Hurricane Impact Window Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441292 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Hurricane Impact Window Market Size

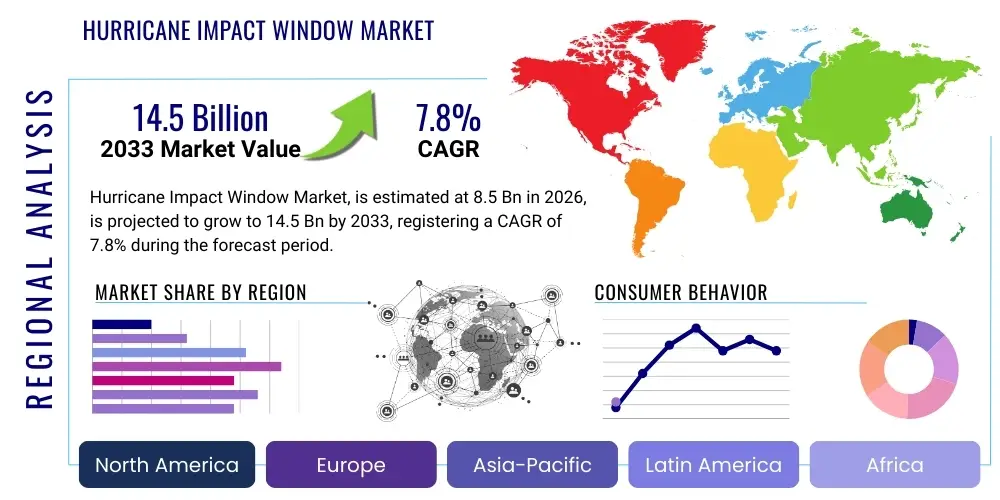

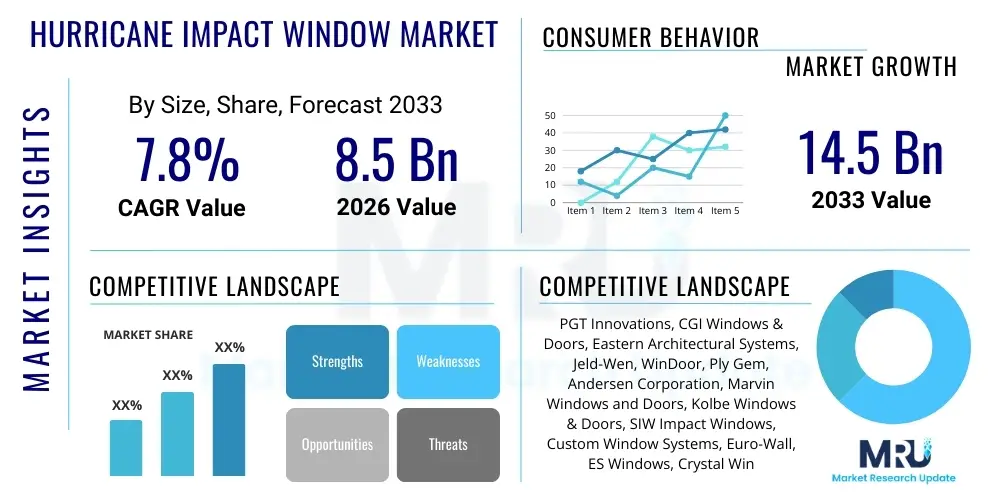

The Hurricane Impact Window Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 14.5 Billion by the end of the forecast period in 2033.

Hurricane Impact Window Market introduction

The Hurricane Impact Window Market encompasses the manufacturing, distribution, and installation of specialized window systems designed to withstand extreme weather conditions, primarily high winds and the impact from wind-borne debris commonly associated with hurricanes and severe tropical storms. These windows are engineered using advanced materials, notably laminated glass composed of a tough interlayer (such as polyvinyl butyral, PVB, or SentryGlas Plus, SGP) sandwiched between two panes of glass, held securely within reinforced frames made typically of aluminum, vinyl, or fiberglass. The primary product description centers on providing superior structural integrity and protection against catastrophic building envelope failure, thereby safeguarding occupants and interior assets during major weather events.

Major applications for hurricane impact windows span the entire construction sector, including new residential constructions, renovation projects in hurricane-prone coastal regions, and various commercial structures such as hotels, hospitals, government buildings, and educational facilities. The increasing frequency and intensity of tropical cyclones, coupled with stricter building codes implemented by regional authorities like the Florida Building Code (FBC) and regulations enforced by organizations such as the Texas Department of Insurance (TDI), serve as major driving factors for market expansion. These codes often mandate the use of certified impact-resistant products in specific Wind-Borne Debris Regions (WBDR).

The core benefits driving consumer adoption include enhanced security against forced entry, significant noise reduction capabilities due to the laminated structure, improved energy efficiency by providing better insulation (especially when combined with low-emissivity coatings or insulated glass units, IGUs), and the elimination of the need for cumbersome external storm shutters. Furthermore, these windows often qualify homes and commercial properties for reduced insurance premiums, presenting a clear long-term financial incentive for property owners in high-risk zones. The convergence of safety requirements, regulatory mandates, and consumer demand for dual-purpose aesthetic and protective solutions is fundamentally accelerating market growth.

Hurricane Impact Window Market Executive Summary

The Hurricane Impact Window Market is experiencing robust growth driven predominantly by escalating climate change risks leading to more intense storm activity and the subsequent tightening of construction standards across vulnerable geographies, especially North America and parts of Asia Pacific. Business trends indicate a shift towards advanced glazing technologies, such as SGP interlayers, offering superior strength and lighter weight compared to traditional PVB, alongside a strong emphasis on integrating smart home features like automated locking and monitoring systems into window frames. Manufacturers are increasingly investing in capacity expansion and strategic partnerships to meet the surging demand for high-performance products that adhere to stringent testing standards, such as ASTM E1886 and E1996 for missile impact resistance.

Regionally, the market is heavily concentrated in coastal areas, with North America, particularly the Southeastern United States (Florida, Texas, Louisiana), acting as the primary revenue generator due to established regulatory requirements and high density of new construction projects. Asia Pacific is emerging as a critical growth region, notably in countries like Japan, the Philippines, and China, where coastal urbanization and exposure to typhoons necessitate similar protective measures, leading to increasing foreign direct investment and technology transfer. The European market, while smaller, is demonstrating growth, focusing on multi-functionality, combining blast resistance or high acoustic insulation with storm protection.

Segment trends reveal that the Residential application segment holds the largest market share, fueled by strong consumer spending on home resilience and renovation projects, while the Commercial segment is projected to exhibit the fastest Compound Annual Growth Rate (CAGR), driven by large-scale infrastructure and hospitality development in coastal resort areas. By material, aluminum frames maintain dominance in commercial high-rise applications due to their structural strength, whereas vinyl frames are increasingly popular in the residential sector due to their cost-effectiveness and excellent thermal properties. The long-term trajectory suggests continued innovation focused on aesthetics, thermal performance, and integration into sustainable, high-performance building designs, mitigating both environmental risks and energy consumption.

AI Impact Analysis on Hurricane Impact Window Market

Common user questions regarding AI's impact on the Hurricane Impact Window Market primarily revolve around how Artificial Intelligence can enhance product performance, optimize manufacturing processes, and improve predictive maintenance and sales forecasting. Users are particularly concerned with whether AI can accelerate the certification process by simulating impact scenarios more accurately than physical testing, thereby reducing research and development costs and time-to-market. Furthermore, there is significant interest in how AI algorithms can analyze complex meteorological data and structural requirements to recommend optimal window specifications (glass thickness, interlayer material, frame reinforcement) for a given geographical location and building design, essentially moving towards prescriptive design solutions.

The consensus suggests that AI integration, while nascent, holds significant potential across the entire value chain. In manufacturing, AI-powered systems are already being implemented for quality control, using computer vision to detect microscopic flaws in laminated glass production and ensuring the integrity of sealants and frame joints, dramatically reducing defect rates. This analytical capability is vital in a sector where product failure can have catastrophic consequences. Moreover, AI models are optimizing supply chain logistics by predicting fluctuations in demand driven by seasonal weather forecasts and regulatory changes, allowing manufacturers to manage inventory of specialized materials like advanced interlayers and high-strength aluminum extrusions more efficiently.

Future expectations center on using Machine Learning (ML) for predictive resilience modeling. AI can leverage massive datasets including historical hurricane damage reports, wind tunnel test results, and material performance metrics under various stress conditions to create highly accurate digital twins of building facades. This enables architects and engineers to test and validate impact window designs virtually against Category 5 wind loads and debris strikes before physical prototypes are created. This transition towards AI-driven simulation and design optimization is expected to lower R&D expenditure, accelerate regulatory approvals, and ultimately yield safer, more cost-effective protective window solutions for the end consumer.

- AI-driven simulation reduces the reliance on costly physical missile impact testing, accelerating product development cycles.

- Machine Learning algorithms optimize manufacturing quality control by detecting structural imperfections in glass lamination and frame assembly.

- Predictive maintenance analytics, powered by AI, forecast potential sealant degradation or hardware failure based on environmental exposure data.

- AI tools analyze meteorological patterns and building codes to provide prescriptive design recommendations for specific storm risk profiles.

- Natural Language Processing (NLP) streamlines compliance checks by rapidly analyzing updates in regional building codes and material certifications.

DRO & Impact Forces Of Hurricane Impact Window Market

The dynamics of the Hurricane Impact Window Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. The primary driver is the accelerating frequency and intensity of tropical storms attributed to climate change, which translates directly into heightened public awareness and political pressure to enhance infrastructural resilience. This climatic reality is further enforced by tightening regulatory frameworks, particularly in coastal states and territories, where updated building codes mandate specific impact ratings (such as large missile level D testing compliance) for all new constructions and substantial renovations. Consumer preference for integrated, aesthetic solutions that eliminate the need for manual storm preparation (e.g., hanging shutters) provides significant market momentum. Furthermore, the insurance industry often incentivizes the installation of certified impact protection through premium discounts, acting as a crucial financial motivator for homeowners and commercial property developers.

However, the market faces notable restraints. The significant initial investment cost associated with high-quality impact windows, which can be 50% to 100% higher than standard windows, presents a substantial barrier to entry, particularly for low-to-middle income housing markets. Supply chain volatility, especially regarding specialized components like structural silicone and the highly durable interlayers (PVB/SGP), can lead to extended lead times and fluctuating production costs. Additionally, the technical complexity of installation requires specialized, certified labor, which remains a limiting factor in rapidly expanding construction markets. Market inertia, particularly in regions where building codes are less strictly enforced or frequently updated, also slows the universal adoption of these premium products.

Opportunities for expansion lie in penetrating emerging coastal markets in Latin America and Asia Pacific that are increasingly exposed to severe weather but currently lack stringent impact protection standards. Technological advancements offer another avenue, particularly the development of ultra-lightweight, high-strength polymers for interlayers and frames, improving handling and energy efficiency while maintaining critical protective capabilities. The market is also poised for growth through retrofitting older structures, as governments often offer incentives or mandates for upgrading vulnerable building stock. The key impact forces driving the market are the regulatory environment (high influence) and consumer safety perception (medium-to-high influence), both of which create inelastic demand. Economic forces, such as fluctuating material costs and mortgage rates, exert medium influence, primarily affecting the short-term affordability and speed of construction projects.

Segmentation Analysis

The Hurricane Impact Window Market segmentation offers a granular view of market structure based on Glazing Type, Frame Material, Application, and Distribution Channel. This detailed categorization helps stakeholders understand specific consumer preferences, technological adoption rates, and regional demand patterns. The core of the market differentiation lies in the material science behind the glazing, where performance requirements dictate the choice between standard laminated setups and higher-strength insulated laminated units which also satisfy stringent energy efficiency codes. Analysis shows that commercial applications often prioritize performance and durability (favoring aluminum and SGP interlayers), while residential applications balance cost, aesthetics, and thermal performance (favoring vinyl and standard PVB interlayers).

Further analysis of segmentation highlights the evolving competitive landscape. Manufacturers are strategically focusing on high-growth segments such as the insulated laminated market, which capitalizes on the dual benefits of storm protection and reduced heating/cooling costs, aligning with global trends toward sustainable construction. The residential renovation segment, distinct from new construction, often presents unique challenges regarding customized sizing and architectural matching, leading to premium pricing opportunities for specialized fabrication companies. Understanding the distribution channel split—between large retailers/contractors (offline) and emerging direct-to-consumer online platforms—is crucial for optimizing supply chain strategy and market outreach.

- By Glazing Type:

- Laminated Glass (Single layer protection)

- Insulated Laminated Glass (Enhanced thermal performance)

- Non-Insulated Laminated Glass

- By Frame Material:

- Aluminum

- Vinyl (PVC)

- Wood

- Fiberglass

- By Application:

- Residential (New Construction, Renovation)

- Commercial (Hospitality, Office Buildings, Retail)

- Industrial

- By Distribution Channel:

- Offline (Direct Sales, Distributors, Specialized Contractors)

- Online (E-commerce Platforms, Manufacturer Websites)

Value Chain Analysis For Hurricane Impact Window Market

The Value Chain of the Hurricane Impact Window Market begins with upstream activities, primarily involving the procurement and processing of raw materials. This includes the production of high-strength glass (often heat-strengthened or tempered), the manufacturing of specialized polymer interlayers like PVB and SGP, and the extrusion of frame materials such as aluminum, vinyl, and fiberglass compounds. Key challenges at this stage include maintaining the purity and consistency of the interlayer polymers, which directly dictate the impact rating, and managing the global supply of specialized low-e coatings and spacers required for insulated units. Effective upstream management requires long-term supplier contracts and strict quality control over material specifications to ensure final product certification.

The midstream phase focuses on manufacturing and assembly. This involves the complex process of lamination (applying heat and pressure in autoclaves to bond the glass and interlayer), cutting and assembling the reinforced frames, and integrating specialized hardware (locks, hinges) designed to withstand extreme shear forces and cyclical wind loads. Certification and testing are critical midstream activities, where prototypes must pass demanding missile impact tests (such as Miami-Dade protocols) and cyclic pressure tests. Manufacturing efficiency is a key differentiator, requiring high precision machinery and automated processes to handle large, heavy impact-resistant glass units while minimizing material waste.

Downstream analysis covers distribution and installation. Distribution channels are typically dual: direct sales to large commercial contractors for major projects, and indirect sales through specialized window and door distributors, retailers, and certified installation companies serving the residential renovation market. Installation is a crucial service component; improper installation voids performance warranties and fails compliance with building codes. Therefore, manufacturers heavily invest in training and certifying installers. The downstream success is measured by lead time, accuracy of fulfillment, and customer satisfaction with the complex installation process, often facilitated by local experts who navigate specific regional permit requirements and inspection processes. Direct distribution channels are gaining importance as they allow greater control over pricing and customer experience, particularly in the high-end custom market.

Hurricane Impact Window Market Potential Customers

The potential customers for Hurricane Impact Windows are broadly categorized into Residential, Commercial, and Institutional end-users residing in or developing properties within high-risk coastal and inland areas susceptible to severe tropical storms and hurricanes. Within the Residential segment, the primary buyers are affluent homeowners engaging in new custom home construction, property owners undertaking large-scale remodeling projects aimed at enhancing home resilience and energy efficiency, and investment property owners seeking to protect assets and qualify for lower insurance premiums. There is also a distinct, growing customer base among second-home owners and retirees prioritizing passive storm protection.

The Commercial sector constitutes a crucial segment, with major buyers including developers of coastal high-rise condominiums and luxury hotels, as these properties require superior aesthetic quality alongside guaranteed structural integrity to ensure continuity of operations during and immediately after a storm event. Additionally, essential services infrastructure, such as hospitals, emergency operations centers, and data centers located in vulnerable zones, represent mandatory buyers, driven by operational continuity regulations. These commercial customers prioritize maximum performance ratings, large span capabilities, and long-term durability under constant exposure to salt spray and harsh UV radiation.

Finally, governmental and institutional buyers, including municipal bodies, schools, and military bases in coastal regions, are significant purchasers. Their purchasing decisions are often dictated by federal and state mandates (e.g., FEMA guidelines for community resilience) and procured through competitive bidding processes, focusing heavily on certifications, warranty duration, and life-cycle cost analysis. These buyers often require specialized products, such as blast-resistant or enhanced security features integrated into the impact window structure, highlighting a niche but high-value customer base within the broader market ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 14.5 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PGT Innovations, CGI Windows & Doors, Eastern Architectural Systems, Jeld-Wen, WinDoor, Ply Gem, Andersen Corporation, Marvin Windows and Doors, Kolbe Windows & Doors, SIW Impact Windows, Custom Window Systems, Euro-Wall, ES Windows, Crystal Window & Door Systems, Lawson Industries, Thermo-Tech, Targa Windows, Simonton Windows, Guardian Glass, Eastman Chemical Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hurricane Impact Window Market Key Technology Landscape

The technological landscape of the Hurricane Impact Window Market is dominated by innovations in glass lamination, frame structural reinforcement, and specialized hardware designed to manage extreme loads. Laminated glass technology is the cornerstone, relying heavily on the interlayer material. While Polyvinyl Butyral (PVB) remains the industry standard for cost-effective protection and acoustic dampening, there is a significant technological migration towards SentryGlas Plus (SGP) interlayers. SGP offers five times the tear strength and 100 times the stiffness of conventional PVB, enabling the design of larger, lighter, and structurally superior windows capable of meeting the highest missile impact requirements (e.g., Missile Level E), which is critical for high-rise commercial structures and FEMA safe rooms.

Frame material technology focuses on enhancing the strength-to-weight ratio and thermal performance. Aluminum frames are evolving with thermal breaks and advanced multi-chambered designs to mitigate conductivity without sacrificing the inherent strength required for large openings. Vinyl (uPVC) frames utilize co-extruded reinforcement (often steel or aluminum inserts) embedded within the frame profiles to provide the rigidity necessary to resist deformation under cyclic pressure testing. Fiberglass technology is gaining traction, offering exceptional durability, resistance to corrosion in harsh coastal environments, and superior thermal insulation properties, positioning it as a premium material blending strength and energy efficiency.

Beyond core materials, specialized sealing and installation technologies are crucial. Advanced structural silicone sealants are mandatory, designed to maintain adhesion between the glass and frame even when the window deflects significantly under extreme wind pressure, preventing water intrusion and catastrophic failure. Furthermore, the integration of low-emissivity (Low-E) coatings and argon gas fill in insulated laminated units is standard, positioning these products not just as protective barriers but as key components in achieving high-performance, energy-efficient building envelopes, crucial for complying with contemporary energy codes like IECC. Hardware technology includes multi-point locking systems and corrosion-resistant fasteners engineered to withstand continuous exposure to salt air and high shear loads.

Regional Highlights

North America is the undisputed leader in the Hurricane Impact Window Market, driven primarily by the high frequency of hurricanes hitting the Gulf Coast and the Eastern Seaboard, particularly the Southeastern U.S. states like Florida, Texas, and the Carolinas. Florida, due to its stringent and continuously updated state-wide building codes (FBC), represents the most mature and dominant sub-market globally, mandating impact-resistant products in specific Wind-Borne Debris Regions (WBDR). High-density coastal development, combined with rising insurance costs and a wealthy homeowner base willing to invest in premium protection, ensures continued market expansion. Manufacturers often base their research, testing facilities, and largest production lines in this region to cater directly to these exacting regulatory and consumer demands, focusing heavily on products compliant with Miami-Dade NOA (Notice of Acceptance) standards.

Asia Pacific (APAC) represents the fastest-growing region, fueled by rapid urbanization along vulnerable coastlines and the increasing severity of typhoons (cyclones) impacting countries like Japan, the Philippines, Vietnam, and coastal China. While building codes in some APAC nations are currently less standardized than in the U.S., governmental focus on disaster resilience and foreign investment in infrastructure projects are driving demand for certified impact products. Japan, with its high seismic and typhoon exposure, is a leader in adopting advanced structural glazing solutions. The expansion of the market here is characterized by technology transfer, with local manufacturers increasingly seeking partnerships with North American and European firms to acquire necessary production techniques and achieve international certification standards for export and domestic use.

Europe’s market presence in dedicated hurricane impact windows is comparatively smaller, focusing instead on multi-functional products that combine blast resistance, high acoustic performance, and wind loading capabilities relevant to coastal storm surges in regions like the Mediterranean and Northern Europe. The demand is often project-specific, integrated into high-security government buildings or specialized coastal infrastructure rather than broad residential mandates. The Middle East and Africa (MEA) and Latin America (LATAM) markets exhibit selective growth. LATAM, especially the Caribbean and Central American nations frequently impacted by hurricanes, shows significant potential but is often constrained by economic factors and less consistently enforced building codes. MEA demand is highly localized, driven by large commercial real estate developments in coastal areas like the UAE and Qatar that require superior weather resilience and security features for luxury high-rises.

- North America: Dominant market share due to stringent codes (FBC, Texas TDI), high storm frequency, and concentration of key manufacturers; focuses on large missile impact resistance (residential and commercial high-rises).

- Asia Pacific (APAC): Fastest growing region, driven by urbanization in typhoon-prone zones (Japan, Philippines, China); characterized by technology transfer and investment in resilient infrastructure.

- Europe: Niche market focusing on multi-functional windows combining wind loading capacity with blast mitigation and high acoustic insulation for coastal applications.

- Latin America (LATAM): High potential in the Caribbean and Central America, demand is growing but constrained by economic volatility and uneven code enforcement.

- Middle East and Africa (MEA): Growth concentrated in high-value coastal commercial projects requiring specialized security and weather resilience features.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hurricane Impact Window Market.- PGT Innovations

- CGI Windows & Doors

- Eastern Architectural Systems

- Jeld-Wen

- WinDoor

- Ply Gem

- Andersen Corporation

- Marvin Windows and Doors

- Kolbe Windows & Doors

- SIW Impact Windows

- Custom Window Systems

- Euro-Wall

- ES Windows

- Crystal Window & Door Systems

- Lawson Industries

- Thermo-Tech

- Targa Windows

- Simonton Windows

- Guardian Glass

- Eastman Chemical Company

Frequently Asked Questions

Analyze common user questions about the Hurricane Impact Window market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for hurricane impact windows?

The primary factor driving demand is the increasing frequency and intensity of tropical storms and hurricanes worldwide, coupled with the implementation of strict, mandatory building codes (such as the Florida Building Code) that require certified impact-resistant protection in high-velocity hurricane zones (HVHZ) for new construction and major renovations.

How do laminated impact windows differ from standard tempered or annealed glass?

Impact windows use laminated glass, consisting of two or more panes bonded by a specialized polymer interlayer (like PVB or SGP). This interlayer holds the glass fragments together upon impact, preventing the breach of the building envelope, unlike standard tempered glass which shatters into small pieces, or annealed glass which breaks easily.

Are aluminum or vinyl frames better for impact windows?

The superior material depends on the application. Aluminum frames offer maximum structural strength for large commercial openings and high-rise buildings. Vinyl (uPVC) frames are preferred in the residential segment for their cost-effectiveness, excellent thermal insulation properties, and resistance to corrosion, often reinforced with internal metal inserts to meet impact requirements.

Does installing impact windows reduce home insurance costs?

Yes, in many hurricane-prone regions, insurance companies offer significant premium discounts (often tied to wind mitigation credits) for properties certified with full impact protection, as these windows substantially reduce the risk of structural damage and water intrusion during a storm event.

What is the technological significance of SentryGlas Plus (SGP) in the market?

SGP is a high-performance interlayer that is significantly stiffer and stronger than standard PVB, enabling the manufacturing of impact windows that meet the highest missile resistance levels (Level E) while offering reduced glass thickness and weight, crucial for architects designing modern, large-format glass facades.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager