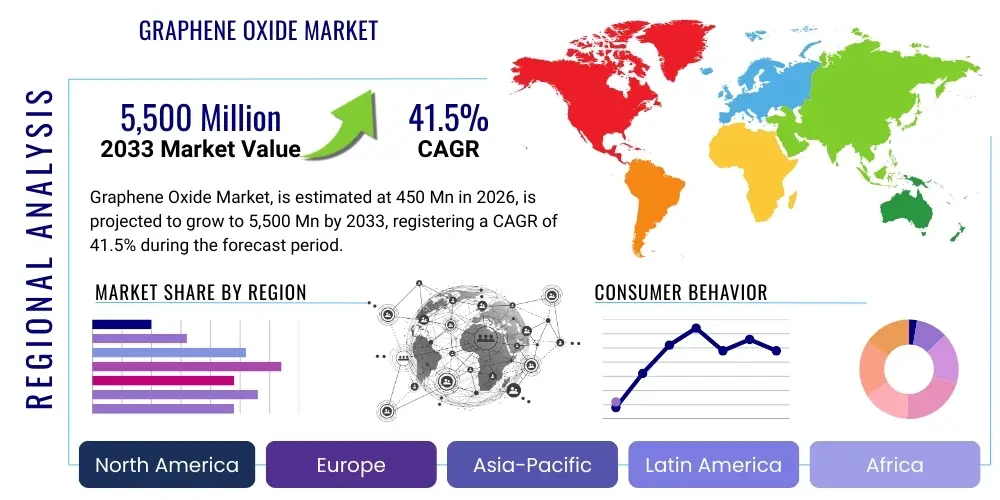

Graphene Oxide Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440784 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Graphene Oxide Market Size

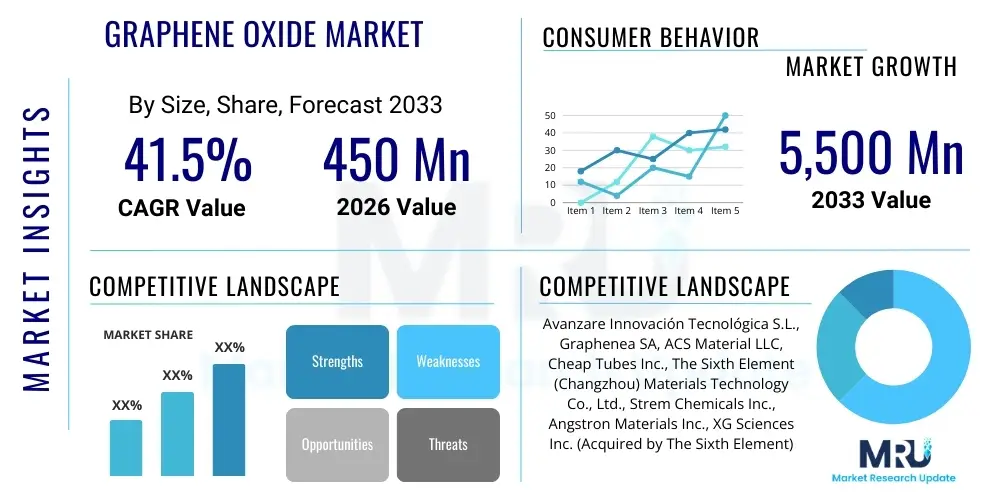

The Graphene Oxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 41.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 5,500 Million by the end of the forecast period in 2033.

Graphene Oxide Market introduction

Graphene Oxide (GO) is a unique two-dimensional material synthesized by oxidizing graphite, resulting in the incorporation of oxygen-containing functional groups such as hydroxyl, carboxyl, and epoxy groups on the carbon lattice. This oxidized structure makes GO highly hydrophilic and easily dispersible in water and various organic solvents, distinguishing it significantly from pristine graphene. The versatility arising from these functional groups allows GO to act as a crucial precursor for mass production of Reduced Graphene Oxide (rGO), which retrieves some of the electrical conductivity lost during the oxidation process, making GO an indispensable intermediate material in advanced nanotechnology and material science. The material’s outstanding mechanical strength, high surface area, and tunable electrical properties position it as a revolutionary component across diverse industrial sectors, spanning from energy storage and biomedical engineering to high-performance composites and environmental remediation.

Major applications of Graphene Oxide are concentrated in areas requiring high performance and lightweight materials. In the energy sector, GO and rGO are heavily utilized in manufacturing advanced battery electrodes, particularly for lithium-ion and supercapacitors, due to their enhanced charge storage capacity and rapid ion transportation kinetics. Biomedical applications leverage GO’s biocompatibility and functionalizability for targeted drug delivery systems, biosensors, and tissue engineering scaffolds. Furthermore, its membrane separation capabilities are being rigorously explored in water purification and desalination technologies, offering superior flux rates and rejection capabilities compared to traditional membrane materials. The ability of GO to be processed via solution-based methods, such as spin coating and ink-jet printing, also facilitates its integration into flexible electronics and transparent conductive films, driving adoption in next-generation display and sensing technologies.

The primary driving factors fueling the rapid expansion of the Graphene Oxide Market include aggressive global investment in nanotechnology research and development, particularly in Asia Pacific; the accelerating demand for high-capacity, durable energy storage solutions necessary for the electric vehicle (EV) and renewable energy sectors; and stringent environmental regulations promoting innovative water treatment solutions. Furthermore, the continuous improvement in synthesis methodologies, leading to reduced production costs and enhanced quality control, is making GO economically viable for large-scale industrial integration. However, the market growth remains closely tied to overcoming challenges related to large-scale, uniform production and addressing regulatory hurdles concerning long-term environmental and biological safety, though ongoing research continually mitigates these concerns through safer and greener synthesis routes.

Graphene Oxide Market Executive Summary

The Graphene Oxide Market is characterized by intense technological innovation and dynamic commercialization strategies, largely driven by strategic partnerships between research institutions and industrial players focused on scaling production. Current business trends indicate a strong shift towards automated, continuous flow synthesis methods, such as modified Hummers and electrochemical exfoliation, replacing traditional batch processes to ensure material consistency and meet burgeoning industrial demand, particularly from automotive and electronics manufacturers. Venture capital funding is increasingly targeting startups specializing in tailored GO derivatives optimized for specific applications, such as highly conductive rGO inks or functionalized GO for robust composite materials, thereby fragmenting the competitive landscape and promoting specialized product offerings rather than generic bulk material sales. Furthermore, the trend toward sustainable manufacturing practices is pressuring producers to develop environmentally friendly synthesis techniques that minimize the use of harsh chemical oxidizers, aligning market expansion with global ecological responsibility initiatives.

Regionally, Asia Pacific (APAC) stands as the dominant market shareholder and is projected to exhibit the highest growth rate throughout the forecast period, primarily due to the concentration of major battery manufacturing giants, robust government support for nanotechnology initiatives in countries like China, South Korea, and Japan, and rapid industrialization demanding advanced materials. North America and Europe, while possessing mature R&D infrastructures, focus more intensely on high-value, niche applications, including advanced biomedical devices, aerospace composites, and military technology, serving as crucial hubs for intellectual property generation and premium product development. The growth in the Middle East and Africa (MEA) and Latin America is currently nascent but accelerating, particularly through investments in water desalination infrastructure and renewable energy projects, where GO membranes and energy storage components provide compelling performance advantages over conventional alternatives.

Segment trends reveal that the composites and polymer additives segment is poised to maintain market dominance, driven by the exceptional mechanical reinforcement GO provides to materials used in aircraft, automobiles, and construction. However, the energy storage segment, encompassing batteries and supercapacitors, is anticipated to register the fastest growth rate, fueled by the global transition to electric mobility and renewable energy integration requiring high-performance, lightweight electrodes. Within the applications, biomedical and healthcare utilization, although smaller in market share currently, is demonstrating explosive growth potential due to breakthroughs in precise cancer therapy, bioimaging agents, and smart wearable sensors leveraging GO's unique surface chemistry and fluorescent properties. The sustained demand across all major segments confirms Graphene Oxide’s transition from a laboratory curiosity to a foundational industrial material.

AI Impact Analysis on Graphene Oxide Market

Analysis of common user questions regarding AI's influence on the Graphene Oxide market reveals significant interest centered around three core themes: accelerated materials discovery, optimization of synthesis and quality control, and prediction of material performance in real-world applications. Users frequently inquire about how Machine Learning (ML) can predict the optimal oxidation parameters (e.g., time, temperature, reactant concentration) necessary to produce GO with precise functional group distributions, thus reducing costly and time-consuming experimental iteration. There is a palpable expectation that AI will revolutionize the characterization process, quickly identifying defects or inconsistencies in large batches, ensuring the high uniformity required for industrial adoption. Furthermore, industry stakeholders are keen to understand how computational models can forecast the integration success of GO into complex matrices like polymers or concrete, significantly de-risking new product development cycles and accelerating time-to-market for GO-enhanced products.

- AI-driven simulation and modeling accelerate the discovery of novel Graphene Oxide derivatives and functionalization chemistries suitable for specific applications (e.g., targeted drug delivery).

- Machine Learning algorithms optimize Graphene Oxide synthesis protocols by identifying ideal reaction parameters (temperature, pH, oxidant ratio) to maximize yield and control defect density, enhancing industrial scalability.

- AI-powered image analysis and spectroscopic data processing enable rapid, non-destructive quality control and characterization of large GO batches, ensuring batch-to-batch consistency essential for high-tech manufacturing.

- Predictive maintenance models utilizing sensor data can forecast equipment failure in GO manufacturing plants, minimizing downtime and reducing operational costs.

- Natural Language Processing (NLP) tools extract and synthesize research findings from massive scientific databases, identifying emerging trends and potential application breakthroughs faster than traditional literature reviews.

- AI assists in designing optimal composite architectures, predicting how GO loading and dispersion affect the ultimate mechanical, thermal, and electrical properties of polymer matrices or cementitious materials.

DRO & Impact Forces Of Graphene Oxide Market

The dynamics of the Graphene Oxide market are profoundly shaped by a confluence of accelerating drivers and constraining restraints, balanced by transformative opportunities. Key drivers include the overwhelming global demand for lightweight, high-strength materials, particularly from the aerospace and automotive sectors seeking fuel efficiency improvements and structural integrity enhancements. Simultaneously, the restraints revolve primarily around the lingering challenge of cost-effective, high-volume production of uniformly high-quality GO, as current synthesis methods often involve corrosive reagents and yield inconsistencies that hinder full-scale industrial integration. Opportunities, however, are vast and capitalize on GO's unique properties, most notably in the rapidly expanding fields of flexible electronics, smart textiles, and advanced point-of-care diagnostics, where GO's conductive and functionalized nature offers unparalleled performance advantages, promising substantial long-term returns for pioneering investors and manufacturers.

Impact forces currently exerting the most influence involve technological substitution and regulatory scrutiny. The threat of substitution from other two-dimensional materials (like transition metal dichalcogenides) or carbon nanotubes, while present, is mitigated by GO's superior processability and functional group chemistry, which often makes it a more suitable precursor for large-scale applications, especially Reduced Graphene Oxide (rGO). Regulatory bodies, particularly in Europe and North America, are increasingly scrutinizing the potential cytotoxicity and environmental fate of GO nanoparticles, which acts as a restraint by necessitating costly toxicological studies and safer handling protocols. Conversely, the high technological intensity of the market means that proprietary synthesis techniques and application patents create high barriers to entry, concentrating market power among early innovators who can consistently deliver material purity and scale, fundamentally influencing pricing strategies and supply chain dynamics globally.

The market faces inherent risks related to supply chain stability for primary raw materials (high-quality graphite) and the volatility associated with chemical inputs (sulfuric acid, potassium permanganate). Mitigating these restraints through diversification and vertical integration is crucial for sustaining growth. The primary long-term opportunity lies in leveraging GO's exceptional barrier properties for packaging, corrosion protection, and advanced filtration systems, which represent multi-billion dollar markets currently dominated by conventional materials. Successfully navigating the nexus between stringent health, safety, and environmental (HSE) standards and the necessity for industrial scale-up will determine the ultimate market trajectory, favoring companies that invest heavily in both process optimization and rigorous safety testing, transforming constraints into competitive differentiators.

Segmentation Analysis

The Graphene Oxide market segmentation provides a comprehensive framework for understanding the diverse applications and end-user uptake across different industrial verticals, categorizing the market primarily by Application, Material Type (Purity/Form), and End-Use Industry. This detailed segmentation highlights that market growth is highly application-dependent; for instance, while the "Composites" segment drives volume, the "Electronics" and "Energy Storage" segments often dictate technology advancements and premium pricing. The foundational categorization based on the form, distinguishing between Graphene Oxide powder, solution/dispersion, and films, reflects differing manufacturing requirements and downstream processing capabilities. Market stakeholders utilize this granular segmentation to tailor product offerings, focusing R&D investment on areas exhibiting the highest growth potential and greatest sensitivity to material performance enhancements, such as high-purity, reduced GO for transparent conductive films or customized functionalized GO for targeted drug delivery platforms.

- By Application:

- Composites and Coatings (Aerospace, Automotive, Construction)

- Energy Storage (Li-ion batteries, Supercapacitors, Fuel Cells)

- Electronics and Photonics (Sensors, Flexible Displays, Transparent Electrodes)

- Biomedical and Healthcare (Drug Delivery, Bioimaging, Biosensors, Tissue Engineering)

- Environmental Applications (Water Treatment Membranes, Air Filtration)

- Catalysis and Chemical Additives

- By Form/Type:

- Graphene Oxide Powder

- Graphene Oxide Dispersion/Solution (Aqueous and Solvent-based)

- Graphene Oxide Films and Sheets

- By End-Use Industry:

- Automotive and Transportation

- Aerospace and Defense

- Electronics and Semiconductors

- Energy (Oil & Gas, Power Generation)

- Healthcare and Pharmaceuticals

- Environmental and Water Management

- Research and Development

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, Japan, South Korea, India)

- Latin America (Brazil, Argentina)

- Middle East and Africa (UAE, Saudi Arabia, South Africa)

Value Chain Analysis For Graphene Oxide Market

The Graphene Oxide value chain begins with the upstream segment, which primarily involves the mining, processing, and purification of high-quality graphite—the essential raw material. This segment is characterized by relatively high consolidation and price sensitivity, as the quality and grade of graphite directly influence the yield and characteristics of the final GO product. Key players in this stage focus on securing reliable, ethically sourced natural graphite or developing synthetic graphite precursors suitable for exfoliation. A critical element in the upstream process is the supply of strong oxidizing agents (like sulfuric acid and potassium permanganate) and other necessary chemicals required for the chemical synthesis routes, where managing hazardous material handling and environmental waste disposal adds complexity and cost to initial production stages.

Midstream activities constitute the core of the market, focusing on the synthesis, functionalization, and mass production of Graphene Oxide and its immediate derivative, Reduced Graphene Oxide (rGO). This stage involves proprietary knowledge regarding synthesis methodologies, including the optimization of the Hummers method, modified Hummers techniques, or electrochemical routes for industrial scalability while maintaining structural integrity and dispersion quality. Distribution channels are relatively short for high-purity GO, often involving direct supply to specialized industrial fabricators or advanced materials research labs. However, for bulk applications like composites, GO is often sold through specialized chemical distributors who can handle hazardous material logistics and integrate the material into regional supply chains, ensuring wide market reach and logistical efficiency across diverse geographical locations.

Downstream analysis focuses on the integration of GO into final products and its utilization by end-user industries. Direct distribution involves supplying GO dispersions or powders directly to large manufacturers in the electronics, automotive, and energy sectors for in-house formulation (e.g., mixing GO into polymers or coating electrodes). Indirect distribution involves material formulators or compounders who process GO into readily usable intermediate products, such as masterbatches, conductive inks, or specific membrane filters, which are then sold to a wider base of original equipment manufacturers (OEMs). The successful penetration of the downstream market relies heavily on collaborative research and validation studies with end-users to ensure seamless integration and demonstrable performance enhancement, thereby bridging the gap between material science innovation and commercial applicability.

Graphene Oxide Market Potential Customers

Potential customers for Graphene Oxide span several high-growth, technology-intensive industries that require materials offering extreme performance attributes, miniaturization, and enhanced longevity. The energy sector represents a massive customer base, specifically manufacturers of advanced lithium-ion batteries and supercapacitors for Electric Vehicles (EVs) and grid storage systems, who utilize GO and rGO to significantly improve electrode conductivity, cyclic stability, and power density. These manufacturers are highly motivated buyers, as GO integration offers a tangible competitive advantage in a rapidly evolving, performance-driven market. Furthermore, major automotive and aerospace manufacturers are significant potential customers, seeking GO-reinforced polymers and composites to achieve substantial weight reduction without compromising mechanical integrity, leading to improved fuel economy and reduced emissions across transportation platforms.

Beyond traditional industrial sectors, the biomedical and healthcare industries are rapidly emerging as high-value, albeit volume-constrained, potential customers. Pharmaceutical companies and medical device manufacturers are keen on utilizing GO’s exceptional surface area and functionalizability for highly precise drug delivery vehicles, particularly for chemotherapy, where targeting capabilities minimize systemic side effects. Additionally, developers of next-generation point-of-care diagnostic tools and biosensors leverage GO’s electrical properties and biocompatibility to create highly sensitive and rapid detection platforms for disease markers. These customers demand exceptionally high purity, stringent regulatory compliance (e.g., FDA approval), and detailed toxicological data, making the purchasing criteria highly specialized and favoring suppliers capable of providing extensive documentation and quality assurance.

Finally, the environmental and infrastructure sectors, including municipal water treatment plants and construction firms, represent scalable long-term customer segments. Water purification companies are actively evaluating GO-based membranes for desalination and contaminant removal due to their unparalleled flux and rejection rates, offering a sustainable solution to global water scarcity. Construction companies are exploring the integration of GO into cement and concrete to enhance strength, reduce permeability, and improve the lifespan of infrastructure projects, particularly in harsh environments. These customers prioritize bulk availability, cost-effectiveness, and verifiable long-term stability and environmental safety, requiring GO suppliers to achieve substantial manufacturing scale and competitive pricing structures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 5,500 Million |

| Growth Rate | 41.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Avanzare Innovación Tecnológica S.L., Graphenea SA, ACS Material LLC, Cheap Tubes Inc., The Sixth Element (Changzhou) Materials Technology Co., Ltd., Strem Chemicals Inc., Angstron Materials Inc., XG Sciences Inc. (Acquired by The Sixth Element), NanoXplore Inc., Global Graphene Group, Time-Nanotex Corporation, GrafTech International Ltd., Heraeus Group, BGT Materials Limited, Chengdu Organic Chemicals Co. Ltd., Thomas Swan & Co. Ltd., Universal Graphene Inc., Stanford Advanced Materials, Cambridge Nanosystems Ltd., Merck KGaA. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Graphene Oxide Market Key Technology Landscape

The technological landscape of the Graphene Oxide market is defined by continuous innovation focused on optimizing synthesis methods for scale, purity, and environmental safety. The Modified Hummers method remains the foundational and most widely adopted technique for mass production due to its high yield and relative simplicity. However, ongoing research aims to refine this process by substituting highly toxic or corrosive reagents (such as sodium nitrate and concentrated sulfuric acid) with greener alternatives or developing closed-loop systems to minimize environmental impact and improve worker safety. Advancements in mild oxidation techniques and the controlled exfoliation of graphite are critical, as they enable producers to precisely control the density and spatial distribution of oxygen functional groups, which directly dictates the material's performance in downstream applications like conductive inks and sensor fabrication, ensuring superior material consistency.

Electrochemical exfoliation has emerged as a disruptive alternative, offering a potentially more scalable and environmentally benign route for GO synthesis. This method involves applying a voltage across graphite electrodes submerged in an electrolyte, facilitating the intercalation and subsequent exfoliation of graphite layers. The primary advantage of electrochemical synthesis is the elimination of strong chemical oxidizers, resulting in a cleaner product and lower operational costs related to waste treatment. However, challenges related to achieving very high oxidation levels and ensuring uniform functionalization across large batches still require further optimization. Companies investing in this technology are strategically positioning themselves to meet future market demands for sustainable materials while potentially bypassing the cost and complexity associated with traditional chemical oxidation methods, which is a major factor driving competitive technological differentiation.

Furthermore, post-synthesis processing technologies, particularly those related to the large-scale reduction of Graphene Oxide (forming rGO), are crucial to the market's growth, especially in electronics and energy storage. Techniques such as thermal reduction, chemical reduction using mild reducing agents (e.g., hydrazine alternatives), and photocatalytic reduction are being refined to produce rGO with maximized electrical conductivity and minimal defect introduction, thereby enhancing device performance. The development of specialized coating and deposition techniques, including roll-to-roll processing for flexible GO films and aerosol jet printing for conductive patterns, is vital for integrating GO derivatives into high-volume manufacturing lines. The convergence of advanced synthesis and precise processing capabilities is transforming GO from a research material into a fully industrialized commodity.

Regional Highlights

The Graphene Oxide market exhibits significant geographical heterogeneity, driven by varying levels of industrial development, governmental support for nanotechnology, and regional concentration of end-use manufacturing capabilities. Asia Pacific (APAC) currently holds the dominant market share and is forecasted to demonstrate the highest growth trajectory, largely attributable to the massive manufacturing bases for lithium-ion batteries and consumer electronics located primarily in China, South Korea, and Japan. Governments across APAC are actively funding large-scale R&D initiatives and establishing state-of-the-art production facilities, particularly in China, which has prioritized advanced materials as a cornerstone of its industrial policy, fostering rapid commercialization and adoption of GO in composites and energy storage applications. This regional dominance is further solidified by lower manufacturing and labor costs, enabling competitive pricing for bulk GO supply globally.

North America and Europe represent mature, high-value markets characterized by a strong focus on advanced, niche applications and stringent quality requirements. In North America, the market growth is underpinned by substantial investment in aerospace and defense sectors, utilizing GO for high-performance composites and lightweight structural components, alongside a robust biomedical research ecosystem driving demand for high-purity functionalized GO in drug delivery and biosensing. European growth is stimulated by ambitious sustainability goals, accelerating the adoption of GO membranes for advanced water treatment and promoting its use in enhancing energy efficiency within the automotive sector. These regions lead global research in environmental safety and standardization, often setting the regulatory benchmarks that influence global market acceptance.

The markets in Latin America (LATAM) and the Middle East & Africa (MEA) are emerging, with growth concentrated in specific applications tailored to regional needs. In the Middle East, substantial investment in large-scale water desalination projects provides a strong impetus for the adoption of GO-based membranes, offering superior efficiency and lower energy consumption compared to conventional thermal methods. In Latin America, particularly Brazil, the automotive and basic chemicals industries are beginning to integrate GO to improve material performance and durability. While these regions possess smaller market shares currently, their strategic focus on large-scale infrastructure development, coupled with increasing energy demands, positions them as crucial long-term growth vectors for Graphene Oxide applications, particularly those related to resource management and sustainable infrastructure.

- Asia Pacific (APAC): Dominates the market due to concentrated battery manufacturing, heavy government subsidies for nanotechnology, and extensive application in consumer electronics and composites (China, South Korea, Japan).

- North America: Focuses on high-value, niche applications in aerospace, defense, and advanced biomedical research, driven by strong private and government R&D funding (U.S., Canada).

- Europe: Growth propelled by stringent environmental regulations, emphasizing GO in advanced filtration (water treatment) and lightweight materials for the automotive industry (Germany, U.K., France).

- Latin America: Emerging market with increasing adoption in infrastructure, construction, and basic chemical industries, particularly in Brazil and Mexico.

- Middle East & Africa (MEA): Key driver is the critical need for advanced water purification and desalination technologies, alongside nascent adoption in oil & gas sector protective coatings (UAE, Saudi Arabia).

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Graphene Oxide Market.- Avanzare Innovación Tecnológica S.L.

- Graphenea SA

- ACS Material LLC

- Cheap Tubes Inc.

- The Sixth Element (Changzhou) Materials Technology Co., Ltd.

- Strem Chemicals Inc.

- Angstron Materials Inc.

- NanoXplore Inc.

- Global Graphene Group

- Time-Nanotex Corporation

- GrafTech International Ltd.

- Heraeus Group

- BGT Materials Limited

- Chengdu Organic Chemicals Co. Ltd.

- Thomas Swan & Co. Ltd.

- Universal Graphene Inc.

- Stanford Advanced Materials

- Cambridge Nanosystems Ltd.

- Merck KGaA

- Suzhou Graphene Nanotech Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Graphene Oxide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Graphene Oxide (GO) and Graphene?

Graphene is a single layer of pure carbon atoms arranged in a honeycomb lattice, possessing exceptional electrical conductivity. Graphene Oxide (GO) is the oxidized form of graphene, containing oxygen-containing functional groups (hydroxyl, carboxyl), which makes it an electrical insulator but highly dispersible in water, facilitating easier processing and functionalization for applications like composites and precursors for Reduced Graphene Oxide (rGO).

Which application segment holds the largest share in the Graphene Oxide Market?

The Composites and Coatings segment currently holds the largest market share, driven by the demand for material reinforcement in aerospace, automotive, and construction industries, where Graphene Oxide significantly improves mechanical strength, thermal stability, and barrier properties of polymers and structural materials.

What are the main constraints hindering the widespread commercialization of GO?

The primary constraints include the high cost associated with synthesizing high-purity, uniform Graphene Oxide at industrial scale, the inherent inconsistencies often found between different production batches, and ongoing regulatory uncertainties and public health concerns regarding the long-term environmental and biological safety (potential cytotoxicity) of GO nanomaterials.

How is the production cost of Graphene Oxide expected to change over the forecast period?

The production cost of Graphene Oxide is projected to decrease significantly over the forecast period (2026–2033). This reduction will be driven by advancements in scalable and greener synthesis methods, such as electrochemical exfoliation and optimized continuous flow chemical processes, leading to higher yields and reduced dependence on expensive, hazardous chemical inputs and waste treatment.

Which region is expected to demonstrate the highest growth rate for Graphene Oxide adoption?

The Asia Pacific (APAC) region is expected to register the highest Compound Annual Growth Rate (CAGR). This accelerating growth is primarily fueled by massive government investments in nanotechnology research, the concentration of global battery manufacturing capabilities, and widespread adoption of GO derivatives in consumer electronics and advanced energy storage systems across China and South Korea.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager