Hybrid Cooling Towers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440758 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Hybrid Cooling Towers Market Size

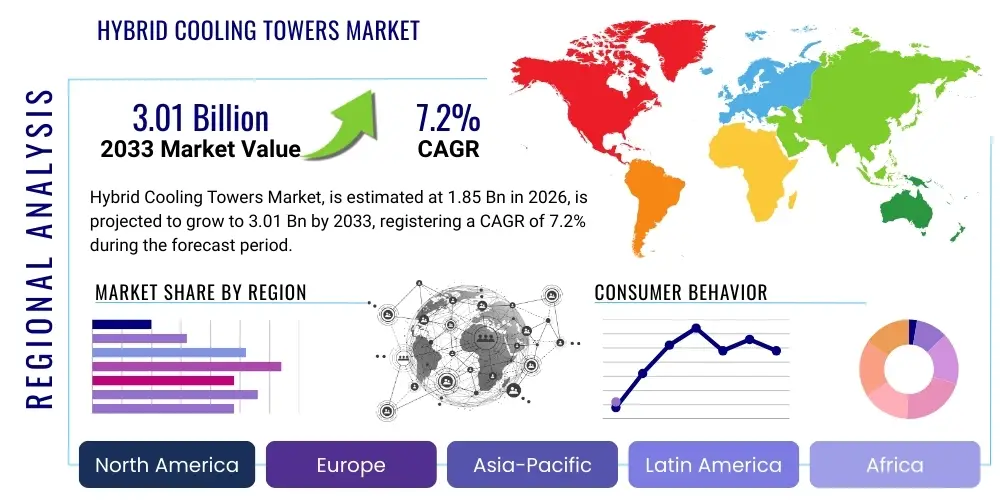

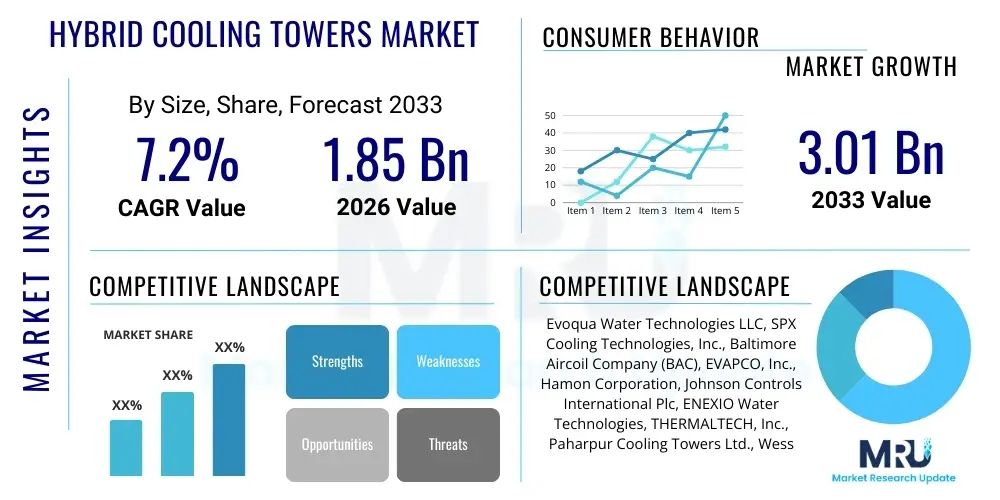

The Hybrid Cooling Towers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.01 Billion by the end of the forecast period in 2033. This growth is underpinned by increasing industrialization, stringent environmental regulations necessitating water and energy conservation, and the growing demand for efficient cooling solutions across various sectors globally. The adoption of hybrid systems provides a crucial balance between water efficiency of dry cooling and the thermal performance of wet cooling, making them an economically viable and environmentally responsible choice for future industrial and commercial applications.

Hybrid Cooling Towers Market introduction

The Hybrid Cooling Towers Market encompasses advanced cooling solutions that integrate both wet (evaporative) and dry (air-cooled) cooling technologies into a single unit. These systems are designed to optimize water and energy consumption while maintaining superior cooling performance, particularly in regions facing water scarcity or strict environmental discharge regulations. Hybrid cooling towers offer a versatile alternative to conventional cooling systems, effectively mitigating issues such as water plume formation, high water consumption, and the risk of Legionella proliferation associated with purely wet cooling towers, while overcoming the lower efficiency of purely dry cooling systems.

Major applications for hybrid cooling towers span a diverse range of industries, including power generation (nuclear, fossil fuel, renewable energy plants), HVAC systems for large commercial and institutional buildings, data centers, manufacturing processes (chemical, petrochemical, food and beverage, automotive), and refrigeration. Their adaptability makes them suitable for environments where both water conservation and consistent thermal performance are critical. The inherent flexibility of hybrid systems allows operators to switch between wet, dry, or hybrid modes depending on ambient conditions, load requirements, and water availability, ensuring optimal operational efficiency and cost-effectiveness.

The primary benefits of hybrid cooling towers include significant water savings compared to traditional wet cooling, reduced chemical treatment costs, minimized plume visibility, lower noise levels, and enhanced resistance to freezing in colder climates. These systems contribute to a smaller environmental footprint by conserving water resources and often reducing energy consumption over their operational lifespan. Driving factors for market growth include escalating industrial demand for cooling, global initiatives for water conservation and sustainable development, increasing regulatory pressures regarding water discharge and air quality, and the rising capital investments in infrastructure and industrial expansion across emerging economies. Furthermore, advancements in materials science and smart control systems are continually improving the efficiency and appeal of hybrid cooling tower technologies, solidifying their position as a preferred cooling solution for a sustainable future.

Hybrid Cooling Towers Market Executive Summary

The Hybrid Cooling Towers Market is experiencing robust growth, driven by an urgent global emphasis on sustainability, water conservation, and energy efficiency across industrial and commercial landscapes. Key business trends indicate a strong shift towards advanced cooling solutions that offer operational flexibility and environmental compliance. Companies are increasingly investing in research and development to enhance the performance of hybrid systems, focusing on intelligent controls, modular designs, and integration with renewable energy sources. This innovation pipeline is crucial for meeting diverse client needs, ranging from large-scale power plants requiring massive cooling capacities to data centers prioritizing uptime and minimal water footprint. Strategic partnerships and mergers among technology providers and engineering firms are also defining the competitive landscape, aiming to offer comprehensive, integrated cooling solutions that address complex industrial challenges and maximize return on investment for end-users.

Regionally, the market exhibits varied growth trajectories influenced by local regulatory frameworks, economic development, and water stress levels. Asia Pacific is poised for significant expansion due to rapid industrialization, urbanization, and the proliferation of data centers, alongside increasing environmental consciousness in countries like China and India. North America and Europe, characterized by mature industrial sectors and stringent environmental regulations, are witnessing a strong adoption of hybrid systems for retrofitting existing facilities and new high-efficiency installations. Latin America, the Middle East, and Africa are emerging markets, with growth spurred by infrastructure development, expanding industrial bases, and a growing recognition of the long-term economic and environmental benefits offered by hybrid cooling technologies. These regions present substantial opportunities for market players to introduce and scale sustainable cooling solutions, often supported by government incentives and policies promoting green technologies.

In terms of segmentation, the market is primarily driven by various product types and end-use industries. The wet-dry hybrid cooling tower segment is dominant due to its balanced approach to water and energy efficiency, offering a superior alternative to purely wet or dry systems. Closed-circuit hybrid towers are also gaining traction, particularly in applications where fluid contamination must be avoided. End-user segments such as power generation, HVAC, and industrial manufacturing continue to be major revenue contributors. The data center segment is experiencing particularly rapid growth, propelled by the exponential increase in digital infrastructure and the critical need for efficient, reliable, and water-conscious cooling. Technological advancements in fan design, fill materials, and smart control systems are further refining these segments, enabling tailored solutions that address specific operational demands and environmental targets across the global market. The trend towards customized, high-performance hybrid systems designed for specific climates and operational parameters is expected to continue shaping market dynamics.

AI Impact Analysis on Hybrid Cooling Towers Market

Users frequently inquire about how Artificial Intelligence can revolutionize the efficiency, maintenance, and operational costs of Hybrid Cooling Towers. Common questions revolve around AI's ability to predict component failures, optimize energy consumption based on real-time data and weather forecasts, and enhance overall system performance. There's also significant interest in AI's role in automating operational adjustments, reducing manual intervention, and ensuring compliance with environmental regulations. Users anticipate AI to bring unprecedented levels of predictive analytics and smart control, leading to substantial reductions in downtime, operational expenditures, and environmental footprint, ultimately making hybrid cooling solutions even more attractive and competitive in the market.

- AI-driven predictive maintenance significantly extends equipment lifespan and reduces unplanned downtime by forecasting potential failures through continuous data analysis.

- Optimized energy consumption is achieved by AI algorithms dynamically adjusting fan speeds, water flow, and operational modes based on real-time thermal load, ambient conditions, and energy pricing.

- Enhanced water management through AI, minimizing blowdown frequency and maximizing cycles of concentration, thereby reducing water usage and chemical treatment needs.

- Real-time performance monitoring and anomaly detection enable immediate identification and resolution of operational inefficiencies, ensuring consistent and optimal cooling.

- Automated compliance reporting and environmental impact assessments, simplifying regulatory adherence and demonstrating sustainability efforts.

- AI-assisted design and simulation tools reduce development costs and time-to-market for new hybrid cooling tower configurations, optimizing for specific site conditions and performance goals.

- Improved operational safety by using AI to detect and prevent hazardous conditions, such as equipment overheating or unusual pressure fluctuations.

- Integration with broader smart building and industrial control systems, allowing for holistic energy management and resource allocation across entire facilities.

DRO & Impact Forces Of Hybrid Cooling Towers Market

The Hybrid Cooling Towers Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. A primary driver is the escalating global demand for efficient and sustainable industrial cooling solutions, fueled by rapid industrialization, urbanization, and the expansion of data centers. Stricter environmental regulations aimed at water conservation and reduced plume emissions further compel industries to adopt hybrid systems. The inherent benefits of these towers, such as reduced water consumption, lower chemical treatment costs, and minimized visual plume, directly address critical operational and environmental concerns, making them a preferred choice for new installations and retrofits alike. Moreover, rising energy costs incentivize the adoption of energy-efficient cooling technologies, where hybrid towers often outperform conventional systems by optimizing operational modes based on external conditions. Continuous advancements in materials science, fan technology, and smart control systems also contribute positively by enhancing the performance, reliability, and cost-effectiveness of these units, making them more attractive to a broader range of end-users.

Despite the strong drivers, several restraints pose challenges to the market's growth. The initial capital investment for hybrid cooling towers is generally higher than that for traditional wet cooling towers, which can be a significant deterrent for smaller businesses or those with limited budgets. The complexity of design, installation, and maintenance for hybrid systems, requiring specialized technical expertise, also represents a barrier to widespread adoption. Furthermore, a lack of widespread awareness and understanding of the long-term benefits and operational savings associated with hybrid technologies can hinder their market penetration, especially in developing regions. While regulations encourage sustainable practices, inconsistencies in policy implementation across different geographies can create an uneven playing field. The presence of well-established conventional cooling solutions, coupled with a certain degree of inertia in adopting new technologies, also presents a challenge, as industries may be reluctant to switch from familiar and less expensive alternatives without clear, compelling demonstrations of superior ROI.

However, substantial opportunities exist for market expansion and innovation. The growing emphasis on corporate social responsibility and sustainable business practices globally presents a significant avenue for hybrid cooling tower manufacturers to position their products as essential components of a green economy. Emerging economies, undergoing rapid industrial and infrastructural development, offer vast untapped markets for these advanced cooling solutions, particularly as they seek to implement more sustainable practices from the outset. The increasing global water stress and the imperative for water security will continue to bolster demand for water-efficient technologies like hybrid cooling towers. Technological advancements, especially in integrating AI and IoT for predictive maintenance, real-time optimization, and remote monitoring, open new pathways for enhancing efficiency and reducing operational costs, thereby increasing the appeal of hybrid systems. Furthermore, the development of modular and standardized hybrid cooling tower designs can simplify installation and maintenance, potentially reducing upfront costs and broadening market accessibility. Strategic partnerships with engineering firms and consulting services to educate end-users on lifecycle cost benefits and environmental compliance also present strong opportunities for market penetration and growth, fostering a deeper understanding of the value proposition.

Segmentation Analysis

The Hybrid Cooling Towers Market is comprehensively segmented to provide granular insights into its diverse components, aiding in targeted market strategies and understanding specific demand patterns. This segmentation is typically performed across various parameters, including type of cooling, capacity, end-use industry, and geographic region. Understanding these distinct segments is crucial for manufacturers to tailor their product offerings, for suppliers to optimize their distribution channels, and for investors to identify high-growth areas. Each segment represents unique customer needs, technological preferences, and regulatory environments, collectively defining the intricate market landscape.

- By Type:

- Wet-Dry Hybrid Cooling Towers: These systems combine the principles of evaporative and dry cooling, offering excellent water savings and plume abatement capabilities. They are ideal for applications requiring a balance of efficiency and environmental performance.

- Closed-Circuit Hybrid Cooling Towers: Also known as fluid coolers, these systems cool a process fluid directly within a coil, preventing contamination. They are highly valued in applications where process fluid purity is paramount, such as data centers and specialized manufacturing.

- By Capacity:

- Small Capacity (<200 Tons): Typically used for commercial HVAC, smaller industrial processes, and light manufacturing.

- Medium Capacity (200-1000 Tons): Common in mid-sized power plants, larger commercial buildings, and medium-scale industrial facilities.

- Large Capacity (>1000 Tons): Primarily deployed in large power generation facilities, heavy industrial plants, and vast data center campuses.

- By End-Use Industry:

- Power Generation: Includes conventional thermal power plants (coal, gas), nuclear power plants, and increasingly, renewable energy facilities that require auxiliary cooling.

- HVAC (Heating, Ventilation, and Air Conditioning): Large commercial buildings, hospitals, universities, and other institutional facilities utilize hybrid cooling towers for efficient climate control.

- Industrial: Encompasses a broad spectrum including chemical processing, petrochemical, food and beverage, automotive manufacturing, pharmaceutical, and metal processing industries.

- Data Centers: Critical for maintaining optimal operating temperatures for servers and IT equipment, driven by increasing data loads and the need for energy and water efficiency.

- Others: Includes refrigeration, district cooling, and specialized manufacturing processes.

- By Material:

- Fiberglass Reinforced Polyester (FRP): Offers excellent corrosion resistance and lightweight properties.

- Galvanized Steel: Economical and robust, but susceptible to corrosion over time without proper treatment.

- Stainless Steel: Provides superior corrosion resistance and longevity, often used in harsh environments or for critical applications.

- Concrete: Typically used for very large, field-erected towers in power plants due to its structural integrity and long lifespan.

Value Chain Analysis For Hybrid Cooling Towers Market

The value chain for the Hybrid Cooling Towers Market is a sophisticated network encompassing raw material suppliers, component manufacturers, core cooling tower manufacturers, system integrators, distribution channels, and end-users, each adding value at different stages. The upstream segment involves the procurement of essential raw materials such as steel, fiberglass, PVC/PP for fill media, and chemicals for water treatment, alongside specialized components like fans, motors, pumps, heat exchangers, and control systems. Key suppliers in this stage focus on providing high-quality, durable materials and technologically advanced components that meet stringent industry standards for efficiency and longevity. Research and development activities, often conducted by component manufacturers or in collaboration with tower builders, are critical in innovating new designs and improving existing technologies to enhance system performance and reduce costs.

Moving downstream, the value chain progresses through the manufacturing and assembly of the hybrid cooling towers, often involving custom engineering to meet specific project requirements. Manufacturers specialize in combining the wet and dry sections, integrating advanced control systems, and ensuring the structural integrity and thermal performance of the units. This stage also includes rigorous testing and quality control. Following manufacturing, system integrators and engineering, procurement, and construction (EPC) firms play a crucial role by designing and installing complete cooling solutions, integrating the hybrid towers into larger industrial or HVAC systems. These integrators often provide consultancy, project management, and commissioning services, ensuring seamless integration and optimal operation.

Distribution channels for hybrid cooling towers are multi-faceted, involving both direct and indirect approaches. Direct channels typically involve manufacturers selling directly to large industrial clients, power generation companies, or major data center operators, often through a dedicated sales force and project management teams. This approach allows for direct communication, customization, and comprehensive after-sales support. Indirect channels involve a network of authorized distributors, resellers, and sales agents who cater to smaller projects, commercial HVAC applications, and regional markets. These intermediaries provide local market presence, technical support, and logistical advantages, expanding the market reach of manufacturers. Both direct and indirect channels are critical for market penetration, with the choice often depending on the scale of the project, the geographical location of the end-user, and the complexity of the cooling requirements. After-sales services, including maintenance, spare parts supply, and performance optimization, form a vital part of the value chain, ensuring the long-term operational efficiency and customer satisfaction, and often representing a significant revenue stream for manufacturers and service providers.

Hybrid Cooling Towers Market Potential Customers

Potential customers for the Hybrid Cooling Towers Market are primarily large-scale industrial entities, commercial enterprises, and critical infrastructure operators that require efficient, reliable, and environmentally responsible thermal management solutions. These end-users are characterized by their significant cooling demands, often operating continuous processes where even minor temperature fluctuations can lead to substantial operational losses or product quality issues. Their purchasing decisions are heavily influenced by factors such as total cost of ownership (TCO), including energy and water consumption, maintenance requirements, regulatory compliance, and the environmental footprint of the cooling system. Furthermore, reliability and longevity are paramount, as these systems represent substantial capital investments and are integral to their core operations.

Key segments of potential customers include power generation companies, ranging from conventional thermal power plants to emerging renewable energy facilities, all seeking to maximize energy output while minimizing environmental impact. The HVAC sector, particularly for large commercial complexes, airports, hospitals, and educational institutions, represents another significant customer base, driven by the need for comfortable indoor environments coupled with energy efficiency. Industrial manufacturers across diverse sectors such as chemicals, petrochemicals, pharmaceuticals, food and beverage, and automotive are continuous users, relying on precise temperature control for their production processes. The rapidly expanding data center industry is a high-growth segment, with operators prioritizing cooling solutions that offer high reliability, scalability, and minimal water usage to support their power-intensive IT infrastructure. These customers are actively seeking innovative solutions that not only meet their immediate cooling needs but also align with their long-term sustainability goals and operational efficiency targets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.01 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Evoqua Water Technologies LLC, SPX Cooling Technologies, Inc., Baltimore Aircoil Company (BAC), EVAPCO, Inc., Hamon Corporation, Johnson Controls International Plc, ENEXIO Water Technologies, THERMALTECH, Inc., Paharpur Cooling Towers Ltd., Wessels Company, Güntner GmbH & Co. KG, Kelvion Holding GmbH, LU-VE Group, Trane Technologies plc, Swegon Group AB, Daikin Industries, Ltd., GEA Group AG, Bell Cooling Tower Co., Inc., Delta Cooling Towers, Inc., Recold, a division of SPX Cooling Technologies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hybrid Cooling Towers Market Key Technology Landscape

The Hybrid Cooling Towers Market is characterized by a dynamic and evolving technology landscape, driven by continuous innovation aimed at enhancing efficiency, reducing environmental impact, and improving operational reliability. A core technological advancement lies in the optimization of the wet and dry coil designs, focusing on maximizing heat transfer efficiency while minimizing pressure drop and material usage. This includes the development of highly efficient fill media with increased surface area and improved water distribution, as well as specialized finned coils for the dry section that can withstand harsh operating conditions. Materials science plays a crucial role, with research into corrosion-resistant alloys, advanced polymers, and composite materials that extend the lifespan of components and reduce maintenance frequency. Furthermore, the integration of energy-efficient fan designs, such as axial and centrifugal fans with variable frequency drives (VFDs), allows for precise control over airflow, significantly reducing power consumption and operational noise levels across varying loads and ambient conditions.

Beyond the fundamental hardware, the most significant technological shifts are occurring in the realm of smart controls and digitalization. Advanced control systems, often incorporating Programmable Logic Controllers (PLCs) and sophisticated algorithms, enable automatic switching between wet, dry, and hybrid operating modes to optimize water and energy usage based on real-time weather data, thermal load, and pre-set environmental targets. The advent of the Internet of Things (IoT) has led to the deployment of numerous sensors that monitor critical parameters like water temperature, flow rates, fan speeds, motor health, and vibration levels. This sensor data is then transmitted to centralized platforms for analysis, providing operators with comprehensive insights into system performance. Cloud-based data analytics and visualization tools further empower facility managers to track key performance indicators (KPIs), identify trends, and make informed decisions for proactive maintenance and operational adjustments. These digital tools enhance not only efficiency but also predictive capabilities, allowing for early detection of potential issues and enabling condition-based maintenance strategies.

The integration of Artificial Intelligence (AI) and machine learning (ML) is rapidly becoming a cornerstone of the next generation of hybrid cooling tower technology. AI algorithms can analyze vast datasets from sensors and historical performance records to predict equipment failures, optimize maintenance schedules, and recommend ideal operating parameters for maximum efficiency and longevity. This predictive intelligence minimizes unplanned downtime, reduces spare parts inventory, and extends the operational life of the entire system. Machine learning models are also being used to refine energy consumption patterns, learning from past operational data to dynamically adjust controls to respond to fluctuating energy prices and demand-side management signals. Furthermore, the development of modular and standardized hybrid cooling tower components is simplifying installation, reducing site-specific engineering requirements, and accelerating deployment times. These technological advancements collectively contribute to a more autonomous, efficient, and sustainable cooling infrastructure, making hybrid cooling towers a sophisticated solution for modern industrial and commercial thermal management challenges.

Regional Highlights

- North America: This region is a mature market driven by stringent environmental regulations, a strong focus on energy efficiency, and a robust industrial sector including power generation, chemical, and an expanding data center footprint. The demand for retrofitting existing facilities with more sustainable cooling solutions is a key driver. Countries like the United States and Canada are early adopters of advanced hybrid cooling technologies, benefiting from well-established infrastructure and significant investment in R&D.

- Europe: Similar to North America, Europe's market is characterized by strict environmental policies, particularly concerning water usage and plume abatement. Countries such as Germany, the UK, and France are leading the adoption due to their developed industrial bases, emphasis on renewable energy integration, and increasing investments in green building initiatives. The region also faces challenges with water scarcity in certain areas, further boosting the demand for water-efficient hybrid cooling solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by rapid industrialization, urbanization, and significant infrastructure development in countries like China, India, Japan, and South Korea. The escalating energy demand, coupled with growing environmental concerns and increasing awareness of sustainable technologies, fuels the adoption of hybrid cooling towers. The proliferation of data centers and manufacturing facilities in the region presents vast opportunities for market expansion.

- Latin America: This region is an emerging market for hybrid cooling towers, with growth supported by industrial expansion, particularly in Brazil and Mexico. Investments in the energy sector, including new power plants and industrial processing facilities, are contributing to market development. Increasing focus on sustainable industrial practices and modernization of existing infrastructure also play a role in market uptake.

- Middle East and Africa (MEA): The MEA market is experiencing gradual growth, primarily driven by investments in infrastructure, power generation, and the booming oil and gas sector. Countries in the Gulf Cooperation Council (GCC) are particularly interested in water-saving technologies due to extreme water scarcity. The development of new commercial and industrial hubs, along with a push towards economic diversification, is creating demand for efficient and robust cooling solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hybrid Cooling Towers Market.- SPX Cooling Technologies, Inc.

- Baltimore Aircoil Company (BAC)

- EVAPCO, Inc.

- Hamon Corporation

- Johnson Controls International Plc

- ENEXIO Water Technologies

- THERMALTECH, Inc.

- Paharpur Cooling Towers Ltd.

- Evoqua Water Technologies LLC

- Wessels Company

- Güntner GmbH & Co. KG

- Kelvion Holding GmbH

- LU-VE Group

- Trane Technologies plc

- Swegon Group AB

- Daikin Industries, Ltd.

- GEA Group AG

- Bell Cooling Tower Co., Inc.

- Delta Cooling Towers, Inc.

- Recold, a division of SPX Cooling Technologies

Frequently Asked Questions

What are the primary benefits of hybrid cooling towers compared to traditional systems?

Hybrid cooling towers offer significant advantages over conventional wet or dry cooling systems, primarily through enhanced water and energy efficiency. They achieve substantial water savings by utilizing dry cooling during favorable ambient conditions, reducing blowdown, and minimizing plume formation. Additionally, they often result in lower operational costs due to reduced chemical treatment needs and optimized energy consumption, while maintaining high thermal performance.

Which industries are the major end-users of hybrid cooling towers?

The major end-users of hybrid cooling towers span several critical industries including power generation (both conventional and renewable energy), large-scale HVAC systems for commercial and institutional buildings, various industrial manufacturing processes (chemical, petrochemical, food and beverage, automotive), and rapidly growing data center facilities. These sectors all require robust, efficient, and often environmentally compliant thermal management solutions.

How do hybrid cooling towers contribute to environmental sustainability?

Hybrid cooling towers significantly contribute to environmental sustainability by reducing water consumption through their optimized wet-dry operation, thereby conserving precious freshwater resources. They also minimize visible water vapor plumes, addressing aesthetic and potential public health concerns, and often lead to lower energy consumption, which translates to a reduced carbon footprint. Their efficient operation also lessens the need for chemical water treatment, reducing chemical discharge into the environment.

What are the key technological advancements driving the hybrid cooling towers market?

Key technological advancements include the integration of advanced control systems with AI and IoT capabilities for real-time optimization, predictive maintenance, and remote monitoring. Innovations in heat exchanger and fill media designs enhance thermal efficiency. Additionally, the development of more durable and corrosion-resistant materials, along with energy-efficient fan designs, are crucial in improving overall system performance, reliability, and longevity.

What is the expected market growth rate for hybrid cooling towers in the coming years?

The Hybrid Cooling Towers Market is projected for robust growth, with a Compound Annual Growth Rate (CAGR) estimated at 7.2% between 2026 and 2033. This growth is primarily driven by increasing global demand for sustainable industrial cooling solutions, stringent environmental regulations, and the expanding industrial and data center sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager