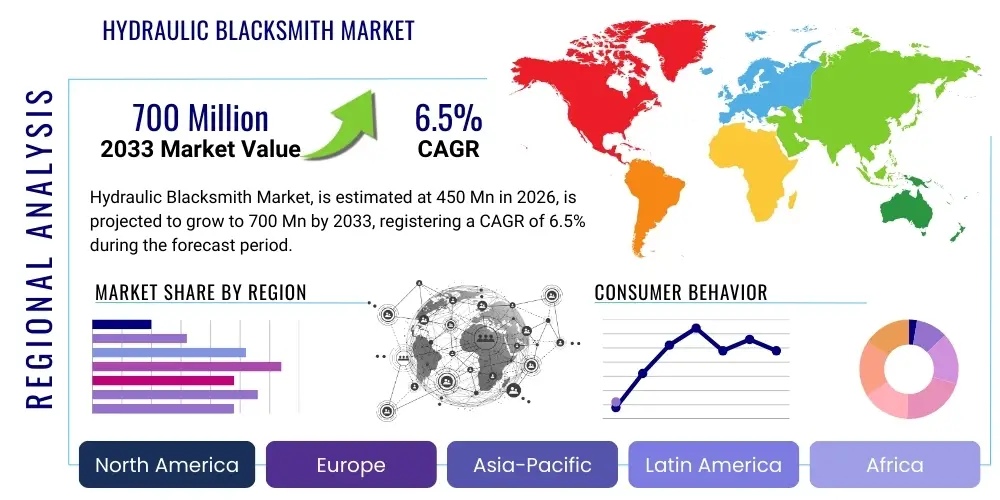

Hydraulic Blacksmith Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441915 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Hydraulic Blacksmith Market Size

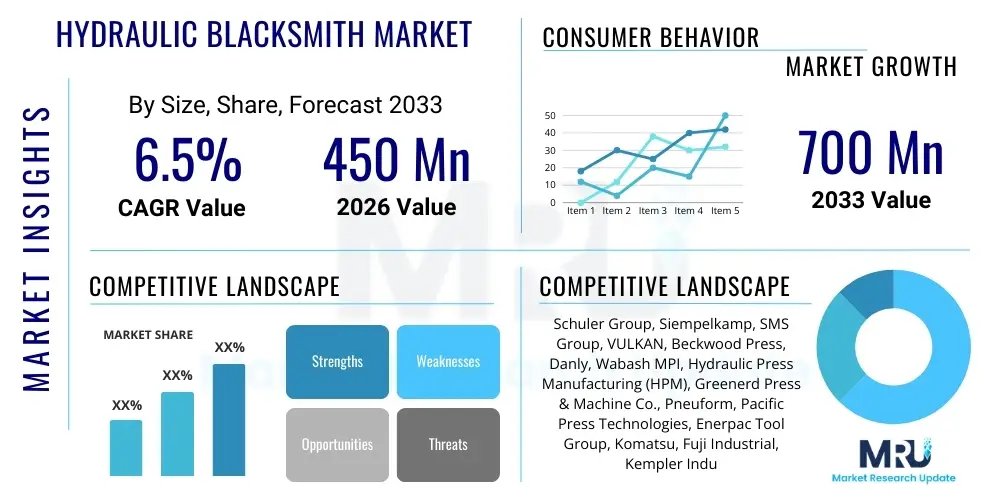

The Hydraulic Blacksmith Market, defined by the sophisticated machinery used for forming and shaping metal through hydraulic power, is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $700 Million by the end of the forecast period in 2033. This steady expansion is driven primarily by the increasing demand for precision-forged components across critical industrial sectors, coupled with the need for safer and more efficient metalworking processes than traditional methods allow. The versatility and scalability of modern hydraulic systems enable manufacturers to undertake diverse applications, ranging from small-batch artisan work to large-scale industrial forging, supporting market valuation growth significantly.

Hydraulic Blacksmith Market introduction

The Hydraulic Blacksmith Market encompasses the design, manufacture, and deployment of hydraulically powered presses and related equipment utilized for hot and cold forging, stamping, and metal shaping processes traditionally associated with blacksmithing. These systems replace manual or steam-powered processes with controlled, high-force hydraulic mechanisms, offering unparalleled precision, repeatability, and safety. Major applications span the automotive industry for component manufacturing (axles, crankshafts), aerospace for specialized high-strength parts, construction for structural elements, and the burgeoning custom and artistic metalworking sector requiring precise force control. Key benefits include enhanced material integrity, reduced operational fatigue, higher throughput, and strict adherence to modern safety standards. The market growth is principally driven by rapid industrialization in developing economies, the sustained demand for lightweight and complex metal components in transportation, and the ongoing technological evolution incorporating automation and digital controls into forging equipment.

Hydraulic Blacksmith Market Executive Summary

The Hydraulic Blacksmith Market is undergoing transformative shifts characterized by robust business trends focusing on digitalization and energy efficiency. Regionally, the Asia Pacific (APAC) continues to dominate market share due to its massive industrial base and governmental investment in manufacturing infrastructure, while North America and Europe prioritize the adoption of high-precision, automated systems for specialized applications. Segment trends indicate a strong preference for vertical hydraulic presses offering superior control and smaller footprint, particularly in high-volume production environments. Furthermore, the market is seeing increased penetration of control systems based on sophisticated Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), leading to improved operational diagnostics and reduced downtime. This combination of geographic expansion, technological maturity, and the sustained global need for durable metal components cements the market's positive outlook through the forecast period.

AI Impact Analysis on Hydraulic Blacksmith Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Hydraulic Blacksmith Market predominantly center on how AI can optimize the forging process parameters, enhance equipment reliability through predictive maintenance, and facilitate rapid design iterations for bespoke metal components. Users are keen to understand if AI can effectively model the complex thermal and mechanical stresses involved in hot forging to minimize defects and material waste, alongside expectations for AI-driven automation that reduces reliance on highly specialized human operators. Concerns often arise about the initial investment required for AI integration and the potential displacement of skilled, traditional labor. Overall, the key theme is the expectation that AI will serve as a transformative tool, moving blacksmithing from a craft relying heavily on experience to a data-driven, highly optimized industrial process, ensuring consistent quality and maximal material utilization across different production scales.

- AI-driven predictive maintenance minimizes unscheduled downtime by analyzing sensor data from hydraulic pumps, valves, and cylinders.

- Generative design tools assist in optimizing forging die geometry, reducing material costs and enhancing component structural integrity.

- Real-time process optimization using machine learning algorithms adjusts forging temperature, force application, and cycle time dynamically for superior quality control.

- Automated quality inspection systems utilize computer vision and AI to detect minute surface defects and dimensional inaccuracies immediately post-forging.

- Enhanced simulation capabilities allow for virtual testing of complex metal deformation processes, accelerating R&D cycles and lowering prototyping costs.

DRO & Impact Forces Of Hydraulic Blacksmith Market

The dynamics of the Hydraulic Blacksmith Market are governed by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces. Key drivers include the overwhelming global need for high-strength, precision-engineered metal components, particularly in the infrastructure, energy, and transportation sectors, coupled with strict regulatory pressures demanding improved worker safety and reduced environmental impact, which modern hydraulic systems inherently offer compared to traditional mechanical presses. Restraints largely involve the significant initial capital outlay required for high-tonnage hydraulic presses and the subsequent need for specialized maintenance personnel, alongside the volatility in raw material prices (steel, aluminum) which directly influences the overall cost of forged products. Opportunities are expansive, rooted in the potential for highly specialized custom forging for emerging technologies such as electric vehicles (EVs) and advanced aerospace materials, alongside market penetration into previously underserved small and medium-sized enterprises (SMEs) through modular and mid-sized equipment offerings. The primary Impact Forces shaping the market trajectory include rapid technological innovation in fluid power efficiency, global trade policies affecting cross-border equipment transfer, and the growing integration of IoT and Industry 4.0 principles into manufacturing workflows, demanding smart, interconnected forging operations.

Segmentation Analysis

The Hydraulic Blacksmith Market is rigorously segmented based on product type, application, component, and operational force, reflecting the diverse requirements of the global manufacturing landscape. Segmentation provides critical insights into purchasing patterns and technological preferences across various industrial sectors. The classification by product type (Vertical vs. Horizontal Presses) dictates factory layout and operational methodology, while the segmentation by application (Automotive, Aerospace, Construction) highlights key end-user demand drivers and quality requirements. Further breakdown by component helps manufacturers focus on optimizing the crucial elements like hydraulic pumps, control valves, and system integrity, ensuring long operational life and reliability. The market's overall growth heterogeneity necessitates a detailed analysis across these axes to identify high-growth niches and optimize strategic resource allocation.

The complexity of modern metal fabrication demands that hydraulic blacksmith equipment be categorized not just by sheer tonnage but also by the level of automation and control systems integrated. High-end segments often feature servo-hydraulic systems that offer superior energy efficiency and positional accuracy, crucial for materials like titanium or specialized alloys used in demanding sectors. Understanding these granular segmentations is vital for stakeholders, as procurement decisions are increasingly influenced by total cost of ownership (TCO), maintenance ease, and adherence to specialized industry standards (e.g., AS9100 for aerospace). The continuous push towards customization has also led to a growing segment of modular systems, allowing buyers to configure machines to specific production needs without massive upfront investment in monolithic equipment.

- By Product Type:

- Vertical Hydraulic Presses

- Horizontal Hydraulic Presses

- C-Frame Presses

- Four-Column Presses

- By Application:

- Automotive & Transportation

- Aerospace & Defense

- Construction & Infrastructure

- General Machinery Manufacturing

- Tooling & Die Making

- Custom & Artistic Forging

- By Component:

- Hydraulic Cylinders

- Hydraulic Pumps and Power Units

- Control Valves and Manifolds

- Control Systems (PLC/CNC)

- Frames and Dies

- By Tonnage/Force:

- Low Tonnage (Up to 500 Tons)

- Medium Tonnage (500 to 2000 Tons)

- High Tonnage (Above 2000 Tons)

Value Chain Analysis For Hydraulic Blacksmith Market

The Value Chain for the Hydraulic Blacksmith Market begins with upstream activities involving the sourcing of highly specialized raw materials, primarily high-grade steel for machine frames and critical components, as well as complex hydraulic system components like precision pumps, high-pressure tubing, and electronic control units. Key upstream challenges revolve around maintaining a reliable supply of specialized hydraulic components that meet stringent pressure and durability specifications. The core manufacturing stage involves the meticulous assembly, calibration, and testing of the hydraulic presses, where integration of proprietary software and control interfaces adds significant value. Downstream activities focus heavily on distribution, installation, and comprehensive after-sales support, including maintenance contracts and spare parts supply, which often represent a high-margin revenue stream for key players.

Distribution channels in this market are bifurcated into direct sales and indirect representation. Direct sales are typically preferred for large-scale, high-tonnage custom systems sold to major manufacturers in aerospace or automotive, ensuring tight control over installation and technical specifications. Indirect distribution leverages specialized industrial equipment dealers and system integrators who possess regional expertise and often package the presses with related peripheral equipment (e.g., heating elements, material handling robots). This dual-channel approach is necessary to cover both specialized, high-value projects and standardized equipment sales to a broader base of SMEs. The overall efficiency of the value chain is increasingly dependent on reducing lead times for complex component manufacturing and streamlining logistics for heavy machinery delivery and installation.

Customer engagement post-sale, facilitated through robust distribution and service networks, is crucial, particularly given the long operational lifespan and high maintenance requirements of these machines. Manufacturers must invest heavily in training and certification of regional service technicians, ensuring rapid response to technical issues that could halt high-volume production lines. The final value delivered to the end-user is measured not just in the machine's initial performance but also in its long-term reliability, uptime, and the technical support available for maximizing its operational efficiency.

Hydraulic Blacksmith Market Potential Customers

The primary customers for hydraulic blacksmith equipment are large-scale industrial entities and specialized fabrication workshops requiring precise, repeatable metal forming capabilities. This includes major automotive manufacturers and their Tier 1 suppliers who need equipment for producing engine parts, chassis components, and specialized structural frames, driven by the shift towards lighter and stronger materials for fuel efficiency. Aerospace and defense contractors constitute another critical segment, demanding ultra-high tonnage presses capable of working with exotic alloys like titanium and nickel-based superalloys for structural elements and turbine components, where quality traceability and certification are paramount. These customers often procure custom-designed, highly automated presses with integrated monitoring systems to comply with rigorous industry standards.

Beyond these large industrial users, the market also serves the construction industry (for heavy structural elements and machinery parts repair), the energy sector (oil and gas, and power generation components), and a growing segment of Small to Medium-sized Enterprises (SMEs) focused on bespoke tooling, die casting, and short-run custom fabrication. SMEs typically opt for mid-tonnage, multipurpose presses that offer flexibility across various tasks. Geographic concentration of these customers is high in industrialized clusters, particularly in East Asia (China, South Korea) and Central Europe (Germany, Italy), where manufacturing output is globally significant, creating continuous demand for upgrades and expansion of forging capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $700 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schuler Group, Siempelkamp, SMS Group, VULKAN, Beckwood Press, Danly, Wabash MPI, Hydraulic Press Manufacturing (HPM), Greenerd Press & Machine Co., Pneuform, Pacific Press Technologies, Enerpac Tool Group, Komatsu, Fuji Industrial, Kempler Industries, DAKE Corp., S.P.P. Hydraulic, Hishinuma Press, Verson, Phoenix Press International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Blacksmith Market Key Technology Landscape

The technological landscape of the Hydraulic Blacksmith Market is rapidly evolving, moving far beyond simple brute force application toward intelligent, networked forging systems. A key trend is the integration of servo-hydraulic technology, which replaces traditional fixed-speed pumps with variable speed drives and motors. This allows for precise control over piston speed and force application throughout the entire stroke, drastically improving energy efficiency by using power only when needed, while simultaneously enhancing the quality and consistency of the forged product. Furthermore, the adoption of advanced sensor arrays (Internet of Things – IoT) is becoming standard, collecting real-time data on temperature, pressure, vibration, and material flow, which feeds into sophisticated control systems (PLCs and CNCs) for immediate process adjustments and proactive diagnostics. This transition aligns the forging industry with broader Industry 4.0 objectives.

Another crucial technological advancement is the focus on robust and intuitive Human-Machine Interfaces (HMIs). Modern HMI panels provide operators with comprehensive graphical displays of process parameters, fault diagnostics, and historical data, making complex machine operation more accessible and reducing the learning curve for specialized tasks. Moreover, safety technology has seen significant enhancements, including light curtains, integrated interlocking mechanisms, and redundant pressure relief systems, meeting increasingly strict international safety standards (e.g., OSHA, CE directives). The development of modular press designs also represents a technological leap, allowing manufacturers to quickly customize press bed sizes, daylight openings, and tonnage capacity using standardized components, reducing both lead times and manufacturing costs, offering flexibility crucial for accommodating varied customer needs and future scaling.

The material handling aspect surrounding hydraulic blacksmith equipment is also undergoing automation via robotics. Collaborative robots (cobots) are increasingly deployed for loading and unloading hot billets, minimizing human exposure to hazardous environments and ensuring rapid cycle times. Precision temperature control systems, leveraging infrared and thermal imaging, ensure that metal billets are forged within their narrow optimal thermal window, preventing microstructural defects. Collectively, these technologies are transforming hydraulic blacksmithing from a heavy-duty, labor-intensive process into a highly technical, data-optimized, and quality-controlled manufacturing discipline essential for producing critical components in high-reliability sectors.

Regional Highlights

- Asia Pacific (APAC): The APAC region is the undisputed leader in the Hydraulic Blacksmith Market, driven by its expansive manufacturing base, particularly in China, India, and Southeast Asia. Rapid urbanization, massive infrastructure projects, and the region's dominance in automotive and general machinery production create sustained, high-volume demand for forging equipment. Governments in this region often provide favorable incentives for industrial modernization, leading to quick adoption of medium to high-tonnage hydraulic presses. China, in particular, drives scale demand, while countries like Japan and South Korea focus on high-precision, technologically advanced systems necessary for micro-forging and specialized electronics components.

- Europe: Europe represents a mature market characterized by stringent quality standards, emphasis on energy efficiency, and a blend of traditional artisan metalworking alongside advanced aerospace and defense manufacturing. Countries such as Germany, Italy, and France are hubs for press manufacturing innovation, specializing in servo-hydraulic systems and highly customized presses compliant with demanding EU safety directives. Growth here is primarily driven by replacement cycles, modernization of existing facilities, and the high-value customization required for luxury automotive and high-performance engineering sectors.

- North America: North America is defined by high technological adoption and a focus on resilience and supply chain localization, particularly post-2020. The market demands advanced, automated presses integrated with IoT for monitoring and predictive maintenance, catering heavily to the demanding aerospace, oil and gas, and heavy equipment manufacturing sectors. The US and Canada invest significantly in R&D, seeking presses capable of handling complex geometries and emerging high-strength alloys crucial for maintaining technological superiority in defense and commercial aviation.

- Latin America (LATAM): This region offers considerable potential, primarily centered in Brazil and Mexico, fueled by expanding domestic automotive assembly and mining industries. The market here is sensitive to commodity prices and foreign investment, often resulting in demand for cost-effective, durable, and reliable mid-range hydraulic presses rather than cutting-edge, highly automated systems. Infrastructure growth acts as a consistent long-term driver, despite periodic economic volatility.

- Middle East and Africa (MEA): The MEA market is exhibiting emerging growth, largely tied to significant government-led investments in economic diversification, particularly in the construction, oil and gas, and developing defense industries (Saudi Arabia, UAE). Demand is highly project-specific, requiring robust equipment capable of operating reliably in harsh environmental conditions. The market for after-sales service and training is crucial here due to lower local technical infrastructure maturity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Blacksmith Market, analyzing their product portfolios, strategic initiatives, and market positioning.- Schuler Group GmbH

- Siempelkamp Maschinen- und Anlagenbau GmbH

- SMS Group GmbH

- Beckwood Press Co.

- VULKAN Group

- Hydraulic Press Manufacturing (HPM)

- Greenerd Press & Machine Co.

- Wabash MPI

- Danly Machine Corp.

- Kempler Industries

- DAKE Corp.

- Pacific Press Technologies Inc.

- Enerpac Tool Group

- Komatsu Ltd.

- Fuji Industrial Co., Ltd.

- S.P.P. Hydraulic

- Phoenix Press International

- Hishinuma Press

- Verson International

- Santec Exim Private Limited

Frequently Asked Questions

Analyze common user questions about the Hydraulic Blacksmith market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between hydraulic and mechanical blacksmith presses?

Hydraulic presses offer constant force application throughout the entire stroke and superior positional control, making them ideal for deep drawing and precise forging. Mechanical presses deliver maximum force only at the bottom of the stroke (B.D.C.), focusing on speed and energy efficiency for repetitive stamping applications.

How is the growth of the electric vehicle (EV) sector impacting the demand for hydraulic blacksmith equipment?

The EV sector increases demand for high-strength, lightweight forged components, particularly aluminum and specialized alloy parts for battery enclosures, motor shafts, and structural chassis elements. This requires high-tonnage hydraulic presses capable of precise cold and hot forging processes essential for maintaining material integrity and reducing vehicle weight.

What key factors should be considered when evaluating the total cost of ownership (TCO) for a new hydraulic press?

TCO evaluation must extend beyond the initial purchase price to include factors such as operational energy consumption (where servo-hydraulics offer significant savings), frequency and cost of hydraulic fluid replacement, complexity and expense of preventative maintenance (especially for cylinders and pumps), and potential downtime costs due to component failure.

What are the typical applications of low-tonnage hydraulic presses in the current market?

Low-tonnage hydraulic presses (under 500 tons) are widely used in smaller fabrication workshops, educational institutions, custom artistic forging, R&D labs for material testing, and for precise bending, straightening, and assembly tasks where massive force is not required but accuracy is paramount, often featuring C-frame or benchtop designs.

How does Industry 4.0 integration benefit hydraulic blacksmith operations?

Industry 4.0 integrates IoT sensors, AI-driven analytics, and cloud connectivity into hydraulic presses, enabling predictive maintenance, real-time process monitoring, automated quality control via computer vision, and remote diagnostics, collectively leading to maximized operational uptime and superior manufacturing quality consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager