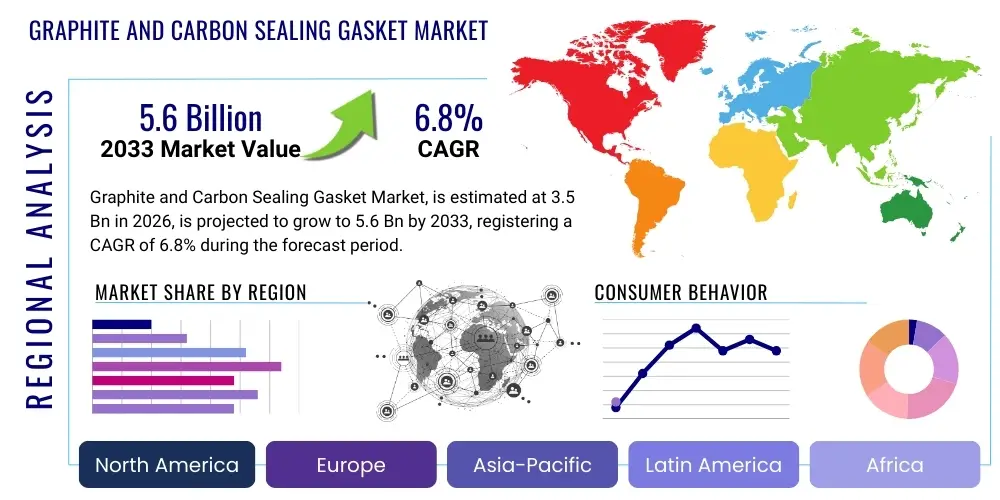

Graphite and Carbon Sealing Gasket Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440851 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Graphite and Carbon Sealing Gasket Market Size

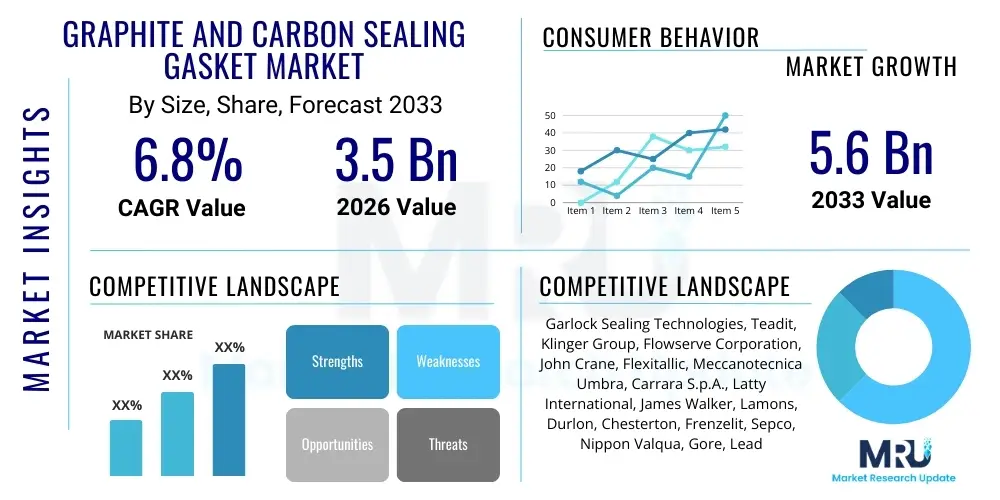

The Graphite and Carbon Sealing Gasket Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.6 Billion by the end of the forecast period in 2033.

Graphite and Carbon Sealing Gasket Market introduction

The Graphite and Carbon Sealing Gasket market encompasses a critical segment within industrial sealing solutions, primarily driven by the exceptional thermal, chemical, and mechanical properties of graphite and carbon materials. These gaskets are engineered to provide robust sealing in extreme operating conditions, including high temperatures, pressures, and corrosive environments, making them indispensable across a multitude of heavy industries. Products range from flexible graphite sheets and carbon fiber composites to specialized spiral wound and kammprofile gaskets that incorporate these advanced materials, designed to prevent leakage of fluids and gases while ensuring system integrity and operational safety. Their primary benefits include superior chemical resistance, high thermal stability, low creep relaxation, and excellent compressibility and recovery, which contribute to extended service life and reduced maintenance costs.

Major applications for graphite and carbon sealing gaskets span sectors such as oil and gas, chemical processing, power generation, automotive, aerospace, and marine industries, where reliable sealing is paramount for efficiency and regulatory compliance. Driving factors for market growth include the escalating demand for energy, rapid industrialization in emerging economies, stringent environmental regulations necessitating leak-free operations, and continuous advancements in material science enabling the development of more durable and high-performance sealing solutions. Furthermore, the increasing complexity of industrial processes and equipment requires gaskets that can withstand increasingly harsh conditions, solidifying the market position of graphite and carbon-based sealing products. The market also benefits from a global focus on reducing emissions and improving energy efficiency, as effective sealing directly contributes to these objectives by preventing energy loss and environmental contamination.

Graphite and Carbon Sealing Gasket Market Executive Summary

The Graphite and Carbon Sealing Gasket market is witnessing robust growth, propelled by sustained industrial expansion, particularly in the energy and chemical sectors. Key business trends include a growing emphasis on high-performance materials capable of operating under increasingly extreme conditions, a shift towards sustainable and emission-reducing sealing solutions, and the increasing adoption of digital tools for gasket design and predictive maintenance. Companies are investing in research and development to enhance material properties, focusing on improved compressibility, chemical inertness, and extended service life to meet evolving industrial demands. Consolidations and strategic partnerships are also becoming prevalent as market players seek to expand their product portfolios and geographical reach, leveraging specialized expertise and manufacturing capabilities.

Regionally, Asia Pacific stands out as a dominant growth engine, fueled by rapid industrialization, infrastructure development, and substantial investments in power generation, chemical, and petrochemical industries across countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demand high-specification gaskets due to stringent environmental regulations and a strong presence of advanced manufacturing and aerospace sectors, focusing on innovation and high-value applications. Segment-wise, flexible graphite remains a cornerstone due to its versatility and wide temperature range, while carbon fiber reinforced gaskets are gaining traction for applications requiring exceptional strength and stiffness. The demand for spiral wound and kammprofile gaskets, often incorporating graphite or carbon fillers, is particularly strong in high-pressure and critical sealing applications within the oil and gas and power sectors, reflecting a broader trend towards enhanced safety and operational reliability.

AI Impact Analysis on Graphite and Carbon Sealing Gasket Market

User inquiries regarding AI's influence on the Graphite and Carbon Sealing Gasket Market often revolve around how artificial intelligence can optimize material development, enhance manufacturing processes, predict product failure, and streamline supply chains. Common themes include the potential for AI-driven material design to create gaskets with superior properties, the application of machine learning in quality control and defect detection during production, and the use of predictive analytics to forecast gasket lifespan and schedule proactive maintenance, thereby reducing downtime and operational costs. There is also significant interest in how AI could impact customization, enabling more precise gasket solutions for niche applications, and how it might contribute to sustainable manufacturing practices by optimizing material usage and reducing waste. Expectations are high for AI to deliver greater efficiency, improved product performance, and enhanced decision-making throughout the gasket lifecycle, from design to end-of-life management.

- AI-driven material informatics accelerates the discovery and development of novel graphite and carbon composites with enhanced thermal, chemical, and mechanical properties, optimizing material selection for specific application requirements.

- Predictive analytics and machine learning algorithms enable proactive maintenance of industrial equipment by forecasting gasket wear and potential failure, thereby minimizing unplanned downtime and improving operational safety.

- AI-powered quality control systems utilize computer vision and sensor data to detect minute defects in gasket manufacturing, ensuring higher product consistency and reducing scrap rates.

- Optimization of manufacturing processes through AI algorithms can lead to increased production efficiency, reduced energy consumption, and better utilization of raw materials, contributing to cost savings and sustainability goals.

- AI assists in supply chain optimization by predicting demand fluctuations, managing inventory levels, and streamlining logistics for raw materials and finished gaskets, enhancing responsiveness to market changes.

- Enhanced gasket design and simulation capabilities using AI allow for rapid prototyping and virtual testing under various operating conditions, reducing physical testing cycles and accelerating time-to-market for new products.

- Automated inspection and robotic handling, powered by AI, can improve safety in manufacturing environments, particularly when handling heavy or high-temperature materials during gasket production.

DRO & Impact Forces Of Graphite and Carbon Sealing Gasket Market

The Graphite and Carbon Sealing Gasket market is significantly shaped by a confluence of driving factors, restraints, and opportunities, alongside various impact forces that influence its trajectory. Key drivers include the escalating demand from robust industrial sectors such as oil and gas, power generation, and chemical processing, all of which require reliable sealing solutions for critical infrastructure. Stringent environmental regulations aimed at reducing emissions and preventing leaks further fuel the adoption of high-performance graphite and carbon gaskets. Technological advancements in material science, leading to enhanced gasket properties and extended service life, also play a crucial role in market expansion, meeting the increasing severity of operational conditions in modern industrial applications. The inherent resilience and superior sealing capabilities of these materials under extreme conditions make them the preferred choice for a wide array of demanding applications.

However, the market faces several restraints, prominently including the volatility of raw material prices, particularly for high-grade graphite and carbon fibers, which can impact manufacturing costs and final product pricing. Competition from alternative sealing materials, such as advanced polymers or specialized metals, also poses a challenge, as end-users continuously evaluate cost-effectiveness versus performance. Furthermore, the high capital investment required for research and development into new material formulations and advanced manufacturing techniques can limit the entry of new players and slow innovation for smaller firms. Economic slowdowns or geopolitical instabilities can also temper industrial growth, subsequently reducing demand for new gaskets and maintenance requirements.

Opportunities for growth are abundant, particularly in emerging economies undergoing rapid industrialization and infrastructure development, which present vast untapped markets for sealing solutions. The global shift towards renewable energy sources, including nuclear, solar thermal, and geothermal power plants, creates new avenues for specialized high-temperature graphite gaskets. Additionally, the growing focus on energy efficiency and predictive maintenance in existing industrial facilities drives demand for superior, longer-lasting gaskets that minimize leakage and reduce operational expenditures. The ongoing development of lightweight and durable materials for the automotive and aerospace industries also opens up niche applications for advanced carbon-based sealing components, promising sustained innovation and market penetration.

Segmentation Analysis

The Graphite and Carbon Sealing Gasket market is broadly segmented based on material type, product type, application, and end-use industry, allowing for a granular understanding of market dynamics and tailored product development strategies. Each segment reflects distinct characteristics in terms of performance requirements, operational environments, and customer preferences. The material type segmentation differentiates between pure graphite, various carbon fiber composites, and blended materials, each offering a unique balance of thermal stability, chemical resistance, and mechanical strength. Product type categorizations help define the form factor and specific design configurations, crucial for meeting diverse sealing challenges across a wide range of industrial equipment. This comprehensive segmentation provides a framework for analyzing specific market niches and identifying opportunities for targeted innovation and market penetration.

- By Material Type:

- Flexible Graphite

- Carbon Fiber

- Compressed Non-Asbestos Fiber (CNFA) with Graphite/Carbon Reinforcement

- Graphite Foil

- Expanded Graphite

- By Product Type:

- Sheet Gaskets

- Spiral Wound Gaskets (with Graphite/Carbon filler)

- Kammprofile Gaskets (with Graphite/Carbon facing)

- Ring Type Joints (RTJs)

- Gland Packings/Braided Packings (Graphite/Carbon based)

- Die-Formed Rings

- By Application:

- Flange Sealing

- Valve Sealing/Packing

- Pump Sealing

- Heat Exchanger Sealing

- Manhole and Handhole Cover Sealing

- Exhaust Systems

- Boilers and Furnaces

- By End-Use Industry:

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Power Generation (Thermal, Nuclear, Renewable)

- Automotive

- Aerospace & Defense

- Marine

- Pulp & Paper

- HVAC

- Mining & Metallurgy

- Food & Beverage

Value Chain Analysis For Graphite and Carbon Sealing Gasket Market

The value chain for the Graphite and Carbon Sealing Gasket market begins with the upstream activities involving the extraction and processing of raw materials, primarily natural graphite and petroleum pitch for synthetic graphite, along with carbon fibers derived from various precursors. These raw materials undergo purification, expansion, and often compounding processes to produce flexible graphite foils, sheets, or carbon yarns. Manufacturers of sealing components then acquire these refined materials to produce a diverse range of gaskets, involving processes such as cutting, molding, winding, and assembly. This upstream segment is characterized by specialized suppliers providing high-purity and performance-grade materials crucial for the final product's integrity and performance under demanding industrial conditions.

The downstream analysis focuses on the distribution channels and the end-users who consume these sealing solutions. Gaskets reach end-users through a multifaceted network comprising direct sales from manufacturers, specialized industrial distributors, wholesale suppliers, and sometimes through engineering procurement and construction (EPC) firms involved in large-scale projects. Direct channels are often preferred for highly customized or high-volume orders for major industrial clients, allowing for direct technical support and tailored solutions. Indirect channels, through distributors and wholesalers, serve a broader customer base, offering convenience and regional accessibility. These channels are critical for market penetration and ensuring timely availability of products for maintenance, repair, and overhaul (MRO) activities, as well as new installations.

The efficiency of the distribution channel is paramount for the market, impacting lead times, inventory management, and customer satisfaction. Direct distribution facilitates closer relationships with key clients, enabling manufacturers to gather direct feedback for product improvement and innovation. Indirect channels leverage the extensive networks and local expertise of distributors to reach a wider array of small to medium-sized enterprises (SMEs) and geographically dispersed customers. Both models are essential, with manufacturers often employing a hybrid approach to optimize market coverage and service quality, ensuring that the right sealing solution reaches the right application with minimal delay and maximum technical support.

Graphite and Carbon Sealing Gasket Market Potential Customers

Potential customers for Graphite and Carbon Sealing Gaskets are predominantly concentrated within heavy industrial sectors where high-performance, durable, and chemically resistant sealing solutions are critical for operational safety, efficiency, and regulatory compliance. These end-users, or buyers, include major operators in the oil and gas industry, encompassing exploration, production, refining, and pipeline transportation companies, which require robust gaskets for flanges, valves, and heat exchangers under extreme pressure and temperature conditions. Similarly, chemical and petrochemical plants are significant consumers due to the need for sealing against aggressive chemicals at elevated temperatures and pressures, where leakage can lead to severe environmental and safety hazards. The reliability of these gaskets is directly linked to plant uptime and prevention of costly emissions.

Furthermore, the power generation sector, covering thermal, nuclear, and increasingly renewable energy facilities, represents a substantial customer base. Power plants rely on graphite and carbon gaskets for boiler components, steam turbines, heat exchangers, and exhaust systems, where high temperatures and pressures are common. The automotive industry also utilizes these gaskets in exhaust systems and engine components, particularly in high-performance or heavy-duty vehicles, owing to their excellent heat resistance. Aerospace and marine industries are additional key segments, where the lightweight, high-temperature capabilities, and superior sealing properties of carbon and graphite materials are highly valued for critical engine and fluid transfer systems. These sectors prioritize material integrity and long-term performance above all else, making graphite and carbon gaskets an ideal choice for their demanding specifications and operational environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Garlock Sealing Technologies, Teadit, Klinger Group, Flowserve Corporation, John Crane, Flexitallic, Meccanotecnica Umbra, Carrara S.p.A., Latty International, James Walker, Lamons, Durlon, Chesterton, Frenzelit, Sepco, Nippon Valqua, Gore, Leader Gasket Technologies, Donit Tesnit, W. L. Gore & Associates |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Graphite and Carbon Sealing Gasket Market Key Technology Landscape

The Graphite and Carbon Sealing Gasket market is continually evolving through the integration of advanced manufacturing techniques and sophisticated material science innovations. A key technological focus is on enhancing the purity, density, and structural integrity of graphite and carbon materials to improve their sealing performance, especially under aggressive chemical and thermal conditions. Technologies such as high-pressure graphite expansion processes and controlled carbonization techniques are crucial for producing materials with superior flexibility, compressibility, and resistance to oxidation. Furthermore, the development of advanced composite structures, where carbon fibers are combined with various binders and reinforcements, allows for the creation of gaskets with tailored mechanical properties and improved resilience against creep and stress relaxation, which are critical for long-term sealing effectiveness in industrial applications.

Another significant aspect of the technology landscape involves precision manufacturing and sealing design software. Computer-aided design (CAD) and finite element analysis (FEA) tools are extensively used to optimize gasket geometry, predict sealing behavior under varying loads and temperatures, and ensure optimal fit and performance for complex flange designs. This digital approach reduces the need for extensive physical prototyping, accelerates product development cycles, and ensures a higher degree of customization for specific client needs. Additionally, surface treatment technologies, including various coatings and impregnation methods, are employed to enhance the chemical resistance of graphite and carbon gaskets, improve their anti-stick properties, and provide additional barriers against fluid permeation, further extending their applicability in corrosive environments.

Moreover, the integration of smart manufacturing principles and IoT into gasket production is an emerging trend. This includes the use of sensors and data analytics to monitor manufacturing processes in real-time, enabling proactive adjustments for quality control and efficiency improvements. Predictive analytics also extends to the application phase, where monitoring systems for critical sealing points can forecast potential gasket failure, allowing for scheduled maintenance and preventing costly unplanned shutdowns. The focus on developing environmentally friendly manufacturing processes and recyclable materials also underpins technological advancements, aligning with global sustainability initiatives and stricter environmental regulations, thereby driving innovation towards greener sealing solutions that maintain high performance standards.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to rapid industrialization, significant investments in power generation, chemical, petrochemical, and automotive industries, particularly in China, India, Japan, and South Korea. The region's expanding manufacturing base and infrastructure development drive high demand for reliable sealing solutions.

- North America: A mature market characterized by stringent environmental regulations and a strong presence of oil & gas, chemical, and aerospace industries. Demand is driven by the need for high-performance, compliant gaskets for critical applications and advanced material innovation.

- Europe: Similar to North America, Europe is a mature market with a focus on advanced engineering, high-quality materials, and strict emission controls. Germany, the UK, and France are key contributors, particularly in the chemical, power generation, and automotive sectors, emphasizing sustainable and high-durability solutions.

- Middle East & Africa (MEA): Experiences substantial growth driven by massive investments in the oil & gas and petrochemical industries. The region's harsh operating conditions necessitate robust, high-temperature, and corrosion-resistant graphite and carbon sealing gaskets.

- Latin America: Shows steady growth, fueled by developing industrial sectors, particularly in Brazil and Mexico, with rising demand from oil & gas, mining, and power generation projects. Infrastructure development and increasing industrial output are key market drivers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Graphite and Carbon Sealing Gasket Market.- Garlock Sealing Technologies

- Teadit

- Klinger Group

- Flowserve Corporation

- John Crane

- Flexitallic

- Meccanotecnica Umbra

- Carrara S.p.A.

- Latty International

- James Walker

- Lamons

- Durlon

- Chesterton

- Frenzelit

- Sepco

- Nippon Valqua

- Gore

- Leader Gasket Technologies

- Donit Tesnit

- W. L. Gore & Associates

Frequently Asked Questions

Analyze common user questions about the Graphite and Carbon Sealing Gasket market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of graphite and carbon sealing gaskets over traditional materials?

Graphite and carbon sealing gaskets offer superior thermal stability, exceptional chemical resistance, excellent compressibility and recovery, and low creep relaxation, making them ideal for high-temperature, high-pressure, and corrosive industrial environments where traditional materials may fail.

Which industries are the major consumers of graphite and carbon sealing gaskets?

The primary consumers are industries such as Oil & Gas, Chemical & Petrochemical, Power Generation (including nuclear and thermal), Automotive, and Aerospace, due to their demanding operational conditions requiring robust and reliable sealing solutions.

How do environmental regulations impact the Graphite and Carbon Sealing Gasket market?

Stringent environmental regulations, particularly regarding fugitive emissions and leak prevention, significantly drive the demand for high-performance graphite and carbon gaskets. These materials ensure leak-free operations, helping industries comply with emissions standards and enhance operational safety.

What emerging trends are shaping the future of the Graphite and Carbon Sealing Gasket market?

Key emerging trends include the development of advanced material composites, integration of AI for predictive maintenance and design optimization, a growing focus on sustainable manufacturing practices, and increasing demand from the renewable energy sector for specialized sealing solutions.

What factors influence the pricing of graphite and carbon sealing gaskets?

Pricing is primarily influenced by the cost and availability of raw materials (high-purity graphite and carbon fibers), manufacturing complexity, technological advancements, research and development investments, and regional supply-demand dynamics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager