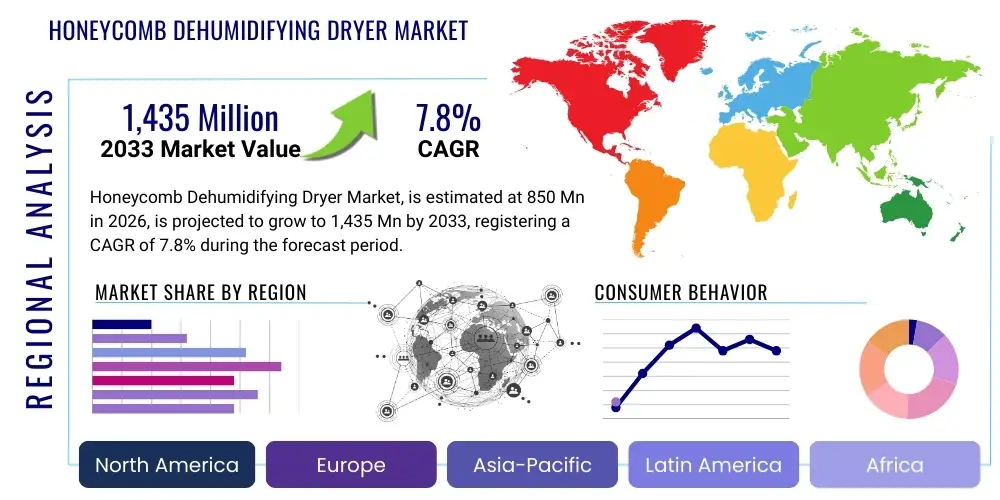

Honeycomb Dehumidifying Dryer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443598 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Honeycomb Dehumidifying Dryer Market Size

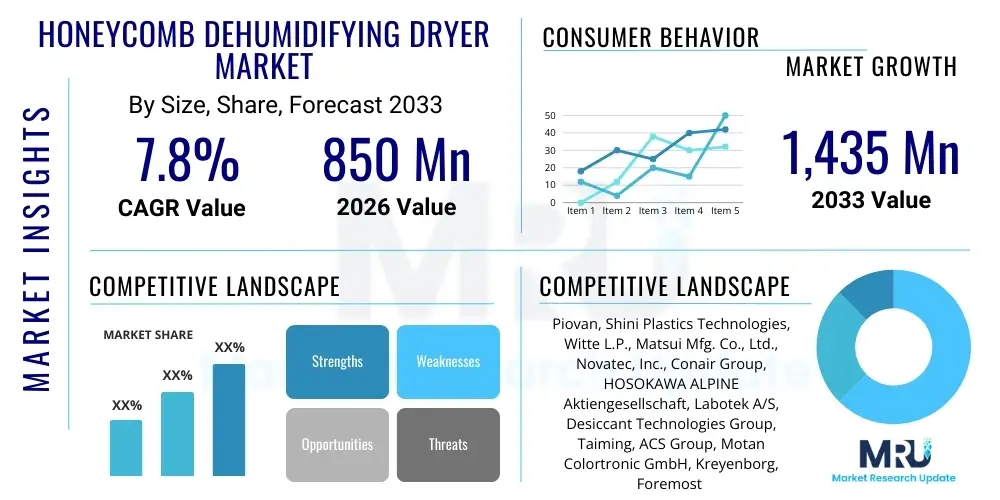

The Honeycomb Dehumidifying Dryer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,435 Million by the end of the forecast period in 2033.

This robust growth trajectory is primarily driven by the escalating demand for high-performance engineering plastics, particularly in the automotive, medical device, and packaging sectors. Honeycomb dehumidifying dryers are critical for processing hygroscopic resins such as PET, PC, ABS, and Nylon, ensuring optimal moisture removal necessary to prevent material degradation (hydrolysis) during molding or extrusion processes. The stringent quality requirements across various end-use industries necessitate precise control over material moisture content, cementing the dryer's role as indispensable auxiliary equipment.

Honeycomb Dehumidifying Dryer Market introduction

The Honeycomb Dehumidifying Dryer Market encompasses the global trade and utilization of equipment designed specifically for removing moisture content from thermoplastic materials prior to processing. These dryers operate based on the principle of desiccant dehumidification, utilizing a rotating honeycomb wheel saturated with a highly effective desiccant material, typically zeolite or silica gel. This mechanism allows for the continuous delivery of extremely dry, low dew point air (often below -40°C) to the drying hopper, ensuring that hygroscopic plastic pellets achieve the required residual moisture level for high-quality molding and extrusion operations.

Major applications for honeycomb dehumidifying dryers span across industries that require the processing of sensitive engineering plastics, including the production of automotive components (e.g., headlights, interior trims), medical disposables (e.g., syringes, IV components), optical discs, and specialized food and beverage packaging (e.g., PET bottles and preforms). The primary benefit derived from using these systems is the prevention of polymer degradation, which otherwise leads to defects such as streaking, brittleness, reduced mechanical strength, and poor surface finish in the final product. Furthermore, modern honeycomb dryers are increasingly integrating energy-saving features, intelligent controls, and remote monitoring capabilities, optimizing operational efficiency and reducing energy consumption compared to conventional hot air or molecular sieve drying systems.

Key driving factors fueling market expansion include the global shift towards lightweight materials in the automotive and aerospace industries, increasing regulatory emphasis on material quality and purity in medical and food contact applications, and the continuous innovation in polymer science leading to the introduction of new, highly hygroscopic specialty resins. Additionally, the proliferation of large-scale injection molding and extrusion plants, particularly in Asia Pacific economies, necessitates high-throughput, reliable drying solutions provided by honeycomb technologies.

Honeycomb Dehumidifying Dryer Market Executive Summary

The Honeycomb Dehumidifying Dryer Market is experiencing dynamic growth fueled by advancements in precision manufacturing and the increasing global consumption of high-grade engineering plastics. Key business trends indicate a strong focus on energy efficiency, with manufacturers prioritizing designs that incorporate closed-loop drying systems, enhanced insulation, and proportional regenerative heaters to minimize energy expenditure and operational costs. Strategic mergers, acquisitions, and technological collaborations are common as key players seek to expand their product portfolios, especially into modular and centralized drying systems tailored for Industry 4.0 environments. The shift towards sustainability is also driving the adoption of units capable of handling bio-based and recycled plastics, which often exhibit higher moisture absorption rates.

Regionally, Asia Pacific maintains market dominance due to its massive concentration of plastics processing and manufacturing hubs, particularly in China, India, and Southeast Asia. Robust demand for consumer electronics, automotive parts, and resilient packaging materials in these regions is the primary catalyst. North America and Europe, while growing at a slower pace, are characterized by a strong demand for advanced, highly automated drying systems that meet stringent environmental and occupational safety standards. These mature markets are driving innovation in predictive maintenance and remote diagnostics functionalities, ensuring maximum uptime for complex processing lines.

Segment trends reveal that the small-to-medium throughput category remains dominant due to the high volume of customized plastic fabrication shops globally. However, the high-throughput segment is exhibiting the fastest growth, primarily driven by large-scale PET preform production and compounding facilities. In terms of technology, closed-loop systems are rapidly replacing open-loop alternatives, especially for highly hygroscopic and costly materials, ensuring minimal exposure to ambient humidity and maximizing drying consistency. The adoption of dual-bed or multi-bed honeycomb structures designed for continuous, uninterrupted operation is also a notable segment trend across various end-user applications.

AI Impact Analysis on Honeycomb Dehumidifying Dryer Market

Common user inquiries regarding AI in the Honeycomb Dehumidifying Dryer Market revolve primarily around predictive maintenance capabilities, energy optimization algorithms, and integration with centralized Manufacturing Execution Systems (MES). Users frequently ask how AI can prevent sudden equipment failures, calculate the precise minimum energy required for specific material batches, and automatically adjust dew point and temperature settings based on real-time ambient conditions and resin characteristics. There is also significant interest in AI models that can analyze historical drying data to suggest optimal processing parameters for novel or difficult-to-dry polymer grades, thus minimizing scrap rates and maximizing production efficiency. The consensus expectation is that AI will transform these auxiliary units from passive components into intelligent, self-optimizing system elements crucial for achieving lean manufacturing goals.

AI is set to revolutionize the efficiency and reliability of honeycomb dryers by enabling sophisticated data processing beyond traditional PLC controls. Machine learning algorithms can analyze vast datasets concerning temperature fluctuations, airflow rates, energy consumption, and material input variables. This analysis allows the system to predict deviations from optimal drying curves before they occur, triggering corrective actions autonomously. For instance, if external humidity increases suddenly, an AI system can anticipate the resultant increase in required regeneration heat and pre-emptively adjust settings, maintaining a stable dew point consistently, which is virtually impossible for manual or basic feedback loop systems to achieve with the same precision.

Furthermore, the integration of AI facilitates seamless communication with primary processing equipment, such as injection molding machines or extruders. This interconnectivity allows the dryer to receive signals about production rates or upcoming material changes, dynamically adjusting its output (flow rate and temperature) to meet demand precisely, thereby eliminating unnecessary heating cycles and significant energy wastage. This shift towards smart, proactive drying management not only reduces operational costs but significantly improves the consistency and quality assurance processes critical for high-stakes industries like medical and automotive manufacturing.

- Enhanced Predictive Maintenance: AI models forecast potential mechanical failures (e.g., desiccant wheel wear, heater element degradation) based on sensor data anomalies, scheduling maintenance proactively.

- Dynamic Energy Optimization: Algorithms adjust regeneration and process temperatures in real-time, minimizing power consumption while ensuring the target dew point is met.

- Automated Recipe Generation: AI analyzes material properties and environmental factors to suggest optimal drying profiles for new or complex polymer batches.

- Improved Quality Control: Real-time correlation of drying parameters with finished product quality metrics (e.g., visual defects, tensile strength) to ensure zero-defect material feeding.

- Seamless MES Integration: AI acts as a smart gateway, linking the dryer's performance data directly into central factory management systems for holistic operational oversight.

DRO & Impact Forces Of Honeycomb Dehumidifying Dryer Market

The Honeycomb Dehumidifying Dryer Market is primarily driven by the escalating demand for high-quality plastic products across crucial sectors, especially automotive lightweighting and precision medical device manufacturing, both of which rely heavily on moisture-sensitive engineering resins. Restraints largely center on the high initial capital investment required for high-end, centralized drying systems compared to localized, less efficient alternatives, alongside the operational challenges posed by regular maintenance and replacement of the desiccant wheel. Significant opportunities lie in the rapid adoption of Industry 4.0 principles, allowing for the development of smart, interconnected drying networks, and the growing focus on recycling plastics, which often necessitates superior drying processes due to variable moisture content. These forces collectively shape the market's trajectory, mandating manufacturers to continuously innovate in energy efficiency and automation.

The impact forces within the market are predominantly technological and regulatory. Technological innovations, such as the development of new desiccant materials with enhanced moisture adsorption capacity and lower regeneration temperatures, provide a strong positive impulse. Furthermore, regulatory forces, particularly concerning energy consumption and carbon emissions (e.g., EU energy directives), compel end-users to upgrade older, inefficient equipment to modern honeycomb dryers, which offer significantly better performance metrics. However, the cyclical nature of the plastics industry and general macroeconomic instability can pose impact forces that temporarily restrain investment in new auxiliary equipment.

The market also faces inherent competitive forces related to differentiation. Manufacturers must continuously justify the higher price point of honeycomb technology over traditional methods by demonstrating substantial, quantifiable reductions in scrap rate, energy savings, and improved polymer mechanical properties. The move towards centralized drying systems represents a major restructuring force, shifting purchasing decisions from decentralized unit acquisition to complex, integrated system procurement involving comprehensive factory planning and infrastructure modifications.

Segmentation Analysis

The Honeycomb Dehumidifying Dryer Market is broadly segmented based on factors such as type, throughput capacity, application, and end-use industry. Segmentation by type typically differentiates between closed-loop (highly preferred for sensitive materials and energy conservation) and open-loop systems. Throughput capacity segmentation (Low, Medium, High) determines suitability for specific production scales, ranging from small-batch compounding to large-volume PET preform production lines. The application and end-use industry breakdowns are crucial for tailoring marketing strategies, reflecting the diverse material requirements and processing standards across sectors like Automotive, Packaging, Electronics, and Medical Devices, each demanding specific dew point precision and drying temperature control.

Understanding these segments provides a refined view of market dynamics. For instance, the Electronics industry places a premium on extremely low dew points (often below -60°C) to prevent static discharge and ensure precision, driving demand for specialized desiccant wheel technology. Conversely, the Packaging segment, particularly PET processing, prioritizes high throughput (often exceeding 1,000 kg/hr) and robust, continuous operation. The increasing demand for customized solutions capable of handling exotic, high-performance resins further necessitates granular segmentation analysis to address niche market requirements effectively.

- By Type:

- Standard Honeycomb Dehumidifiers

- Centralized Dehumidifying Systems (Large Scale)

- Compact/Portable Dehumidifying Dryers

- Closed-Loop Dehumidifying Dryers

- By Throughput Capacity:

- Low Throughput (Below 100 kg/hr)

- Medium Throughput (100–500 kg/hr)

- High Throughput (Above 500 kg/hr)

- By Application/Resin Type:

- Polyethylene Terephthalate (PET)

- Polycarbonate (PC)

- Polyamide (PA/Nylon)

- Polymethyl Methacrylate (PMMA)

- Acrylonitrile Butadiene Styrene (ABS)

- Other Engineering Plastics (e.g., PBT, PEEK)

- By End-Use Industry:

- Packaging (Bottles, Films)

- Automotive (Interior/Exterior Components)

- Electronics and Electrical Components

- Medical Devices and Healthcare

- Construction

- Consumer Goods

Value Chain Analysis For Honeycomb Dehumidifying Dryer Market

The value chain for the Honeycomb Dehumidifying Dryer Market begins with upstream activities involving the sourcing of critical components, predominantly high-efficiency desiccant materials (zeolites, molecular sieves), specialized heat exchange components, blowers, and precision control systems (PLCs, sensors). Suppliers of these raw materials and components must adhere to strict quality specifications as the performance of the final dryer unit heavily relies on the thermal stability and adsorption capacity of the desiccant wheel and the reliability of heating elements. Manufacturers focus on integrating these components efficiently, emphasizing modular design and energy-saving features during the assembly phase. Strategic relationships with desiccant providers are essential to ensure a stable supply of high-performance materials.

Downstream analysis highlights the complexity of distribution and end-user engagement. Distribution channels are typically a mix of direct sales forces, particularly for large, customized centralized systems targeting major plastics processors, and indirect channels relying on specialized industrial equipment distributors and local agents. These indirect channels often provide value-added services such as installation, maintenance, and operator training, particularly in emerging markets where direct manufacturer presence is limited. Successful market penetration relies heavily on the distributor’s technical expertise regarding auxiliary equipment and their established relationships with local injection molding, blow molding, and extrusion firms.

The final stage involves the end-user operations, where the dryer is integrated into the plastics processing line. Post-sale services, including scheduled maintenance, repair, and replacement of the desiccant wheel, constitute a critical part of the value chain, generating substantial aftermarket revenue. Manufacturers increasingly leverage digital platforms for remote diagnostics and predictive maintenance support (Direct Channel support), enhancing customer loyalty and reducing downtime. Efficient logistics, minimizing the delivery time for large machinery, also play a crucial role in maintaining competitiveness throughout the value delivery process.

Honeycomb Dehumidifying Dryer Market Potential Customers

Potential customers for Honeycomb Dehumidifying Dryers primarily comprise companies engaged in the precision processing of hygroscopic polymer resins. The largest buyer segment is the plastics conversion industry, including injection molders, extruders, and blow molders, who require pre-conditioning of materials to maintain stringent quality standards necessary for their end products. These customers are driven by the need to minimize scrap rates caused by moisture-induced defects and to ensure the mechanical and aesthetic properties of their finished goods meet client specifications, particularly in highly regulated fields like medical and aerospace components. Manufacturers of PET preforms for the beverage and packaging industry represent a massive, specialized customer base due to the sheer volume and high throughput requirements associated with bottle production.

Another crucial customer group includes compounders and resin manufacturers themselves. These entities often use dehumidifying dryers in their processes to ensure the base material or compounded pellets are delivered to the final processor with minimal moisture content, thereby improving the marketability and ease of use of their products. Furthermore, original equipment manufacturers (OEMs) specializing in complete production lines often act as indirect buyers, integrating dehumidifying dryers as standard auxiliary components within their total machinery package before delivery to the end-user. This segment prioritizes seamless integration, reliability, and compact design.

Emerging customers include businesses involved in recycling engineering plastics. Recycled materials often have highly variable and generally higher moisture levels compared to virgin resins, necessitating robust and highly efficient drying solutions to ensure consistent quality when re-introducing the material into the supply chain. These customers place a high value on flexibility and the dryer's ability to handle mixed or contaminated material streams effectively, utilizing technology capable of deep dehumidification.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,435 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Piovan, Shini Plastics Technologies, Witte L.P., Matsui Mfg. Co., Ltd., Novatec, Inc., Conair Group, HOSOKAWA ALPINE Aktiengesellschaft, Labotek A/S, Desiccant Technologies Group, Taiming, ACS Group, Motan Colortronic GmbH, Kreyenborg, Foremost Machine Builders, Bry-Air, SMT-Drying, Nissei Plastic Industrial Co., Ltd., Universal Dynamics, Inc. (Una-Dyn), Dr. Boy GmbH & Co. KG, Dri-Air Industries, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Honeycomb Dehumidifying Dryer Market Key Technology Landscape

The technological landscape of the Honeycomb Dehumidifying Dryer Market is characterized by continuous refinement aimed at improving energy efficiency, precision control, and integration capabilities. The core technology remains the rotating honeycomb desiccant wheel, utilizing highly porous materials like molecular sieves or specialty zeolites optimized for maximum moisture adsorption and low regeneration heat requirements. Recent advancements focus on optimizing the geometric structure of the wheel and improving the desiccant material's lifespan and resistance to contamination. Furthermore, high-efficiency blowers and enhanced insulation techniques are now standard, significantly reducing heat loss and overall power consumption compared to previous generations.

A major development driving the market is the widespread adoption of closed-loop drying systems. These systems recycle the process air, minimizing heat and energy waste, and crucially, preventing the dried material from coming into contact with ambient moisture or contaminants. This is vital for high-purity applications, such as medical and optical components. Supporting this is the increasing integration of sophisticated PLC control systems featuring color touchscreens and advanced monitoring capabilities. These controllers allow for precise tuning of dew point, temperature, and airflow based on material-specific recipes, ensuring optimal drying parameters are maintained automatically.

Furthermore, the market is rapidly adopting technologies aligned with Industry 4.0. This includes integration with centralized material conveying systems and networking capabilities that enable remote diagnostics, performance monitoring, and data logging. Variable frequency drives (VFDs) are being utilized extensively to modulate blower and heater outputs based on real-time throughput demands, achieving substantial energy savings during partial load operation. The development of dual-bed or multi-wheel configurations ensures continuous, non-stop operation even during the desiccant regeneration phase, maximizing production uptime, which is a critical factor for high-volume processors like PET preform manufacturers.

Regional Highlights

The global Honeycomb Dehumidifying Dryer Market exhibits significant regional disparities in adoption rate and technological maturity, primarily dictated by local manufacturing density, regulatory environments, and industry composition.

- Asia Pacific (APAC): APAC is the epicenter of global plastics manufacturing and holds the largest market share, driven primarily by China, India, and ASEAN countries. This region's dominance stems from massive capacity expansion in electronics, automotive manufacturing, and food/beverage packaging (PET). The market here is characterized by high demand for both affordable, high-throughput systems and advanced, energy-efficient units used in precision manufacturing zones. Government initiatives promoting domestic manufacturing and foreign direct investment continue to solidify APAC's leading position, with a growing trend towards centralized drying solutions in new factory builds.

- North America: This region represents a mature market focused heavily on technological sophistication and operational efficiency. Demand is concentrated in specialized sectors such as medical device manufacturing, aerospace components, and advanced automotive applications requiring stringent quality control and verification. Key players emphasize integration with facility-wide automation systems, remote monitoring, and energy optimization features. The stringent regulatory environment regarding material quality and energy standards mandates continuous equipment upgrades, driving steady demand for high-end, closed-loop honeycomb dryers.

- Europe: The European market is defined by strict environmental regulations and a strong emphasis on sustainability and energy efficiency (AEO principles). Demand is robust, particularly in Germany, Italy, and Central Europe, catering to high-precision industries like specialized packaging and high-performance automotive polymers. European customers prioritize dryers with low carbon footprints, excellent insulation, and superior energy recovery mechanisms. There is a strong uptake of modular, flexible systems suitable for smaller, highly specialized manufacturing operations focusing on premium polymer grades and recycled materials.

- Latin America: This region shows promising growth, although it is constrained by economic volatility. Brazil and Mexico are the primary markets, driven by the expanding packaging sector and localized automotive production. The demand is typically for cost-effective, durable medium-throughput systems. As manufacturing standards improve and foreign investment increases, there is a gradual shift towards more technologically advanced, reliable drying solutions to compete globally.

- Middle East and Africa (MEA): MEA is currently the smallest market but is experiencing growth fueled by industrial diversification efforts, particularly in the packaging and infrastructure development sectors in the GCC countries. Investment is focused on establishing large-scale industrial parks, creating nascent demand for high-capacity centralized drying infrastructure. Challenges include logistics complexity and the need for equipment rugged enough to handle extreme ambient temperatures and high humidity levels prevalent in coastal areas.

The APAC region's substantial manufacturing base for plastics conversion ensures its continued dominance in market size. However, North America and Europe lead in terms of innovation and the adoption of cutting-edge, smart drying technologies. The investment cycle in these regions is shorter, focusing on high ROI through energy savings and scrap reduction. The growth in specialized polymer use worldwide continues to reinforce the necessity of honeycomb drying technology across all geographical segments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Honeycomb Dehumidifying Dryer Market.- Piovan S.p.A.

- Shini Plastics Technologies, Inc.

- Witte L.P.

- Matsui Mfg. Co., Ltd.

- Novatec, Inc.

- Conair Group

- HOSOKAWA ALPINE Aktiengesellschaft

- Labotek A/S

- Desiccant Technologies Group

- Taiming Plastics Machinery Co., Ltd.

- ACS Group

- Motan Colortronic GmbH

- Kreyenborg Plant Technology GmbH & Co. KG

- Foremost Machine Builders, Inc.

- Bry-Air, Inc.

- SMT-Drying

- Nissei Plastic Industrial Co., Ltd.

- Universal Dynamics, Inc. (Una-Dyn)

- Dr. Boy GmbH & Co. KG

- Dri-Air Industries, Inc.

Frequently Asked Questions

Analyze common user questions about the Honeycomb Dehumidifying Dryer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a honeycomb dehumidifying dryer over conventional desiccant dryers?

The primary advantage lies in the continuous, uninterrupted operation enabled by the rotating honeycomb wheel, which simultaneously adsorbs moisture and regenerates, ensuring a consistently stable and extremely low dew point (typically below -40°C). Conventional twin-tower systems require periodic switching, leading to temporary dew point spikes or flow interruptions, which can compromise material quality.

Which specific plastic materials necessitate the use of honeycomb dehumidifying technology?

Honeycomb dehumidifiers are essential for highly hygroscopic engineering plastics such as Polyethylene Terephthalate (PET), Polycarbonate (PC), Polyamides (Nylon/PA), Polybutylene Terephthalate (PBT), and certain bio-plastics and recycled resins. These materials readily absorb atmospheric moisture, which, if not removed, leads to hydrolysis and severe degradation during high-temperature processing.

How do modern honeycomb dryers contribute to energy consumption reduction in plastics processing?

Modern systems achieve energy reduction through multiple strategies, including utilizing closed-loop air circuits that retain heat, incorporating Variable Frequency Drives (VFDs) to match blower output to demand, and employing proportional regeneration heaters. The efficiency of the specialized desiccant materials also allows for regeneration at lower temperatures, further minimizing energy input.

What factors are driving the shift toward centralized dehumidifying systems?

The shift toward centralized systems is driven by economies of scale, superior moisture control consistency across multiple processing machines, and reduced maintenance complexity. Centralized units offer better utilization rates and simplify factory layout, aligning with Industry 4.0 principles of integrated material handling and minimized operational footprint.

What is the typical lifespan and maintenance requirement for the desiccant honeycomb wheel?

The lifespan of a high-quality desiccant wheel typically ranges from five to ten years, depending on operating conditions and air purity. Maintenance primarily involves ensuring the air filters are clean and regularly monitoring the dew point output. Contamination by plastic dust or volatile compounds can degrade the desiccant material, necessitating more frequent cleaning or replacement.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager