High-Purity Limestone Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441286 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

High-Purity Limestone Market Size

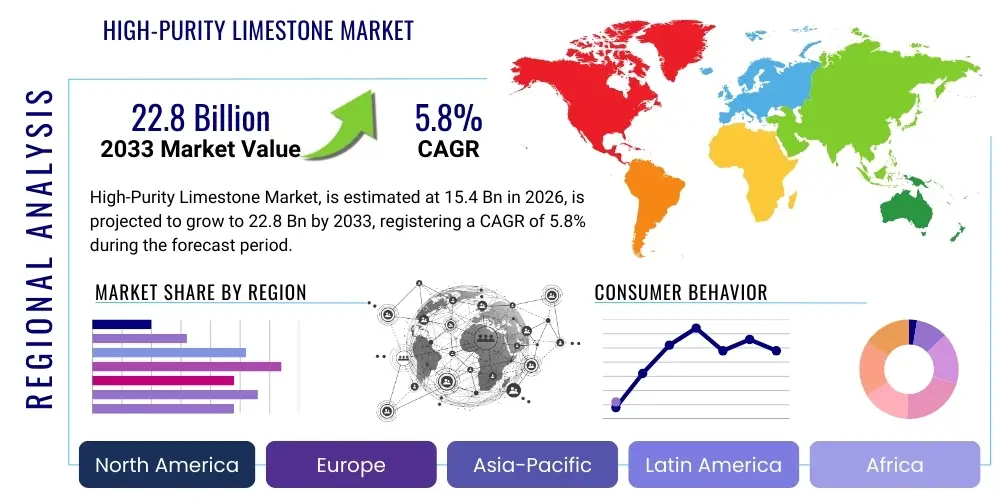

The High-Purity Limestone Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 15.4 Billion in 2026 and is projected to reach USD 22.8 Billion by the end of the forecast period in 2033.

High-Purity Limestone Market introduction

The High-Purity Limestone Market encompasses the mining, processing, and distribution of calcium carbonate (CaCO3) deposits characterized by extremely low levels of impurities, typically less than 1% silica, alumina, and iron oxides. This specialized mineral product is essential across several heavy industries where the performance and quality of the end-product are critically dependent on the purity of raw materials. Key applications span metallurgy, where it serves as a fluxing agent in steel production; environmental controls, particularly in Flue Gas Desulfurization (FGD) systems to mitigate sulfur emissions; and chemical manufacturing, acting as a crucial precursor for the production of quicklime and hydrated lime.

The demand trajectory for high-purity limestone is intrinsically linked to global industrial output, particularly in rapidly urbanizing and industrializing regions like Asia Pacific. The product's inherent benefits, such as its cost-effectiveness as a neutralizing agent, high reactivity, and availability, cement its role as a foundational industrial material. Driving factors include stringent environmental regulations compelling industries, such as power generation and cement manufacturing, to adopt efficient scrubbing technologies, thereby increasing the consumption of limestone for sulfur dioxide removal. Furthermore, the expansion of the global steel industry and infrastructure projects, which necessitate vast quantities of cement and construction materials, continue to underpin market growth.

High-purity limestone is categorized based on its chemical composition and physical properties, including whiteness, hardness, and grain size distribution. Beyond its bulk use in construction and metallurgy, highly specialized grades are utilized in niche, high-value applications such as pharmaceutical fillers, food-grade calcium supplements, and high-quality paper production where brightness and freedom from contaminants are paramount. The market structure is highly dependent on logistics, quarry location, and proximity to major industrial consumers, leading to significant regional market differentiations and competitive landscapes focused on optimizing supply chain efficiency and product consistency.

High-Purity Limestone Market Executive Summary

The High-Purity Limestone Market is undergoing a transformation driven by sustainability mandates and technological advancements aimed at enhancing resource efficiency and product consistency. Business trends highlight a strong movement towards vertical integration among major producers, enabling better control over mining operations, processing quality, and logistics, thereby maximizing profit margins and ensuring long-term supply stability for key clients. Furthermore, merger and acquisition activities are prominent, particularly as companies seek to secure strategic quarry locations closer to rapidly growing consumption centers in Southeast Asia and parts of Africa. Investments in advanced beneficiation and grinding technologies are crucial, focusing on producing finer grades of limestone (micronized calcium carbonate) required for specialty applications like plastics and paint fillers, diversifying revenue streams beyond traditional bulk uses.

Regional trends indicate that the Asia Pacific (APAC) region remains the dominant growth engine, propelled by unprecedented infrastructure development and robust growth in the steel, cement, and power generation sectors, particularly in China and India. North America and Europe, characterized by mature industrial bases, exhibit growth primarily driven by regulatory requirements, specifically the mandatory implementation of FGD systems in thermal power plants and the increasing adoption of Ground Calcium Carbonate (GCC) in the paper industry as an environmentally friendlier alternative to traditional pigments. Segment trends reveal that the Metallurgy and Flue Gas Desulfurization applications collectively account for the largest market share, while the Agriculture segment, driven by the need for soil pH management and nutrient enrichment, is poised for accelerated growth, especially with increasing global pressure on agricultural yield optimization.

The market faces structural challenges related to environmental permitting for new quarry sites and the substantial energy costs associated with processing and transportation, which necessitate continuous innovation in sustainable mining practices and energy efficiency. However, the burgeoning demand for high-quality lime products in chemical synthesis and emerging applications in carbon capture technologies present significant opportunities. The market's future will be defined by the successful integration of digitalization in logistics and production monitoring, ensuring high-quality, traceable supply chains that meet the demanding specifications of end-user industries.

AI Impact Analysis on High-Purity Limestone Market

Common user questions regarding AI's impact on the High-Purity Limestone Market frequently revolve around optimizing extraction logistics, predictive maintenance of heavy machinery, and leveraging advanced analytics for quality control and resource mapping. Users are keen to understand how AI can reduce operational costs, particularly fuel consumption and unplanned downtime, which are significant expenditures in quarrying operations. Another key theme concerns the use of machine learning algorithms to analyze geological data, thereby improving the precision of drilling and blasting patterns, minimizing waste, and maximizing the yield of high-purity reserves. Furthermore, there is growing interest in using AI and image processing to automate the sorting and grading of limestone chips during processing, ensuring consistent adherence to stringent purity requirements set by industries such as pharmaceuticals and specialty chemicals, minimizing human error and variability.

- Deployment of AI-powered predictive maintenance models for crushers, screeners, and grinding mills, significantly reducing unplanned operational downtime.

- Optimization of energy consumption in calcination processes (kilns) using machine learning to adjust temperature profiles based on real-time material feedback.

- Enhanced geological modeling and resource estimation through AI analysis of seismic and drilling data, maximizing yield from existing quarry reserves.

- Automation of quality control using computer vision systems to detect impurities (silica, iron) in processed limestone streams in real-time.

- Improved supply chain logistics and transportation scheduling by leveraging AI algorithms to minimize fuel costs and optimize delivery routes to end-user facilities.

- Implementation of AI in safety monitoring systems, detecting potential hazards in complex quarry environments and improving overall worker safety protocols.

DRO & Impact Forces Of High-Purity Limestone Market

The dynamics of the High-Purity Limestone Market are dictated by a balanced interplay of robust industrial demand (Drivers) and increasing regulatory hurdles (Restraints), mitigated by the potential for specialized product development (Opportunities) and amplified by external market shifts (Impact Forces). The core driving force is the escalating global focus on environmental compliance, particularly the widespread adoption of Flue Gas Desulfurization (FGD) systems, which rely heavily on high-purity limestone as an absorbent. This is complemented by persistent demand from the steel and construction sectors, foundational elements of global economic development, especially in emerging economies undergoing rapid infrastructure modernization. However, these drivers are counterbalanced by severe restraints, including high capital intensity for setting up new processing plants, stringent environmental clearances required for quarry expansion, and the escalating cost and volatility of energy inputs necessary for mining, crushing, and calcination processes.

Opportunities in the market primarily reside in innovation and diversification. The development of ultra-fine and micronized calcium carbonate (MCC/GCC) tailored for high-value industries—such as polymer additives, specialized coatings, and nutraceuticals—offers higher margin potential compared to bulk commodity sales. Furthermore, the exploration of limestone's potential role in emerging environmental technologies, such as enhanced weathering techniques for carbon sequestration, presents a long-term growth opportunity aligned with global climate mitigation efforts. The impact forces shaping the market include fluctuating energy prices, which directly influence processing costs, and evolving international trade policies that affect mineral sourcing and cross-border material movement. Additionally, technological innovations in material substitution, while currently minimal, pose a potential long-term threat if cheaper, equally effective alternatives to limestone emerge in specific applications like cement production.

Overall, the market remains cyclical, tied strongly to global macroeconomic health, yet it is increasingly fortified by non-cyclical, mandatory demand originating from environmental protection legislation. The ability of key market players to secure long-term, high-quality reserves, invest in efficient logistics networks, and adhere rigorously to product quality standards will be the deciding factors in maintaining competitive advantage amidst rising operational costs and heightened scrutiny regarding the environmental footprint of quarrying activities. Strategic investment in low-carbon processing techniques and advanced logistics optimization becomes paramount for sustainable growth.

Segmentation Analysis

The High-Purity Limestone Market is comprehensively segmented primarily based on Product Type, Application, and Geographical Region, allowing for a detailed understanding of diverse demand patterns and market penetration strategies. Segmentation by Product Type typically distinguishes between high-calcium limestone (pure CaCO3 content) and dolomite (calcium magnesium carbonate), reflecting their distinct chemical properties and specific end-use requirements. High-calcium limestone dominates the market due to its necessity in chemical manufacturing, FGD, and filler applications, while dolomite is vital for refractories and specialized metallurgical fluxes where magnesium content is beneficial.

Application-based segmentation is crucial as it dictates the required purity levels, particle size, and overall volume demand. The largest application segments are industrial, including Steel Manufacturing (fluxing agent), Cement and Lime Production (essential raw material), and Environmental Control (FGD). However, niche, high-growth segments such as Agriculture (soil conditioners and feed additives) and specialty Chemical Synthesis require significantly stricter quality specifications, commanding premium prices and fostering competitive differentiation based on advanced processing capabilities. This multidimensional segmentation allows stakeholders to target investment towards high-growth, high-value niches while maintaining a stable revenue base through bulk industrial supply contracts.

- By Product Type:

- High-Calcium Limestone

- Dolomite

- Magnesian Limestone

- By Application:

- Construction and Infrastructure (Aggregates)

- Cement and Lime Manufacturing

- Steel Manufacturing and Metallurgy (Fluxing Agent)

- Flue Gas Desulfurization (FGD) and Environmental Control

- Chemical and Industrial Fillers (Plastics, Paints, Sealants)

- Agriculture (Soil Conditioners and Animal Feed)

- Glass and Ceramics Production

- Paper Manufacturing (Ground Calcium Carbonate - GCC)

- Water Treatment and Purification

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Southeast Asia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (Saudi Arabia, UAE, South Africa, Rest of MEA)

Value Chain Analysis For High-Purity Limestone Market

The value chain of the High-Purity Limestone Market begins with rigorous Upstream Analysis, which involves geological exploration, identification of high-quality reserves, land acquisition, and permitting, followed by the actual quarrying and mining operations. Crucial stages at this phase include overburden removal, drilling, blasting, and primary crushing. Since the purity of the raw material dictates its market value, effective geological resource management and precise extraction techniques are critical to minimizing contamination right from the source. Capital expenditures in this upstream phase are substantial, necessitating detailed economic feasibility studies and long-term investment commitments from market players. Processing facilities, often located adjacent to the quarry, handle secondary crushing, screening, washing, and, if required, grinding or calcination (to produce lime), adding significant value through refinement and specialized product formulation.

The Midstream component focuses on logistics and processing efficiency. Due to the high-volume, low-value nature of bulk limestone, transportation costs represent a major proportion of the final delivered price, making geographical proximity to end-users a paramount competitive factor. Distribution channels are varied, incorporating both Direct and Indirect methodologies. Direct sales involve long-term contracts with major industrial consumers like steel mills, power generation facilities, and large cement producers, often utilizing dedicated rail lines, barges, or specialized trucking fleets for high-volume delivery. This ensures stable demand and predictable revenue streams. Indirect channels involve regional distributors or traders who serve smaller construction firms, agricultural cooperatives, or specialized chemical processors, providing flexible, smaller-batch supplies tailored to local market needs and logistical constraints.

Downstream Analysis centers on the numerous industrial and specialized applications. Key downstream consumers are the metallurgy sector, which demands high-reactivity limestone for slag removal; the construction sector, requiring aggregates and cement precursors; and the environmental sector, demanding precise chemical composition for FGD effectiveness. Technological advancements downstream, such as the increasing demand for ultra-fine Ground Calcium Carbonate (GCC) in high-speed paper machines and paint formulations, necessitate continuous investment in sophisticated micronization equipment by limestone processors. The stability of the downstream consumption is tightly linked to infrastructure spending and regulatory enforcement, emphasizing the need for producers to maintain diverse end-market exposure to mitigate sectoral risks.

High-Purity Limestone Market Potential Customers

The High-Purity Limestone Market caters to a diverse portfolio of industries, signifying robust and varied demand across global economic sectors. Primary customers are large-scale industrial complexes that utilize limestone either as a principal raw material or as a critical processing aid. This includes integrated steel manufacturers (EAF and BOF processes), where limestone is essential for desulfurization and slag formation to remove impurities, and major cement and quicklime producers, for whom limestone is the fundamental ingredient for clinker production and subsequent lime manufacturing. These customers typically require extremely large volumes under long-term supply agreements, prioritizing consistency, chemical purity, and logistical reliability.

Beyond the heavy industrial segments, environmental technology providers and utility companies operating coal-fired power plants represent critical customers due to strict emissions control mandates. These facilities purchase vast quantities of pulverized limestone for Flue Gas Desulfurization (FGD) systems to neutralize sulfur dioxide emissions, driven entirely by government regulations (e.g., EPA standards in the US or EU directives). Furthermore, the chemical processing industry, including producers of precipitated calcium carbonate (PCC), calcium chloride, and other calcium-based derivatives, relies on high-purity feedstocks to ensure the final product quality meets industrial or food-grade specifications, demanding the highest levels of mineral purity.

In the specialty and non-traditional sectors, potential customers include agricultural cooperatives and large farming enterprises that utilize limestone (aglime) for soil amendment, pH balancing, and calcium enrichment in animal feed. The paper, plastics, and paint industries serve as major buyers of refined, micronized limestone products (GCC/PCC), where the high brightness, low abrasiveness, and consistent particle distribution of the mineral function as cost-effective functional fillers and pigments, improving product performance and reducing reliance on more expensive alternatives like titanium dioxide. The market for these specialty customers is characterized by smaller volumes but significantly higher value propositions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.4 Billion |

| Market Forecast in 2033 | USD 22.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Carmeuse, Lhoist, Graymont Limited, Mississippi Lime Company, US Aggregates, Minerals Technologies Inc., Imerys S.A., Sibelco, Calcinor S.A., Todaka Mining Co., Ltd., Schaefer Kalk GmbH & Co. KG, Buzzi Unicem, Heidelberg Materials, Cemex S.A.B. de C.V., Omya AG, China Resources Cement Holdings Limited, The DeLong Co., Inc., Adbri Limited, Votorantim Cimentos, ArcelorMittal Mining. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High-Purity Limestone Market Key Technology Landscape

The technological landscape of the High-Purity Limestone Market is primarily focused on enhancing efficiency in three core areas: extraction, purification, and particle size reduction. In extraction, technologies such as precision blasting using electronic detonators and advanced seismic surveys are employed to minimize rock fragmentation outside the desired parameters, thereby optimizing yield and reducing waste. Furthermore, autonomous hauling and drilling systems are increasingly being piloted to improve operational safety, reduce labor costs, and allow for continuous operation in harsh quarry environments. These smart mining technologies rely heavily on GPS and sensor fusion to ensure efficient material handling from the quarry face to the primary crusher, maintaining a high throughput necessary for bulk material supply.

Purification and processing technologies are critical for achieving the "high-purity" required for specialty applications. Advanced beneficiation techniques, including froth flotation and specialized heavy media separation, are utilized to remove unwanted mineral impurities (such as quartz and clay) that standard crushing and screening cannot eliminate. The implementation of high-intensity magnetic separators is also crucial in removing trace amounts of iron oxides, which are detrimental in applications like glass manufacturing and high-brightness fillers. Process control systems utilizing spectroscopy and X-ray fluorescence (XRF) analyzers allow for continuous, real-time chemical composition checks, ensuring that the processed material consistently meets the stringent specifications of end-users.

Perhaps the most intensive area of technological investment is in comminution and classification, specifically focused on producing ultra-fine particles. Air classifiers and vertical roller mills (VRMs) are essential for achieving the micronized grades required for Ground Calcium Carbonate (GCC) used in paper and plastics. These technologies enable precise control over particle size distribution (PSD), which directly affects the functional properties of the filler, such as oil absorption, whiteness, and rheology. Manufacturers are also exploring environmentally friendly processing methods, including waste heat recovery in calcination kilns and dry processing techniques, to address the high energy consumption and environmental impact historically associated with limestone refinement, aligning technological improvements with corporate sustainability goals.

Regional Highlights

- Asia Pacific (APAC): APAC is unequivocally the largest and fastest-growing market for high-purity limestone, primarily driven by China and India. The region's immense population base necessitates continuous investment in foundational industries such as cement, steel, and power generation. Rapid urbanization and massive government-led infrastructure projects, including high-speed rail networks and mega-cities, underpin the demand for high volumes of aggregates and cement precursors. Furthermore, the region is seeing significant adoption of FGD technologies, particularly in China and India, as air quality regulations become increasingly strict, creating a steady, mandated demand for high-purity limestone for environmental control applications. The competitive landscape is fragmented, featuring both large multinational corporations and numerous powerful local players capitalizing on geographically advantageous quarry sites.

- North America: The North American market is characterized by maturity, stable demand, and exceptionally high product quality requirements, particularly from specialty chemical, pharmaceutical, and paper industries. Growth in this region is less dependent on new infrastructure build-out and more reliant on maintenance, replacement demand, and regulatory compliance. Environmental mandates, particularly those concerning industrial emissions and water quality, are key market drivers. Major limestone producers in the U.S. and Canada prioritize operational efficiency, safety, and establishing sophisticated logistics networks (rail and water transport) to supply dispersed industrial centers efficiently. Innovation often focuses on premium, value-added products like ultra-fine Ground Calcium Carbonate (GCC) for use in the highly competitive North American paper and plastics markets.

- Europe: The European High-Purity Limestone Market is heavily influenced by EU environmental policies, which drive demand for limestone in FGD and in sustainable construction practices. The region features strong demand from Germany, France, and Italy, supporting robust metallurgical and chemical industries. Strict quarrying regulations and high energy costs push manufacturers toward high-efficiency processing and optimization of existing quarry reserves rather than new site development. The focus here is increasingly shifting towards circular economy principles, exploring the use of limestone and lime products in waste treatment and resource recovery processes. Furthermore, the demand for specialty limestone products in the production of Precipitated Calcium Carbonate (PCC) for high-end paper coatings remains a crucial segment, reflecting Europe's advanced manufacturing capabilities.

- Latin America: Latin America exhibits moderate growth, intrinsically linked to the economic stability and infrastructure investment levels of major economies like Brazil and Mexico. High-purity limestone consumption is primarily concentrated in the cement, lime, and steel sectors, supporting regional construction and manufacturing demands. Logistical challenges, including poor road infrastructure in remote mining areas, often restrict cost-effective supply, leading to a highly localized market structure. Opportunities are emerging in the agricultural sector, where expansive farming operations require soil conditioning products, creating a stable but volume-sensitive demand stream for aglime. Economic volatility, however, remains a key restraint on large-scale, long-term investments in quarry expansion and technology upgrades.

- Middle East and Africa (MEA): The MEA region is experiencing significant, though concentrated, growth, driven by massive construction and industrial diversification projects in the Gulf Cooperation Council (GCC) countries. High demand exists for high-quality limestone in large-scale cement manufacturing facilities supporting landmark infrastructure projects. In South Africa and specific parts of the Middle East, the metallurgical sector contributes substantial demand. Future growth will be tied to investments in water treatment facilities (desalination and municipal water purification) and the expansion of the chemical sector, which requires stable, high-purity mineral inputs. Regional market dynamics are heavily influenced by government-led industrial policies and the availability of affordable energy inputs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High-Purity Limestone Market.- Carmeuse

- Lhoist

- Graymont Limited

- Mississippi Lime Company

- US Aggregates

- Minerals Technologies Inc.

- Imerys S.A.

- Sibelco

- Calcinor S.A.

- Todaka Mining Co., Ltd.

- Schaefer Kalk GmbH & Co. KG

- Buzzi Unicem

- Heidelberg Materials

- Cemex S.A.B. de C.V.

- Omya AG

- China Resources Cement Holdings Limited

- The DeLong Co., Inc.

- Adbri Limited

- Votorantim Cimentos

- ArcelorMittal Mining

Frequently Asked Questions

Analyze common user questions about the High-Purity Limestone market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between standard limestone and high-purity limestone?

High-purity limestone is defined by its minimal content of impurities, typically containing over 97% Calcium Carbonate (CaCO3) and low concentrations of silica, alumina, and iron oxides. Standard limestone is used primarily for construction aggregates, whereas high-purity grades are essential for chemical processes, steel metallurgy, and environmental scrubbing where impurity levels critically affect process efficiency and final product quality.

Which application segment drives the largest demand for high-purity limestone globally?

The largest application segment driving global demand is the combination of Cement and Lime Manufacturing alongside Metallurgy and Flue Gas Desulfurization (FGD). The environmental sector, driven by stringent government mandates to reduce sulfur dioxide emissions from power plants, ensures a robust, continuous demand stream for the limestone used as a scrubbing agent.

How does the quality of limestone reserves affect market pricing and competitiveness?

The geological quality of limestone reserves directly dictates market pricing. Higher purity reserves reduce the need for expensive beneficiation and processing, yielding products suitable for high-margin specialty markets (e.g., paper and pharma). Companies with access to strategically located, high-quality reserves gain a significant competitive advantage due to lower operational costs and the ability to meet premium specifications.

What role does Ground Calcium Carbonate (GCC) play in the high-purity limestone market?

Ground Calcium Carbonate (GCC) is a key value-added product derived from high-purity limestone. GCC involves ultra-fine grinding and is used extensively as a functional filler and coating pigment in the paper, plastics, and paint industries, offering improved brightness, opacity, and lower cost compared to synthetic alternatives. The demand for GCC often commands premium pricing over bulk limestone commodity grades.

What are the main logistical challenges faced by high-purity limestone suppliers?

Logistical challenges are dominated by the need to efficiently transport large volumes of a high-density, low-value commodity. High-purity limestone suppliers must optimize transport via rail, barge, and dedicated trucking fleets to minimize costs and transit times, as transportation expenses often form a significant percentage of the final delivered cost, especially over long distances.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager