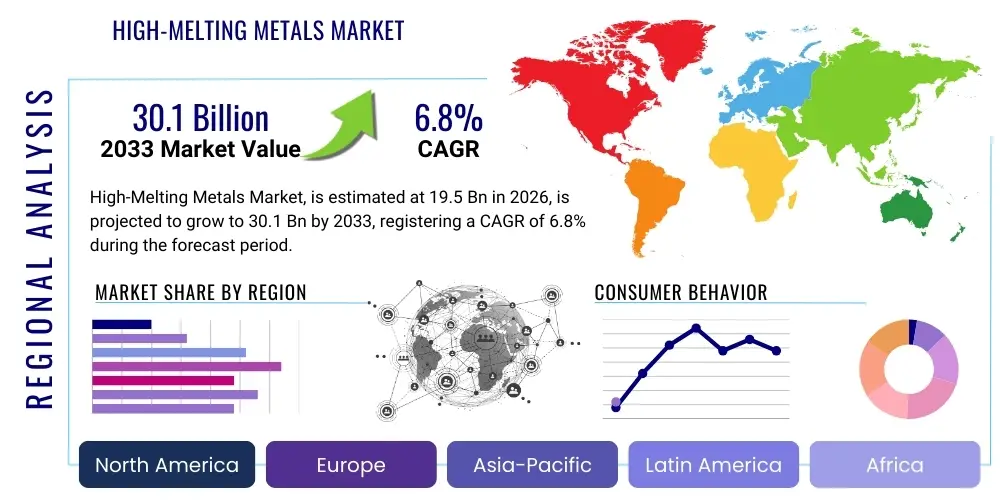

High-Melting Metals Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440845 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

High-Melting Metals Market Size

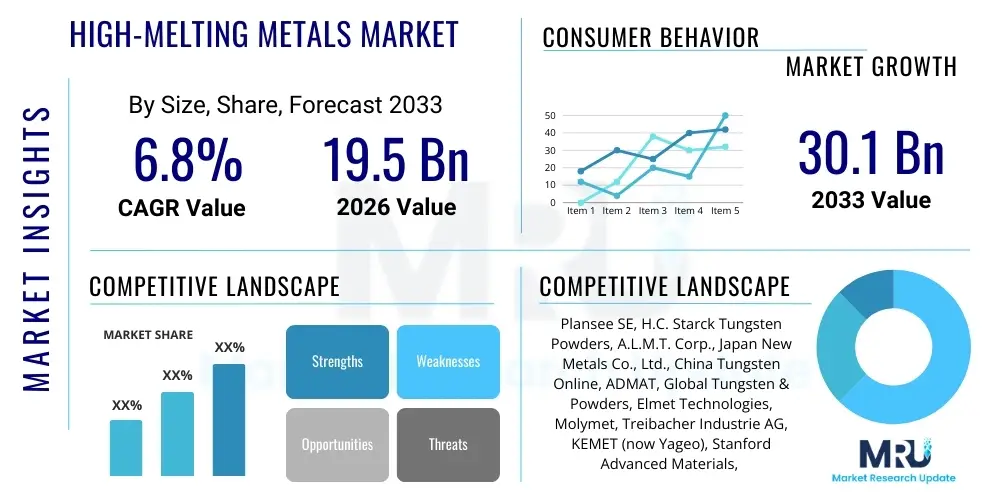

The High-Melting Metals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 19.5 billion in 2026 and is projected to reach USD 30.1 billion by the end of the forecast period in 2033. This robust growth is primarily driven by escalating demand from high-technology industries requiring materials capable of withstanding extreme conditions, including high temperatures, corrosive environments, and significant mechanical stress.

High-Melting Metals Market introduction

High-melting metals, also known as refractory metals, are a class of metallic materials characterized by their exceptionally high melting points, superior hardness, and excellent resistance to heat, corrosion, and wear. These unique properties make them indispensable in a wide array of critical applications where conventional metals would fail. The primary members of this group include tungsten, molybdenum, tantalum, niobium, and rhenium, each offering distinct advantages for specific industrial requirements. Their atomic structures provide remarkable thermal stability and strength at elevated temperatures, which are crucial for performance in demanding environments.

The product range within the high-melting metals market encompasses various forms such as powders, rods, wires, sheets, and custom-fabricated components, tailored to meet diverse end-user specifications. Major applications span across critical sectors including aerospace and defense, electronics and semiconductors, industrial furnaces, chemical processing, and energy generation. In aerospace, these metals are vital for jet engine components, rocket nozzles, and heat shields due to their high-temperature stability. The electronics industry relies on them for filaments, sputtering targets, and heat sinks in advanced devices, leveraging their electrical conductivity and thermal management capabilities. Their inherent benefits include unparalleled thermal stability, exceptional strength-to-weight ratios at high temperatures, and resistance to chemical attack, enabling superior performance and extended lifespan of components in extreme operational conditions.

Driving factors for the High-Melting Metals Market include the relentless innovation in high-tech industries demanding increasingly resilient materials, particularly in the development of next-generation aircraft, advanced semiconductor devices, and efficient energy systems. The global push towards renewable energy technologies, such as solar power and advanced nuclear reactors, further fuels demand for materials that can withstand harsh operating conditions. Moreover, the expanding additive manufacturing sector is creating new avenues for complex component fabrication using high-melting metal powders, facilitating lighter, stronger, and more intricate designs. Geopolitical considerations and supply chain resilience also play a significant role, emphasizing the strategic importance of these materials.

High-Melting Metals Market Executive Summary

The High-Melting Metals Market is experiencing substantial growth, propelled by robust demand from high-performance applications across several key industries. Business trends indicate a strong focus on research and development to enhance material properties, develop novel alloys, and improve manufacturing processes, including advanced powder metallurgy and additive manufacturing techniques. Companies are increasingly investing in sustainable production methods and exploring recycling initiatives to address environmental concerns and optimize resource utilization. Strategic partnerships and collaborations between material suppliers, component manufacturers, and end-use industries are becoming more prevalent, aimed at fostering innovation and ensuring a stable supply chain for these critical materials. Furthermore, the market is characterized by intense competition, driving players to differentiate through product quality, technical expertise, and customer service.

Regional trends highlight the Asia Pacific region as the dominant market, primarily driven by rapid industrialization, burgeoning electronics manufacturing, and significant investments in aerospace and defense sectors, particularly in countries like China, Japan, and South Korea. North America and Europe also hold substantial market shares, fueled by established aerospace, automotive, and medical industries, coupled with a strong emphasis on technological advancements and stringent performance requirements. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, attributed to developing industrial infrastructure, increasing foreign investments, and rising demand for high-tech components. The distribution of manufacturing capabilities and raw material resources significantly influences regional market dynamics, leading to specialized production hubs and complex global supply networks.

Segment trends underscore the prominence of tungsten and molybdenum due to their widespread use in electronics, industrial furnaces, and defense applications, owing to their superior strength and thermal properties. Tantalum and niobium are gaining traction in medical implants and specialized electronics, driven by their biocompatibility and corrosion resistance. The aerospace and defense sector remains a significant end-use segment, continually demanding lighter, stronger, and more heat-resistant materials for critical components. The growing adoption of high-melting metals in additive manufacturing is a notable trend, offering unprecedented design freedom and reducing material waste, thereby opening new growth avenues for powder-form metals. Moreover, increasing environmental regulations are prompting a shift towards more sustainable and efficient material usage, influencing innovation in alloy development and processing technologies.

AI Impact Analysis on High-Melting Metals Market

User inquiries concerning AI's impact on the High-Melting Metals Market frequently revolve around its potential to revolutionize material discovery, optimize manufacturing processes, enhance supply chain resilience, and open new application frontiers. Common questions explore how AI can accelerate the design of novel high-melting alloys with tailored properties, predict material performance under extreme conditions, and streamline complex production steps like smelting, purification, and fabrication. There is significant interest in AI's role in predictive maintenance for refractory components, improving efficiency in high-temperature industrial furnaces, and mitigating risks associated with raw material sourcing and geopolitical volatility. Users are also keen to understand how AI-driven insights can lead to more sustainable practices and reduce the environmental footprint of high-melting metal production, alongside enabling the development of advanced materials for emerging technologies such such as quantum computing and advanced fusion energy.

- AI accelerates the discovery and design of novel high-melting alloys by simulating properties and predicting performance, reducing traditional R&D cycles.

- AI optimizes complex manufacturing processes such as additive manufacturing (3D printing) of high-melting metal powders, improving material utilization and product consistency.

- AI enhances quality control through real-time data analysis, identifying defects and ensuring stringent material specifications are met during production.

- AI-powered predictive maintenance models extend the lifespan of high-temperature industrial equipment and components made from refractory metals, minimizing downtime.

- AI improves supply chain visibility and resilience, enabling better forecasting of demand, managing inventory, and identifying alternative sourcing options for critical raw materials.

- AI supports the development of sustainable production methods, including energy optimization in processing and advanced recycling techniques for high-melting metals.

- AI facilitates the creation of new application areas by enabling the design of materials with previously unattainable property combinations, particularly in extreme environments.

- AI aids in understanding material degradation mechanisms at atomic levels, leading to more robust and durable high-melting metal components for demanding sectors.

- AI contributes to energy efficiency by optimizing furnace operations and high-temperature processes where high-melting metals are extensively used.

DRO & Impact Forces Of High-Melting Metals Market

The High-Melting Metals Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. Key drivers include the escalating demand from high-growth industries such as aerospace and defense, electronics, and energy, all of which require materials capable of operating under extreme conditions of heat, corrosion, and wear. The continuous pursuit of technological advancement in jet engines, advanced semiconductors, and nuclear reactors necessitates materials with superior thermal stability and mechanical strength, directly boosting the demand for high-melting metals. Furthermore, the burgeoning electric vehicle (EV) sector and the expansion of additive manufacturing techniques are creating new avenues for specialized high-melting metal components and powders. Global urbanization and industrialization also contribute to increased infrastructure development, requiring durable materials for various industrial applications. These factors collectively create a strong foundation for sustained market expansion, pushing innovation in material science and engineering.

However, the market faces several significant restraints that could impede its growth. High production costs associated with the extraction, purification, and processing of high-melting metals, often involving complex and energy-intensive methods, pose a considerable challenge. The volatility of raw material prices and the concentration of mining and processing facilities in a few regions can lead to supply chain disruptions and geopolitical risks, impacting market stability. Stringent environmental regulations related to mining and processing operations, coupled with concerns about the environmental footprint of these industries, add to operational complexities and costs. The technical challenges involved in fabricating complex components from these materials, due to their inherent hardness and brittleness, also contribute to higher manufacturing expenses and limited design flexibility for certain applications. These restraints necessitate ongoing innovation in processing technologies and a focus on sustainable practices to mitigate their impact.

Despite the challenges, numerous opportunities exist that promise to fuel future market growth. The increasing adoption of 5G and 6G technologies, along with advancements in quantum computing, will drive demand for high-melting metals in highly specialized electronic components that require exceptional thermal management and electrical properties. The ongoing global energy transition, particularly the expansion of renewable energy sources like concentrated solar power and advanced nuclear fission/fusion reactors, presents a significant opportunity for materials that can withstand ultra-high temperatures and harsh environments. Furthermore, the medical sector's growing need for biocompatible and corrosion-resistant materials for implants and surgical instruments, leveraging the properties of tantalum and niobium, offers a strong growth avenue. The continuous evolution of additive manufacturing technologies is creating new possibilities for producing intricate, lightweight, and high-performance components, thus expanding the application scope for high-melting metal powders. These opportunities highlight the critical role of these metals in enabling future technological advancements and addressing global challenges, underscoring their strategic importance in the materials landscape.

Segmentation Analysis

The High-Melting Metals Market is meticulously segmented across various dimensions, including type, application, and form, providing a granular view of its diverse landscape and market dynamics. This segmentation allows for a comprehensive understanding of specific material demands, end-user preferences, and technological requirements across different industrial verticals. The market's intricate structure reflects the specialized nature of these metals and their tailored functionalities for high-performance applications. Each segment showcases unique growth drivers and challenges, influenced by technological advancements, regulatory frameworks, and shifting economic conditions. Analyzing these segments individually and collectively offers critical insights for strategic planning and investment decisions within the market.

- By Type:

- Tungsten

- Molybdenum

- Tantalum

- Niobium

- Rhenium

- Chromium

- Hafnium

- Vanadium

- Others (e.g., Zirconium, Titanium, Scandium)

- By Application:

- Aerospace & Defense (e.g., jet engine components, rocket nozzles, heat shields, missile parts)

- Electronics & Semiconductors (e.g., filaments, sputtering targets, heat sinks, interconnects, X-ray tubes)

- Industrial Furnaces & Heating Elements (e.g., vacuum furnaces, high-temperature kilns, annealing equipment)

- Chemical Processing (e.g., heat exchangers, corrosion-resistant linings, process equipment)

- Energy (e.g., nuclear reactor components, solar power systems, wind turbine components, fusion energy research)

- Medical & Dental (e.g., surgical instruments, implants, radiation shielding, dental prosthetics)

- Automotive (e.g., engine parts, catalytic converters, spark plugs, sensors)

- Additive Manufacturing (3D printing of complex components)

- Other Industrial Applications (e.g., tool & die, glass manufacturing)

- By Form:

- Powder

- Rods & Bars

- Wires

- Sheets & Plates

- Foils

- Sputtering Targets

- Custom Fabrications

Value Chain Analysis For High-Melting Metals Market

The value chain for the High-Melting Metals Market is complex and highly specialized, beginning with the upstream processes of raw material extraction and beneficiation. This initial stage involves mining primary ores, which often contain low concentrations of these metals, followed by complex metallurgical processes such as crushing, grinding, flotation, and chemical leaching to concentrate the desired metal oxides. Further refining steps, including calcination and reduction, are necessary to produce pure metal powders or ingots. These upstream activities are capital-intensive and require advanced technological expertise due to the extreme conditions and specialized equipment involved in processing refractory ores. Geopolitical factors significantly influence this stage, as key deposits are concentrated in specific regions, impacting global supply stability and pricing. Investment in sustainable mining practices and responsible sourcing is increasingly critical for maintaining market access and meeting environmental compliance.

Midstream activities involve the conversion of raw metal forms into semi-finished products and specialized components. This stage includes powder metallurgy for producing high-purity powders with specific particle sizes, rolling, forging, and drawing processes to create rods, wires, sheets, and plates, and advanced machining techniques for sputtering targets and custom fabrications. Given the hardness and high melting points of these metals, these manufacturing processes demand specialized equipment, high energy inputs, and skilled labor. Innovation in these midstream processes focuses on improving material properties, reducing waste, and enabling the production of more complex geometries, particularly through advanced additive manufacturing technologies. Quality control and material testing are paramount at this stage to ensure the final products meet the stringent performance requirements of downstream applications.

Downstream activities encompass the distribution and end-use application of high-melting metals. Distribution channels vary, including direct sales from manufacturers to large industrial clients, through specialized distributors for smaller orders, and via global trading networks. Direct channels are common for highly customized products and long-term contracts in critical sectors like aerospace. Indirect channels, involving intermediaries, cater to a broader market, offering logistical support and technical expertise. End-users in industries such as aerospace, electronics, energy, and medical integrate these metals into their final products, often requiring further processing or assembly. The effectiveness of the value chain relies on strong collaboration between all stakeholders, from miners to end-product manufacturers, to ensure seamless supply, maintain quality standards, and drive innovation that addresses evolving market needs and technological advancements. The entire chain emphasizes reliability and precision due to the high-stakes applications of these materials.

High-Melting Metals Market Potential Customers

The High-Melting Metals Market serves a diverse and specialized customer base, primarily comprising industries that demand materials with exceptional performance characteristics under extreme conditions. Potential customers are typically manufacturers of high-technology components and systems where thermal stability, corrosion resistance, and mechanical strength at elevated temperatures are non-negotiable. These include major original equipment manufacturers (OEMs) in aerospace and defense, such as aircraft engine producers, missile system developers, and space exploration agencies, who rely on these metals for critical components like turbine blades, rocket nozzles, and heat shields. The electronics and semiconductor industry represents another significant customer segment, with companies manufacturing microprocessors, high-power electronic devices, display technologies, and medical imaging equipment utilizing high-melting metals for filaments, sputtering targets, and heat management solutions. Their demand is driven by the continuous miniaturization and performance enhancement of electronic devices.

Beyond aerospace and electronics, the industrial furnace and heating element sector is a key buyer, requiring high-melting metals for components that operate in high-temperature vacuum and controlled atmosphere environments. Chemical processing industries, including those involved in aggressive chemical reactions, are also significant customers, leveraging the superior corrosion resistance of tantalum and niobium for heat exchangers, reaction vessels, and piping. The energy sector, encompassing nuclear power plants, concentrated solar power facilities, and emerging fusion energy research, represents a growing customer base, as these metals are essential for components exposed to extreme heat and radiation. Medical and dental device manufacturers utilize high-melting metals like tantalum for biocompatible implants, surgical tools, and radiation therapy equipment, driven by their inertness and strength. Furthermore, the automotive industry, particularly for high-performance and electric vehicle applications, increasingly seeks these materials for advanced engine components, sensors, and battery technologies. Research institutions and additive manufacturing service providers also form a crucial segment of potential customers, driving innovation and prototyping new applications for these advanced materials.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 19.5 billion |

| Market Forecast in 2033 | USD 30.1 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plansee SE, H.C. Starck Tungsten Powders, A.L.M.T. Corp., Japan New Metals Co., Ltd., China Tungsten Online, ADMAT, Global Tungsten & Powders, Elmet Technologies, Molymet, Treibacher Industrie AG, KEMET (now Yageo), Stanford Advanced Materials, ALB Materials Inc., Fir Metal, M.C.P. Group, American Elements, ATI (Allegheny Technologies Incorporated), VSMPO-AVISMA Corporation, Sandvik AB, Sumitomo Electric Industries, Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High-Melting Metals Market Key Technology Landscape

The High-Melting Metals Market is underpinned by a sophisticated and continuously evolving technology landscape, crucial for overcoming the inherent challenges of processing these materials and unlocking new applications. Advanced powder metallurgy (PM) techniques are central to the production of high-purity high-melting metal components, enabling precise control over microstructure, density, and mechanical properties. This includes hot isostatic pressing (HIP), cold isostatic pressing (CIP), and various sintering methods, which are vital for achieving near-net-shape components with superior performance. Furthermore, specialized melting and refining technologies, such as vacuum arc remelting (VAR) and electron beam melting (EBM), are employed to achieve ultra-high purity metals, essential for demanding applications in electronics and medical devices. These processes minimize impurities that could compromise the material's integrity at extreme temperatures or in corrosive environments, ensuring the metals meet stringent performance criteria.

Additive manufacturing (AM), particularly technologies like Electron Beam Powder Bed Fusion (EB-PBF) and Laser Powder Bed Fusion (L-PBF), represents a transformative technological advancement in the high-melting metals sector. AM enables the fabrication of complex geometries and intricate internal structures that are impossible to achieve with traditional manufacturing methods, leading to lighter, stronger, and more efficient components. This capability is especially valuable for aerospace and defense applications where design optimization is critical. Developments in surface engineering and coating technologies also play a significant role, enhancing the oxidation and corrosion resistance of high-melting metals, thereby extending their operational life in harsh environments. These coatings can significantly improve the performance of components that are subjected to aggressive chemical agents or high-temperature oxidative atmospheres, broadening their applicability in challenging industrial settings.

Material characterization and testing technologies are equally crucial, ranging from advanced microscopy techniques (SEM, TEM) for microstructural analysis to sophisticated mechanical testing (tensile, creep, fatigue) at elevated temperatures. These technologies ensure product quality, validate material performance, and guide further material development. Moreover, computational materials science and artificial intelligence (AI) are rapidly emerging as pivotal tools, facilitating in-silico design of new high-melting alloys, predicting material behavior, and optimizing processing parameters. AI-driven simulations can accelerate the discovery of novel compositions with enhanced properties, reduce the need for extensive experimental trials, and streamline the entire R&D pipeline. The integration of Industry 4.0 principles, including sensor networks and data analytics in manufacturing processes, further contributes to operational efficiency, predictive maintenance, and overall product reliability, thereby solidifying the technological foundation of the high-melting metals market.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, driven by rapid industrialization, burgeoning electronics manufacturing, and significant investments in aerospace, defense, and energy sectors, particularly in China, Japan, South Korea, and India. The region benefits from both large-scale production capabilities and robust end-user demand, making it a pivotal hub for high-melting metals.

- North America: A major market fueled by a mature aerospace and defense industry, extensive research and development activities, and a strong focus on advanced manufacturing technologies. The presence of leading technology companies and strict performance requirements in critical applications sustains high demand.

- Europe: Holds a significant share, characterized by advanced industrial capabilities in automotive, aerospace, medical, and industrial equipment sectors. Countries like Germany, France, and the UK are key contributors, driven by innovation, stringent quality standards, and a push towards sustainable material solutions.

- Latin America: Emerging market with increasing industrialization and investments in infrastructure and energy projects. Growth is attributed to developing manufacturing capabilities and rising demand from the automotive and construction sectors, albeit from a lower base compared to other regions.

- Middle East and Africa (MEA): Growing market, influenced by expanding oil and gas industry infrastructure, diversification efforts into manufacturing and technology, and increasing investments in defense and aerospace. Regional economic development initiatives are expected to boost demand for high-performance materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High-Melting Metals Market.- Plansee SE

- H.C. Starck Tungsten Powders

- A.L.M.T. Corp.

- Japan New Metals Co., Ltd.

- China Tungsten Online

- ADMAT (Advanced Metal Technologies Co., Ltd.)

- Global Tungsten & Powders (GTP)

- Elmet Technologies

- Molymet (Molibdenos y Metales S.A.)

- Treibacher Industrie AG

- KEMET (now part of Yageo Corporation)

- Stanford Advanced Materials

- ALB Materials Inc.

- Fir Metal

- M.C.P. Group

- American Elements

- ATI (Allegheny Technologies Incorporated)

- VSMPO-AVISMA Corporation

- Sandvik AB

- Sumitomo Electric Industries, Ltd.

Frequently Asked Questions

Analyze common user questions about the High-Melting Metals market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are high-melting metals and their primary characteristics?

High-melting metals, also known as refractory metals, are metallic elements characterized by exceptionally high melting points, typically above 2000 degrees Celsius. Key properties include superior hardness, excellent resistance to heat, corrosion, and wear, and high strength at elevated temperatures. Common examples include tungsten, molybdenum, tantalum, and niobium, which are critical for applications demanding extreme performance.

What are the major applications of high-melting metals?

High-melting metals are indispensable across various high-tech industries. Major applications include aerospace and defense (jet engines, rocket nozzles), electronics and semiconductors (filaments, sputtering targets, heat sinks), industrial furnaces (heating elements, vacuum components), chemical processing (corrosion-resistant equipment), energy (nuclear, solar), and medical implants due to their unique properties.

What factors are driving the growth of the High-Melting Metals Market?

Market growth is primarily driven by increasing demand from high-technology sectors like aerospace, defense, and electronics, which require materials capable of withstanding extreme conditions. Additionally, the expansion of additive manufacturing, advancements in renewable energy technologies, and the rising need for high-performance materials in the automotive and medical fields are significant growth catalysts.

What challenges does the High-Melting Metals Market face?

The market faces several challenges, including high production costs associated with extraction and processing, complex manufacturing techniques due to material hardness, volatility in raw material prices, and potential supply chain disruptions influenced by geopolitical factors. Strict environmental regulations and the energy-intensive nature of production also pose significant hurdles for market players.

How is AI impacting the High-Melting Metals Market?

AI is significantly impacting the market by accelerating the discovery and design of novel alloys, optimizing complex manufacturing processes such as additive manufacturing, enhancing quality control through predictive analysis, and improving supply chain resilience. AI-driven simulations and data analytics also aid in predictive maintenance and the development of sustainable production methods, creating new opportunities for material innovation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- High-melting Metals Market Statistics 2025 Analysis By Application (Steel Industry, Electronics and Electrical Industry, Carbide Tools and Wear Parts, Chemical Industry, Medical Industry, Others), By Type (Molybdenum Metal, Tungsten Metal, Niobium Metal, Tantalum Metal, Rhenium Metal), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- High-melting Metals Market Statistics 2025 Analysis By Application (Steel Industry, Electronics and Electrical Industry, Carbide Tools and Wear Parts, Chemical Industry, Medical Industry), By Type (Molybdenum Metal, Tungsten Metal, Niobium Metal, Tantalum Metal, Rhenium Metal), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager