Hot Runner Controller Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443030 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Hot Runner Controller Market Size

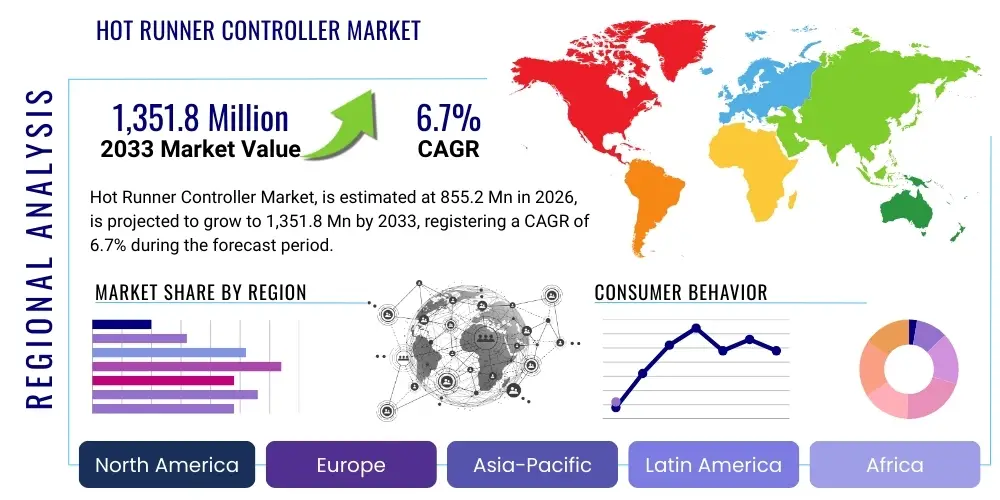

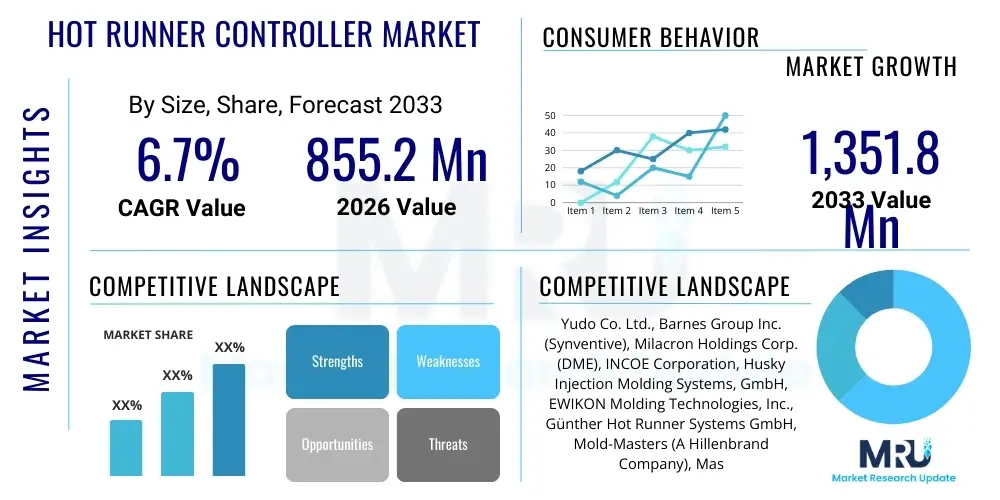

The Hot Runner Controller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 855.2 Million in 2026 and is projected to reach USD 1,351.8 Million by the end of the forecast period in 2033.

Hot Runner Controller Market introduction

The Hot Runner Controller Market centers around advanced thermal management systems crucial for optimizing plastic injection molding processes. Hot runner controllers regulate the temperature of molten plastic within the hot runner manifold and nozzles, ensuring consistent flow, preventing premature solidification, and maintaining optimal melt viscosity before injection into the mold cavity. These systems are fundamental in achieving high-quality molded parts, reducing material waste (by eliminating or minimizing sprues and runners), and significantly shortening cycle times, thereby boosting manufacturing efficiency across various sectors.

The product portfolio encompasses various control technologies, ranging from basic open-loop systems to sophisticated multi-zone, closed-loop controllers utilizing Proportionate-Integral-Derivative (PID) algorithms for extremely precise temperature management. Major applications span industries requiring high-volume, precision plastic components, including automotive (dashboards, lighting), medical devices (syringes, diagnostic components), packaging (caps, containers), and consumer electronics (casings, connectors). The core benefit derived from adopting these controllers is the substantial improvement in molding repeatability and product quality, minimizing defects such as flashing, short shots, and material degradation due to overheating.

Driving factors propelling market expansion include the increasing demand for precision molded parts in the expanding automotive and medical sectors, coupled with global trends toward automation and Industry 4.0 integration in manufacturing environments. Furthermore, stringent requirements for material efficiency and sustainability drive manufacturers to invest in hot runner technology to minimize plastic scrap and enhance overall resource utilization. The continuous innovation in sensor technology and communication protocols also contributes to the market growth by offering more reliable and responsive control solutions.

Hot Runner Controller Market Executive Summary

The global Hot Runner Controller Market is characterized by robust business trends focusing on digitalization and predictive maintenance capabilities. Key industry players are increasingly shifting towards integrating controllers with centralized Manufacturing Execution Systems (MES) and utilizing Industrial Internet of Things (IIoT) frameworks to facilitate remote monitoring, data logging, and self-optimization capabilities. This trend is driven by the necessity for zero-defect manufacturing and enhanced operational transparency, allowing molders to preemptively address potential thermal inconsistencies and minimize costly downtime. Furthermore, the development of modular and scalable controller designs allows manufacturers greater flexibility in adapting systems to varying mold complexities and production scales, ensuring wider market penetration.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrial expansion, particularly in China, India, and Southeast Asian countries, where automotive production and consumer electronics manufacturing are burgeoning. North America and Europe maintain significant market shares, characterized by demand for high-end, multi-cavity systems necessary for complex medical and high-tolerance aerospace components. These developed regions lead in the adoption of advanced control algorithms and energy-efficient systems, driven by high labor costs and strict energy consumption regulations. The focus in these mature markets remains on system reliability and long-term total cost of ownership (TCO).

In terms of segment trends, the market exhibits a strong preference for multi-zone controllers over single-zone counterparts, reflecting the complexity of modern molds and the need for localized temperature precision across numerous gates. By end-user, the automotive industry maintains the largest share due to the sheer volume and complexity of plastic components utilized, demanding high repeatability and throughput. Technology-wise, sophisticated touchscreen interfaces and user-friendly software for temperature profiling are becoming standard requirements, enhancing ease of operation and minimizing operator error.

AI Impact Analysis on Hot Runner Controller Market

User inquiries regarding AI's impact on the Hot Runner Controller Market primarily revolve around themes of predictive failure analysis, automated process optimization, and integration with digital twins. Users frequently ask how AI can move temperature control beyond traditional PID loops, whether AI can automatically compensate for ambient temperature fluctuations or material variations in real-time, and if AI-powered diagnostics can predict component wear in heating elements or sensors before catastrophic failure. Key themes center on achieving 'autonomous molding' where the controller dynamically adjusts parameters based on historical data and machine learning models, minimizing human intervention and maximizing efficiency.

AI algorithms are poised to transform hot runner control systems by enabling predictive process control and drastically improving energy efficiency. By analyzing massive datasets collected from sensors regarding melt pressure, temperature deviations, and cycle times, AI models can learn the thermal dynamics of specific molds. This allows the controller to anticipate future deviations and apply corrective actions proactively, achieving thermal stability faster and maintaining tighter tolerances than traditional control systems. This capability is critical for molding expensive, high-performance engineering plastics where precise thermal profiles are non-negotiable.

Furthermore, the integration of machine learning facilitates condition monitoring and predictive maintenance for the hot runner system itself. AI analyzes current fluctuations, temperature stability patterns, and sensor drift to predict the remaining useful life (RUL) of critical components like heating coils, thermocouples, and gate actuators. This shift from reactive or preventive maintenance to predictive maintenance significantly reduces unplanned downtime, optimizing overall equipment effectiveness (OEE) and minimizing scrap rates associated with component failure during production runs. This leads to higher utilization rates and lower operational costs for end-users.

- AI enables predictive thermal compensation, adjusting heat input based on anticipated process variables rather than reactionary feedback.

- Machine Learning algorithms optimize ramp-up times and minimize overshoot, conserving energy and reducing material stress.

- AI integration facilitates predictive maintenance of heating elements and thermocouples, reducing unexpected system failures.

- Digital twins powered by AI simulate mold thermal behavior, accelerating setup and validating complex temperature profiles virtually.

- Automated anomaly detection identifies subtle deviations indicative of mold fouling or material inconsistencies, enhancing quality control.

DRO & Impact Forces Of Hot Runner Controller Market

The Hot Runner Controller Market dynamics are driven by the pervasive need for efficiency and quality in plastic manufacturing, yet constrained by technological complexity and high initial investment. The primary drivers include the expanding demand for precision components across sectors like medical devices and electric vehicles, coupled with the inherent cost-saving benefits of waste reduction offered by hot runner systems. Opportunities arise from technological advancements, particularly in integrating controllers with IIoT and cloud computing for enhanced diagnostics and remote serviceability, paving the way for advanced smart factory implementations. Conversely, the market faces restraints such as the substantial upfront cost associated with multi-zone controllers and the required skilled labor for complex mold setups and maintenance, particularly in developing economies.

The core Impact Forces shaping the market involve intense competitive rivalry among established manufacturers who continuously innovate in control accuracy and user interface design. Supplier power is moderate, influenced by the specialized nature of components like PID chips and high-accuracy thermocouples. Buyer power remains significant, particularly among large automotive Tier 1 suppliers, who demand customized, high-performance, and reliable systems with long warranties. Substitution threats are low, as cold runner systems are inherently less efficient for precision molding, but technological leaps in alternative processing methods (like additive manufacturing for prototypes) pose a long-term, moderate threat.

- Drivers: Rising global demand for high-precision, thin-walled plastic parts; focus on material waste reduction (sustainability); adoption of automated and high-cavitation molds.

- Restraints: High initial investment cost of sophisticated multi-zone systems; dependency on highly skilled technicians for complex troubleshooting; long maintenance downtime compared to simpler systems.

- Opportunities: Integration of controllers with Industry 4.0 standards (IIoT, M2M communication); development of wireless and portable control units for increased flexibility; expansion into untapped emerging manufacturing hubs.

- Impact Forces: Intense competition driving continuous innovation in temperature control algorithms; significant buyer leverage due to large capital investments; high barriers to entry due to required R&D and precision manufacturing capabilities.

Segmentation Analysis

The Hot Runner Controller Market is comprehensively segmented based on three primary metrics: the Type of Control Zone (determining the complexity of temperature management), the End-User Industry (defining application specifics and volume demand), and the Technology/Modularity (reflecting system capabilities and physical configuration). Analyzing these segments provides strategic insights into market penetration strategies and technological roadmaps. The multi-zone controllers segment dominates the market due to the proliferation of complex, high-cavitation molds across automotive and medical manufacturing, requiring granular thermal regulation across numerous points to ensure uniformity and part integrity. By technology, stackable and modular controllers are gaining traction, offering scalability and ease of maintenance.

- By Type of Control Zone:

- Single Zone Controllers

- Multi-Zone Controllers (Dominant Segment)

- By End-User Industry:

- Automotive Industry

- Packaging Industry

- Medical Industry

- Consumer Electronics

- Others (e.g., Aerospace, Construction)

- By Technology/Modularity:

- Standard/Fixed Controllers

- Modular/Stackable Controllers

Value Chain Analysis For Hot Runner Controller Market

The value chain for the Hot Runner Controller Market begins with upstream activities involving the sourcing and processing of specialized electronic components and hardware. This includes high-precision microcontrollers, advanced temperature sensors (thermocouples), power supply units, and specific high-durability housing materials. Component suppliers, particularly those providing specialized PID controllers and solid-state relays (SSRs), play a critical role, influencing the final system accuracy and reliability. Effective upstream management focuses on securing reliable component supplies and maintaining high quality standards, as system failure often stems from sensor or relay malfunction.

Midstream involves the core manufacturing and assembly of the controller units, focusing on software development, calibration, and rigorous quality testing. Key activities include designing user interfaces, implementing complex closed-loop control algorithms, and integrating communication modules for networking capability. Downstream activities encompass distribution, installation, commissioning, and crucial post-sale support. Due to the technical nature of the product, distribution often involves specialized direct sales teams or highly trained indirect distributors who can offer localized technical support and maintenance contracts.

The distribution channel is generally characterized by a hybrid approach. Direct sales are preferred for large Original Equipment Manufacturers (OEMs) and major Tier 1 suppliers requiring customized solutions and extensive integration services. Indirect channels, utilizing regional distributors and system integrators, are essential for reaching smaller job shops and localized mold makers. Effective value capture occurs through specialized system integration services and long-term maintenance agreements, ensuring sustained revenue streams beyond the initial hardware sale.

Hot Runner Controller Market Potential Customers

Potential customers for the Hot Runner Controller Market are predominantly injection molding houses that operate high-volume, high-precision manufacturing processes. These customers span various end-user industries where dimensional accuracy, material efficiency, and surface finish are critical requirements. The primary targets include large-scale automotive component manufacturers (Tier 1 and Tier 2 suppliers) specializing in interior parts, external body components, and increasingly, battery housing components for electric vehicles, which demand highly reliable and consistent thermal management.

Another crucial segment comprises medical device manufacturers and pharmaceutical packaging producers. These sectors require controllers capable of ultra-high precision and validated processes, often operating high-cavitation molds for products like syringes, testing kits, and sterile caps. The stringent regulatory environment in medical manufacturing necessitates controllers with robust data logging, traceability features, and verified temperature consistency to ensure product safety and regulatory compliance. Furthermore, the packaging sector, particularly those focusing on thin-walled, high-speed containers and closures, relies heavily on advanced controllers to achieve minimal cycle times and low material consumption.

The growing consumer electronics industry, specializing in complex, multi-material enclosures and connectors, also represents a significant customer base. These manufacturers often utilize multi-gate and sequential valve gate (SVG) systems, requiring highly sophisticated multi-zone controllers to manage complex flow patterns and aesthetic quality. The continuous pressure on reducing time-to-market and increasing product complexity in consumer electronics drives consistent investment in advanced hot runner control technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 855.2 Million |

| Market Forecast in 2033 | USD 1,351.8 Million |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Yudo Co. Ltd., Barnes Group Inc. (Synventive), Milacron Holdings Corp. (DME), INCOE Corporation, Husky Injection Molding Systems, GmbH, EWIKON Molding Technologies, Inc., Günther Hot Runner Systems GmbH, Mold-Masters (A Hillenbrand Company), Mastip Technology Ltd., Athena Controls, Delta Temperature Control, Gammaflux L.P., CACO Pacific Corporation, Fast Heat UK, Tool-Temp AG, Omron Corporation, Meusburger Georg GmbH & Co KG, HRSflow (ITW), KLN Ultraschall GmbH, TRICOR Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hot Runner Controller Market Key Technology Landscape

The current technology landscape in the Hot Runner Controller Market is dominated by advanced closed-loop systems utilizing high-speed digital PID (Proportional-Integral-Derivative) control algorithms. These systems continuously monitor temperature fluctuations via highly accurate Type J or Type K thermocouples embedded near the gates and rapidly adjust power delivery through solid-state relays (SSRs) to maintain set points within very narrow tolerances (typically ±0.5°C). The evolution of multi-zone controllers has pushed manufacturers toward integrating features like power surge protection, ground fault detection, and sophisticated diagnostics to enhance system reliability and minimize potential mold damage due to overheating.

A significant technological trend involves the shift towards enhanced connectivity and communication capabilities, driven by the principles of Industry 4.0. Modern controllers are increasingly equipped with Ethernet/IP, PROFINET, and OPC UA protocols, allowing seamless communication with molding machines, centralized MES, and cloud-based analytical platforms. This connectivity enables remote diagnostics, centralized recipe management, and the crucial implementation of energy monitoring tools that optimize power consumption based on production schedules and material requirements. User interfaces are also evolving, favoring large, intuitive touchscreen displays that simplify temperature profiling and alarm management.

Furthermore, specialized technologies such as sequential valve gating (SVG) control are becoming mainstream, particularly for large automotive panels and complex parts requiring precise melt flow control across multiple injection points. SVG controllers manage the opening and closing sequence of individual gate pins with precise timing, ensuring weld line mitigation and optimal filling patterns. The development of self-tuning controllers, which automatically adjust PID parameters based on real-time process inputs and thermal characteristics, represents the cutting edge, further reducing setup time and optimizing performance across various tooling configurations and material grades.

Regional Highlights

- Asia Pacific (APAC): APAC is the fastest-growing and largest market due to burgeoning automotive manufacturing, high-volume consumer electronics production, and significant foreign direct investment into manufacturing infrastructure, particularly in China, South Korea, and India. The rapid adoption of high-cavitation molds to meet global demand for packaging and appliance components necessitates advanced multi-zone hot runner controllers, driving unparalleled growth in both volume and technological complexity. Localized manufacturing hubs are increasingly demanding modular and cost-effective solutions tailored for scalable factory floor integration.

- North America: North America holds a significant market share, characterized by high demand for sophisticated controllers used in high-tolerance sectors like medical devices, aerospace, and specialized automotive components (e.g., lightweight materials for EVs). The market favors premium, high-accuracy multi-zone controllers with advanced diagnostics and robust IIoT integration capabilities to adhere to stringent quality standards and traceability requirements, especially FDA compliance for medical plastics.

The market in the United States and Canada is mature, prioritizing efficiency, labor cost savings, and investment in automation technologies. Manufacturers seek controllers that minimize energy consumption and integrate seamlessly with existing robotic handling and supervisory control systems. Innovation is driven by the need for quick mold changeover systems, favoring modular and highly portable controller designs that maximize machine uptime.

While volume growth is slower compared to APAC, the average selling price (ASP) for hot runner controllers remains high, reflecting the demand for customized, high-performance systems and superior after-sales service. Strategic investments are focused on controllers capable of managing engineering polymers and exotic materials requiring extremely narrow thermal windows.

- Europe: Europe represents a strong and technologically advanced market, largely driven by the premium automotive sector (Germany, France, Italy) and the established medical and packaging industries. European manufacturers are leaders in adopting energy-efficient solutions and complex molding techniques, requiring controllers optimized for high-cavitation, high-speed applications and sustainable manufacturing practices.

Regulatory pressures, particularly concerning energy consumption and environmental impact, mandate the use of highly efficient hot runner systems. This drives demand for controllers with sophisticated power management features, predictive tuning, and comprehensive data logging capabilities to comply with regional manufacturing standards and quality assurance protocols. Germany, being a hub for advanced molding technology, consistently demands the latest innovations in hot runner control.

The European market shows a pronounced preference for systems that offer long-term reliability and precise temperature control, mitigating risks associated with high material costs. Manufacturers are also increasingly seeking controllers compatible with standardized fieldbus communication protocols to ensure seamless integration into complex automated production lines typical of centralized European factories.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, primarily centered around major economies like Brazil and Mexico, which serve as crucial manufacturing bases for automotive assembly and consumer goods destined for North American markets. Market penetration is gradually increasing as local manufacturers recognize the quality and efficiency advantages of transitioning from cold runner systems.

Growth is often driven by international companies establishing local production facilities, bringing standardized global hot runner control technology with them. Cost sensitivity remains a major factor; hence, there is a balanced demand for both reliable, standard multi-zone controllers and entry-level digital systems. Infrastructure challenges sometimes necessitate controllers built to withstand less stable power supplies and higher operational temperatures.

- Middle East and Africa (MEA): MEA is the least developed market for hot runner controllers, though specific countries, particularly the UAE and Saudi Arabia (driven by packaging and basic consumer plastics manufacturing), show nascent growth. The market is highly reliant on imported technology and subject to oil price volatility impacting local industrial investment.

Demand is currently concentrated in sectors related to rigid packaging, infrastructure, and non-durable consumer goods. Future growth potential exists, linked to planned diversification of economies away from fossil fuels and increased focus on developing local downstream plastics processing capabilities. Initial demand focuses on cost-effective, durable, and easily maintainable control solutions.

The robust expansion of the middle class and subsequent rise in disposable income are fueling mass production activities, particularly in injection molding for white goods and electronics. Governments across the region are investing heavily in smart manufacturing initiatives, which encourages molders to upgrade from traditional cold runner systems to efficient hot runner technologies. This technological transition, combined with lower operational costs relative to Western counterparts, solidifies APAC's dominance in market growth, although competition remains fierce, driving down component pricing.

India and Southeast Asian nations (Vietnam, Thailand, Malaysia) are emerging as key secondary manufacturing hubs, attracting capacity relocation and spurring demand for reliable, mid-range hot runner control systems. The emphasis here is on controllers offering durability and basic networking capabilities suitable for integration within developing industrial ecosystems. Investment in training and technical support infrastructure is crucial for successful market penetration in these regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hot Runner Controller Market.- Yudo Co. Ltd.

- Barnes Group Inc. (Synventive)

- Milacron Holdings Corp. (DME)

- INCOE Corporation

- Husky Injection Molding Systems, GmbH

- EWIKON Molding Technologies, Inc.

- Günther Hot Runner Systems GmbH

- Mold-Masters (A Hillenbrand Company)

- Mastip Technology Ltd.

- Athena Controls

- Delta Temperature Control

- Gammaflux L.P.

- CACO Pacific Corporation

- Fast Heat UK

- Tool-Temp AG

- Omron Corporation

- Meusburger Georg GmbH & Co KG

- HRSflow (ITW)

- KLN Ultraschall GmbH

- TRICOR Systems Inc.

Frequently Asked Questions

Analyze common user questions about the Hot Runner Controller market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a multi-zone hot runner controller in injection molding?

A multi-zone hot runner controller is designed to independently regulate the temperature across numerous heating points (zones) within the hot runner manifold and nozzles. Its primary function is to maintain precise, stable melt temperature uniformity, which is critical for preventing plastic degradation, eliminating cold slugs, minimizing material waste, and ensuring high-quality, repeatable molded parts, particularly in complex, multi-cavity molds.

How does the integration of Industry 4.0 affect the efficiency of hot runner control systems?

Industry 4.0 integration significantly enhances efficiency by enabling real-time data exchange (IIoT), remote diagnostics, and predictive maintenance. Controllers can communicate seamlessly with MES and ERP systems, allowing for centralized temperature profile management, automated fault detection, and optimization of power consumption, ultimately maximizing machine uptime and reducing operational costs.

Which end-user industry accounts for the largest demand for hot runner controllers globally?

The Automotive Industry consistently accounts for the largest demand segment globally. This is driven by the sheer volume, increasing complexity, and stringent quality requirements for plastic components used in vehicles, ranging from interior panels and lighting systems to structural elements, all of which benefit significantly from the precision and waste reduction capabilities of advanced hot runner control technology.

What are the key advantages of closed-loop PID control over open-loop systems in hot runner controllers?

Closed-loop PID (Proportional-Integral-Derivative) control offers significantly superior temperature accuracy and stability compared to open-loop systems. It constantly measures the actual temperature (feedback), calculates the difference from the setpoint, and instantly adjusts the power output. This proactive adjustment minimizes temperature overshoot and drift, crucial for processing sensitive engineering plastics and achieving tight dimensional tolerances.

What technological trends are expected to drive future growth in the hot runner controller market?

Future growth will be driven by the adoption of AI-powered predictive control (moving beyond standard PID), enhanced self-tuning capabilities to minimize operator input, and the development of highly modular, stackable controller designs. Furthermore, the increasing demand for sequential valve gating (SVG) systems and greater emphasis on energy monitoring and efficiency features will be pivotal technological drivers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager