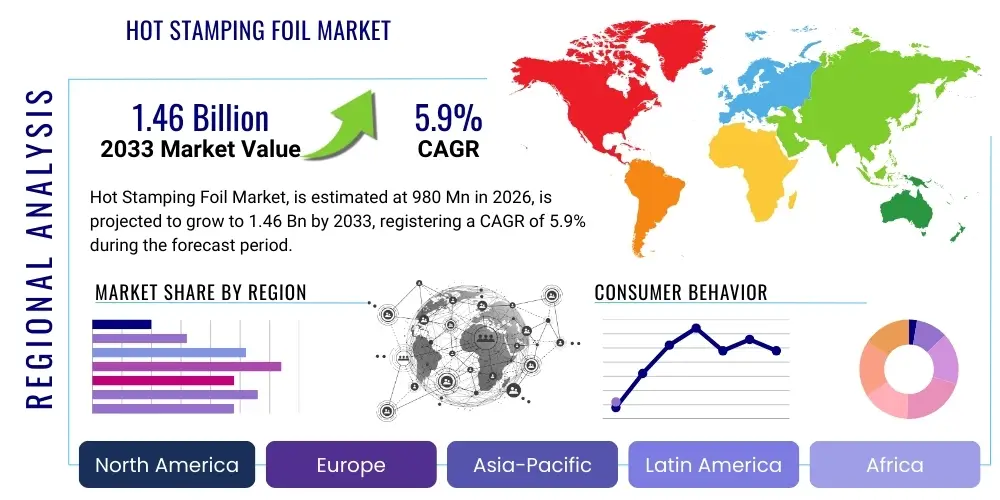

Hot Stamping Foil Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440767 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Hot Stamping Foil Market Size

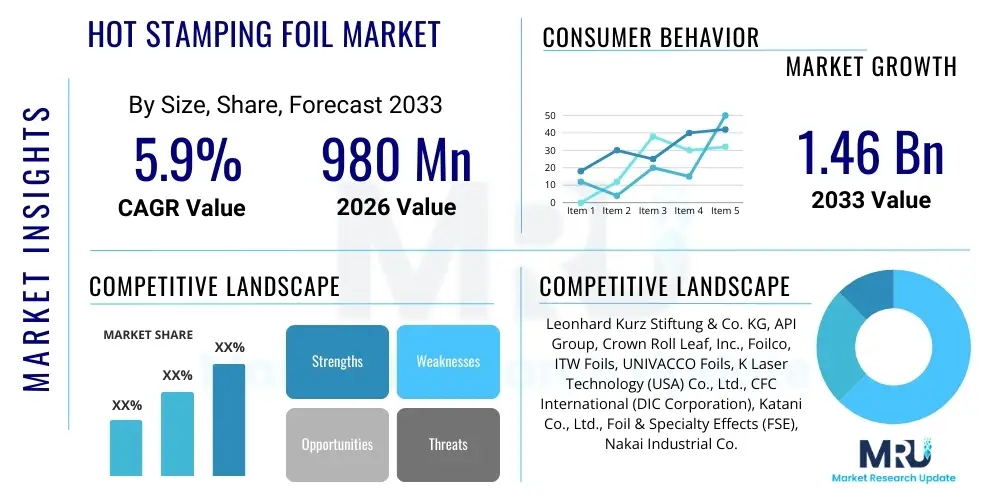

The Hot Stamping Foil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.9% between 2026 and 2033. The market is estimated at USD 980 Million in 2026 and is projected to reach USD 1.46 Billion by the end of the forecast period in 2033. This growth trajectory is underpinned by rising consumer demand for premium packaging, increasing focus on brand authentication, and the expansion of key end-use industries across various global regions.

Hot Stamping Foil Market introduction

The Hot Stamping Foil Market encompasses the production and distribution of foils used in a decorative and functional printing process known as hot stamping. This technique involves transferring a thin layer of metallic, pigment, or holographic material onto a substrate using heat and pressure. The market is characterized by a diverse range of products designed to enhance the aesthetic appeal, perceived value, and security features of various items, making them highly desirable across numerous commercial applications.

Product descriptions within this market range from conventional metallic foils that provide a luxurious sheen to pigment foils offering vibrant, opaque colors, and holographic foils engineered for intricate visual effects and anti-counterfeiting measures. These foils are typically multi-layered structures consisting of a carrier film (often polyester), a release layer, a lacquer layer, the decorative or functional layer (e.g., aluminum, pigment), and an adhesive layer. The precise composition of these layers dictates the foil's performance characteristics, including adhesion, scratch resistance, and suitability for different substrates such as paper, plastic, leather, and textiles.

Major applications for hot stamping foils span across diverse industries, including packaging for food and beverages, cosmetics, and tobacco, as well as graphic arts for greeting cards, book covers, and labels. Furthermore, they are extensively used in textile ornamentation, automotive interior embellishments, and for security features on passports, banknotes, and branded goods. The primary benefits derived from hot stamping include superior visual appeal, tactile enhancement, increased brand recognition, and robust anti-counterfeiting capabilities. Key driving factors for market growth include the rising global demand for luxury goods, the increasing importance of brand differentiation in competitive markets, and the continuous innovation in foil technologies enabling broader application possibilities and enhanced durability.

Hot Stamping Foil Market Executive Summary

The Hot Stamping Foil Market is experiencing robust expansion, driven by evolving business trends that prioritize consumer engagement and product aesthetics. A significant business trend is the growing demand for customization and personalization in packaging and product design, which hot stamping foils effectively cater to by offering a wide array of colors, finishes, and holographic patterns. Furthermore, sustainability is becoming a pivotal trend, compelling manufacturers to innovate with eco-friendly foils and more efficient application processes. The increasing focus on anti-counterfeiting measures, especially in luxury and pharmaceutical sectors, is also fueling the adoption of holographic and security foils, thereby contributing to the market's upward trajectory.

Regional trends indicate that the Asia Pacific (APAC) region is poised for the most significant growth, attributed to rapid industrialization, expanding manufacturing bases, and rising disposable incomes driving consumer demand for premium products in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate steady growth, largely due to sustained demand from the luxury packaging, automotive, and graphic arts sectors, alongside a strong emphasis on innovation in sustainable and digitally-enabled hot stamping solutions. Latin America, the Middle East, and Africa are emerging as promising markets, buoyed by economic development and increasing globalization that introduces sophisticated branding and packaging standards.

Segment trends reveal that metallic foils continue to hold a dominant share due to their classic appeal and versatility, but holographic and specialty foils are rapidly gaining traction due to their enhanced security features and unique visual effects. In terms of application, the packaging sector remains the largest consumer, driven by the omnipresent need for attractive and secure product presentation across food and beverage, cosmetics, and consumer electronics industries. Within end-use segments, the luxury packaging market, including cosmetics and high-end alcohol, represents a particularly strong growth area, as brand owners continuously seek to differentiate their products through superior visual and tactile finishes offered by hot stamping foils. The convergence of these business, regional, and segment trends points towards a dynamic and expanding market landscape for hot stamping foils.

AI Impact Analysis on Hot Stamping Foil Market

The impact of Artificial Intelligence (AI) on the Hot Stamping Foil Market is primarily anticipated in optimizing various stages of the manufacturing, design, and application processes, leading to enhanced efficiency, reduced waste, and improved product quality. Common user questions often revolve around how AI can streamline design creation, predict maintenance needs for hot stamping machines, enhance quality control, and potentially automate parts of the production workflow. Users are keen to understand if AI can help in material selection for specific applications, optimize foil consumption, or even contribute to the development of novel foil types with advanced properties. The overarching themes reflect expectations for increased precision, cost-effectiveness, and responsiveness to market demands, alongside potential concerns about initial investment costs and the need for specialized expertise.

AI's influence is expected to touch upon several critical areas. In the design phase, AI-powered algorithms can analyze market trends and consumer preferences to suggest optimal foil patterns, colors, and textures, accelerating the product development cycle and ensuring designs are highly marketable. Predictive analytics, driven by AI, can monitor machine performance data to anticipate potential malfunctions in hot stamping equipment, enabling proactive maintenance and significantly reducing downtime, thus improving overall operational efficiency. Furthermore, AI can enhance quality control by identifying microscopic defects in foil application or material composition that might be imperceptible to the human eye, ensuring consistent quality and minimizing wastage due to imperfections. Supply chain management can also benefit immensely from AI, as it can optimize inventory levels, forecast demand more accurately, and identify potential disruptions, leading to a more resilient and cost-effective supply chain for raw materials and finished foils.

- AI-driven design optimization for patterns and visual effects, reducing development time.

- Predictive maintenance for hot stamping machinery, minimizing downtime and operational costs.

- Enhanced quality control systems through AI-powered visual inspection, ensuring flawless application.

- Optimized inventory management and demand forecasting for raw materials and finished foils.

- Development of smart foils with integrated AI-readable features for advanced anti-counterfeiting.

- Personalization and mass customization capabilities through AI-guided printing parameters.

- Energy consumption reduction by optimizing machine settings based on real-time data analysis.

DRO & Impact Forces Of Hot Stamping Foil Market

The Hot Stamping Foil Market is significantly shaped by a confluence of drivers, restraints, and opportunities, alongside various impact forces that influence its trajectory. Key drivers include the escalating demand for visually appealing and premium packaging across industries such as cosmetics, food & beverage, and tobacco, where brand differentiation is paramount. The increasing need for anti-counterfeiting solutions, especially in pharmaceutical and luxury goods sectors, further propels the adoption of holographic and security foils. Moreover, rising disposable incomes in emerging economies are fueling consumer preferences for high-end products, directly stimulating the demand for hot stamping foil applications that enhance product perceived value and aesthetic appeal. The versatility of hot stamping foils, allowing application on a wide range of substrates, also serves as a strong market driver, expanding its potential uses across various product categories and materials. Lastly, advancements in printing and converting technologies have made hot stamping more efficient and accessible, contributing to its broader adoption.

However, the market faces several restraints that could impede its growth. The relatively high cost of hot stamping equipment and specialized foils, compared to other printing methods, can deter smaller businesses or those with budget constraints. Environmental concerns related to the disposal of plastic carrier films and the chemical composition of some foils pose a challenge, pushing for the development of more sustainable and eco-friendly alternatives. Intense competition from alternative decorative printing techniques, such as cold foil transfer, digital printing, and direct printing, also acts as a restraint, as these methods offer different sets of advantages in terms of cost, speed, or environmental impact. Fluctuations in the prices of raw materials, such as polyester film, pigments, and metallic powders, can impact production costs and profit margins for foil manufacturers, creating market volatility.

Opportunities for growth in the hot stamping foil market are abundant and primarily revolve around innovation and market expansion. The development of sustainable and biodegradable foils presents a significant opportunity to address environmental concerns and appeal to eco-conscious brands and consumers. The integration of hot stamping foils with smart packaging solutions, incorporating features like NFC/RFID tags or augmented reality triggers, can unlock new functionalities and enhance consumer engagement. Furthermore, expansion into emerging markets, particularly in Asia Pacific and Latin America, where industrialization and consumer spending are on the rise, offers substantial growth avenues. The continued evolution of digital hot stamping technologies, which allow for shorter runs and greater customization, also presents a lucrative opportunity to cater to niche markets and specialized applications. These drivers, restraints, and opportunities collectively interact with market impact forces such as buyer power, supplier power, threat of new entrants, threat of substitutes, and competitive rivalry, defining the dynamic landscape of the hot stamping foil industry.

Segmentation Analysis

The Hot Stamping Foil Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics. This segmentation helps in analyzing market trends, identifying lucrative opportunities, and strategizing for specific product types, applications, and end-use industries. The market is primarily categorized by Type, Application, and End-Use Industry, each offering distinct insights into consumer preferences and industrial demands.

By dissecting the market along these various parameters, stakeholders can gain a granular perspective on where growth is strongest and where innovation is most required. Understanding these segments is crucial for manufacturers to tailor their product offerings, for suppliers to optimize their raw material provision, and for investors to identify promising areas for capital deployment. Each segment, from the basic material composition to the final product application, plays a vital role in shaping the overall market landscape and defining competitive strategies.

- By Type

- Metallic Foils: Gold, Silver, Bronze, and other metallic colors.

- Pigment Foils: Matte, Glossy, Pearlescent, and other colored opaque foils.

- Holographic Foils: Standard, Custom, and Security holograms.

- Specialty Foils: Pearl, Diffractive, Scratch-off, Textured, Transparent, etc.

- By Application

- Packaging: Food & Beverage, Cosmetics & Personal Care, Tobacco, Consumer Electronics, Pharmaceuticals.

- Graphics: Greeting Cards, Books & Magazines, Labels, Posters, Security Documents.

- Textile: Apparel, Fashion Accessories, Home Furnishings.

- Security: Brand Protection, Anti-Counterfeiting, Official Documents.

- Automotive: Interior Components, Logos, Badges.

- Others: Furniture, Plastics, Leather Goods, Promotional Items.

- By End-Use Industry

- Food & Beverage Industry

- Cosmetics & Personal Care Industry

- Tobacco Industry

- Consumer Electronics Industry

- Pharmaceuticals Industry

- Textiles & Apparel Industry

- Automotive Industry

- Building Materials Industry

- Others (e.g., Luxury Goods, Stationery)

Value Chain Analysis For Hot Stamping Foil Market

The value chain for the Hot Stamping Foil Market is a complex network involving several stages, from the procurement of raw materials to the final application of the foil on end-user products. Understanding this chain is crucial for identifying areas of efficiency, potential bottlenecks, and opportunities for value addition. The upstream analysis focuses on the supply of critical raw materials and components necessary for foil manufacturing, which forms the bedrock of the entire industry. Key upstream suppliers include manufacturers of polyester films (serving as the carrier), release agents, various lacquers, pigments, dyes, metalizing agents (like aluminum powder), and specialized adhesives. The quality and consistent supply of these raw materials directly impact the final product's performance and cost. Innovation at this stage, particularly in developing sustainable or high-performance materials, can significantly influence the market's direction and competitive landscape.

Midstream activities involve the actual manufacturing of hot stamping foils by specialized producers. This stage includes processes such as coating, metallization, lacquering, and slitting, where raw materials are transformed into finished foil rolls. These manufacturers often invest heavily in R&D to develop new foil types, improve adhesion properties, enhance durability, and introduce innovative visual effects or security features. Downstream analysis then concentrates on the distribution and application of these foils. This segment includes converters and printers who purchase foils and apply them to various substrates for brand owners and product manufacturers. Converters specialize in preparing the foils for specific printing presses, while printers integrate the hot stamping process into their overall production lines, often working directly with brand owners to achieve desired aesthetic and functional outcomes. The efficiency and expertise of these downstream players are vital for the successful market penetration and adoption of hot stamping foils.

Distribution channels play a pivotal role in connecting foil manufacturers with their diverse customer base. These channels can be broadly categorized into direct and indirect methods. Direct distribution typically involves large foil manufacturers selling directly to major brand owners or large-scale printing houses, allowing for tailored solutions and closer relationships. Indirect distribution, on the other hand, involves a network of distributors, agents, and wholesalers who procure foils from manufacturers and supply them to smaller printers, graphic designers, or regional businesses. These intermediaries provide vital logistical support, local market knowledge, and often offer technical assistance to their clients, thereby extending the reach of foil manufacturers. The choice of distribution channel often depends on the manufacturer's market strategy, the geographic spread of their customer base, and the specific needs of different market segments, all contributing to the overall efficiency and effectiveness of the hot stamping foil value chain.

Hot Stamping Foil Market Potential Customers

The Hot Stamping Foil Market serves a broad spectrum of potential customers, essentially encompassing any industry that benefits from enhanced product aesthetics, brand differentiation, or security features. The primary end-users and buyers of hot stamping foils are typically businesses involved in manufacturing, printing, and branding, seeking to elevate their product presentation and protect their intellectual property. One significant customer segment includes packaging manufacturers who utilize foils to create premium packaging for food and beverages, cosmetics, tobacco, and consumer electronics. These manufacturers are driven by the need to capture consumer attention on crowded retail shelves, convey a sense of luxury or quality, and comply with brand guidelines that often specify metallic or holographic accents. The cosmetic and personal care industry, in particular, relies heavily on hot stamping for its high-end product containers, showcasing intricate designs and luxurious finishes that appeal to discerning consumers.

Another crucial customer segment consists of printing houses and commercial printers that offer hot stamping as part of their comprehensive printing services. These companies cater to diverse clients across graphic arts, including producers of greeting cards, book covers, magazines, labels, and promotional materials. For them, hot stamping foils represent a value-added service that allows their clients to achieve distinctive visual effects and tactile experiences, differentiating their printed products in a competitive market. Furthermore, security document producers and organizations involved in anti-counterfeiting measures are significant buyers of holographic and specialized security foils. These foils are integral in securing banknotes, passports, government documents, and branded goods against forgery, making them indispensable for ensuring authenticity and protecting brand integrity across various industries. The demand from this segment is consistently high due to the ever-present threat of counterfeiting and the continuous need for advanced security features.

Beyond these core segments, potential customers also include manufacturers in the textile and apparel industry looking to add decorative elements to clothing, footwear, and accessories, as well as automotive suppliers using foils for interior trim components, logos, and badging to enhance vehicle aesthetics. Luxury goods manufacturers, including those producing leather goods, high-end stationery, and promotional items, also constitute a significant customer base, leveraging hot stamping for its ability to convey elegance and exclusivity. The diversified nature of these end-users underscores the versatility and wide applicability of hot stamping foils, making the market resilient to fluctuations in any single industry and offering continuous growth opportunities across multiple sectors globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 980 Million |

| Market Forecast in 2033 | USD 1.46 Billion |

| Growth Rate | 5.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Leonhard Kurz Stiftung & Co. KG, API Group, Crown Roll Leaf, Inc., Foilco, ITW Foils, UNIVACCO Foils, K Laser Technology (USA) Co., Ltd., CFC International (DIC Corporation), Katani Co., Ltd., Foil & Specialty Effects (FSE), Nakai Industrial Co., Ltd., KURZ TRANSFER PRODUCTS, Inc., Newfoil Machines Ltd., Astor Universal, Luminescence International Ltd., Oasys, Inc., Anstey, Polinas Corporate, Kolon Global Corporation, Guanghui Hot Stamping Material Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hot Stamping Foil Market Key Technology Landscape

The Hot Stamping Foil Market is continuously evolving, driven by technological advancements aimed at improving application efficiency, expanding material versatility, and enhancing product performance. One of the most significant technological trends is the development and refinement of digital hot stamping, which allows for short runs, variable data printing, and greater design flexibility without the need for traditional dies. This technology uses digital printing heads to apply an adhesive pattern, which then attracts metallic or pigment foil, offering unprecedented customization and personalization capabilities. This innovation is particularly attractive for niche markets, prototyping, and products requiring intricate, variable designs, addressing the growing demand for bespoke packaging and graphics. The precision and speed offered by digital methods are set to revolutionize how hot stamping is integrated into modern production lines.

Another critical area of technological innovation lies in the material science of the foils themselves. Manufacturers are constantly researching and developing new formulations for release layers, lacquers, and adhesives to improve adhesion to a wider range of challenging substrates, enhance scratch and abrasion resistance, and extend the durability of the hot stamped image. This includes the development of thinner foils that require less material, contributing to sustainability efforts, and foils with enhanced thermal stability for high-speed application processes. Furthermore, there is a strong focus on creating eco-friendly and sustainable foils, such as those made from recycled content, biodegradable polymers, or water-based adhesives, to address environmental concerns and meet the growing demand for green packaging solutions from brands and consumers alike. The integration of advanced coating technologies allows for multi-functional foils that not only decorate but also provide barrier properties or incorporate smart features.

The machinery used for hot stamping is also undergoing significant technological upgrades. Modern hot stamping machines are increasingly incorporating automation, sophisticated temperature and pressure control systems, and faster cycle times to boost productivity and reduce operational costs. Advancements in die-making technology, including the use of precision CNC machining and laser engraving, allow for the creation of extremely fine details and intricate textures, broadening the creative possibilities for designers. Furthermore, the convergence of hot stamping with other printing technologies, such as cold foil transfer and hybrid printing solutions, offers printers greater versatility and efficiency, enabling them to produce complex decorative effects in a single pass. These technological strides collectively enhance the market's capabilities, making hot stamping a more versatile, efficient, and sustainable decorative and functional solution across various industries, thereby driving its continued growth and relevance in the modern printing landscape.

Regional Highlights

- North America: This region represents a mature yet stable market, characterized by high demand from the luxury packaging, automotive, and graphic arts sectors. Innovation in sustainable foils and digital hot stamping solutions is a key trend. The presence of major brand owners and a strong emphasis on brand protection drive the demand for high-security and aesthetic foils.

- Europe: Similar to North America, Europe is a well-established market with a strong focus on high-quality and sustainable packaging solutions. Strict environmental regulations are fostering the adoption of eco-friendly foils and production processes. Germany, France, and Italy are significant contributors, driven by their robust cosmetics, automotive, and food & beverage industries.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, increasing disposable incomes, and the booming manufacturing sector, particularly in China, India, and Southeast Asian countries. The rising middle class's demand for branded and premium products fuels the need for attractive and secure packaging. Local manufacturers are expanding capabilities, and foreign players are investing heavily.

- Latin America: This region is experiencing steady growth, supported by economic development and an expanding consumer base. Brazil and Mexico are leading markets, with increasing demand from the food & beverage, cosmetics, and tobacco industries for enhanced product presentation and anti-counterfeiting measures. Market penetration is gradually increasing as local businesses adopt advanced packaging and branding techniques.

- Middle East and Africa (MEA): The MEA market is emerging, driven by infrastructure development, growth in the luxury goods sector, and an increasing awareness of brand importance. The demand for premium packaging in the GCC countries and the need for security features in various products contribute to market expansion, albeit from a lower base compared to developed regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hot Stamping Foil Market.- Leonhard Kurz Stiftung & Co. KG

- API Group

- Crown Roll Leaf, Inc.

- Foilco

- ITW Foils

- UNIVACCO Foils

- K Laser Technology (USA) Co., Ltd.

- CFC International (DIC Corporation)

- Katani Co., Ltd.

- Foil & Specialty Effects (FSE)

- Nakai Industrial Co., Ltd.

- KURZ TRANSFER PRODUCTS, Inc.

- Newfoil Machines Ltd.

- Astor Universal

- Luminescence International Ltd.

- Oasys, Inc.

- Anstey

- Polinas Corporate

- Kolon Global Corporation

- Guanghui Hot Stamping Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Hot Stamping Foil market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is hot stamping foil and how does it work?

Hot stamping foil is a multi-layered material used to transfer decorative or functional elements onto a substrate. It works by applying heat and pressure with a die, which releases the desired layer (e.g., metallic, pigment, holographic) from a carrier film and bonds it permanently onto the product surface, creating a distinctive finish.

What are the primary applications of hot stamping foil?

Hot stamping foils are widely used across diverse industries for packaging (cosmetics, food & beverage, tobacco), graphic arts (greeting cards, book covers), textiles, security documents (anti-counterfeiting), and automotive interiors, primarily to enhance aesthetic appeal, brand recognition, and product security.

What factors are driving the growth of the Hot Stamping Foil Market?

Key drivers include the increasing global demand for premium and luxury packaging, the critical need for brand differentiation in competitive markets, rising concerns about anti-counterfeiting, and growing disposable incomes that fuel consumer preference for high-quality, visually appealing products across various end-use industries.

Are there sustainable or eco-friendly options available in the hot stamping foil market?

Yes, the market is seeing a growing trend towards sustainability. Manufacturers are developing eco-friendly hot stamping foils using recycled content, biodegradable carrier films, and water-based adhesives. These innovations aim to reduce environmental impact and meet the demands of environmentally conscious brands and consumers.

How is AI impacting the Hot Stamping Foil Market?

AI is influencing the market by optimizing design processes, enabling predictive maintenance for hot stamping machinery, enhancing quality control through advanced inspection, and improving supply chain efficiency. It also supports the development of smart foils and facilitates greater personalization and customization in applications, leading to higher precision and reduced waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Hot Stamping Foil Market Statistics 2025 Analysis By Application (Plastic, Paper), By Type (Metallic Hot Stamping Foil, Pigment Hot Stamping Foil, Holographic Hot Stamping Foil), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Hot Stamping Foil Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Metallic Hot Stamping Foil, Pigment Hot Stamping Foil, Hologram Hot Stamping Foil, Others), By Application (Automobile, Cosmetic, Home Appliances, Consumer Electronics, Cigarette and Wine Packaging, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager