynamic fluid systems, such as hydraulics, chemical processing, oil and gas extraction, and power generation.

The core product features a bourdon tube or diaphragm mechanism enclosed in a durable casing, typically stainless steel or high-grade plastic, depending on the required media compatibility and environment. The filling of high-purity glycerin minimizes wear and tear on the delicate internal gearing, particularly the movement linkage, thereby preventing premature failure often associated with dry gauges subjected to severe mechanical stress. Furthermore, glycerin acts as an effective heat sink, helping to dissipate localized heat buildup which could otherwise skew readings or damage components. This combination of mechanical protection and thermal stability reinforces the gauges' standing as a preferred solution for demanding applications requiring continuous, precise pressure monitoring.

Major applications for glycerin fillable pressure gauges span infrastructure, manufacturing, and resource management. In the hydraulic power units used in heavy construction and aerospace, they provide vital safety and operational feedback. Within chemical and petrochemical plants, their resistance to corrosion (when paired with suitable casing materials) and ability to withstand aggressive media ensure reliable performance. The driving factors behind market growth include increasing global investments in industrial automation, stringent safety regulations mandating accurate pressure measurement in high-risk zones, and the continuous necessity for equipment maintenance and replacement across mature industrial economies. The operational benefits—longevity, reliability, and precision—continue to solidify their foundational role in industrial instrumentation.

Glycerin Fillable Pressure Gauges Market Executive Summary

The Glycerin Fillable Pressure Gauges Market is experiencing consistent growth driven primarily by ongoing industrial expansion in emerging economies and the modernization of infrastructure across developed regions. Key business trends highlight a shift toward specialized, high-accuracy gauges capable of integrating into industrial internet of things (IIoT) frameworks, often referred to as 'smart' or 'hybrid' gauges that combine analog reliability with digital output capabilities. Manufacturers are focusing on enhancing material science to improve resistance against corrosive media and extreme temperatures, ensuring broader application scope. Consolidation among major players and strategic partnerships aimed at strengthening distribution networks in niche industrial segments are defining the competitive landscape. Supply chain resilience, particularly regarding specialized metallic components and calibration services, remains a critical operational focus.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, extensive investments in chemical processing, power generation, and water treatment infrastructure in countries like China, India, and Southeast Asia. North America and Europe, while mature markets, emphasize replacement demand and the adoption of high-specification gauges that meet increasingly rigorous environmental and safety standards, particularly within pharmaceutical and high-tech manufacturing. The demand in Latin America and the Middle East & Africa (MEA) is closely tied to commodity pricing fluctuations, notably in the oil and gas and mining sectors, where the gauges are essential for safe extraction and transport operations. Infrastructure revitalization projects globally are expected to provide sustained revenue streams throughout the forecast period.

Segment trends demonstrate robust demand for stainless steel casing gauges due to their superior corrosion resistance and durability, especially in harsh environments like offshore drilling and food processing. By pressure range, the high-pressure gauges (above 1000 psi) segment is exhibiting accelerated growth, reflecting the increasing prevalence of high-power hydraulic and pneumatic systems. Furthermore, the oil and gas, chemical and petrochemical, and water and wastewater treatment industries remain the dominant end-user segments, each requiring continuous, reliable pressure monitoring for safety and process efficiency. The focus on preventive maintenance and asset integrity management systems further supports the steady uptake of these durable, liquid-filled instruments over traditional dry gauges.

AI Impact Analysis on Glycerin Fillable Pressure Gauges Market

User queries regarding AI's impact on the pressure gauge market frequently center on three core themes: the potential displacement of analog instruments by smart sensors, the application of machine learning for predictive maintenance, and the role of AI in quality control and calibration. Users often express concern about whether traditional mechanical gauges will become obsolete, balanced by interest in how AI can enhance the performance and longevity of existing analog infrastructure. The central consensus among industry stakeholders is that AI will not eliminate glycerin-filled gauges but will rather augment their functionality. AI algorithms process data streams from sensors (often accompanying hybrid gauges) to predict mechanical failure, optimize maintenance schedules, and detect anomalies long before a mechanical breakdown occurs. This transformation shifts the value proposition from merely displaying pressure to providing proactive asset management insights.

The implementation of AI/ML models significantly improves the manufacturing processes for these precision instruments. In the production phase, AI can analyze visual and operational data collected during component assembly and final calibration, ensuring zero-defect output and highly precise calibration results that are difficult to achieve consistently through purely human-driven processes. Furthermore, AI-driven demand forecasting optimizes inventory management and supply chain logistics for manufacturers and distributors, ensuring that specific gauge types (e.g., high-pressure, corrosion-resistant) are available precisely when regional industrial projects require them. This integration reduces waste, improves response times, and ultimately enhances the overall efficiency of the market ecosystem, ensuring the continued viability of high-quality, liquid-filled analog gauges as reliable physical endpoints in a smart factory environment.

The primary expectation is that AI will facilitate the transition towards a 'hybrid instrumentation' approach. While the inherent dampening benefits of glycerin remain essential for mechanical protection in high-vibration settings, AI interprets the data generated by adjacent digital transmitters attached to these gauges. This analysis allows end-users to maximize the operational lifespan of the installed base. Common questions also address the cost-effectiveness of implementing AI-based monitoring solutions, suggesting a strong market appetite for retrofitting existing industrial infrastructure with smarter monitoring capabilities, rather than completely replacing reliable mechanical gauges with costly, fully digital counterparts.

- AI optimizes predictive maintenance schedules for gauges in critical assets.

- Machine learning algorithms enhance manufacturing precision and automated calibration processes.

- AI analyzes vibrational data from mechanical processes to detect early signs of gauge wear or failure.

- Integration of AI with hybrid gauges enables real-time performance monitoring and anomaly detection.

- Improved supply chain efficiency and inventory management through AI-driven demand forecasting.

DRO & Impact Forces Of Glycerin Fillable Pressure Gauges Market

The market for Glycerin Fillable Pressure Gauges is fundamentally shaped by a combination of stringent safety regulations and the inherent demands of industrial operational efficiency. Drivers include the global mandate for safer industrial environments, which necessitates highly reliable and accurate pressure measurement devices, particularly in sectors dealing with volatile substances. The superior vibration and pulsation dampening capability offered by the glycerin filling significantly extends gauge longevity in challenging machinery applications (e.g., pumps, compressors), reducing maintenance downtime and operational expenses, which acts as a powerful economic driver. Furthermore, the persistent growth in heavy industries such as oil and gas, chemical processing, power generation (especially renewable energy infrastructure which involves complex fluid dynamics), and specialized manufacturing segments continuously generates replacement and expansion demand for these durable instruments.

Restraints, however, pose challenges to sustained growth. A notable constraint is the increasing adoption of digital pressure sensors and transducers, which offer enhanced accuracy, remote monitoring capabilities, and easy integration into IIoT networks. While glycerin gauges offer superior mechanical durability, their lack of inherent digital output often requires additional transmitters, increasing the total cost of ownership in fully automated facilities. Price sensitivity in highly commoditized industrial applications, especially in emerging markets where dry gauges offer a lower initial cost, also restricts growth potential. Moreover, the specific maintenance requirements associated with liquid-filled gauges, such as occasional refilling or ensuring seal integrity, represent minor operational hurdles compared to sealed digital alternatives.

Opportunities for market expansion are centered on innovation and diversification. The development of 'hybrid' gauges—combining the mechanical resilience of glycerin filling with integrated digital communication capabilities (e.g., HART, wireless)—presents a significant avenue for growth, bridging the gap between analog reliability and digital connectivity. Expanding applications in niche areas requiring ultra-high purity or specialized media compatibility, such as semiconductor manufacturing and pharmaceutical bioreactors, necessitates the development of specialized gauges using materials like Monel or PTFE. Furthermore, the strong emphasis on asset integrity management and preventive maintenance programs globally creates opportunities for manufacturers to position their gauges not just as measurement tools, but as critical components within a larger industrial safety and efficiency ecosystem, capitalizing on the longevity benefit conferred by the glycerin filling.

Segmentation Analysis

The Glycerin Fillable Pressure Gauges Market is comprehensively segmented based on several key operational and structural parameters, allowing for detailed market targeting and product customization. Primary segmentation involves the type of case material used, the specific pressure measurement range, the size or diameter of the dial, and critically, the final end-user industry. These segments reflect the diverse requirements of industrial users, ranging from sanitary requirements in food and beverage production to extreme durability and high-pressure ratings demanded by offshore oil exploration. Analyzing these segments provides strategic insights into consumer preferences, technological gaps, and regional demand patterns.

The segmentation by end-user industry is particularly vital as it dictates the required material compatibility, ingress protection (IP) rating, and certification standards. For instance, the chemical processing industry heavily favors stainless steel cases with specialized internal components to resist corrosion, whereas the HVAC and utility sectors might prioritize cost-effective brass or plastic components for less demanding applications. Technological evolution is also driving segmentation, with a growing distinction between standard analog gauges and hybrid models that incorporate internal microprocessors or transmitters, thus merging traditional mechanical benefits with modern digital functionality.

Understanding the market by pressure range is essential for manufacturers tailoring product lines, as accuracy and robustness requirements intensify significantly at higher pressure limits. Low-pressure gauges (under 100 psi) are used broadly in air and water systems, while high-pressure variants (above 5,000 psi) are critical for hydraulic presses and specialized industrial machinery. This detailed segmentation allows stakeholders to accurately gauge demand shifts, optimize production capabilities, and strategically position products to address specific industrial pain points related to vibration, corrosion, and accuracy maintenance under operational stress.

- By Type

- Stainless Steel Case Glycerin Gauges

- Brass Case Glycerin Gauges

- Plastic Case Glycerin Gauges

- Specialized Material (Monel, PTFE-coated) Gauges

- By Pressure Range

- Low Pressure Gauges (0–100 psi)

- Medium Pressure Gauges (100–1000 psi)

- High Pressure Gauges (Above 1000 psi)

- Vacuum/Compound Gauges

- By Dial Size (Diameter)

- 1.5 inch to 2.5 inch

- 3 inch to 4 inch

- 6 inch and Above

- By End-User Industry

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Water and Wastewater Treatment

- HVAC and Refrigeration

- Food and Beverage and Pharmaceutical (Sanitary Applications)

- Power Generation (Conventional and Renewables)

- Hydraulics and Pneumatics

Value Chain Analysis For Glycerin Fillable Pressure Gauges Market

The value chain for Glycerin Fillable Pressure Gauges begins with the upstream sourcing of specialized raw materials, primarily high-grade stainless steel (304/316) or brass for casings and wetted parts (bourdon tube, socket), and high-purity glycerin or glycerin/water mixtures for the filling medium. The precision manufacturing phase involves intricate processes such as stamping, welding, movement linkage assembly, and critical calibration. Quality assurance and certification (e.g., ASME, EN, ISO) are integrated into this phase, ensuring that the gauges meet defined accuracy and reliability standards. Efficient upstream procurement, especially securing specialized alloys and ensuring the purity of the glycerin, is paramount to maintaining high product quality and competitive manufacturing costs.

Mid-stream activities focus on inventory management, specialized testing (e.g., pressure cycling, temperature testing), and packaging tailored for industrial environments. The distribution channel is bifurcated into direct sales channels, typically utilized for large OEM agreements or complex, custom orders, and indirect channels, which rely heavily on industrial distributors, wholesalers, and specialized instrumentation supply houses. Indirect channels are crucial for reaching diverse small-to-medium enterprises and handling aftermarket replacement demand efficiently. Distributors often provide value-added services such as local calibration, minor modifications (e.g., specific dial markings), and technical support, playing a vital role in market penetration and customer relationship management.

Downstream activities involve installation, operation, and maintenance. End-users require reliable technical documentation and, increasingly, access to aftermarket services like re-calibration and repair. The longevity provided by the glycerin filling reduces the frequency of replacement, but it necessitates specialized service providers capable of handling liquid-filled gauges. The shift towards IIoT is introducing a new downstream component: system integrators who incorporate these gauges into larger digital monitoring networks, linking the reliable mechanical data point with predictive analytics software. The efficiency of the distribution network and the responsiveness of aftermarket service providers significantly influence customer loyalty and the overall effectiveness of the product in industrial settings.

Glycerin Fillable Pressure Gauges Market Potential Customers

The potential customers for Glycerin Fillable Pressure Gauges are diverse and broadly categorized into industries where fluid pressure control is critical, dynamic processes are common, and harsh operating conditions (vibration, pulsation, corrosive media) prevail. The primary end-users include large-scale industrial operators and original equipment manufacturers (OEMs). OEMs integrate these gauges directly into their machinery, such as hydraulic power units, industrial compressors, refrigeration systems, and specialized processing equipment. The decision-making unit often involves procurement managers, plant safety officers, and maintenance engineers who prioritize instrument reliability, compliance with international standards, and total cost of ownership over the instrument's lifecycle.

In terms of specific sectors, the oil and gas industry represents a foundational customer base, utilizing these gauges extensively across drilling rigs, pipelines, and refineries to ensure operational safety and monitor complex fluid transfer processes under extreme vibration. Similarly, the chemical and petrochemical sectors rely on these instruments for measuring pressure within reactors, mixers, and filtration systems where high temperatures and corrosive vapors necessitate the robust, sealed design offered by glycerin-filled devices. These industries demand gauges with specialized wetted materials (e.g., 316L stainless steel) to guarantee media compatibility and long-term integrity, driving demand for premium products.

Beyond heavy industry, customers in food and beverage and pharmaceutical manufacturing require sanitary-design glycerin-filled gauges (often diaphragm seals attached) that prevent contamination while withstanding cleaning processes. The hydraulic and pneumatic sector, covering manufacturing, construction, and heavy machinery operation, is a consistent buyer due to the inherent pulsating nature of their systems, making the dampening function of glycerin essential. Utilities, including power generation and water treatment facilities, also form a significant customer segment, utilizing these gauges for monitoring boiler pressure, turbine control systems, and municipal distribution networks, emphasizing reliable operation in static, but critical, environmental monitoring points.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,150.5 Million |

| Market Forecast in 2033 | USD 1,600.8 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WIKA Instrument, Ashcroft, NOSHOK, Winters Instruments, ENFM Pressure Gauges, Omega Engineering, Dwyer Instruments, U.S. Gauge (Ametek), PIC Gauges, Reotemp Instrument, BD SENSORS, Eurolec, Setra Systems, OsiSense, SIKA, Bourdon, Nagano Keiki, Keller, Nuova Fima, General Instruments Consortium |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glycerin Fillable Pressure Gauges Market Key Technology Landscape

The technology landscape of the Glycerin Fillable Pressure Gauges Market is characterized by a mature core technology constantly being refined through material science advancements and integration with smart digital capabilities. The foundational technology revolves around the bourdon tube or diaphragm mechanism—proven mechanical principles that translate pressure into mechanical movement of a pointer. Key technological refinements focus on the wetted parts, where manufacturers employ advanced corrosion-resistant alloys, such as Monel and Hastelloy, to extend the gauge life in highly aggressive media environments typical of chemical processing. The glycerin filling itself is a technological consideration; modern gauges utilize high-purity, often food-grade, glycerin or silicone oils (for extreme temperature applications) to optimize viscosity and ensure minimal thermal coefficient changes, maintaining reading accuracy across varying ambient temperatures. Specialized welding techniques, particularly orbital welding, are employed in sanitary gauges to ensure smooth, crevice-free surfaces that prevent bacterial buildup, critical for food and pharma applications.

A major technological trend reshaping the market is the development of hybrid gauges. These instruments incorporate traditional mechanical pressure measurement capabilities, benefiting from the glycerin dampening, while simultaneously embedding electronic sensors or transmitters within the case. This allows the gauge to provide both a reliable, local analog reading for immediate field checks and a synchronized digital signal for integration into Plant SCADA or Distributed Control Systems (DCS). Communication protocols like HART, Foundation Fieldbus, and even low-power wireless standards (e.g., LoRaWAN) are increasingly being built into the gauge head or transmitter accessories, effectively future-proofing the mechanical instrument in the age of IIoT. This hybrid approach caters to the dual industrial need for operational resilience (analog backup) and data accessibility (digital integration).

Furthermore, technology related to safety and material compliance is constantly evolving. Manufacturers utilize advanced pressure relief mechanisms and restricted flow orifices to enhance safety, especially for gauges installed in oxygen service or high-pressure steam applications. For the internal movement, precision gearing materials, often made from specialized brass or stainless steel alloys, are micro-machined to minimize friction and hysteresis, thus sustaining high accuracy over millions of pressure cycles. The overall focus is on creating instruments that are not just durable and shock-resistant due to the glycerin, but also highly accurate and fully compliant with stringent industrial standards (e.g., API, ASME B40.100), leveraging advanced manufacturing and calibration technologies like automated laser etching for precise dial markings and robotic calibration benches for repeatable performance testing.

Regional Highlights

- Asia Pacific (APAC) Dominance: APAC is the largest and fastest-growing market for Glycerin Fillable Pressure Gauges, primarily fueled by massive infrastructure development and rapid industrialization, particularly in chemical processing, petrochemicals, power generation, and water utility expansion across China, India, and Southeast Asian nations. The region’s focus on establishing robust manufacturing hubs requires reliable, cost-effective instrumentation that can withstand demanding production environments. Government initiatives promoting industrial safety and environmental compliance further necessitate the adoption of accurate and durable pressure measurement devices.

- North America (NA) Maturity and High Specification Demand: The North American market is characterized by high replacement demand and a strong emphasis on premium, high-specification gauges. Key growth areas include the oil and gas sector (especially shale extraction operations requiring high-pressure, vibration-resistant gauges) and sophisticated manufacturing sectors like aerospace and pharmaceuticals. Regulatory frameworks, such as those governed by OSHA and stringent EPA requirements, drive demand for certified, high-accuracy instruments that guarantee consistent performance and minimize operational risk, often favoring hybrid gauges with digital output capability.

- Europe (EU) Regulatory Compliance and Process Optimization: Europe represents a mature market driven by strict safety and quality standards (e.g., ATEX directives for explosive atmospheres and PED for pressure equipment). The emphasis is on process efficiency, energy optimization, and sustainability in chemical, utility, and heavy machinery manufacturing. Demand is sustained by the continuous upgrade of aging industrial infrastructure and a high preference for suppliers who meet rigorous European certification requirements. Germany, the UK, and Italy remain key consumers, leading in the adoption of specialized and technologically advanced models.

- Middle East and Africa (MEA) Oil & Gas Investment: The MEA market growth is intrinsically linked to investments in the oil, gas, and petrochemical sectors. Major upstream and downstream projects, particularly in Saudi Arabia, UAE, and Qatar, require vast quantities of robust, corrosion-resistant gauges suitable for high-temperature and high-pressure applications. While the market can be volatile due to commodity price fluctuations, long-term national visions emphasizing diversification and industrial base expansion ensure sustained demand for critical instrumentation.

- Latin America (LATAM) Infrastructure Investment and Mining: Growth in LATAM is concentrated in key industrial nations like Brazil and Mexico. The mining sector, alongside water and wastewater treatment projects, provides steady demand. Economic fluctuations can impact large-scale capital projects, but the essential nature of the gauges in existing industrial maintenance ensures consistent consumption, particularly favoring durable, easily maintainable glycerin-filled variants over highly sensitive electronic alternatives in remote or challenging operational sites.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glycerin Fillable Pressure Gauges Market.- WIKA Instrument, LP

- Ashcroft Inc.

- NOSHOK, Inc.

- Winters Instruments

- Omega Engineering, Inc.

- Dwyer Instruments, LLC

- U.S. Gauge (Ametek)

- PIC Gauges, Inc.

- Reotemp Instrument Corporation

- BD SENSORS GmbH

- Eurolec Instruments Ltd.

- Setra Systems, Inc.

- OsiSense (Schneider Electric)

- SIKA Dr. Siebert & Kühn GmbH & Co. KG

- Bourdon Haenni (Chauvin Arnoux Group)

- Nagano Keiki Co., Ltd.

- Keller America, Inc.

- Nuova Fima S.p.A.

- General Instruments Consortium

- ENFM Pressure Gauges

Frequently Asked Questions

Analyze common user questions about the Glycerin Fillable Pressure Gauges market and generate a concise list of summarized FAQs reflecting key topics and concerns.Why are glycerin fillable pressure gauges preferred over dry gauges in industrial environments?

Glycerin filling is preferred because it effectively dampens the pointer movement, protecting the internal mechanism from damage caused by high vibration and rapid pressure pulsation common in pumps, compressors, and hydraulic systems. This dampening action ensures accurate readings, prevents premature wear and tear, and significantly extends the operational lifespan of the gauge in harsh conditions.

What is the typical lifespan and maintenance requirement for a glycerin-filled pressure gauge?

A high-quality glycerin-filled gauge can last significantly longer than a dry gauge, often exceeding five to seven years in high-stress applications due to internal lubrication and protection. Maintenance is generally minimal but may require periodic re-calibration (typically annually) and occasional replacement if the seal leaks or the liquid filling discolors, although modern seals minimize leakage issues.

How does the glycerin filling affect the accuracy and temperature range of the gauge?

The glycerin filling stabilizes the pointer, improving readability and perceived accuracy under dynamic conditions. High-purity glycerin or specialized silicone oil fillings are used to ensure minimal volume expansion or contraction across a wide operational temperature range, thus maintaining intrinsic measurement accuracy. Manufacturers specify thermal deviation compensation figures to ensure reliability in fluctuating temperatures.

Which end-user industries represent the highest growth potential for glycerin-filled gauges?

The highest growth potential is concentrated in industries undergoing rapid expansion and modernization, particularly the chemical and petrochemical sectors, the water and wastewater treatment infrastructure, and specialized manufacturing areas like food and beverage (due to sanitary requirements) and pharmaceutical production, all of which require durable, reliable, vibration-resistant instrumentation.

Are digital pressure sensors likely to replace glycerin fillable pressure gauges entirely?

No, complete replacement is unlikely. While digital sensors offer enhanced connectivity and remote data, glycerin-filled gauges offer unmatched mechanical resilience, reliability as a local visual reference, and lower maintenance costs in harsh, high-vibration environments. The market is trending toward 'hybrid' solutions where the glycerin gauge serves as the robust mechanical baseline, augmented by digital transmitters for smart system integration.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager